[Z06] How Many Z06 Owners Are Running Solid Stainless Exhaust Valves?

#241

Safety Car

Not to mention... Katech_Jason has been clear: they feel OEM guides are perfectly acceptable, but their chosen supplier (also great rep) can't source them. So I don't think they have to defend anything other than using the parts available to them at the time.

Might as well say WCCH will have to defend using solid stem valves because the titanium exhaust valves from katech weren't available prior to a month ago - even though they might prove to be superior?

Might as well say WCCH will have to defend using solid stem valves because the titanium exhaust valves from katech weren't available prior to a month ago - even though they might prove to be superior?

#242

Team Owner

Thread Starter

Anyone telling me that the stock exhaust valves are OK, above the sounds of popping motors, I'm going to question.

If I'm on the Titanic, and it's sinking in the middle of the North Atlantic, I'm going to be skeptical if the captain and his crew tells me that all is well. I don't care what their background is. I'm looking for the life boats. Even if the lifeboats haven't been spintron tested. Let the cap'n and his crew stay onboard.

Their warranty, is one year on street vehicles. So for northeastern owners, it really works out to about a 6 month warranty, since many of those cars are only in use for about that length of time out of a year, and obviously only at risk for failure, while they are in use.

You pay for that warranty, in their pricing. Look at what a cam swap will cost you. SO bringing up the fact that they offer a "warranty" and WCCH doesn't is a joke.

Like anyone else, they aren't going to honor that warranty, unless it is a street vehicle. They aren't going to sponsor your racing program.

The bottom line here, is when they say that they "don't know" what the cause of this guide wear is, and then go about offering up a "fix", which is mostly a replacement of worn parts, and a substitution for the guides and intake valves, nobody bats an eye.

But if anyone else's fix is used, well then some in here are quick to holler that it's voodoo.

After all, they feel like they already have "the fix". Which they say is bronze guides, stock exhaust valves, and ti/moly coated intake valves.

So if that is "the fix", then once applied, you don't have to fool with "the problem" anymore.

Regardless of what it was.

Last edited by '06 Quicksilver Z06; 12-29-2012 at 12:00 PM.

#243

Team Owner

#244

Team Owner

Coincidentally Mike, your rockers arrived at WCCH for the CHE upgrade, and I called today to check the progress.

BTW Howie, when these are ready, mine will become available if you are still interested.

Had the chance to talk to Dave, and when you start talking to these guys, you end up staying on the phone longer than what you expected.

Anyway, a call meant to be only about 2-3 minutes long to inquire about my rockers, ended up becoming a 30 minute conversation with Dave.

BTW Howie, when these are ready, mine will become available if you are still interested.

Had the chance to talk to Dave, and when you start talking to these guys, you end up staying on the phone longer than what you expected.

Anyway, a call meant to be only about 2-3 minutes long to inquire about my rockers, ended up becoming a 30 minute conversation with Dave.

1. They are installing their new equipment and cleaning shop

2. Certain guys keep them on the phone for 30 minutes shooting the breeze

Now the least you can do is pass on the enlightenment that was bestowed upon you today. BTW: I got off in less than 2 minutes

I already told Richard to get me new CHE rockers. But if yours become available before hand let me know.

DH

#245

Team Owner

I believe the front straight at WSIR is 1/4 mile. Let me take you for a ride and I'm sure I can get you excited. Excitement lasts for 25 minutes at a time, not 11 seconds

..............

..............

I doubt you would be as excited as our Trophy Girl, Amber ....

DH

Last edited by Dirty Howie; 12-29-2012 at 01:51 AM.

#246

Team Owner

Thread Starter

I called today as well and talked to him for the first time. I was checking to see if they had inspected my heads which they received on Monday. They had not for two reasons:

1. They are installing their new equipment and cleaning shop

2. Certain guys keep them on the phone for 30 minutes shooting the breeze

Now the least you can do is pass on the enlightenment that was bestowed upon you today. BTW: I got off in less than 2 minutes

I already told Richard to get me new CHE rockers. But if yours become available before hand let me know.

DH

1. They are installing their new equipment and cleaning shop

2. Certain guys keep them on the phone for 30 minutes shooting the breeze

Now the least you can do is pass on the enlightenment that was bestowed upon you today. BTW: I got off in less than 2 minutes

I already told Richard to get me new CHE rockers. But if yours become available before hand let me know.

DH

We talked springs, dual vs beehive, and advantages and disadvantages of each. Spring install heights, harmonics, valve float, spring surge and spintron testing.

Types of rocker arms and the indications for roller rockers.

#247

Burning Brakes

#249

Team Owner

Thread Starter

....

Bronze guides are the fix for the problem. Rich has seen bronze guides wear with stock intake valves and THAT is the reason Katech uses molybdenum-coated titanium intake valves when using bronze guides. We found that the chrome nitride coating on the intake valves was too harsh on the bronze. Like WCCH, we polished them and saw some improvement, but it was not to our liking so we used the Ti/Mo intake valves. If you completely follow our advice you will not have a problem.

Bronze guides are the fix for the problem. Rich has seen bronze guides wear with stock intake valves and THAT is the reason Katech uses molybdenum-coated titanium intake valves when using bronze guides. We found that the chrome nitride coating on the intake valves was too harsh on the bronze. Like WCCH, we polished them and saw some improvement, but it was not to our liking so we used the Ti/Mo intake valves. If you completely follow our advice you will not have a problem.

If they even thought that it was, they would not be standing so strongly in their statement as to what "the fix" is.

And with regard to bronze guides being "inferior", and thus less desirable, Katech_Jason had this to say earlier, when you and your other buddy, MTRC6Z, tried the following approach, in an attempt to cast doubt on, and discredit the use of, bronze guides in the management of this problem:

...Assuming everything is properly installed and all geometry is good there's no reason not to use the stock guide. Of course IF everyhting ain't properly installed with good geometry the bronze guide ain't gunna fix anything anyway...IMHO the ONLY reason to down-grade to a bronze guide is IF you can't get a stock guide..

Cheers, Paul.

Cheers, Paul.

Simply put, the OEM sintered guides are superior (all other things being equal) due to their hardness, wear characteristics, alloy and heat dissipation. There IS a reason OEM uses them - and its not because of bronze's availability or cost.

The issues are when other things interact negatively (geometry, tolerance, the valve design or coating, etc). Most of the big name builders here will say as much - the common denominator is sourcing (or working through those other variables).

The issues are when other things interact negatively (geometry, tolerance, the valve design or coating, etc). Most of the big name builders here will say as much - the common denominator is sourcing (or working through those other variables).

None of which fix "bad geometry".

They apparently do not feel that it is a "geometry" issue, as their "fix" is not directed towards addressing "geometry".

Anyone waiting for them to come back now and say that the issue IS geometry, and in so saying, effectivel admitting that they have been recommending a "fix" which does not address geometry, and is thus ineffective, well if you're waiting for that, be prepared for a long wait.

The reason why, is because you have a tendency to make many comments with no research, no phone calls, no personal investigation whatsoever. For example, your comment:

If you actually call WCCH, they will tell you, that the approach that they have thus far used with SS valves and bronze valve guides, has a track record, it has worked, and they have gotten good results with it.

They will go on to say that the new hollow stemmed titanium exhaust valves coming from Del West, they have obviously not done any heads with these valves yet.

At this time, they recommend, if you are having your heads done, that you stick with what has proven to work thus far.

Yes, and they are OK with the factory two-piece valves, properly installed

..and because of that they are now offering a coated Ti exhaust valve that is lighter than the factory valve and about $1100/set for forum members should they choose to go the light weight route.

..and because of that they are now offering a coated Ti exhaust valve that is lighter than the factory valve and about $1100/set for forum members should they choose to go the light weight route.

However if Katech comes back now and says.; "You know guys, it was a geometry problem, all along. And the fix we have mentioned before, doesn't address that", then they are going to be a lot of questions as to why they didn't figure that out in the first place.

Neither WCCH, nor Katech, has said that this is a "geometry" problem. And I doubt that either is ever going to.

So anyone in a time frame, and currently needing or wanting to address this matter, waiting for that to happen before they move, likely need not wait any longer, because neither is going to call it a geometry problem now, and with good reason......because they apparently don't believe that it is a geometry problem.

The greatest impetus for this to be recognized as a "geometry problem" is not coming from any of the shops or vendors in here, which have collectively seen perhaps hundreds of LS7 heads to this point. No, that impetus is coming from that thread.

Anyone wanting to hang their hats on the findings produced by that thread, is of course welcome to do so.

I'll stick with the professionals, even though there are subtle or if you want to argue, "significant" differences in their recommendations for a "fix", none of them is talking "geometry" as a prime cause for this issue we are seeing .

Last edited by '06 Quicksilver Z06; 12-29-2012 at 12:24 PM.

#250

#251

Team Owner

Thread Starter

If you want to argue that installing new guides fix bad geometry, well then you have an equal burden to prove that it does, as I do, to prove that it doesn't.

Be my guest and put up your example of where it did in one of these LS7 heads.

#252

Team Owner

Thread Starter

Oh, BTW Mark, I was looking at that article you pointed to me earlier on spintron testing.

http://www.gmhightechperformance.com...er_system.html

And I noticed again what spring they were using so I did a little more research on that spring.

They were using the PSI-LS 1511 in that test, and a 98 gram valve.

I did a quick search of the PSI-LS 1511 and I looked at the seat pressures and install heights.

Forgive me but I'm working from my iPad and it is difficlut to keep up with the tabs and paste the links into notes. But I was able to find this with regard to spring pressures for that spring.

http://www.cvproducts.com/upfiles/PSI%20SPECS.pdf

http://forums.trailvoy.com/showthread.php?p=1121078

http://forums.corvetteforum.com/c6-t...post1580158741

http://www.ls2.com/usa/showthread.php?p=8463411

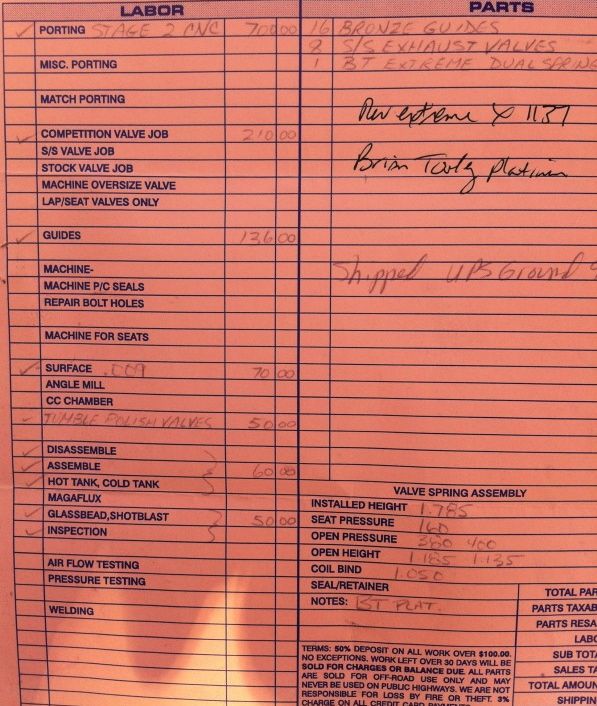

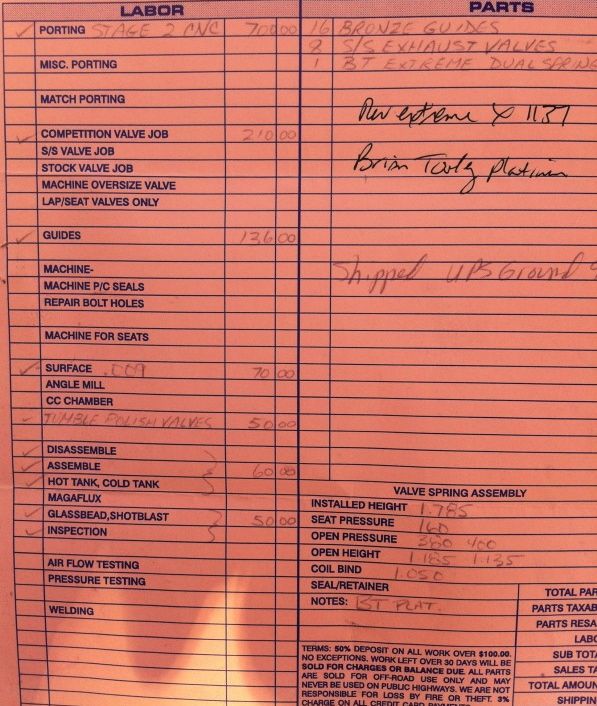

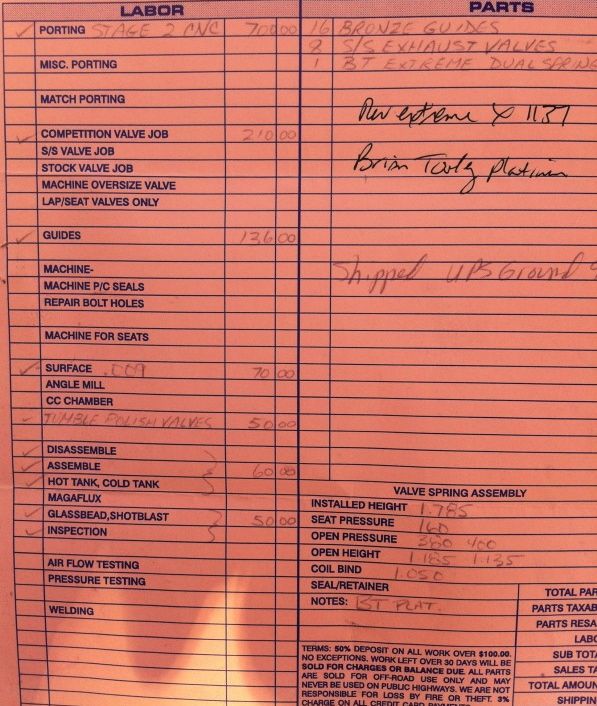

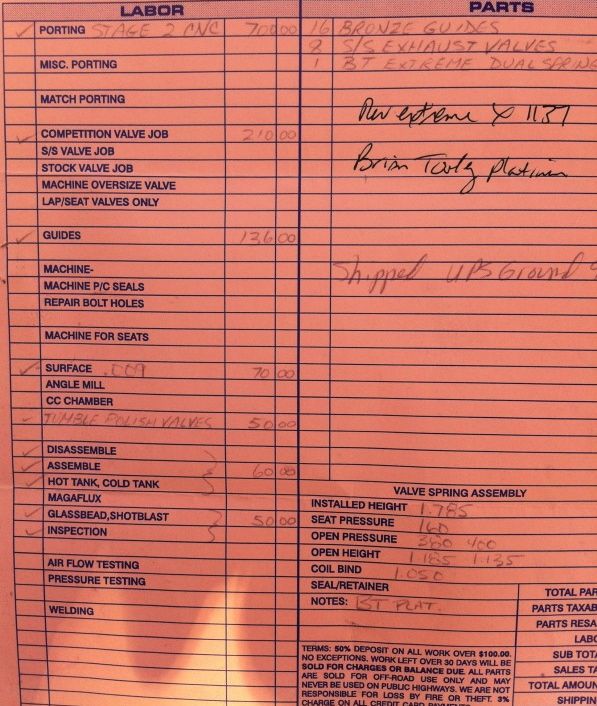

And then I briefly looked at my own seat pressures from when I had my heads done.

I have not had a chance to throughly compare, but I'm posting this up for themembersip to see, so that they can compare.

Just looking at it and looking at my own seat pressures, open and close, vs the spring pressures of the spring used in that test, is it any wonder why they got the undesirable results in that test that they did?

I believe that this spring, the PSI1511LS is the same spring that Katech sells on their site and with their packages.

Thoughts anyone? As I am on the way home now.

http://www.gmhightechperformance.com...er_system.html

And I noticed again what spring they were using so I did a little more research on that spring.

They were using the PSI-LS 1511 in that test, and a 98 gram valve.

I did a quick search of the PSI-LS 1511 and I looked at the seat pressures and install heights.

Forgive me but I'm working from my iPad and it is difficlut to keep up with the tabs and paste the links into notes. But I was able to find this with regard to spring pressures for that spring.

http://www.cvproducts.com/upfiles/PSI%20SPECS.pdf

http://forums.trailvoy.com/showthread.php?p=1121078

http://forums.corvetteforum.com/c6-t...post1580158741

http://www.ls2.com/usa/showthread.php?p=8463411

And then I briefly looked at my own seat pressures from when I had my heads done.

I have not had a chance to throughly compare, but I'm posting this up for themembersip to see, so that they can compare.

Just looking at it and looking at my own seat pressures, open and close, vs the spring pressures of the spring used in that test, is it any wonder why they got the undesirable results in that test that they did?

I believe that this spring, the PSI1511LS is the same spring that Katech sells on their site and with their packages.

Thoughts anyone? As I am on the way home now.

Last edited by '06 Quicksilver Z06; 12-29-2012 at 02:11 PM.

#253

If a valve seat exceeds the normal or professionally accepted concentricity (centering) spec with respect to the valve guide, would you categorize that as "bad geometry", or would you at least agree that it could cause or lead to "bad geometry"?

#254

#256

Team Owner

Thread Starter

Point to the redone heads which you know for a fact, corrected that?

I have been out clearing the snow from my driveway since I got home.

What did you think of the spring pressures?

#257

Team Owner

Thread Starter

Got you on the list Troy.

By chance, do you know which springs you're running?

Looking back, I hate I didn't include this information in the original post wherever I could. The spring pressures. That will be my next SS valve thread. "If you are running solid stainless valves, then what springs are you running?"

It would have made the thread even more helpful than it is now. If people are considering this mod, then the more information on valve springs and their selection, the better.

We ought to just have a valve spring thread, but it is going to require someone like a vendor who knows valve springs inside and out, to set it up. I'll start looking. Hopefully one of them is reading this, and is game.

The good thing is that we have right around 110 members in here that I have been able to find in here, or who have responded in this thread, or both, who are running solid stainless valves.

I think that's pretty good.

Last edited by '06 Quicksilver Z06; 12-31-2012 at 11:23 AM.

#258

Burning Brakes

Oh, BTW Mark, I was looking at that article you pointed to me earlier on spintron testing.

http://www.gmhightechperformance.com...er_system.html

And I noticed again what spring they were using so I did a little more research on that spring.

They were using the PSI-LS 1511 in that test, and a 98 gram valve.

I did a quick search of the PSI-LS 1511 and I looked at the seat pressures and install heights.

Forgive me but I'm working from my iPad and it is difficlut to keep up with the tabs and paste the links into notes. But I was able to find this with regard to spring pressures for that spring.

http://www.cvproducts.com/upfiles/PSI%20SPECS.pdf

http://forums.trailvoy.com/showthread.php?p=1121078

http://forums.corvetteforum.com/c6-t...post1580158741

http://www.ls2.com/usa/showthread.php?p=8463411

And then I briefly looked at my own seat pressures from when I had my heads done.

I have not had a chance to throughly compare, but I'm posting this up for themembersip to see, so that they can compare.

Just looking at it and looking at my own seat pressures, open and close, vs the spring pressures of the spring used in that test, is it any wonder why they got the undesirable results in that test that they did?

I believe that this spring, the PSI1511LS is the same spring that Katech sells on their site and with their packages.

Thoughts anyone? As I am on the way home now.

http://www.gmhightechperformance.com...er_system.html

And I noticed again what spring they were using so I did a little more research on that spring.

They were using the PSI-LS 1511 in that test, and a 98 gram valve.

I did a quick search of the PSI-LS 1511 and I looked at the seat pressures and install heights.

Forgive me but I'm working from my iPad and it is difficlut to keep up with the tabs and paste the links into notes. But I was able to find this with regard to spring pressures for that spring.

http://www.cvproducts.com/upfiles/PSI%20SPECS.pdf

http://forums.trailvoy.com/showthread.php?p=1121078

http://forums.corvetteforum.com/c6-t...post1580158741

http://www.ls2.com/usa/showthread.php?p=8463411

And then I briefly looked at my own seat pressures from when I had my heads done.

I have not had a chance to throughly compare, but I'm posting this up for themembersip to see, so that they can compare.

Just looking at it and looking at my own seat pressures, open and close, vs the spring pressures of the spring used in that test, is it any wonder why they got the undesirable results in that test that they did?

I believe that this spring, the PSI1511LS is the same spring that Katech sells on their site and with their packages.

Thoughts anyone? As I am on the way home now.

I sent this to you on PM but noticed you posted here, so I'll share on the forum too.

The Katech catalog says the installed height for PSI-1511 springs on the LS7 is 1.85", and lists the seat pressure as 120lbs @ 1.80". That means the seat pressure @ 1.85" is even less... 100.8 lbs by my calculations.

You take the difference in height and multiply by the spring rate provided:

(1.85in - 1.80in) x 384 lbs/in = 19.2lbs

You subtract because you are un-compressing the spring by 0.05" from 1.80" to 1.85", so...

120lbs - 19.2 lbs = 100.8 lbs.

Now compare 100.8lbs @ 1.85" installed height to your 160lbs @ 1.785" installed height. You are looking at nearly 60lbs extra on the seat to control against valve bounce compared to the set up used in the article.

#259

Team Owner

Thread Starter

Ricky,

I sent this to you on PM but noticed you posted here, so I'll share on the forum too.

The Katech catalog says the installed height for PSI-1511 springs on the LS7 is 1.85", and lists the seat pressure as 120lbs @ 1.80". That means the seat pressure @ 1.85" is even less... 100.8 lbs by my calculations.

You take the difference in height and multiply by the spring rate provided:

(1.85in - 1.80in) x 384 lbs/in = 19.2lbs

You subtract because you are un-compressing the spring by 0.05" from 1.80" to 1.85", so...

120lbs - 19.2 lbs = 100.8 lbs.

Now compare 100.8lbs @ 1.85" installed height to your 160lbs @ 1.785" installed height. You are looking at nearly 60lbs extra on the seat to control against valve bounce compared to the set up used in the article.

I sent this to you on PM but noticed you posted here, so I'll share on the forum too.

The Katech catalog says the installed height for PSI-1511 springs on the LS7 is 1.85", and lists the seat pressure as 120lbs @ 1.80". That means the seat pressure @ 1.85" is even less... 100.8 lbs by my calculations.

You take the difference in height and multiply by the spring rate provided:

(1.85in - 1.80in) x 384 lbs/in = 19.2lbs

You subtract because you are un-compressing the spring by 0.05" from 1.80" to 1.85", so...

120lbs - 19.2 lbs = 100.8 lbs.

Now compare 100.8lbs @ 1.85" installed height to your 160lbs @ 1.785" installed height. You are looking at nearly 60lbs extra on the seat to control against valve bounce compared to the set up used in the article.

And yes, I saw these springs on page 34 of the Katech Catalog http://www.katechengines.com/street_...%20version.pdf

Let me make sure I follow you.

My install height is 1.785" for my BT Dual Platinums, set up by WCCH into my redone heads.

And the install height for the PSI-1511 springs on the LS7 according to Katech's site, is 1.85"

The seat pressure of the PSI-1511 at 1.80 is 120lbs.

But at that install height of 1.85, works out to 100.8lbs.

And the actual install height is supposed to be 1.85" for the LS7.

And at that height, the spring pressure is right around 60lbs less than what mine is.

I was looking at the post by FNBADAZ06, the part in bold.

When I finally put the Katech 110 Torquer in my LS7, I'm going with the beehive spring route. Katech has done a ton of R&D on valve train harmonics, and based on their testing they spec this spring for all their street engine packages.....hard to beat that.

Torquer 110 Specifications 220 / 244 @ .050, .615 / .648 lift, 110 LSA +004

The matching Katech high lift valve springs used...

"

This 65g lightweight beehive spring is Katech's default for all engine packages. Optron valvetrain dynamics testing revealed this spring was the best choice to keep lightweight valves such as LS6 and LS7 in control.

Spring Specifications

Weight 65g

OD 1.290

ID .630

Install height LS6 1.800

Install height LS7 1.850

Seat Pressure LS6 120lbs.

Seat Pressure LS7 113lbs

Open Pressure 360lbs @ 1.175

Rate 384 lb/in

Max lift LS6 .625

Max lift LS7 .700

Coil Bind 1.100

"

Torquer 110 Specifications 220 / 244 @ .050, .615 / .648 lift, 110 LSA +004

The matching Katech high lift valve springs used...

"

This 65g lightweight beehive spring is Katech's default for all engine packages. Optron valvetrain dynamics testing revealed this spring was the best choice to keep lightweight valves such as LS6 and LS7 in control.

Spring Specifications

Weight 65g

OD 1.290

ID .630

Install height LS6 1.800

Install height LS7 1.850

Seat Pressure LS6 120lbs.

Seat Pressure LS7 113lbs

Open Pressure 360lbs @ 1.175

Rate 384 lb/in

Max lift LS6 .625

Max lift LS7 .700

Coil Bind 1.100

"

Last edited by '06 Quicksilver Z06; 12-29-2012 at 07:30 PM.

#260

Burning Brakes

Wow. That is significant.

Let me make sure I follow you.

My install height is 1.785" for my BT Dual Platinums, set up by WCCH into my redone heads.

And the install height for the PSI-1511 springs on the LS7 according to Katech's site, is 1.85"

The seat pressure of the PSI-1511 at 1.80 is 120lbs.

But at that install height of 1.85, works out to 100.8lbs.

And the actual install height is supposed to be 1.85" for the LS7.

And at that height, the spring pressure is right around 60lbs less than what mine is.

I was looking at the post by FNBADAZ06, the part in bold.

Let me make sure I follow you.

My install height is 1.785" for my BT Dual Platinums, set up by WCCH into my redone heads.

And the install height for the PSI-1511 springs on the LS7 according to Katech's site, is 1.85"

The seat pressure of the PSI-1511 at 1.80 is 120lbs.

But at that install height of 1.85, works out to 100.8lbs.

And the actual install height is supposed to be 1.85" for the LS7.

And at that height, the spring pressure is right around 60lbs less than what mine is.

I was looking at the post by FNBADAZ06, the part in bold.

For instance the OEM stock springs are installed at 1.96" height from what I've found.

I am scratching my head at the 113lbs @ 1.85" though...

If you do the calculation the other way, go from 120lbs @ 1.80" to the open pressure at 1.175" it works out.

(1.80in - 1.175in) x 384 lbs/in = 240 lbs

This time you add since you are compressing 0.625in from 1.80in to 1.175in.

120lbs + 240lbs = 360lbs @ 1.175in this matches the spring specs and FNBADAZ06s quote.

The spring rate is linear.

I won't belabor the math, but for a seat pressure of 113lbs with this spring, the install height would be ~1.82"

Either way 160lbs is much more than 113lbs or 100.8lbs.

EDIT: Installing a spring at a taller height also allows more room before coil bind and a higher lift cam. If you notice the PSI spring is rated for a 0.625" lift, but the torquer cams have more exhaust lift at 0.648". Installing the PSI 1511 at 1.85" vice 1.80" on the LS7 allows 0.05" more lift with the spring to accommodate the torquer cams 0.648" lift.

Last edited by Rock36; 12-29-2012 at 05:07 PM.