[Z06] LS7 fail data thread

#1

Le Mans Master

Thread Starter

Okay guys, before saying "not another one". Simple premise to this thread. I have a hypothesis that I need actual data to prove. Please respond to this if you have had a VALVE or VALVETRAIN related engine problems with AFTERMARKET rocker arms only. I am not interested in any failures with stock valvetrain. That data is readily available. Thank you.

Last edited by Pb82 Ronin; 06-18-2013 at 11:32 PM.

#3

Team Owner

Define aftermarket rocker arms? Comp or CHE upgrade to stock rocker arms count? Those are still stock rockers with different bearings.

#4

Race Director

There are very few aftermarket rocker arm choices for the LS7. Yella, Harland, and a couple shaft mount systems. Other than outright failures of the aftermarket arms, I haven't seen a valve drop LS7 that was running an aftermarket rocker, that I can remember.

#5

Safety Car

Not saying OP can't research - just that I expect very low yield on his hypothesis given the multitude of variables (and low n values) he'll likely encounter.

#6

Le Mans Master

Thread Starter

To clarify...CHE bearing upgrades DO NOT count as aftermarket. They utilize the factory rocker arm geometry. Only full aftermarket conversions count. Yella terra, Jesel, etc...these are the guys I need to hear from. I like the results thus far. Promising to say the least...

Again...if you have experienced a SINGLE engine hiccup with aftermarket rocker arms equipped...please, PLEASE respond!

Again...if you have experienced a SINGLE engine hiccup with aftermarket rocker arms equipped...please, PLEASE respond!

Last edited by Pb82 Ronin; 06-18-2013 at 11:36 PM.

#7

Okay guys, before saying "not another one". Simple premise to this thread. I have a hypothesis that I need actual data to prove. Please respond to this if you have had a VALVE or VALVETRAIN related engine problems with AFTERMARKET rocker arms only. I am not interested in any failures with stock valvetrain. That data is readily available. Thank you.

http://forums.corvetteforum.com/c6-z...post1574483942

http://forums.corvetteforum.com/c6-z...post1569177250

http://forums.corvetteforum.com/c6-z...post1569423714

I'd just say, that if you are looking down the geometry rabbit hole, and at roller rockers as the answer to this issue, then just consider the case above.

#8

Le Mans Master

Thread Starter

Thanks for the post Quick. There is one example...however he did state that he did not know why the 2nd motor failed. Or if he did, I didn't read that far.

So thus far the lay of the land goes:

1 possible failure on 1 engine.

Still need confirmed data for valve train induced failures. Anybody else?

So thus far the lay of the land goes:

1 possible failure on 1 engine.

Still need confirmed data for valve train induced failures. Anybody else?

#9

Thanks for the post Quick. There is one example...however he did state that he did not know why the 2nd motor failed. Or if he did, I didn't read that far.

So thus far the lay of the land goes:

1 possible failure on 1 engine.

Still need confirmed data for valve train induced failures. Anybody else?

So thus far the lay of the land goes:

1 possible failure on 1 engine.

Still need confirmed data for valve train induced failures. Anybody else?

I'll link to the post.

#10

Race Director

I believe the Roller tipped rocker arm is a solution to the issue, but you have to know 100% you haven't already started to wear in the guides. I would also look at the Crower shaft mount system as the BEST solution in terms of running roller tipped rockers. Since it requires machining of the pedestals, you might as well have new guides put in the heads while the machining for the Crower system is being done. I do know of an LS7 running a LARGE solid roller cam with the crower system and it is running just fine. He his hard on it when driven and no issues so far.

#11

Le Mans Master

Thread Starter

I have to laugh at the term "dropped valve". To "drop a valve" to me means that the valve retainer or retainers failed. That would be the only literal way for a valve to "drop" into the cylinder, unless it breaks at the shaft. Guide wear can happen all day long, seals can leak like a submarine and the valve will never "drop". Valve springs have broken and still not "dropped" valves because the retainer is doing what it's designed to do. The term "drop" is used so loosely here that it makes me wonder what people are actually referring to in regards to a valve "dropping". When a stock sodium filled (hollow stem) valve fails because of shaft breakage...I can see how this could be an issue for customers and with GM quality control. However, what would cause a valve to break at the shaft? The only thing I can think of would be a terrible pre-load (or more relevantly, side load) on the valve itself. The only thing that would cause this is bad rocker arm geometry. I first caught a glimpse of this possibility when I switched to Yella Terra's. The exhaust rockers moved over a quarter inch when bolt tension was released...that was a HUGE eyebrow raiser for me. That also spawned my hypothesis that all these valve train failures were due to poor rocker arm geometry rather than bad guides. Guides don't just go bad. They need an outside influence and external forces acting on them to wear enough to cause issues. The only thing that could do this is rocker geometry or sh*tty materials. But when you start seeing solid (aftermarket steel) valves failing in the same fashion as the hollows...makes you wonder. If the material was suspect...then switching to solids should alleviate the problem, right? This is not the case. Well maybe its the valve guide material then? Can't be. All sorts of guides in all sorts of materials are used in thousands of street/race applications. The LS7 is no different.

Did anyone besides me notice that the intake valves don't suffer from same sh*tty rocker arm geometry as the exhaust side? They are completely straight with a nice wear pattern on the tip. Coincidence that they haven't suffered the same fate? I think not. I could see plainly that my exhaust rockers had horrible geometry based on the wear pattern visible on the tip. How many intake valves were the failed or "dropped" valves? I'm actually seeking data here. Please list your valve failures intake OR exhaust while equipped with aftermarket rockers. At this point ALL failure data with aftermarket rockers is relevant. I'm assessing that MOST (most input simply because I haven't seen/evaluated every aftermarket rocker arm possible yet) aftermarket arms solve the poor geometry thus relieving the aforementioned side loading and rapid guide wear. Discussion is obviously welcome. Please do not cloud my thread with, "well my shop says this caused this" type rhetoric...I need input from folks that know what wear patterns and rocker geometry mean and how the affect the valve train. Please do not take offense to that statement...it is not designed to be instigating in nature. I just have a tendency to not really listen to folks that don't wrench on their own cars...force of habit I suppose.

Did anyone besides me notice that the intake valves don't suffer from same sh*tty rocker arm geometry as the exhaust side? They are completely straight with a nice wear pattern on the tip. Coincidence that they haven't suffered the same fate? I think not. I could see plainly that my exhaust rockers had horrible geometry based on the wear pattern visible on the tip. How many intake valves were the failed or "dropped" valves? I'm actually seeking data here. Please list your valve failures intake OR exhaust while equipped with aftermarket rockers. At this point ALL failure data with aftermarket rockers is relevant. I'm assessing that MOST (most input simply because I haven't seen/evaluated every aftermarket rocker arm possible yet) aftermarket arms solve the poor geometry thus relieving the aforementioned side loading and rapid guide wear. Discussion is obviously welcome. Please do not cloud my thread with, "well my shop says this caused this" type rhetoric...I need input from folks that know what wear patterns and rocker geometry mean and how the affect the valve train. Please do not take offense to that statement...it is not designed to be instigating in nature. I just have a tendency to not really listen to folks that don't wrench on their own cars...force of habit I suppose.

Last edited by Pb82 Ronin; 06-19-2013 at 11:24 PM.

#12

I think that the lash cap on the intake valve gives the rocker pad a lot more room to work, and therefore the ability to achieve a good wear pattern even if things are not perfectly lined up and centered.

As to the rocker arm 'slop', I suspect this is a design feature that allows the rocker to self-center between the pushrod and the valve stem, just like the old small block chevy stud/ball mounted rockers. Unless improperly tightened (crooked) I don't think it hurts anything. I do agree that the wear pattern on many exhaust rockers are a problem... but I don't know if this is the chicken or the egg (i.e., if the patterned developed after the guide wear allowed the stem to move around, or if it caused the guide wear). Clearly the small valve stem tip and the amount of lift does not leave much room for error in rocker pad to valve stem tip alignment.

Personally I think that properly installing a lash cap on the exhaust valve could go a long way into cleaning up the issue between the rocker and stem. Whether this would address the current guide wear situation is another matter.

As to the rocker arm 'slop', I suspect this is a design feature that allows the rocker to self-center between the pushrod and the valve stem, just like the old small block chevy stud/ball mounted rockers. Unless improperly tightened (crooked) I don't think it hurts anything. I do agree that the wear pattern on many exhaust rockers are a problem... but I don't know if this is the chicken or the egg (i.e., if the patterned developed after the guide wear allowed the stem to move around, or if it caused the guide wear). Clearly the small valve stem tip and the amount of lift does not leave much room for error in rocker pad to valve stem tip alignment.

Personally I think that properly installing a lash cap on the exhaust valve could go a long way into cleaning up the issue between the rocker and stem. Whether this would address the current guide wear situation is another matter.

#13

Le Mans Master

Thread Starter

I agree to an extent. Putting a lash cap on the exhaust valve is more of a band-aid fix IMO. Sure it will provide a better "wear pattern" due to a larger contact area. But the poor rocker geometry is the real problem IMO. I can see and agree with some of your logic though. The intake side lash cap I'm sure assists with a cleaner wear pattern...but the rocker itself is a non-offset, unlike the exhaust side. So the geometry isn't the same on the intake side. I also feel this is why all the valve failures have been exhaust and not intake.

I hope this conversation inspires people to rip off some valve covers and look into their own valvetrains to see some wear patterns. Excessive valve side-load is a HUGE problem and an engine killer, especially on a ZO6 (LS7).

I hope this conversation inspires people to rip off some valve covers and look into their own valvetrains to see some wear patterns. Excessive valve side-load is a HUGE problem and an engine killer, especially on a ZO6 (LS7).

#14

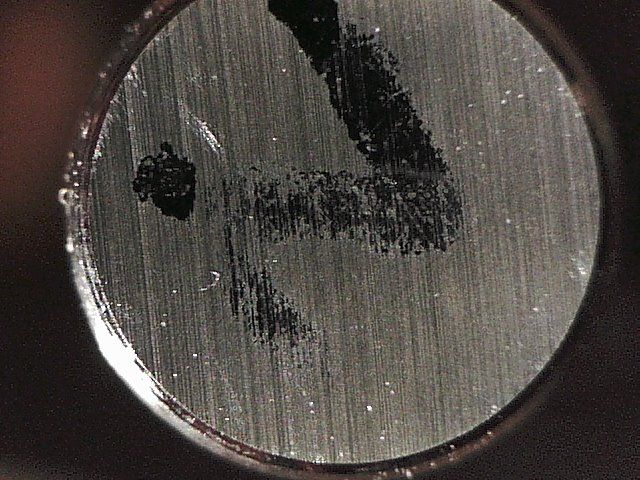

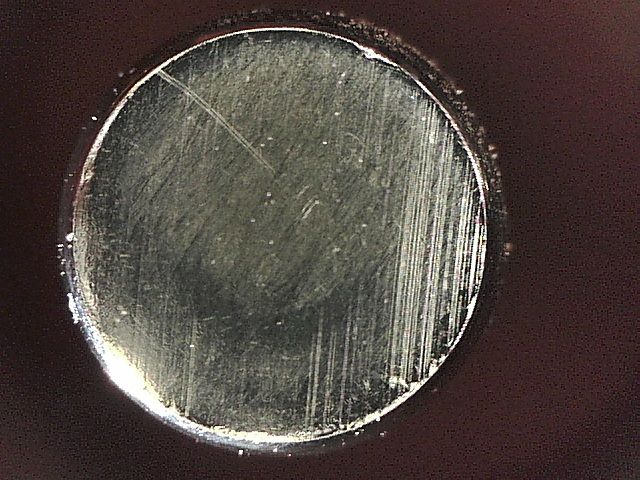

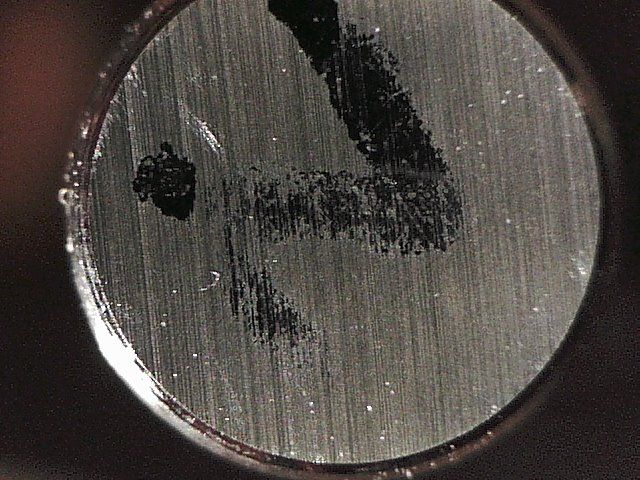

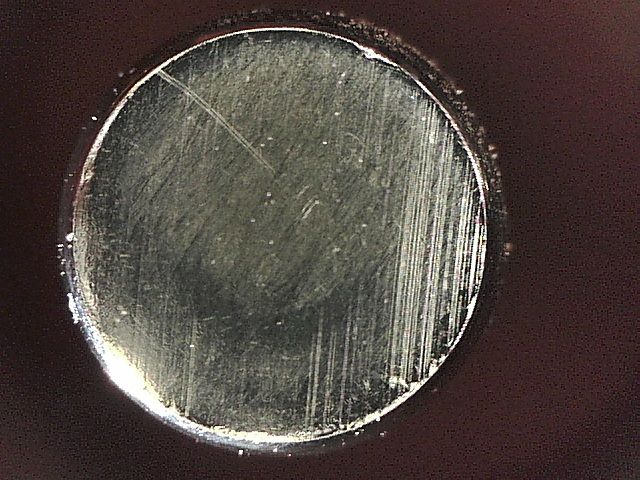

If you want to see a real fail and a possible clue into side load just look at an OEM LS7 exhaust valve stem tip under magnification...

New:

======================================== =========

Used (30K miles):

======================================== =========

Really used (44K miles):

Soooo, I think you may be on the right track with the roller tipped rocker.

.

New:

======================================== =========

Used (30K miles):

======================================== =========

Really used (44K miles):

Soooo, I think you may be on the right track with the roller tipped rocker.

.

Last edited by Mark2009; 06-20-2013 at 07:56 PM.

#15

Le Mans Master

Thread Starter

Damn Mark...that in an excellent find! I'm curious where you found that and how do we know it's an LS7 for sure? And how is it for sure it's an exhaust valve of an LS7? Only reason I ask...the last picture shows a pretty centered wear pattern. This concerns me...I should've taken pics of mine when I had them off. I just never thought about it at the time. I wasn't really deep into this forum or the vette world at the time. Had I known...I for sure would have taken pics of every exhaust valve tip to show my wear patterns. The rockers I still have though...I need to bring them out of storage.

Almost 500 views and no concerned parties that want to contribute? I'm really thinking that the lack of data is really solidifying my hypothesis. I gonna need to do some testing of my own...unfortunately I don't have an extra amount of time to conduct some lab coat type experiments. I will get there...but, come one guys. Anyone have failures with aftermarket (correctly aligned) rocker arms?

Still thinking on it...

Almost 500 views and no concerned parties that want to contribute? I'm really thinking that the lack of data is really solidifying my hypothesis. I gonna need to do some testing of my own...unfortunately I don't have an extra amount of time to conduct some lab coat type experiments. I will get there...but, come one guys. Anyone have failures with aftermarket (correctly aligned) rocker arms?

Still thinking on it...

Last edited by Pb82 Ronin; 06-20-2013 at 11:30 PM.

#16

Edit: Make that 32... I gave one away.

.

Last edited by Mark2009; 06-21-2013 at 10:35 AM.

#17

I'm sure a roller tipped rocker will reduce side load, and may be recommended for a bronze guide, but it's looking like sloppy machining/QC is the root cause of the current issue.

Problem is the additional weight and/or expense of that type rocker.

#18

Le Mans Master

Thread Starter

Totally agree. GM should've seen this problem years ago. It's amazing that they turn a blind eye to something this PAINFULLY obvious. I'd actually like to take some exhaust valves and hit them with dye-chem and run them through a few revolutions and take pictures. Show proof to GM execs and rub that salt deep in the wounds.

#19

Le Mans Master

Thread Starter

Revived! Any inputs?

#20

Le Mans Master

Thread Starter

Bump, all these motors still going strong eh?