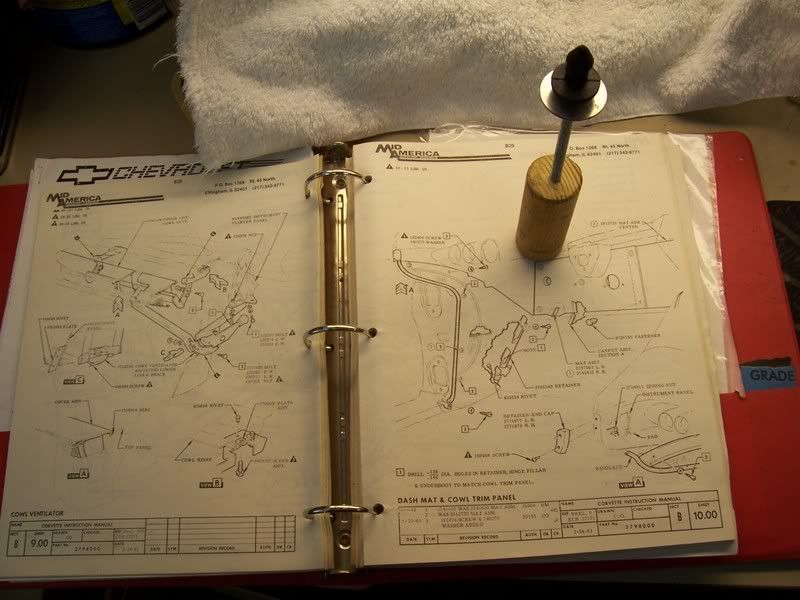

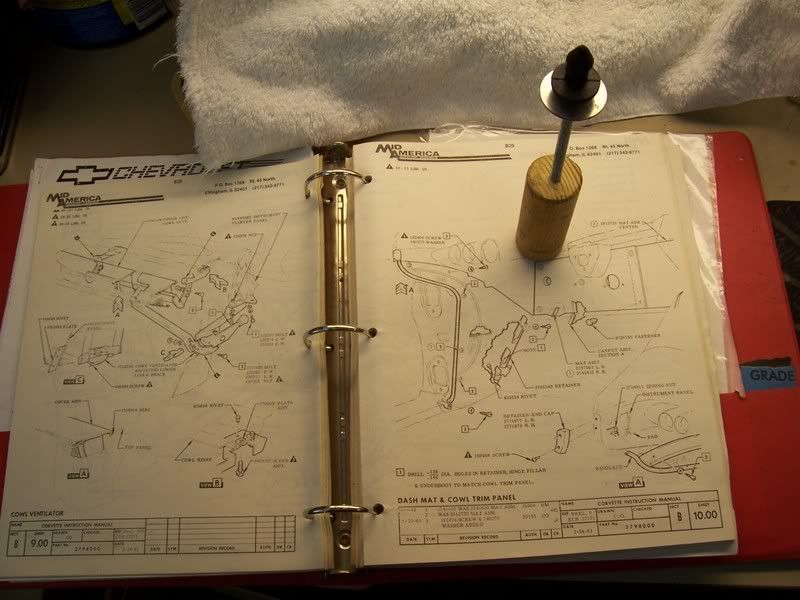

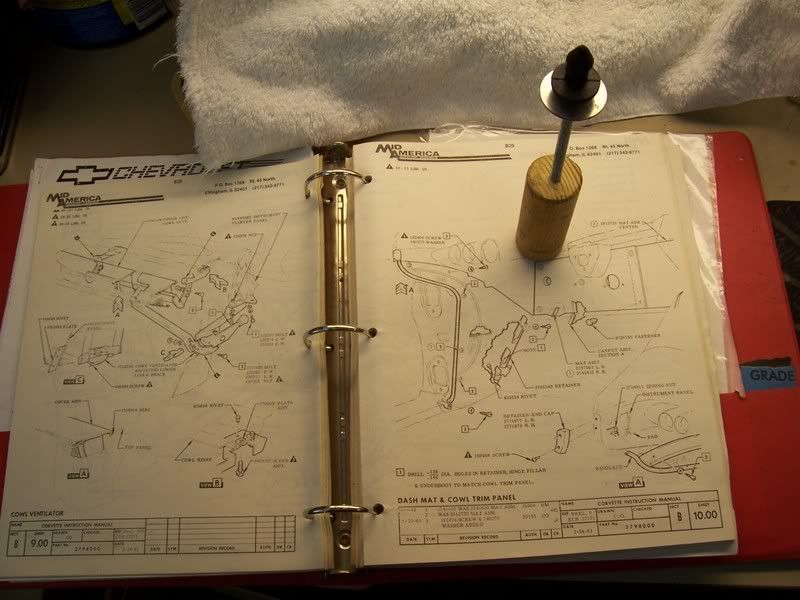

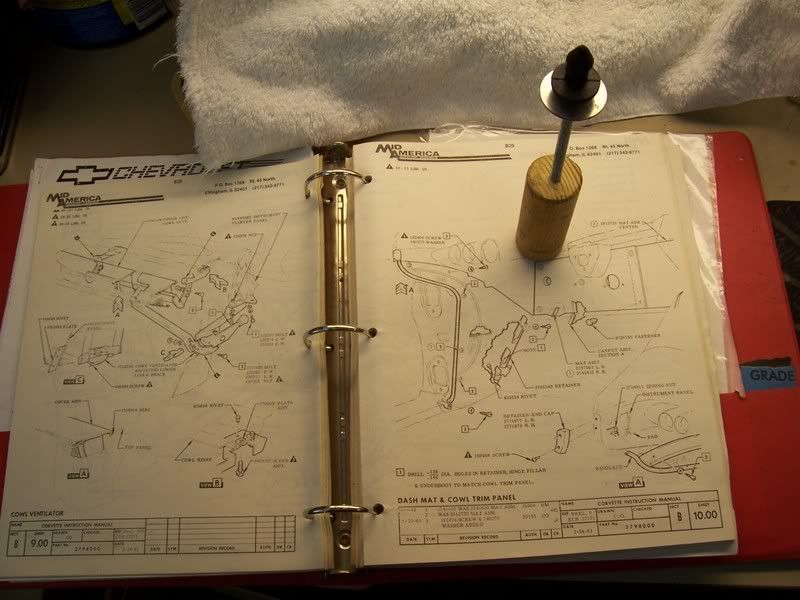

Made a cool tool!

#1

Melting Slicks

Thread Starter

Anyone installed a firewall pad lately. Well let me tell you its a bear without a special tool. I could not get the tip of the fastner to go through the pad and the firewall and catch. I tried to use a punch but only pushed through the fastner. Figured there must be a tool for this so I went to see my friend at Va Vettes. He thought for a minute and said, lets make one. He's one of those engineer types. Soo! here is what we came up with and it works like a charm.

Short section of wood closet rod (cost $0) found in bottom of old tool box

Short section 1/4x20 threaded rod (cost $0) found in junk box

2 1/4x20 nuts (cost $0) everybody has a couple extra nuts

1 large 1/4 fender washer (cost $0) left over from last restoration job

Thanks to Va Vettes!

Enjoy

Some progress, back end is done and most trim on.

C1 Guys "Gotta Love This"

Earl

Short section of wood closet rod (cost $0) found in bottom of old tool box

Short section 1/4x20 threaded rod (cost $0) found in junk box

2 1/4x20 nuts (cost $0) everybody has a couple extra nuts

1 large 1/4 fender washer (cost $0) left over from last restoration job

Thanks to Va Vettes!

Enjoy

Some progress, back end is done and most trim on.

C1 Guys "Gotta Love This"

Earl

#4

Anyone installed a firewall pad lately. Well let me tell you its a bear without a special tool. I could not get the tip of the fastner to go through the pad and the firewall and catch. I tried to use a punch but only pushed through the fastner. Figured there must be a tool for this so I went to see my friend at Va Vettes. He thought for a minute and said, lets make one. He's one of those engineer types. Soo! here is what we came up with and it works like a charm.

Short section of wood closet rod (cost $0) found in bottom of old tool box

Short section 1/4x20 threaded rod (cost $0) found in junk box

2 1/4x20 nuts (cost $0) everybody has a couple extra nuts

1 large 1/4 fender washer (cost $0) left over from last restoration job

Thanks to Va Vettes!

Enjoy

Hey Earl,

Had the same problem this summer, LIC has a tool that works similar as the one you made. As you said if you aren't careful you punch through the end. I bought an extra pack for that reason.

Good luck with the restoration!!

Shooter

Short section of wood closet rod (cost $0) found in bottom of old tool box

Short section 1/4x20 threaded rod (cost $0) found in junk box

2 1/4x20 nuts (cost $0) everybody has a couple extra nuts

1 large 1/4 fender washer (cost $0) left over from last restoration job

Thanks to Va Vettes!

Enjoy

Hey Earl,

Had the same problem this summer, LIC has a tool that works similar as the one you made. As you said if you aren't careful you punch through the end. I bought an extra pack for that reason.

Good luck with the restoration!!

Shooter

#7

Team Owner

Member Since: Oct 2000

Location: Washington Michigan

Posts: 38,899

Received 1,859 Likes

on

1,102 Posts

That's exactly what we used on the line in the plant, except ours was made from a phillips screwdriver, end ground to a round shape, with a washer brazed to the shaft so the shaft was about 1/4" longer than the rubber plug (as yours is). The plugs were heated in a bench-top tray under a heat lamp, and the shaft part of the plug was dipped in a 50-50 Joy soap/water solution before installing them; the inside guy pushed them through, and the outside guy grabbed the tip with a pair of duckbill pliers and pulled to seat the plug.

#9

Le Mans Master

#10

Melting Slicks

Thread Starter

That's exactly what we used on the line in the plant, except ours was made from a phillips screwdriver, end ground to a round shape, with a washer brazed to the shaft so the shaft was about 1/4" longer than the rubber plug (as yours is). The plugs were heated in a bench-top tray under a heat lamp, and the shaft part of the plug was dipped in a 50-50 Joy soap/water solution before installing them; the inside guy pushed them through, and the outside guy grabbed the tip with a pair of duckbill pliers and pulled to seat the plug.

Earl

#11

Race Director

Funny you should say that, using a worn out phillips. That was our first thought, but we had no welder. My friend said hay lets use this old 1/4-20 threaded rod and that way you can set the depth where you want it. Plans are to take the washer and have it tacked to the first nut as that was the weak link, washer would fall off after installation. To me this is some of the fun while restring a car. If it was easy everybody would be doing it.

Earl

Earl

Dave

Dave

#12

Le Mans Master

Dave, how ironic, you were just talking about this yesterday.

Earl, great job on the tool, pics, and installation. She's looking great!

#13

Team Owner

Member Since: Jan 2007

Location: cookeville tennessee

Posts: 28,847

Received 1,762 Likes

on

1,529 Posts

Anyone installed a firewall pad lately. Well let me tell you its a bear without a special tool. I could not get the tip of the fastner to go through the pad and the firewall and catch. I tried to use a punch but only pushed through the fastner. Figured there must be a tool for this so I went to see my friend at Va Vettes. He thought for a minute and said, lets make one. He's one of those engineer types. Soo! here is what we came up with and it works like a charm.

Short section of wood closet rod (cost $0) found in bottom of old tool box

Short section 1/4x20 threaded rod (cost $0) found in junk box

2 1/4x20 nuts (cost $0) everybody has a couple extra nuts

1 large 1/4 fender washer (cost $0) left over from last restoration job

Thanks to Va Vettes!

Enjoy

Some progress, back end is done and most trim on.

C1 Guys "Gotta Love This"

Earl

Short section of wood closet rod (cost $0) found in bottom of old tool box

Short section 1/4x20 threaded rod (cost $0) found in junk box

2 1/4x20 nuts (cost $0) everybody has a couple extra nuts

1 large 1/4 fender washer (cost $0) left over from last restoration job

Thanks to Va Vettes!

Enjoy

Some progress, back end is done and most trim on.

C1 Guys "Gotta Love This"

Earl