Making caliper shim

#1

Pro

Thread Starter

Looking to use old pad backing to take up some pedal travel. Any easy recommendations on getting off remaining brake pad material? (Soak in solvent, etc?)

#4

Drifting

Jim

#5

Pro

Thread Starter

#6

Pro

I'm getting ready to make some prototypes for C5s from .063"" titanium. If you want to wait a week I may be able to sell you a set of 4. I own a machine shop and seeing that Hardbrakes is the only place that sells these things there might be an opportunity for my company to make these things just for a couple of vehicles.

#7

Pro

A couple of years ago I called Carbotech and bought a set of backing plates (pads just minus the friction material) for my StopTechs. I don't remember how much they charged but they might be worth a call.

#8

Instructor

I had to do it once in a pinch. I just chiseled the remaining pad off and then took an angle grinder with a flap disk to the rest. It cleaned up pretty nice. Took about 10-15 minutes a side.

#10

Drifting

I just use old worn down pads (past the wear grove) that aren't tapered. Usually one shim only on a corner which is enough to make up the thickness difference between a new set of pads and a worn out set -- like when going from worn race pads to newer street pads. It doesn't hurt anything to have pad material on the "shim".

--Dan

--Dan

#11

Safety Car

Member Since: Nov 2000

Location: Shenandoah Valley Virginia

Posts: 4,549

Likes: 0

Received 27 Likes

on

24 Posts

It's easy to get the remaining pad material off the backing plate and make an inexpensive set of shims. Use a bench grinder and the coarse grinding wheel. It will take the remaining material off quickly. Then just retract piston and slide them in. I use them on my Wilwood calipers when pads are about 1/2 gone. The shims keep the pistons deep in the calipers away from the brake dust and track garbage that can score them.

#12

Melting Slicks

#14

Pro

Thread Starter

Thanks!

#15

Tech Contributor

Member Since: Oct 1999

Location: Charlotte, NC (formerly Endicott, NY)

Posts: 40,078

Received 8,915 Likes

on

5,326 Posts

When I installed them with a set of padlets I had a continuously soft pedal no matter how much bleeding I did. Pulled the shims out and got an instant hard brake pedal. They were getting caught up in the springs and flexing under pressure and then moving back after the pedal was released. Drove me nuts for about a week.

Bill

#16

Safety Car

I just use old worn down pads (past the wear grove) that aren't tapered. Usually one shim only on a corner which is enough to make up the thickness difference between a new set of pads and a worn out set -- like when going from worn race pads to newer street pads. It doesn't hurt anything to have pad material on the "shim".

--Dan

--Dan

#17

Burning Brakes

From what I understand, it's not about pedal travel, as that is already taken care of everytime you release the brakes and the brake fluid gets released. What you want is the piston to stay inside the caliper as much as possible, also increasing the distance between the caliper piston and brake disk so that you don't overheat the fluid and caliper. Ok fine!

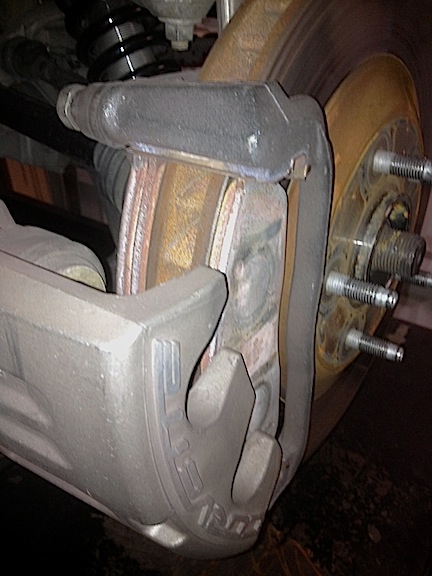

So guys, please post a pic of the 'shim' you put in there. Are there no concerns about having an extra piece of metal that's not really held in place? Are the pad sliders thick enough to hold the 3mm thick metal plate and another pad in there safely? Do you just put them in there or do you have something in between, like brake grease or something?

I'm asking all this because if there is a benefit, I might do it myself, but I just want to be assured it's safe and understand it correctly.

Thanks.

So guys, please post a pic of the 'shim' you put in there. Are there no concerns about having an extra piece of metal that's not really held in place? Are the pad sliders thick enough to hold the 3mm thick metal plate and another pad in there safely? Do you just put them in there or do you have something in between, like brake grease or something?

I'm asking all this because if there is a benefit, I might do it myself, but I just want to be assured it's safe and understand it correctly.

Thanks.

#19

Drifting

From what I understand, it's not about pedal travel, as that is already taken care of everytime you release the brakes and the brake fluid gets released. What you want is the piston to stay inside the caliper as much as possible, also increasing the distance between the caliper piston and brake disk so that you don't overheat the fluid and caliper. Ok fine!

So guys, please post a pic of the 'shim' you put in there. Are there no concerns about having an extra piece of metal that's not really held in place? Are the pad sliders thick enough to hold the 3mm thick metal plate and another pad in there safely? Do you just put them in there or do you have something in between, like brake grease or something?

I'm asking all this because if there is a benefit, I might do it myself, but I just want to be assured it's safe and understand it correctly.

Thanks.

So guys, please post a pic of the 'shim' you put in there. Are there no concerns about having an extra piece of metal that's not really held in place? Are the pad sliders thick enough to hold the 3mm thick metal plate and another pad in there safely? Do you just put them in there or do you have something in between, like brake grease or something?

I'm asking all this because if there is a benefit, I might do it myself, but I just want to be assured it's safe and understand it correctly.

Thanks.

I've run with the worn-down pads as shims for several years on the street, for autox, and for HPDE with no issues. I run one shim per caliper which is enough for me. I don't do anything special. No grease. Nothing to hold the shim in place. Just make sure it's sliding freely just as the pad does.

FYI -- I am using Carbotech pads, usually the XP10s, which have a smooth backing plate. I change to the 1521s for extended street use.

--Dan

#20

Former Vendor

They're "pad spacers" or "wear plates". Ideally they go behind BOTH pads- inner and outer to keep the caliper centered correctly. Their main purpose is to control piston extension and keep bore conentricity under control. As the pads wear down the pistons become extended in the bores. That leads to the possibility of the piston becoming cocked or misaligned in the bore. That in turn prevents proper release and pull back leading to excessive pad wear, tapering and possibly caliper body damage. By installing the pad wear plate behind the pad you simply keep more of the piston in the bore longer.

Titanium ones are usually much thinner: .035-.065" thick and are intended more for heat rejection. They can be used both with and without conventional spacers. Thicker Ti does not make a better thermal barrier that's why they are thin. The Ti is also more expensive to produce.

Typically they run about 1/8" thick. You can stack them up if you like but as was mentioned above; if they are not flat you're going to know it as they will create a spongy pedal feel. Hence the grinding idea is not quite ideal.

On a sliding caliper you'll need to make certain the outer plate is secure to the caliper- that can be a problem if it uses clips. This is not the issue on a race caliper tho.

Titanium ones are usually much thinner: .035-.065" thick and are intended more for heat rejection. They can be used both with and without conventional spacers. Thicker Ti does not make a better thermal barrier that's why they are thin. The Ti is also more expensive to produce.

Typically they run about 1/8" thick. You can stack them up if you like but as was mentioned above; if they are not flat you're going to know it as they will create a spongy pedal feel. Hence the grinding idea is not quite ideal.

On a sliding caliper you'll need to make certain the outer plate is secure to the caliper- that can be a problem if it uses clips. This is not the issue on a race caliper tho.

Last edited by Todd TCE; 05-08-2013 at 04:20 PM.

That's how I did mine.

That's how I did mine.