Spark Dwell Time

#1

Melting Slicks

Thread Starter

Member Since: Feb 2002

Location: Winston Salem NC

Posts: 2,613

Likes: 0

Received 0 Likes

on

0 Posts

I posted this in Tuning. Maybe someone here knows.

I have an LS7 crate engine in a 2003 C5. The Spark Dwell Time for the LS7 is lower than for the LS1. I'm using the LS7 table since I don't want to burn up the LS7 coil packs.

It doesn't seem to outwardly make any difference which table I use.

Any reasons why the LS7 times are lower?

I have an LS7 crate engine in a 2003 C5. The Spark Dwell Time for the LS7 is lower than for the LS1. I'm using the LS7 table since I don't want to burn up the LS7 coil packs.

It doesn't seem to outwardly make any difference which table I use.

Any reasons why the LS7 times are lower?

#2

Melting Slicks

Are the coils different part numbers? It may be that the LS7 coils have a different number of windings which would require less saturation time to achieve the same or more secondary output.

Just hypothetical.....

For that matter, next LS7 we get I'll scope the primary and secondary (voltage), and the coil saturation, in both time and amperes.

Just hypothetical.....

For that matter, next LS7 we get I'll scope the primary and secondary (voltage), and the coil saturation, in both time and amperes.

I posted this in Tuning. Maybe someone here knows.

I have an LS7 crate engine in a 2003 C5. The Spark Dwell Time for the LS7 is lower than for the LS1. I'm using the LS7 table since I don't want to burn up the LS7 coil packs.

It doesn't seem to outwardly make any difference which table I use.

Any reasons why the LS7 times are lower?

I have an LS7 crate engine in a 2003 C5. The Spark Dwell Time for the LS7 is lower than for the LS1. I'm using the LS7 table since I don't want to burn up the LS7 coil packs.

It doesn't seem to outwardly make any difference which table I use.

Any reasons why the LS7 times are lower?

The following users liked this post:

Fiberbundle (12-27-2022)

#3

Melting Slicks

Thread Starter

Member Since: Feb 2002

Location: Winston Salem NC

Posts: 2,613

Likes: 0

Received 0 Likes

on

0 Posts

Are the coils different part numbers? It may be that the LS7 coils have a different number of windings which would require less saturation time to achieve the same or more secondary output.

Just hypothetical.....

For that matter, next LS7 we get I'll scope the primary and secondary (voltage), and the coil saturation, in both time and amperes.

Just hypothetical.....

For that matter, next LS7 we get I'll scope the primary and secondary (voltage), and the coil saturation, in both time and amperes.

The LS1 packs require 4-5 times the dwell at low voltage and high RPM's. But as we get closer to 13 volts the dwell table values are less than 2x at high RPM's.

I don't think there are any other factors influencing the output, but it would be nice to be certain.

Thanks for the response. I would be very interested in what you find.

Joe

#4

Supporting Vendor

Member Since: Jul 2003

Location: http://www.mphparts.com 800-364-1975

Posts: 6,486

Likes: 0

Received 2 Likes

on

1 Post

Not a lot of guys doing LS7 swaps *and* looking at ancillary tables like the spark dwell table -- I hope that you find a clear/concise answer but suspect that you won't. Trial and error is what this is probably going to boil down to.

I think that the worst that could happen with insufficient dwell time (e.g., using the lower LS7 table) is you will get weak or no spark, which will become apparent during tuning. Unfortunately, an aggressive dwell time may not be apparent until a few months later when coils mysteriously start going bad.

Good luck and let us know what you end up doing!

I think that the worst that could happen with insufficient dwell time (e.g., using the lower LS7 table) is you will get weak or no spark, which will become apparent during tuning. Unfortunately, an aggressive dwell time may not be apparent until a few months later when coils mysteriously start going bad.

Good luck and let us know what you end up doing!

#5

Melting Slicks

Thread Starter

Member Since: Feb 2002

Location: Winston Salem NC

Posts: 2,613

Likes: 0

Received 0 Likes

on

0 Posts

Not a lot of guys doing LS7 swaps *and* looking at ancillary tables like the spark dwell table -- I hope that you find a clear/concise answer but suspect that you won't. Trial and error is what this is probably going to boil down to.

I think that the worst that could happen with insufficient dwell time (e.g., using the lower LS7 table) is you will get weak or no spark, which will become apparent during tuning. Unfortunately, an aggressive dwell time may not be apparent until a few months later when coils mysteriously start going bad.

Good luck and let us know what you end up doing!

I think that the worst that could happen with insufficient dwell time (e.g., using the lower LS7 table) is you will get weak or no spark, which will become apparent during tuning. Unfortunately, an aggressive dwell time may not be apparent until a few months later when coils mysteriously start going bad.

Good luck and let us know what you end up doing!

Thanks for the feedback

Joe

#6

Melting Slicks

Saturation, both amount of amperage draw, and time it takes to saturate completely (the latter being the most important in this case). There are seemingly insignificant portions of the waveform that mean specific things.

The first few micro seconds of the amp ramp, as the electrons "rush in" and begin the saturation process, makes a specific pattern that directly relates to integrity of the primary side, and the clear seperation from the secondary side.

This is done using an inductive amp probe.

At the same time, using a second channel on the same scope, you can view the primary voltage, and determine several things about that as well. The integrity of the switching device, whether its a current limiting system or not, integrity of the secondary side (yes, from the primary side voltage) etc.

Using a third channel (4 channel scope, all of this is being plotted at the same time) you can monitor the secondary voltage.

And as the primary collapses, and the coil fires the secondary side, you again can determine several different things. secondary coil integrity, resistance of the plug wire, plug itself, and even a little about whats happening inside the cylinder. the plug firing line portion of the pattern will look different depending on cylinder pressure (low comp, hi comp) fuel mixture (lean or rich) and how wide the plug is gapped.

I have actually scoped ignition systems and made DEAD ON diagnosis of things like bad coils, closed plug gaps, lean conditions from injector flow problems, verbally, before ever pulling a part!!

So, basically, you can determine why there is a difference in the dwell time, using these techniques, and information. If they are different part numbers, they will probably act diffferently electrically.

Last edited by edcmat-l1; 07-03-2007 at 08:37 AM.

#8

Melting Slicks

The important part of all that blah that I posted, is the length of time they take to saturate.

What you would see, on a scope, from one coil to another, would be a difference in the amp ramp. Which is nothing more than a picture of the rate of electron flow into the primary coil. Or more commonly called, saturation.

Ignition coils arent supposed to reach complete saturation. Some peak sharply before discharging. Some flatten out on top. But its the inclination of the ramp that tells the story of the resistance and total winding of the primary. I'll pm you a couple ignition amp patterns tomorrow. I have several hundred scope patterns of all sorts I've been saving up over several years. I'll make sure to get a hold of a ls7 just to check this out.

I was aware of the coil dwell tables, but didnt know the dwell time was different from ls1 to ls7.

You got my curiosity up now.

PS saw your same thread on ls1tech. not much info over there

#9

Supporting Vendor

Member Since: Jul 2003

Location: http://www.mphparts.com 800-364-1975

Posts: 6,486

Likes: 0

Received 2 Likes

on

1 Post

Still though, I think the net result is that gojo is no closer to knowing what the exact values should be -- am I right? But by analyzing the amp ramp rate he could tell if the reason why the calibration tables are different is due to the coils, or something else in the ignition.

Although I love to know the "why" just because I am a tinkerer at heart, it still seems like the fastest approach to knowing which dwell table is more correct is to use the least agressive one and see if it leads to ignition related tuning problem.

Or am I way off base on that?

Always eager to learn,

Tony

#10

Melting Slicks

Thread Starter

Member Since: Feb 2002

Location: Winston Salem NC

Posts: 2,613

Likes: 0

Received 0 Likes

on

0 Posts

This is the LS7 table. At these volts the tables are closer.

.RPMS................LABELS.......Volts

...........11.0.........12.0......13 .0.......14.0......15.0

.....0 5.091165 4.392080 3.890562 3.465032 3.145884

..400 4.984783 4.346488 3.875365 3.465032 3.130687

..800 4.893598 4.270500 3.860167 3.449834 3.130687

1200 4.863203 4.300895 3.829772 3.434637 3.100292

1600 4.832808 4.255302 3.784180 3.373847 3.054699

2000 4.711228 4.164117 3.708192 3.313057 3.009107

2400 4.422475 3.905760 3.465032 3.085094 2.781144

2800 4.331290 3.844970 3.419439 3.039502 2.750749

3200 4.240105 3.768982 3.343452 2.993909 2.705157

3600 4.148920 3.692995 3.297859 2.948317 2.674762

4000 4.027340 3.601810 3.221872 2.887527 2.613972

4400 3.966550 3.556217 3.176279 2.841934 2.568379

4800 3.799377 3.404242 3.039502 2.735552 2.492391

5200 3.601810 3.221872 2.887527 2.598774 2.370811

5600 3.389044 3.054699 2.735552 2.461996 2.249231

6000 3.237069 2.917922 2.629169 2.386009 2.188441

6400 3.130687 2.841934 2.583576 2.355614 2.158046

6800 2.948317 2.674762 2.431601 2.218836 2.036466

7200 2.735552 2.492391 2.264429 2.066861 1.899689

7600 2.537984 2.325219 2.112454 1.930084 1.778109

8000 2.401206 2.218836 2.021269 1.854096 1.717318

LS1 table

LABELS........................Volts

RPM.......11.0........12.0........13.0.. ....14.0......15.0

....0 5.243141 4.498463 4.042537 3.601810 3.297859

.400 5.243141 4.498463 4.042537 3.601810 3.297859

.800 5.243141 4.498463 4.042537 3.601810 3.297859

1200 5.243141 4.498463 4.042537 3.601810 3.297859

1600 5.243141 4.498463 4.042537 3.601810 3.297859

2000 5.243141 4.498463 4.042537 3.601810 3.297859

2400 5.243141 4.498463 4.042537 3.601810 3.297859

2800 5.243141 4.498463 4.042537 3.601810 3.297859

3200 5.151955 4.407278 3.996945 3.601810 3.297859

3600 5.106363 4.407278 3.996945 3.601810 3.297859

4000 4.999980 4.300895 3.905760 3.495427 3.252267

4400 4.954388 4.300895 3.844970 3.404242 3.206674

4800 4.848005 4.194512 3.753785 3.297859 3.100292

5200 4.848005 4.194512 3.692995 3.206674 2.993909

5600 4.848005 4.194512 3.692995 3.206674 2.993909

6000 4.848005 4.194512 3.692995 3.206674 2.993909

6400 4.848005 4.194512 3.692995 3.206674 2.993909

6800 4.848005 4.194512 3.692995 3.206674 2.993909

7200 4.848005 4.194512 3.692995 3.206674 2.993909

7600 4.848005 4.194512 3.692995 3.206674 2.993909

8000 4.848005 4.194512 3.692995 3.206674 2.993909

.RPMS................LABELS.......Volts

...........11.0.........12.0......13 .0.......14.0......15.0

.....0 5.091165 4.392080 3.890562 3.465032 3.145884

..400 4.984783 4.346488 3.875365 3.465032 3.130687

..800 4.893598 4.270500 3.860167 3.449834 3.130687

1200 4.863203 4.300895 3.829772 3.434637 3.100292

1600 4.832808 4.255302 3.784180 3.373847 3.054699

2000 4.711228 4.164117 3.708192 3.313057 3.009107

2400 4.422475 3.905760 3.465032 3.085094 2.781144

2800 4.331290 3.844970 3.419439 3.039502 2.750749

3200 4.240105 3.768982 3.343452 2.993909 2.705157

3600 4.148920 3.692995 3.297859 2.948317 2.674762

4000 4.027340 3.601810 3.221872 2.887527 2.613972

4400 3.966550 3.556217 3.176279 2.841934 2.568379

4800 3.799377 3.404242 3.039502 2.735552 2.492391

5200 3.601810 3.221872 2.887527 2.598774 2.370811

5600 3.389044 3.054699 2.735552 2.461996 2.249231

6000 3.237069 2.917922 2.629169 2.386009 2.188441

6400 3.130687 2.841934 2.583576 2.355614 2.158046

6800 2.948317 2.674762 2.431601 2.218836 2.036466

7200 2.735552 2.492391 2.264429 2.066861 1.899689

7600 2.537984 2.325219 2.112454 1.930084 1.778109

8000 2.401206 2.218836 2.021269 1.854096 1.717318

LS1 table

LABELS........................Volts

RPM.......11.0........12.0........13.0.. ....14.0......15.0

....0 5.243141 4.498463 4.042537 3.601810 3.297859

.400 5.243141 4.498463 4.042537 3.601810 3.297859

.800 5.243141 4.498463 4.042537 3.601810 3.297859

1200 5.243141 4.498463 4.042537 3.601810 3.297859

1600 5.243141 4.498463 4.042537 3.601810 3.297859

2000 5.243141 4.498463 4.042537 3.601810 3.297859

2400 5.243141 4.498463 4.042537 3.601810 3.297859

2800 5.243141 4.498463 4.042537 3.601810 3.297859

3200 5.151955 4.407278 3.996945 3.601810 3.297859

3600 5.106363 4.407278 3.996945 3.601810 3.297859

4000 4.999980 4.300895 3.905760 3.495427 3.252267

4400 4.954388 4.300895 3.844970 3.404242 3.206674

4800 4.848005 4.194512 3.753785 3.297859 3.100292

5200 4.848005 4.194512 3.692995 3.206674 2.993909

5600 4.848005 4.194512 3.692995 3.206674 2.993909

6000 4.848005 4.194512 3.692995 3.206674 2.993909

6400 4.848005 4.194512 3.692995 3.206674 2.993909

6800 4.848005 4.194512 3.692995 3.206674 2.993909

7200 4.848005 4.194512 3.692995 3.206674 2.993909

7600 4.848005 4.194512 3.692995 3.206674 2.993909

8000 4.848005 4.194512 3.692995 3.206674 2.993909

#13

Melting Slicks

Sorry, I didn't mean to sound like the ONLY approach one could take in this situation was trial and error. With the right knowledge and equipment, there's always a way to dissect this stuff, and I'm both intrigued and impressed by your post.

Still though, I think the net result is that gojo is no closer to knowing what the exact values should be -- am I right? But by analyzing the amp ramp rate he could tell if the reason why the calibration tables are different is due to the coils, or something else in the ignition.

Although I love to know the "why" just because I am a tinkerer at heart, it still seems like the fastest approach to knowing which dwell table is more correct is to use the least agressive one and see if it leads to ignition related tuning problem.

Or am I way off base on that?

Always eager to learn,

Tony

Still though, I think the net result is that gojo is no closer to knowing what the exact values should be -- am I right? But by analyzing the amp ramp rate he could tell if the reason why the calibration tables are different is due to the coils, or something else in the ignition.

Although I love to know the "why" just because I am a tinkerer at heart, it still seems like the fastest approach to knowing which dwell table is more correct is to use the least agressive one and see if it leads to ignition related tuning problem.

Or am I way off base on that?

Always eager to learn,

Tony

And you have to be able to determine, using all this new found info, if increasing or decreasing the dwell time is having the effect on the secondary side that you want (increased voltage discharge) and whether or not its harming the coil.

Although the secondary voltage output is determined by the resistance of the secondary side. The voltage required to jump the gap.

#14

Melting Slicks

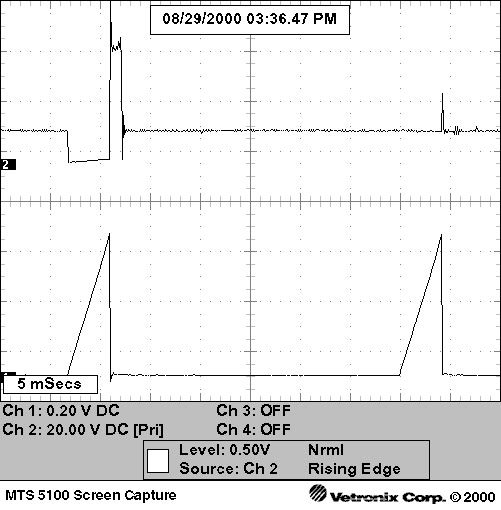

In this image, focus on the left side of the screen. This is a DIS setup, and the second amp ramp is waste spark.

This first image is of the primary voltage and current flow (amperage) of an ignition coil when its cold. This car had misfire issues after it got hot. notice how the amp ramp was steep, pointed at the top, and has a clean discharge, the falling edge on the right.

The sharp peak means the coil never reached complete saturation (which it shouldnt)

The voltage on channel 1 show the coil being switched on (grounded) and then released from ground and the corresponding spike from the primary coil collapsing. If the secondary had issues such as high resistance, this is where it would show up. On the falling side of the amp ramp, and the right side of the voltage wave.

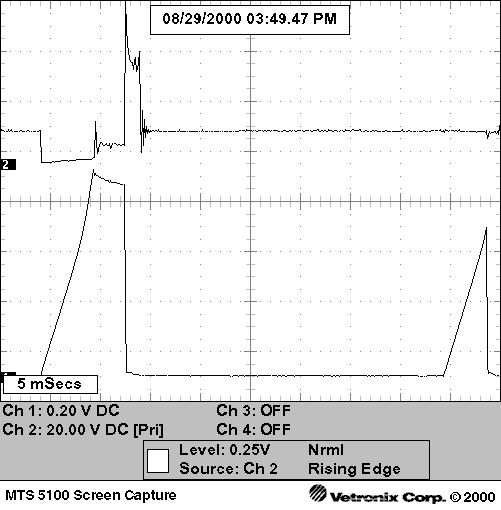

Again, looking at the left side of the screen, you can see that after the vehicle got hot, something changed. The triggering device (pcm, or ign module) went into current limiting mode, evidenced by the step in the primary voltage (channel one) and the flattening out of the amp ramp. You can clearly see how the two coincide. This is a built in protection mechanism.

Right before the ignition switching device went into current limiting, you can see how the amp ramp changed angles, indicating a change in resistance.

#15

Melting Slicks

This is the first few micro seconds of an amp ramp. This is a bad ignition coil.

Same vehicle, good coil. The little squigglys (technical term) are what you want to see. I just know if the arent there, or if theres just a couple, theres something wrong with the primary side of the coil. Mainly, an open in the winding.

#16

Melting Slicks

Thread Starter

Member Since: Feb 2002

Location: Winston Salem NC

Posts: 2,613

Likes: 0

Received 0 Likes

on

0 Posts

Ed,

Interesting stuff. It would be nice if I could do it.

Can I change spark dwell and see results on a dyno, if there are any resulting changes.

I've been looking for spark dwell modifiers in the LS7 file. There is a "spark dwell temperature" modifier table that the LS1 doesn't have. The changes are out to 2 decimals. Is that amount significant?

Joe

Interesting stuff. It would be nice if I could do it.

Can I change spark dwell and see results on a dyno, if there are any resulting changes.

I've been looking for spark dwell modifiers in the LS7 file. There is a "spark dwell temperature" modifier table that the LS1 doesn't have. The changes are out to 2 decimals. Is that amount significant?

Joe

#17

Melting Slicks

Ed,

Interesting stuff. It would be nice if I could do it.

Can I change spark dwell and see results on a dyno, if there are any resulting changes.

I've been looking for spark dwell modifiers in the LS7 file. There is a "spark dwell temperature" modifier table that the LS1 doesn't have. The changes are out to 2 decimals. Is that amount significant?

Joe

Interesting stuff. It would be nice if I could do it.

Can I change spark dwell and see results on a dyno, if there are any resulting changes.

I've been looking for spark dwell modifiers in the LS7 file. There is a "spark dwell temperature" modifier table that the LS1 doesn't have. The changes are out to 2 decimals. Is that amount significant?

Joe

As for seeing results on a dyno, there shouldnt be any improvement unless you're starting with insufficient spark.

#18

Melting Slicks

Thread Starter

Member Since: Feb 2002

Location: Winston Salem NC

Posts: 2,613

Likes: 0

Received 0 Likes

on

0 Posts

Spark dwell multiplier:

LABELS..............................Volt s

Coil Temp °C

.............11..........12..........13. .........14........15

-40 0.878917 0.894543 0.910168 0.925793 0.933606

-25 0.878917 0.894543 0.910168 0.925793 0.933606

-10 0.878917 0.894543 0.910168 0.925793 0.933606

5 0.878917 0.894543 0.910168 0.925793 0.933606

20 0.878917 0.894543 0.910168 0.925793 0.933606

35 0.898449 0.910168 0.921887 0.933606 0.941418

50 0.914074 0.925793 0.933606 0.945325 0.953137

65 0.929699 0.941418 0.949231 0.957043 0.960950

80 0.949231 0.953137 0.964856 0.968762 0.968762

95 0.968762 0.972669 0.976575 0.980481 0.984388

110 0.988294 0.988294 0.988294 0.988294 0.988294

125 0.980481 0.984388 0.988294 0.988294 0.988294

140 0.917980 0.941418 0.964856 0.988294 0.988294

155 0.917980 0.941418 0.964856 0.988294 0.988294

170 0.917980 0.941418 0.964856 0.988294 0.988294

185 0.917980 0.941418 0.964856 0.988294 0.988294

200 0.917980 0.941418 0.964856 0.988294 0.988294

#19

Melting Slicks

Okay, so if for some reason the LS7 table is too low then raising dwell would show up on a dyno?

Spark dwell multiplier:

LABELS..............................Volt s

Coil Temp °C

.............11..........12..........13. .........14........15

-40 0.878917 0.894543 0.910168 0.925793 0.933606

-25 0.878917 0.894543 0.910168 0.925793 0.933606

-10 0.878917 0.894543 0.910168 0.925793 0.933606

5 0.878917 0.894543 0.910168 0.925793 0.933606

20 0.878917 0.894543 0.910168 0.925793 0.933606

35 0.898449 0.910168 0.921887 0.933606 0.941418

50 0.914074 0.925793 0.933606 0.945325 0.953137

65 0.929699 0.941418 0.949231 0.957043 0.960950

80 0.949231 0.953137 0.964856 0.968762 0.968762

95 0.968762 0.972669 0.976575 0.980481 0.984388

110 0.988294 0.988294 0.988294 0.988294 0.988294

125 0.980481 0.984388 0.988294 0.988294 0.988294

140 0.917980 0.941418 0.964856 0.988294 0.988294

155 0.917980 0.941418 0.964856 0.988294 0.988294

170 0.917980 0.941418 0.964856 0.988294 0.988294

185 0.917980 0.941418 0.964856 0.988294 0.988294

200 0.917980 0.941418 0.964856 0.988294 0.988294

Spark dwell multiplier:

LABELS..............................Volt s

Coil Temp °C

.............11..........12..........13. .........14........15

-40 0.878917 0.894543 0.910168 0.925793 0.933606

-25 0.878917 0.894543 0.910168 0.925793 0.933606

-10 0.878917 0.894543 0.910168 0.925793 0.933606

5 0.878917 0.894543 0.910168 0.925793 0.933606

20 0.878917 0.894543 0.910168 0.925793 0.933606

35 0.898449 0.910168 0.921887 0.933606 0.941418

50 0.914074 0.925793 0.933606 0.945325 0.953137

65 0.929699 0.941418 0.949231 0.957043 0.960950

80 0.949231 0.953137 0.964856 0.968762 0.968762

95 0.968762 0.972669 0.976575 0.980481 0.984388

110 0.988294 0.988294 0.988294 0.988294 0.988294

125 0.980481 0.984388 0.988294 0.988294 0.988294

140 0.917980 0.941418 0.964856 0.988294 0.988294

155 0.917980 0.941418 0.964856 0.988294 0.988294

170 0.917980 0.941418 0.964856 0.988294 0.988294

185 0.917980 0.941418 0.964856 0.988294 0.988294

200 0.917980 0.941418 0.964856 0.988294 0.988294

That being said, if you're using LS7 coils, I would use LS7 tables.

Same goes for LS1 coils. Use the corresponding tables.

#20

Melting Slicks

Thread Starter

Member Since: Feb 2002

Location: Winston Salem NC

Posts: 2,613

Likes: 0

Received 0 Likes

on

0 Posts