Upgrading stock steering pump for hydro & jeep box

#1

Melting Slicks

Thread Starter

I've been doing a lot of research on what is needed to power both the hydro brake assist unit and aftermarket jeep steering box.

I have a hydro unit from hydratech http://www.hydratechbraking.com/products/c3vette_a/ without lineset.

And I have a modified jeep box power steering from Corvette Steering http://www.corvettesteering.com/corvette%20parts.htm

These are both parts that I have acquired over the past two years.

I have also been reading on this forum about the experience with running both of these upgrades and the tax it has on the stock power steering pump. I have heard from a few that they go thru stock pumps like they change their socks. I have heard the stock pumps work fine if your running one or the other but not both. With futher research on a few other product specific forums I have seen that the main cause of pump failure in the vette or other cars such as mustangs, camaros and trucks is backpressure. Too much backpressure caused from both the hydro unit and the power steering to the pump resoviour backs up the entire system to the point the pump is pushing against a brick wall burning up the pump. First thing is to make sure you have the T fitting correctly. The steering should enter the striaght thru T fitting as the hydro unit should enter the perpendicular part as the hydro unit expells less fluid. But sometimes even this is not enough releif of backpressure on the pump. This theory works with both a jeep box or steeroids rack and pinion, as long as they run off the steering pump.

So to fix this many have gone to an aftermarket steering pump such as a KRC pump with remote reservoir and plumb the tank with two returns. This releases all backpressure and the aftermarket pump can have the output fitting changed to adjust the flow to help with the sensitive jeep box steering. These pumps are expensive. Great pumps but expensive. Some others have changed the T fitting to a Y shape fitting to smooth out the flow but this still causes small backpressure b/c there is only one entrance to the pump reservoir.

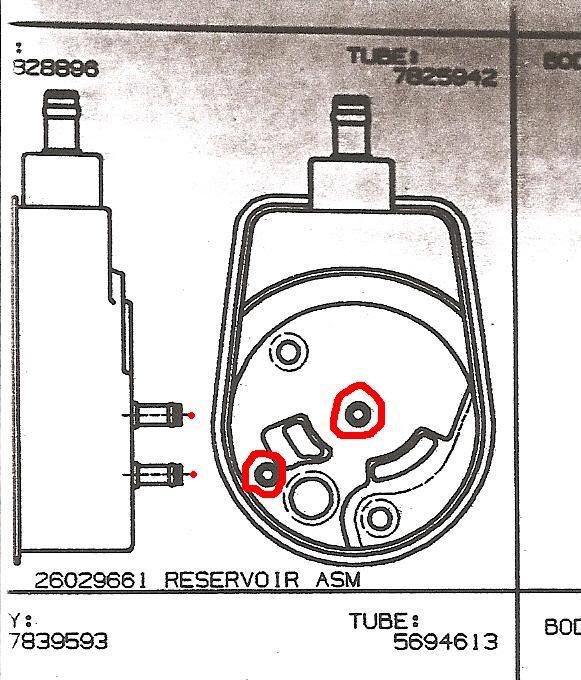

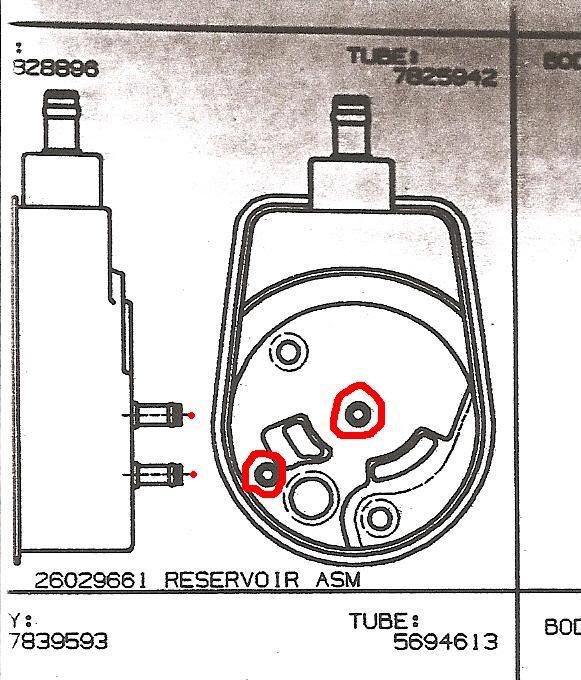

So to fix this I spoke with a few people with extensive experience with the vette pumps and where I could place a second return fitting on the reservoir. This is the diagram I was provided for optimum fluid return to releive the pump of any added pressure.

The main return (center) which was the 90 degree bent tube is where you want the power steering return to go as that flows the most fluid.

The second return hole (lower left) is where the hydro unit will return its fluid.

Here's the stock unit unmodified.

You must take the pump apart in order to safely weld/braze the new -6an weld on fittings to the outside of the tank. You don't want to run the risk of melting any o-rings or seals.

Cut off the 90 degree slip on hose nipple and drill it out to match the -6an weld on fitting. Also drill the second return hole. The factory used some sort of bronze/brass high temp soldier to fix the 90 degree hose barb to the reservoir. You cannot use typical soldier as the melting point is too low.

This is the steel -6an weld on bung that I used for both return spouts.

http://store.summitracing.com/partde...5&autoview=sku

My MIG welder hasn't been working properly and I was afraid I would burn thru the thin metal of the reservoir with my stick welder so I had a local welding place use brass and braze the 6an bungs to the reservoir. They said this would seal it perfectly and be plenty strong.

Here's what I ended up with...

POR-15'd it black....

Now its ready to go in....

Next up is to build the lines.

I used all Aeroquip lines and fittings as a personal preference.

-6an Aeroquip SS teflon lines and -6an Aeroquip fittings.

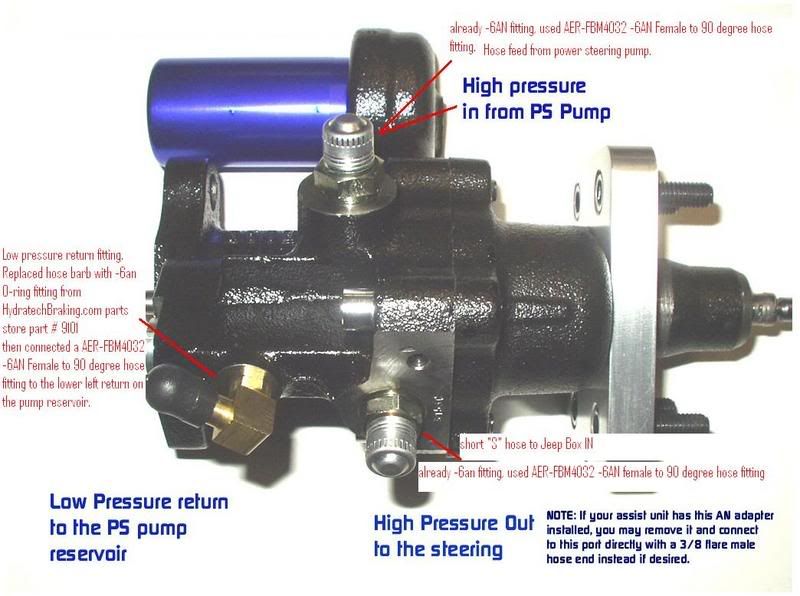

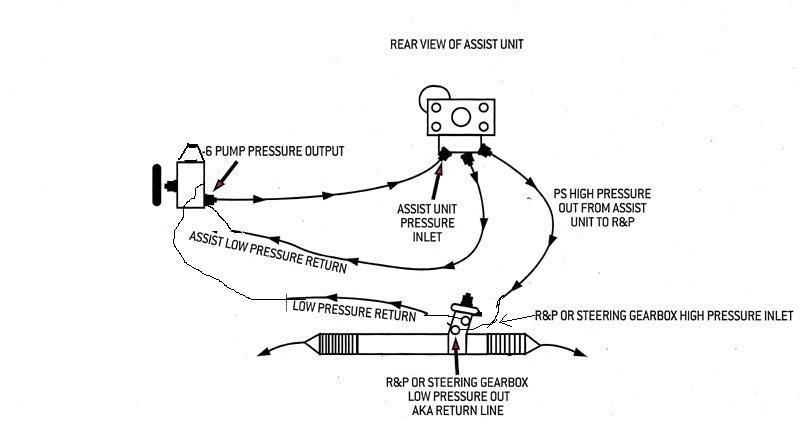

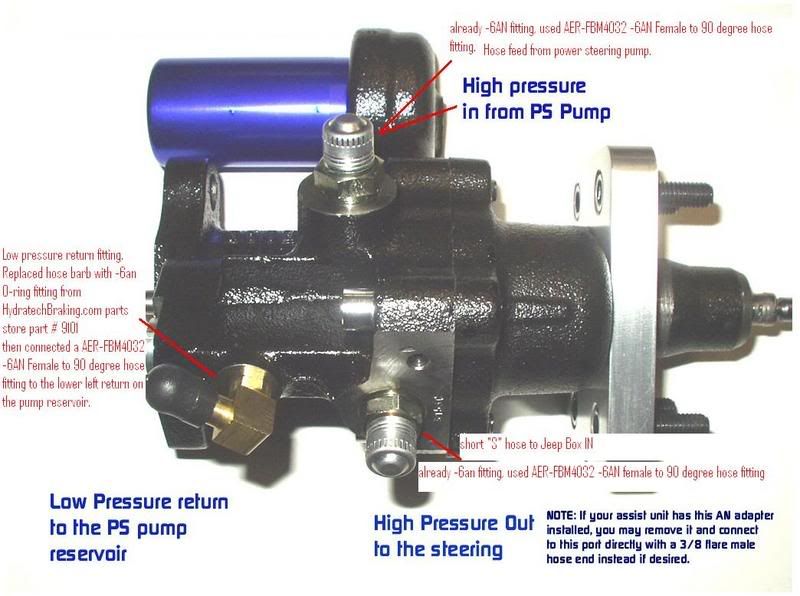

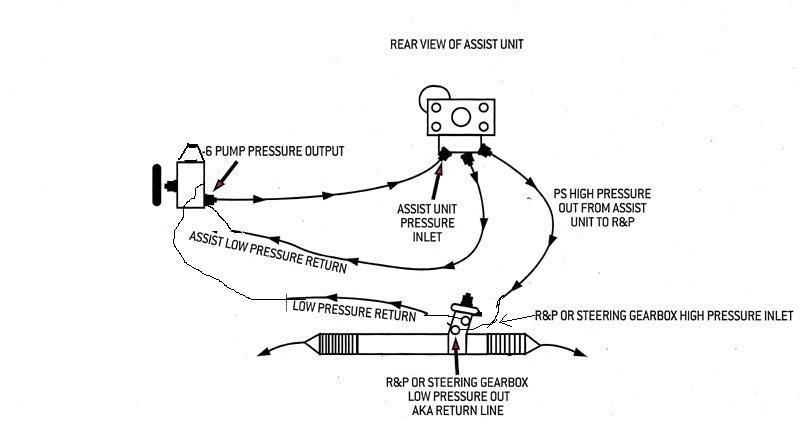

Here are the diagrams I used.

Both my hydroboost unit and the jeep box already had 6an fittings in them.

The Jeep box used Jegs a Large 18mm O-ring fitting Earls Part # 991956ERL which was the inlet pressure side furthest from the engine.

It also used a smaller 16mm O-ring fitting Earls Part # 991955ERL as the outlet port that goes to the center return on the reservoir.

The modified reservoir already had the 6an weld on fittings and the only fitting I changed on the hydro unit was the return which is now a Hydratech part # HBS-9101 b/c I wanted to use SS braided hose instead of a hose barb and hose clamp.

AND I used an AER-FBM1144 fitting on the outlet port on the power steering pump so I could run an SS braided hose.

All other fittings were 90 degree female to hose fittings AER-FBM4032. I needed a 45 degree female to hose fitting for the hydro return line to fit amongst the other 90 degree fittings on the pump.

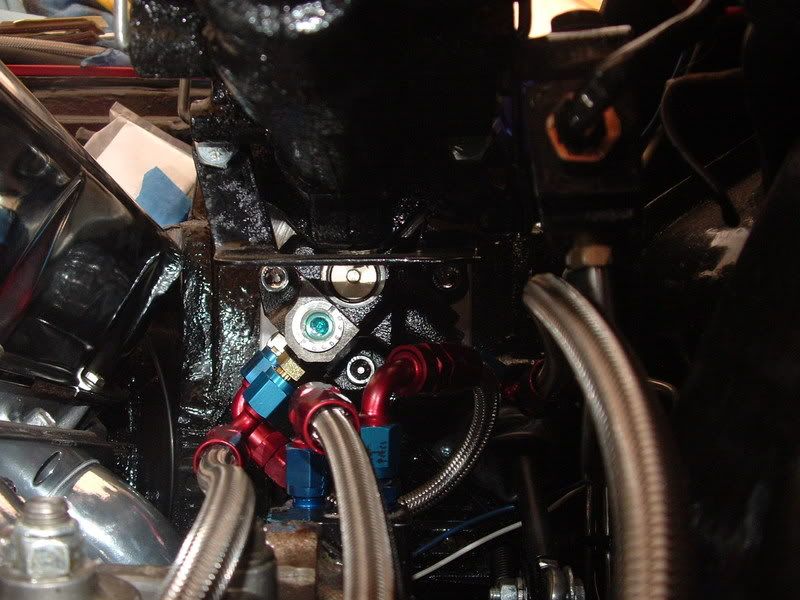

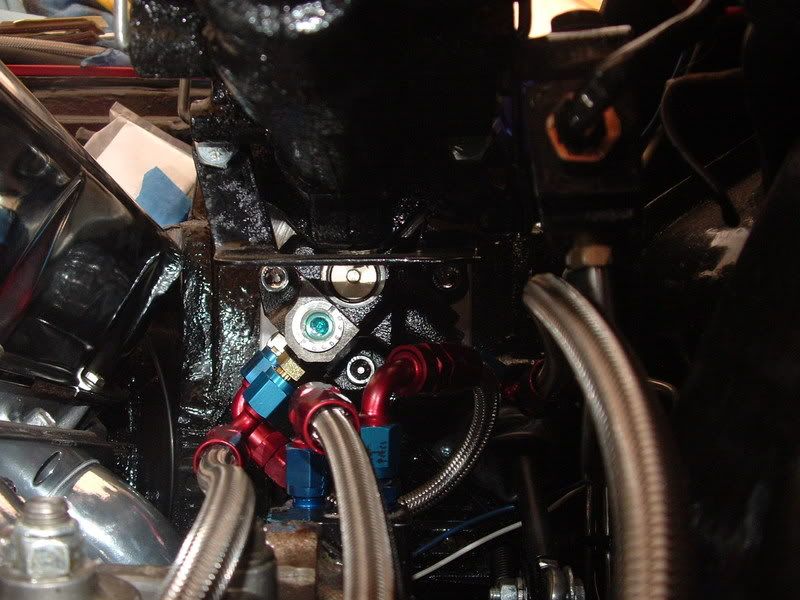

Here are a few pics of the finished product. I left a lot of slack in the lines to keep them away from the header and incase I ever go to a rack setup I should be alright.

I used a very sharp chisel I bought from home depot and a wood workbench to cut the lines. I read about this being a very clean and quick method. Sometimes cutting them with a saw or sissor type tool can fray the edges and be a PIA to fit into the AN fittings. I also used some Earls lubricant to fit them together.

View from below of the power steering pump...

View of the lines coming off of the hydro and jeep box...

Lines coming off of hydro...

Let me know if you have any questions. I think I have provided all the part #'s needed.

I have a hydro unit from hydratech http://www.hydratechbraking.com/products/c3vette_a/ without lineset.

And I have a modified jeep box power steering from Corvette Steering http://www.corvettesteering.com/corvette%20parts.htm

These are both parts that I have acquired over the past two years.

I have also been reading on this forum about the experience with running both of these upgrades and the tax it has on the stock power steering pump. I have heard from a few that they go thru stock pumps like they change their socks. I have heard the stock pumps work fine if your running one or the other but not both. With futher research on a few other product specific forums I have seen that the main cause of pump failure in the vette or other cars such as mustangs, camaros and trucks is backpressure. Too much backpressure caused from both the hydro unit and the power steering to the pump resoviour backs up the entire system to the point the pump is pushing against a brick wall burning up the pump. First thing is to make sure you have the T fitting correctly. The steering should enter the striaght thru T fitting as the hydro unit should enter the perpendicular part as the hydro unit expells less fluid. But sometimes even this is not enough releif of backpressure on the pump. This theory works with both a jeep box or steeroids rack and pinion, as long as they run off the steering pump.

So to fix this many have gone to an aftermarket steering pump such as a KRC pump with remote reservoir and plumb the tank with two returns. This releases all backpressure and the aftermarket pump can have the output fitting changed to adjust the flow to help with the sensitive jeep box steering. These pumps are expensive. Great pumps but expensive. Some others have changed the T fitting to a Y shape fitting to smooth out the flow but this still causes small backpressure b/c there is only one entrance to the pump reservoir.

So to fix this I spoke with a few people with extensive experience with the vette pumps and where I could place a second return fitting on the reservoir. This is the diagram I was provided for optimum fluid return to releive the pump of any added pressure.

The main return (center) which was the 90 degree bent tube is where you want the power steering return to go as that flows the most fluid.

The second return hole (lower left) is where the hydro unit will return its fluid.

Here's the stock unit unmodified.

You must take the pump apart in order to safely weld/braze the new -6an weld on fittings to the outside of the tank. You don't want to run the risk of melting any o-rings or seals.

Cut off the 90 degree slip on hose nipple and drill it out to match the -6an weld on fitting. Also drill the second return hole. The factory used some sort of bronze/brass high temp soldier to fix the 90 degree hose barb to the reservoir. You cannot use typical soldier as the melting point is too low.

This is the steel -6an weld on bung that I used for both return spouts.

http://store.summitracing.com/partde...5&autoview=sku

My MIG welder hasn't been working properly and I was afraid I would burn thru the thin metal of the reservoir with my stick welder so I had a local welding place use brass and braze the 6an bungs to the reservoir. They said this would seal it perfectly and be plenty strong.

Here's what I ended up with...

POR-15'd it black....

Now its ready to go in....

Next up is to build the lines.

I used all Aeroquip lines and fittings as a personal preference.

-6an Aeroquip SS teflon lines and -6an Aeroquip fittings.

Here are the diagrams I used.

Both my hydroboost unit and the jeep box already had 6an fittings in them.

The Jeep box used Jegs a Large 18mm O-ring fitting Earls Part # 991956ERL which was the inlet pressure side furthest from the engine.

It also used a smaller 16mm O-ring fitting Earls Part # 991955ERL as the outlet port that goes to the center return on the reservoir.

The modified reservoir already had the 6an weld on fittings and the only fitting I changed on the hydro unit was the return which is now a Hydratech part # HBS-9101 b/c I wanted to use SS braided hose instead of a hose barb and hose clamp.

AND I used an AER-FBM1144 fitting on the outlet port on the power steering pump so I could run an SS braided hose.

All other fittings were 90 degree female to hose fittings AER-FBM4032. I needed a 45 degree female to hose fitting for the hydro return line to fit amongst the other 90 degree fittings on the pump.

Here are a few pics of the finished product. I left a lot of slack in the lines to keep them away from the header and incase I ever go to a rack setup I should be alright.

I used a very sharp chisel I bought from home depot and a wood workbench to cut the lines. I read about this being a very clean and quick method. Sometimes cutting them with a saw or sissor type tool can fray the edges and be a PIA to fit into the AN fittings. I also used some Earls lubricant to fit them together.

View from below of the power steering pump...

View of the lines coming off of the hydro and jeep box...

Lines coming off of hydro...

Let me know if you have any questions. I think I have provided all the part #'s needed.

Last edited by 68 NJConv 454; 10-01-2007 at 04:36 PM.

#2

Team Owner

Member Since: Oct 2004

Location: Springfield MO

Posts: 23,831

Likes: 0

Received 6 Likes

on

6 Posts

St. Jude Donor '07

I just installed a power steering cooler in my pump return line to help keep things under control. I wasn't aware of the recommendation to hook up the steering for through flow on the tee, I'll have to reverse my hookup.

#3

Team Owner

Funny, I have had a stock '87 PS pump on my car for 12 years now...never changed it once AFAIK it was on that scrap/accident victim '87 from the factory....

so to make it 20 years old now.....when I put it on my car, I pulled the brass nut and the internal reg parts from the stock '72 pump, plugged them into the '87 serp drive pump, went ahead and got an '88 a/c bracket and compressor, and bolted it all up.....this in '95 or so....

in '01-02 I swapped in the Grand Am rack/pinion...same as Steeroids, doing my own install....never touched the pump, plugged it in, worked fine.....

a bit over a year ago, I put in the hydroboost junkyard brake booster and used all original lines in the stock configuration...Teed off the two return lines with a 3/8 hose tee, using the same stock p/s black tank reservoir as a early C4...

never once a hint of any pump failures, car drives/handles/stops just like it should....fluid is fine, checked it yesterday for first time in 6 months or so....

I fail to see a problem.....

Methinks you all putting too much 'science/engineering' into this, just hook the damn thing up and you fine.....the old '72 Vbelt pump and the newer pump are nearly identical....

so to make it 20 years old now.....when I put it on my car, I pulled the brass nut and the internal reg parts from the stock '72 pump, plugged them into the '87 serp drive pump, went ahead and got an '88 a/c bracket and compressor, and bolted it all up.....this in '95 or so....

in '01-02 I swapped in the Grand Am rack/pinion...same as Steeroids, doing my own install....never touched the pump, plugged it in, worked fine.....

a bit over a year ago, I put in the hydroboost junkyard brake booster and used all original lines in the stock configuration...Teed off the two return lines with a 3/8 hose tee, using the same stock p/s black tank reservoir as a early C4...

never once a hint of any pump failures, car drives/handles/stops just like it should....fluid is fine, checked it yesterday for first time in 6 months or so....

I fail to see a problem.....

Methinks you all putting too much 'science/engineering' into this, just hook the damn thing up and you fine.....the old '72 Vbelt pump and the newer pump are nearly identical....

#4

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

Great posting! I would like to add just two things. Number one, the location of the return spouts on the reservoir is very important. Use the locations described and don't deviate from them. Otherwise you can get into aireation problems.

Number two, you sketch as the to the line connections is not correct as drawn. The port and line that is described as the pressure line connection to the gear and the low pressure line to the gear should be reversed. The low pressure line always connects to the port nearest the input shaft on the gear. This gear port takes the 5/8 or the 16mm nut. The pressure port takes the 11/16 or the 18mm nut. Don't mix these two ports or you will be in big trouble.

Jim

Number two, you sketch as the to the line connections is not correct as drawn. The port and line that is described as the pressure line connection to the gear and the low pressure line to the gear should be reversed. The low pressure line always connects to the port nearest the input shaft on the gear. This gear port takes the 5/8 or the 16mm nut. The pressure port takes the 11/16 or the 18mm nut. Don't mix these two ports or you will be in big trouble.

Jim

#5

Melting Slicks

Thread Starter

"Return lines? The best answer is to either obtain a pump housing with twin return line nipples, or install a second return line nipple into your existing reservoir. If this concept doesn't exactly thrill you, the return line T fitting design can work properly instead, though it must be installed and oriented correctly, which is where some people don't pay attention / screw it up. Here's the deal: Know that you will always have a high rate of low pressure return flow from the steering box, vs the only time you have return flow out of the assist unit is when you are letting off the brakes, at which point only about a tablespoon of fluid gets exhausted out of the return line of the brake assist unit. Knowing this, you will see why it is absolutely imperative that the high rate of flow coming out of the steering box must be allowed to flow STRAIGHT THROUGH the long / straight run of the T fitting, and the perpendicular hose nipple sticking out of the right / left of the T is where the assist unit return line connects. This allows the tablespoon of ps fluid that gets exhausted out of the assist unit to simply slide in with the rest of the fluid flowing through the straight run of the T fitting. The installation of a cooler or a filter between the T fitting and the ps pump reservoir IS going to cause enough backpressure / restriction to flow to cause backpressure on the return line connected to the assist unit = malfunctions of mild to severe form, depending on just how much backpressure exists. Customers that don't follow the directions have been known to call in stating: "my brake pedal applies by itself the minute I start the engine", to where we immediately know that there is a backpressure situation, almost always caused by improper orientations of the T fitting, or caused by a restriction to flow by a cooler or filter. We then have them replumb the return line T fitting correctly, AFTER any such coolers / filters = mint. I will say that if you have installed a VERY high flow pump, that there may be simply too much flow in the return line coming out of the steering box, and it will be mandatory to install an independant second return. You will only find this with pumps flowing more than 5 GPM (gallons per minute), vs most automotive / truck applications will only flow about 3.5 - 4.5 GPM. Summary? Most of the stuff you're hearing about is because people aren't paying attention to the instructions, and overall don't understand "what makes these things tick". I will say that the most optimum way to set up the system IS to install an independant / individual return line fitting on the ps pump reservoir, though this is a task that most will not want to get into - hence the T fitting design (which can, does, and will work fine, as long as the aforementioned informations are taken into account). "

Second paragraph in the Reply. http://www.hydratechbraking.com/foru...topic.php?t=38

#6

Melting Slicks

Thread Starter

I don't see a point of installing a stock C3 pump into a car when I can modify it now instead of the first time I break down on the side of the road.

#7

Melting Slicks

Thread Starter

Number two, you sketch as the to the line connections is not correct as drawn. The port and line that is described as the pressure line connection to the gear and the low pressure line to the gear should be reversed. The low pressure line always connects to the port nearest the input shaft on the gear. This gear port takes the 5/8 or the 16mm nut. The pressure port takes the 11/16 or the 18mm nut. Don't mix these two ports or you will be in big trouble.Jim

I gave Tom @ Corvette Steering a call on Thursday when I was installing the fittings and he mentioned the large 18mm fitting is the inlet port from the hydro unit/steering pump and the 16mm which I beleive is closest to the engine to be the outlet port.

I will have to check my notes when I get home tonight to confirm but I'm pretty sure thats what I got from the conversation. But I'll check.

And Jim, thanks for your help in this upgrade

#8

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

Yes, the Jeep box connections.

However, the same applies to the Steeroids rack & pinion gear and all Saginaw power gears. The port nearest the input shaft is always the low pressure return to the pump. The other port is the high pressure inlet from the pump (or from the Hydroboost unit.)

Jim

However, the same applies to the Steeroids rack & pinion gear and all Saginaw power gears. The port nearest the input shaft is always the low pressure return to the pump. The other port is the high pressure inlet from the pump (or from the Hydroboost unit.)

Jim

#9

Melting Slicks

Thread Starter

Yes, the Jeep box connections.

However, the same applies to the Steeroids rack & pinion gear and all Saginaw power gears. The port nearest the input shaft is always the low pressure return to the pump. The other port is the high pressure inlet from the pump (or from the Hydroboost unit.)

Jim

However, the same applies to the Steeroids rack & pinion gear and all Saginaw power gears. The port nearest the input shaft is always the low pressure return to the pump. The other port is the high pressure inlet from the pump (or from the Hydroboost unit.)

Jim

#11

Team Owner

Member Since: Oct 2004

Location: Springfield MO

Posts: 23,831

Likes: 0

Received 6 Likes

on

6 Posts

St. Jude Donor '07

Read this...took it right from the Hydratech website forum.

"Return lines? The best answer is to either obtain a pump housing with twin return line nipples, or install a second return line nipple into your existing reservoir. If this concept doesn't exactly thrill you, the return line T fitting design can work properly instead, though it must be installed and oriented correctly, which is where some people don't pay attention / screw it up. Here's the deal: Know that you will always have a high rate of low pressure return flow from the steering box, vs the only time you have return flow out of the assist unit is when you are letting off the brakes, at which point only about a tablespoon of fluid gets exhausted out of the return line of the brake assist unit. Knowing this, you will see why it is absolutely imperative that the high rate of flow coming out of the steering box must be allowed to flow STRAIGHT THROUGH the long / straight run of the T fitting, and the perpendicular hose nipple sticking out of the right / left of the T is where the assist unit return line connects. This allows the tablespoon of ps fluid that gets exhausted out of the assist unit to simply slide in with the rest of the fluid flowing through the straight run of the T fitting. The installation of a cooler or a filter between the T fitting and the ps pump reservoir IS going to cause enough backpressure / restriction to flow to cause backpressure on the return line connected to the assist unit = malfunctions of mild to severe form, depending on just how much backpressure exists. Customers that don't follow the directions have been known to call in stating: "my brake pedal applies by itself the minute I start the engine", to where we immediately know that there is a backpressure situation, almost always caused by improper orientations of the T fitting, or caused by a restriction to flow by a cooler or filter. We then have them replumb the return line T fitting correctly, AFTER any such coolers / filters = mint. I will say that if you have installed a VERY high flow pump, that there may be simply too much flow in the return line coming out of the steering box, and it will be mandatory to install an independant second return. You will only find this with pumps flowing more than 5 GPM (gallons per minute), vs most automotive / truck applications will only flow about 3.5 - 4.5 GPM. Summary? Most of the stuff you're hearing about is because people aren't paying attention to the instructions, and overall don't understand "what makes these things tick". I will say that the most optimum way to set up the system IS to install an independant / individual return line fitting on the ps pump reservoir, though this is a task that most will not want to get into - hence the T fitting design (which can, does, and will work fine, as long as the aforementioned informations are taken into account). "

Second paragraph in the Reply. http://www.hydratechbraking.com/foru...topic.php?t=38

"Return lines? The best answer is to either obtain a pump housing with twin return line nipples, or install a second return line nipple into your existing reservoir. If this concept doesn't exactly thrill you, the return line T fitting design can work properly instead, though it must be installed and oriented correctly, which is where some people don't pay attention / screw it up. Here's the deal: Know that you will always have a high rate of low pressure return flow from the steering box, vs the only time you have return flow out of the assist unit is when you are letting off the brakes, at which point only about a tablespoon of fluid gets exhausted out of the return line of the brake assist unit. Knowing this, you will see why it is absolutely imperative that the high rate of flow coming out of the steering box must be allowed to flow STRAIGHT THROUGH the long / straight run of the T fitting, and the perpendicular hose nipple sticking out of the right / left of the T is where the assist unit return line connects. This allows the tablespoon of ps fluid that gets exhausted out of the assist unit to simply slide in with the rest of the fluid flowing through the straight run of the T fitting. The installation of a cooler or a filter between the T fitting and the ps pump reservoir IS going to cause enough backpressure / restriction to flow to cause backpressure on the return line connected to the assist unit = malfunctions of mild to severe form, depending on just how much backpressure exists. Customers that don't follow the directions have been known to call in stating: "my brake pedal applies by itself the minute I start the engine", to where we immediately know that there is a backpressure situation, almost always caused by improper orientations of the T fitting, or caused by a restriction to flow by a cooler or filter. We then have them replumb the return line T fitting correctly, AFTER any such coolers / filters = mint. I will say that if you have installed a VERY high flow pump, that there may be simply too much flow in the return line coming out of the steering box, and it will be mandatory to install an independant second return. You will only find this with pumps flowing more than 5 GPM (gallons per minute), vs most automotive / truck applications will only flow about 3.5 - 4.5 GPM. Summary? Most of the stuff you're hearing about is because people aren't paying attention to the instructions, and overall don't understand "what makes these things tick". I will say that the most optimum way to set up the system IS to install an independant / individual return line fitting on the ps pump reservoir, though this is a task that most will not want to get into - hence the T fitting design (which can, does, and will work fine, as long as the aforementioned informations are taken into account). "

Second paragraph in the Reply. http://www.hydratechbraking.com/foru...topic.php?t=38

#12

Team Owner

absolutely imperative that the high rate of flow coming out of the steering box must be allowed to flow STRAIGHT THROUGH the long / straight run of the T fitting, and the perpendicular hose nipple sticking out of the right / left of the T is where the assist unit return line connects.

Uh....NO, I just went and checked, my 3/8 T fitting is inline to the HB unit, and the PS rack comes into the 'side' of it.....been that way for about a year now, been about 8 months since the Spal install, when I moved the fluid canister to the frame rail, instead of the front crossmember, I dunno how it was hooked in before, just what is now, for 8 months....never an issue....

JIM....I distinctly remember changing the pump valves over, between my '72 pump and the '87 pump in the car now...running the '72 pump stuff....what are the valving differances...you posted that once and I lost it, of course....

Uh....NO, I just went and checked, my 3/8 T fitting is inline to the HB unit, and the PS rack comes into the 'side' of it.....been that way for about a year now, been about 8 months since the Spal install, when I moved the fluid canister to the frame rail, instead of the front crossmember, I dunno how it was hooked in before, just what is now, for 8 months....never an issue....

JIM....I distinctly remember changing the pump valves over, between my '72 pump and the '87 pump in the car now...running the '72 pump stuff....what are the valving differances...you posted that once and I lost it, of course....

#13

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

I'm afraid that you have found someone with a worse short term memory than yourself. I can find the flows for the C3 Corvette pump but what kind of 87 pump did you have? Which way did you swap the pump discharge parts, from 87 to 72 or vise versa?

Jim

Jim

#14

Melting Slicks

Thread Starter

Uh....NO, I just went and checked, my 3/8 T fitting is inline to the HB unit, and the PS rack comes into the 'side' of it.....been that way for about a year now, been about 8 months since the Spal install, when I moved the fluid canister to the frame rail, instead of the front crossmember, I dunno how it was hooked in before, just what is now, for 8 months....never an issue....

...you must be the luckiest guy with a vette if parts installed incorrectly can function correctly.

...you must be the luckiest guy with a vette if parts installed incorrectly can function correctly. The T fitting may work for you but I can't understand how. If it aint broke then don't fix it...but for someone just installing this system I would "recommend" following the directions, experience and knowledge of the company who sells the product and backs its performance and function with a warantee. I have read from more than one with specific knowledge of the power steering system and hydroboost combination and they all agree with the Hydroboost post above. I do hope your system keeps functioning flawlessly.

The T fitting may work for you but I can't understand how. If it aint broke then don't fix it...but for someone just installing this system I would "recommend" following the directions, experience and knowledge of the company who sells the product and backs its performance and function with a warantee. I have read from more than one with specific knowledge of the power steering system and hydroboost combination and they all agree with the Hydroboost post above. I do hope your system keeps functioning flawlessly. Maybe your 87 pump flows less fluid than a stock C3 and therefore you have less backpressure and don't notice it in the pedal? possible.

#15

Melting Slicks

Thread Starter

Yes, the Jeep box connections.

However, the same applies to the Steeroids rack & pinion gear and all Saginaw power gears. The port nearest the input shaft is always the low pressure return to the pump. The other port is the high pressure inlet from the pump (or from the Hydroboost unit.)

Jim

However, the same applies to the Steeroids rack & pinion gear and all Saginaw power gears. The port nearest the input shaft is always the low pressure return to the pump. The other port is the high pressure inlet from the pump (or from the Hydroboost unit.)

Jim

#16

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

I had a team of technicians and first year engineers that actually routed all of the power steering hoses in all GM passenger cars and light trucks (back in the 70s and early 80s). The production hoses were all "idiot proofed." The pump outlet nut was always 5/8 or 16mm. The gear inlet was always 11/16 or 18mm. That way you could never install the pressure hose backwards. The return from the gear was always 5/8 or 16mm.

So the Hydroboost unit was plumbed into the system with the same philosophy. 5/8 or 16mm out of the pump. 11/16 or 18mm into the Hydroboost. 5/8 or 16mm back out of the Hydroboost. And 11/16 or 18mm into the gear. As I recall, the return from the Hydroboost was just a spout. Otherwise I assume that the return port would have been 5/8 or 16mm.

BTW, when GM went to metric o-ring ports for the 1980 model year, the Hydroboost unit would have converted to metric o-rings at the same time.

I was concerned that people that were fabricating their own hoses could in fact follow the sketch and plumb the hydroboost outlet hose to the return port on the gear.

Jim

So the Hydroboost unit was plumbed into the system with the same philosophy. 5/8 or 16mm out of the pump. 11/16 or 18mm into the Hydroboost. 5/8 or 16mm back out of the Hydroboost. And 11/16 or 18mm into the gear. As I recall, the return from the Hydroboost was just a spout. Otherwise I assume that the return port would have been 5/8 or 16mm.

BTW, when GM went to metric o-ring ports for the 1980 model year, the Hydroboost unit would have converted to metric o-rings at the same time.

I was concerned that people that were fabricating their own hoses could in fact follow the sketch and plumb the hydroboost outlet hose to the return port on the gear.

Jim

#17

Drifting

Wow what a nice job and a great post with good information! Must have taken you as long to document this as it did to do the job!

Thanks for this, might be my next winter project.

Bill

Thanks for this, might be my next winter project.

Bill

#18

Melting Slicks

Thread Starter

BTW, when GM went to metric o-ring ports for the 1980 model year, the Hydroboost unit would have converted to metric o-rings at the same time.

I was concerned that people that were fabricating their own hoses could in fact follow the sketch and plumb the hydroboost outlet hose to the return port on the gear.

Jim

I was concerned that people that were fabricating their own hoses could in fact follow the sketch and plumb the hydroboost outlet hose to the return port on the gear.

Jim

If you see anything else inaccurate with my above post let me know...or if you would like more info posted.

I try to remember to take tons of pics while I'm out working on the car for my records and to make a post if needed.

This forum members help me out tremendously so I like to try to contribute back.

#19

Great write-up and great choice using the brazing method to secure those fittings to the pump housing. I used silver brazing rod to make some custom hard fuel lines for an EFI application. The nice thing about brazing is it's easier to get a leak free seal vs. MIG welding, especially when trying to stick two different types of metal together with vastly different thicknesses. I'm no pro at brazing, or welding for that matter, but I found it easier to learn than fusion welding, it's allot like soldering but uses higher temps.