Damper balancing

#1

Race Director

Thread Starter

My mechanic did the front cover & upper oil pan & main seal today. The damper had a big gouge in it under the seal area & replaced the damper with a new stock one.

He reused the bolt & said it would be fine.

Question is the balance.

He drilled out balance holes to match the original & reinstalled it (as indexed with witness marks)

The engine seems smooth/fine with no difference that I can tell thru the rpm range.

This seem ok?

No guesses please, only if you have actually done this work.

How else would you restore the original balance?

I can't think of a way.

He reused the bolt & said it would be fine.

Question is the balance.

He drilled out balance holes to match the original & reinstalled it (as indexed with witness marks)

The engine seems smooth/fine with no difference that I can tell thru the rpm range.

This seem ok?

No guesses please, only if you have actually done this work.

How else would you restore the original balance?

I can't think of a way.

#2

Safety Car

You NEVER reuse the stock bolt... it will not be fine. Take it back and make him pull the rack again and put in a new OEM bolt with some red loc-tite and follow the OEM torque to yield stretch procedure.

1. Use old bolt to seat the pulley. Torque to 250 ft/lbs (I always quit around 200)

2. Install new bolt and torque to 37 ft/lbs

3. Stretch bolt 140 degrees

From LS1howto.com

or

Buy the fancy ARP bolt and some of their moly-lube and take it to him.

Mark my words... the re-used old bolt WILL back out.

1. Use old bolt to seat the pulley. Torque to 250 ft/lbs (I always quit around 200)

2. Install new bolt and torque to 37 ft/lbs

3. Stretch bolt 140 degrees

From LS1howto.com

Seat your pulley back onto the snout of the crankshaft as best you can by hand. If you purchased a longer crank bolt, start threading this in now and pull the pulley on about a 1/4 or 1/2 an inch and remove the longer bolt. Use your old stock crank pulley bolt to pull the pulley onto the crankshaft until the bolt seems to get impossible to turn. Grab your biggest torque wrench and attempt to torque that bolt down to 240lbft. I have always stopped at 200lbft on my installs and I've never had a problem, so if you can't hit 240 (which I never have), don't worry about it. Now, break the bolt free and remove it.

Take your NEW crank pulley bolt and thread it in all the way by hand. Torque this bolt to 37lbft. Now, we need to stretch the bolt into place. Get your breaker bar and pipe extension, and try to turn the bolt 140degrees past where it is at now, keeping in mind the engine will be trying to turn some and those are degrees you can't count. Again, I always seem to get about 90-100 degrees worth (estimating, knowing what 90 degrees looks like) and leave it as is so don't worry about going crazy here.

Once the pulley is installed, the timing cover should be nice and centered around it, so we can now tighten all 10 of those timing cover bolts. Torque them to 18lbft on the bolts you can get a torque wrench on, and just make the others you can't get the wrench on about as tight as those. Now reinstall your A/C pulley using a 15mm socket wrench. Reinstall the A/C belt at this time.

Take your NEW crank pulley bolt and thread it in all the way by hand. Torque this bolt to 37lbft. Now, we need to stretch the bolt into place. Get your breaker bar and pipe extension, and try to turn the bolt 140degrees past where it is at now, keeping in mind the engine will be trying to turn some and those are degrees you can't count. Again, I always seem to get about 90-100 degrees worth (estimating, knowing what 90 degrees looks like) and leave it as is so don't worry about going crazy here.

Once the pulley is installed, the timing cover should be nice and centered around it, so we can now tighten all 10 of those timing cover bolts. Torque them to 18lbft on the bolts you can get a torque wrench on, and just make the others you can't get the wrench on about as tight as those. Now reinstall your A/C pulley using a 15mm socket wrench. Reinstall the A/C belt at this time.

Buy the fancy ARP bolt and some of their moly-lube and take it to him.

Mark my words... the re-used old bolt WILL back out.

Last edited by travisnd; 11-04-2011 at 10:08 AM.

#3

Race Director

Thread Starter

You NEVER reuse the stock bolt... it will not be fine. Take it back and make him pull the rack again and put in a new OEM bolt with some red loc-tite and follow the OEM torque to yield stretch procedure.

1. Use old bolt to seat the pulley. Torque to 250 ft/lbs (I always quit around 200)

2. Install new bolt and torque to 37 ft/lbs

3. Stretch bolt 140 degrees

From LS1howto.com

or

Buy the fancy ARP bolt and some of their moly-lube and take it to him.

Mark my words... the re-used old bolt WILL back out.

1. Use old bolt to seat the pulley. Torque to 250 ft/lbs (I always quit around 200)

2. Install new bolt and torque to 37 ft/lbs

3. Stretch bolt 140 degrees

From LS1howto.com

or

Buy the fancy ARP bolt and some of their moly-lube and take it to him.

Mark my words... the re-used old bolt WILL back out.

What about the BALANCE procedure?

#4

Race Director

I think the balancers are neutral, you should not need to drill anything out. I've used OEM and ATI, and as far as I know they should be balanced when you get them.

#5

Race Director

Thread Starter

So we drilled holes to match.

My understanding (and I could be all wet) is that the rotating assembly from flywheel forward to crank shaft and out to the balancer is all balanced out "as one" at the time the motor is built by drilling holes or adding weights (in the holes) to the balancer.

There are some "harmonics" vibrations as the crank spins that the balancer takes out & this final process "optimizes" the balance.

Any engine builders want to chime in, please do.

#6

Race Director

Thread Starter

Here is info about ATI balancing

Zero balance units have each part individually balanced to two-tenths of a gram. These units should not be drilled and should not be on the crankshaft for balancing. Install the damper at engine assembly. Since the inertia weight in the Super Damper is not bonded, it may not be on center until the engine is started. The damper may show out of balance until the engine reaches 2000 RPM the first time and the inertia weight centers itself.

So it sounds like they have a means of balancing themselves when the motor first runs 2000 rpm.

Nothing so far about balancing a STOCK damper.

Zero balance units have each part individually balanced to two-tenths of a gram. These units should not be drilled and should not be on the crankshaft for balancing. Install the damper at engine assembly. Since the inertia weight in the Super Damper is not bonded, it may not be on center until the engine is started. The damper may show out of balance until the engine reaches 2000 RPM the first time and the inertia weight centers itself.

So it sounds like they have a means of balancing themselves when the motor first runs 2000 rpm.

Nothing so far about balancing a STOCK damper.

#7

Melting Slicks

Member Since: Sep 2003

Location: If you don't weigh in you don't wrestle Road America

Posts: 3,031

Likes: 0

Received 73 Likes

on

54 Posts

All LS series balancers should be zero balanced.

Otherwise every time you changed clutches/balancers it would require you to rebalance everything.

Any stock balancer that you get should be zero balanced from GM, I still have balancers and clutch assemblies checked at my local machine shop just so that I'm sure. Especially if it's going to see track use.

I wouldn't have "drilled it to match" the one you took off. I would've just had it checked so that it was zero balanced - hope you don't have an issue.

I agree with travisnd - you should've used a new GM bolt or went ATI - they had a ton of issues with 05 LS2's having balancers coming loose - that's when they came out with the fancy shim David was talking about above.

Otherwise every time you changed clutches/balancers it would require you to rebalance everything.

Any stock balancer that you get should be zero balanced from GM, I still have balancers and clutch assemblies checked at my local machine shop just so that I'm sure. Especially if it's going to see track use.

I wouldn't have "drilled it to match" the one you took off. I would've just had it checked so that it was zero balanced - hope you don't have an issue.

I agree with travisnd - you should've used a new GM bolt or went ATI - they had a ton of issues with 05 LS2's having balancers coming loose - that's when they came out with the fancy shim David was talking about above.

#8

Melting Slicks

All LS series balancers should be zero balanced.

Otherwise every time you changed clutches/balancers it would require you to rebalance everything.

Any stock balancer that you get should be zero balanced from GM, I still have balancers and clutch assemblies checked at my local machine shop just so that I'm sure. Especially if it's going to see track use.

I wouldn't have "drilled it to match" the one you took off. I would've just had it checked so that it was zero balanced - hope you don't have an issue.

I agree with travisnd - you should've used a new GM bolt or went ATI - they had a ton of issues with 05 LS2's having balancers coming loose - that's when they came out with the fancy shim David was talking about above.

Otherwise every time you changed clutches/balancers it would require you to rebalance everything.

Any stock balancer that you get should be zero balanced from GM, I still have balancers and clutch assemblies checked at my local machine shop just so that I'm sure. Especially if it's going to see track use.

I wouldn't have "drilled it to match" the one you took off. I would've just had it checked so that it was zero balanced - hope you don't have an issue.

I agree with travisnd - you should've used a new GM bolt or went ATI - they had a ton of issues with 05 LS2's having balancers coming loose - that's when they came out with the fancy shim David was talking about above.

The flywheel and pressure plate are not zero balanced individually or as a set.

This was debated to death a few years ago.

LS motors are externally balanced.

I'm not 100% sure about the balancer but I feel it is zero balanced.

It is not keyed. Correct??

#9

Run 2 laps at the track it starting making noise and leaking oil, the balancer started walking out.

I was and still am pissed!! Spent $350 on entry fees and lost chance to win 2 A6's.

----------

John

#10

Drifting

My ls6 balancer had holes drilled and pins added. I replaced with a aftermarket under-drive and proceeded to break timing chains. I have read on this forum and ls1tech that the ls engines are final balanced externally. When I finally pulled the motor I saw that the flywheel also had weights added.

#11

Race Director

Thread Starter

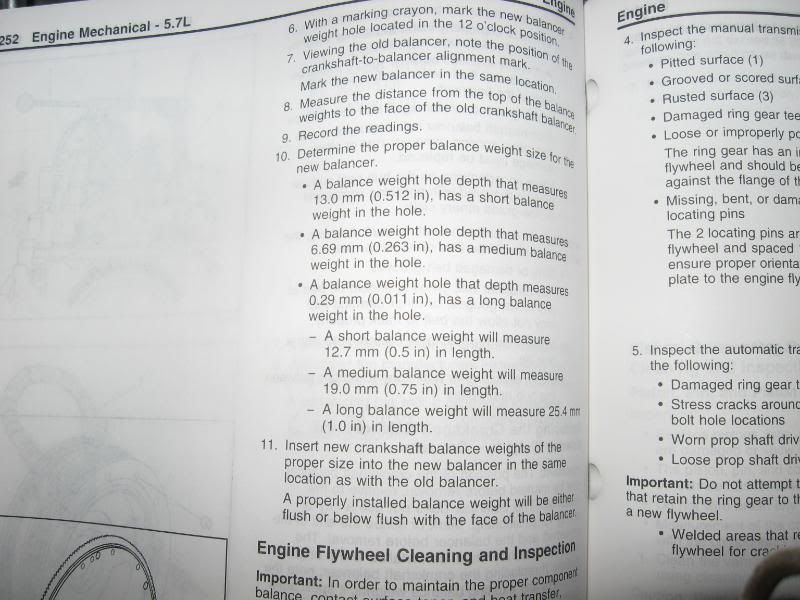

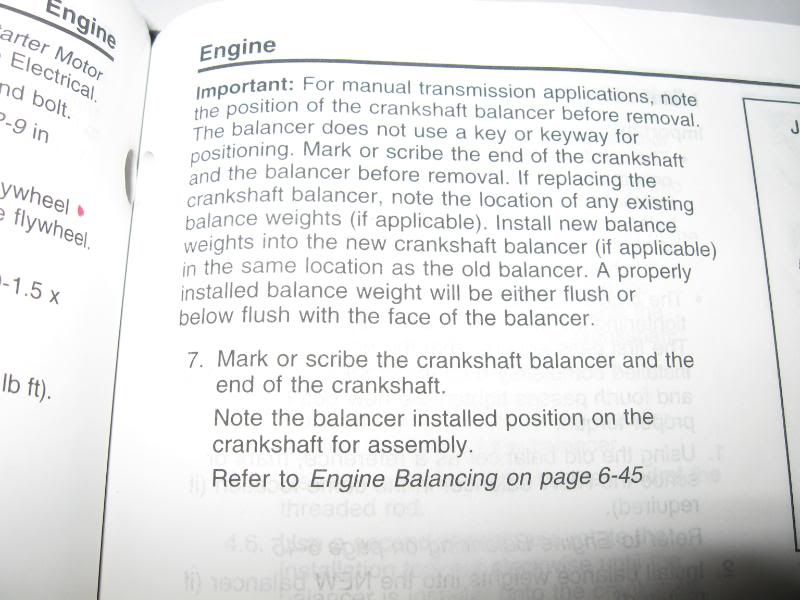

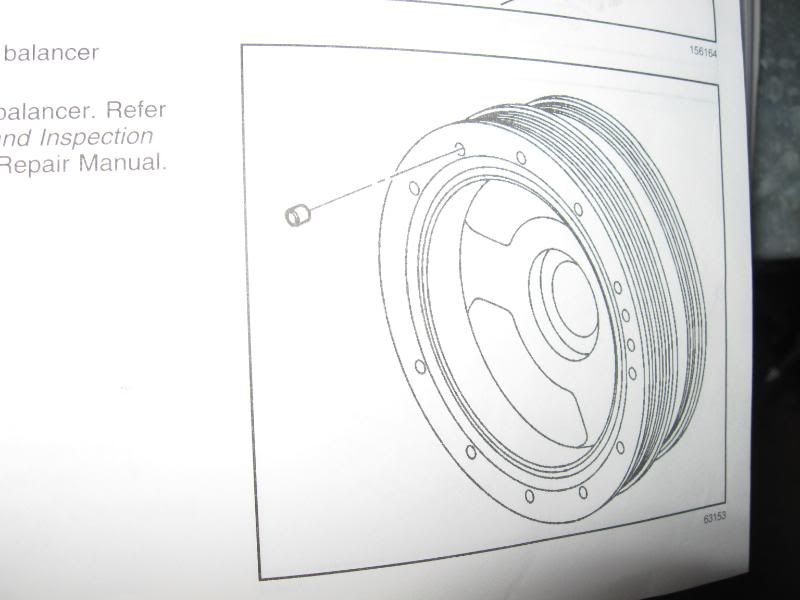

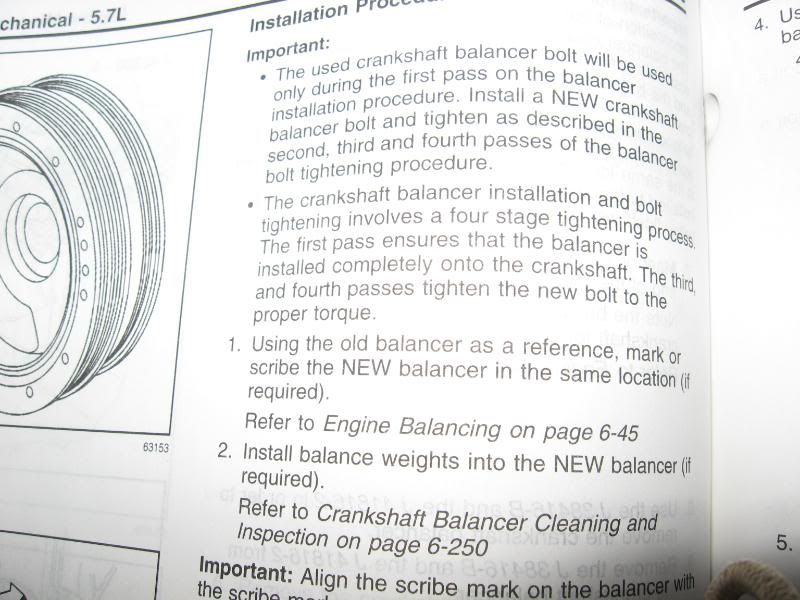

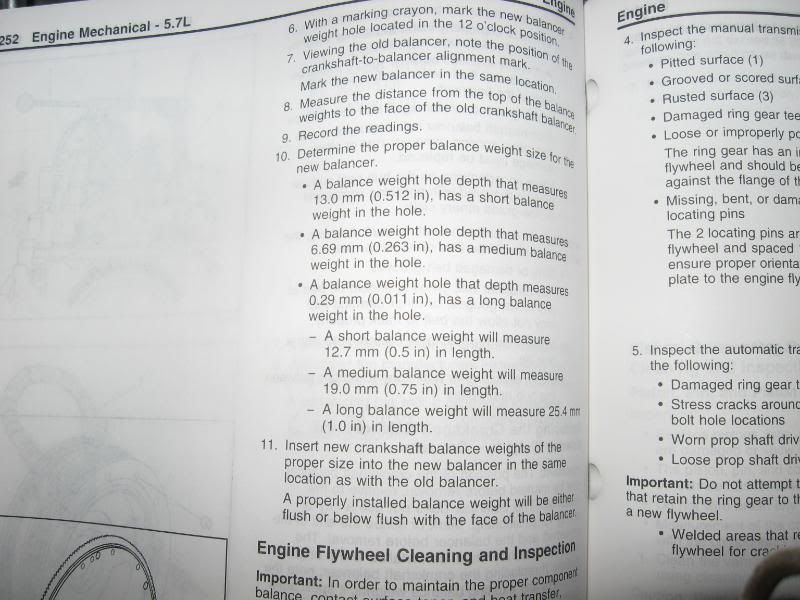

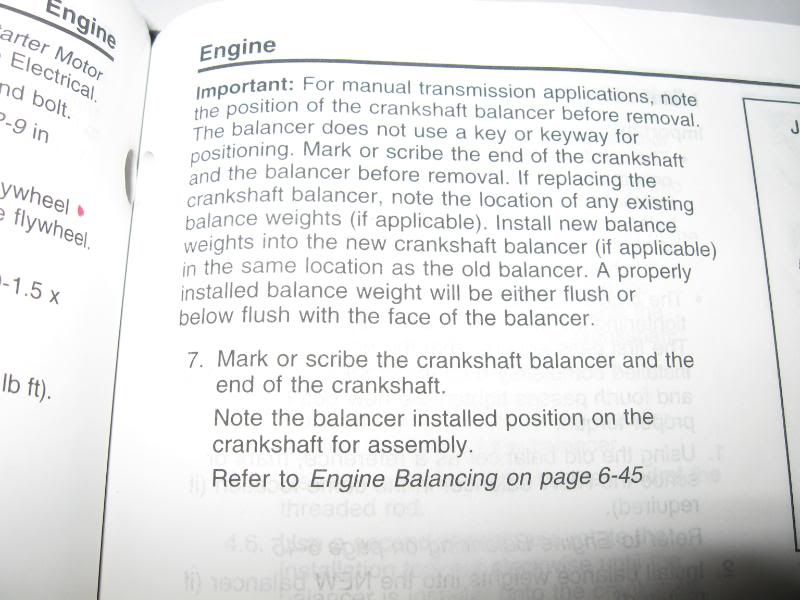

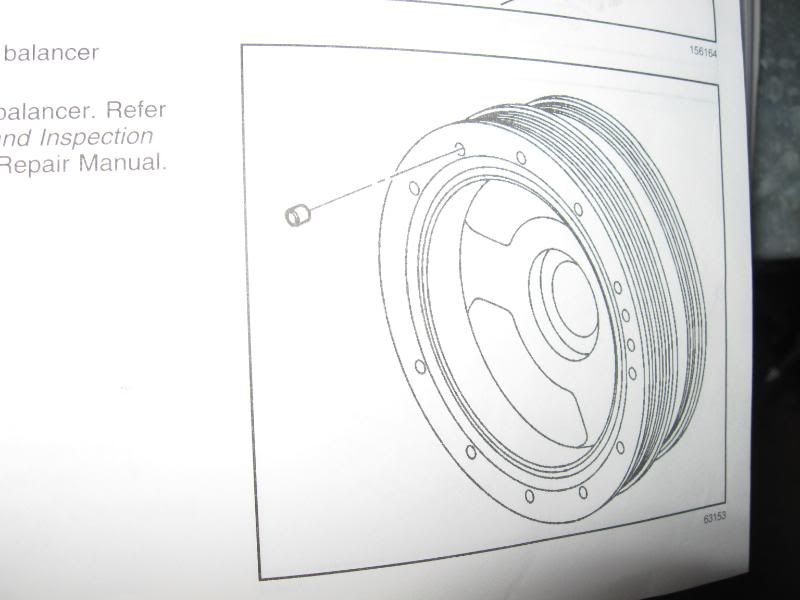

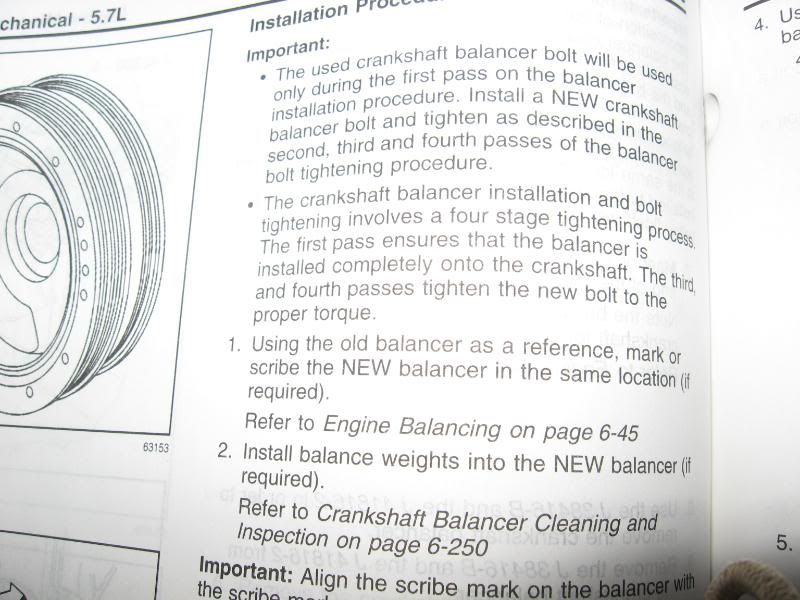

From the FSM

So the summary (for stock damper)

Mark (index) old one to crank

Line up old & new

Mark (index) new one & transfer/add weights (apparently they are not included with damper - real smart GM thanks)

Install new one - line up index

So I paid $95 hr to a specialist who has been doing it for years, who doesn't know this & I have to figure it out myself.

Sheesh.

This is why I would HATE letting anyone touch my car.

Grrrr.

I just hope it's not off that much.

So the summary (for stock damper)

Mark (index) old one to crank

Line up old & new

Mark (index) new one & transfer/add weights (apparently they are not included with damper - real smart GM thanks)

Install new one - line up index

So I paid $95 hr to a specialist who has been doing it for years, who doesn't know this & I have to figure it out myself.

Sheesh.

This is why I would HATE letting anyone touch my car.

Grrrr.

I just hope it's not off that much.

Last edited by froggy47; 11-05-2011 at 01:32 PM.

#12

Safety Car

Yes the FSM tells you to mark the location of the OEM balancer etc. etc. However, I have installed ATI 10% underdrive balancers on 3 different engines now w/o an issue. I have had issues with clutch balancing where I had to have a new clutch off-balanced to match the clutch I took off to make everything right, but never an issue with a balancer.

People that break timing chains generally use a cheap balancer or something 25% underdriven which can't provide the needed dampening characteristics. For a long time ATI wouldn't make anything smaller than the 10%. However, the drag racing crowd demanded them so ATI started making them.

10% underdrive ATI for me... nothing else. Not to be a jerk, but if your mechanic re-used the old bolt and did so without pinning it then it will back out eventually.

People that break timing chains generally use a cheap balancer or something 25% underdriven which can't provide the needed dampening characteristics. For a long time ATI wouldn't make anything smaller than the 10%. However, the drag racing crowd demanded them so ATI started making them.

10% underdrive ATI for me... nothing else. Not to be a jerk, but if your mechanic re-used the old bolt and did so without pinning it then it will back out eventually.

#13

Race Director

Thread Starter

Yes the FSM tells you to mark the location of the OEM balancer etc. etc. However, I have installed ATI 10% underdrive balancers on 3 different engines now w/o an issue. I have had issues with clutch balancing where I had to have a new clutch off-balanced to match the clutch I took off to make everything right, but never an issue with a balancer.

People that break timing chains generally use a cheap balancer or something 25% underdriven which can't provide the needed dampening characteristics. For a long time ATI wouldn't make anything smaller than the 10%. However, the drag racing crowd demanded them so ATI started making them.

10% underdrive ATI for me... nothing else. Not to be a jerk, but if your mechanic re-used the old bolt and did so without pinning it then it will back out eventually.

People that break timing chains generally use a cheap balancer or something 25% underdriven which can't provide the needed dampening characteristics. For a long time ATI wouldn't make anything smaller than the 10%. However, the drag racing crowd demanded them so ATI started making them.

10% underdrive ATI for me... nothing else. Not to be a jerk, but if your mechanic re-used the old bolt and did so without pinning it then it will back out eventually.

Appreciate the posts, I will watch the sob with an eagle eye.

I need to just buy a damn lift & do EVERYTHING myself.

#14

Race Director

Thread Starter

Well he street drove it with a few hard romps about 50 miles & so far the do over is dry, I safety wired the balancer bolt so it's not going anywhere.

Will see how it holds on track, when I go to the next DE.

Thanks all.

Will see how it holds on track, when I go to the next DE.

Thanks all.

#15

Drifting

Member Since: Dec 2005

Location: Dayton, OH

Posts: 1,822

Likes: 0

Received 0 Likes

on

0 Posts

People that break timing chains generally use a cheap balancer or something 25% underdriven which can't provide the needed dampening characteristics. For a long time ATI wouldn't make anything smaller than the 10%. However, the drag racing crowd demanded them so ATI started making them.

ATI makes a damper for the ASA LS1 motors and it has a 60% under-drive. The "hub" which is the pulley part of the damper assembly is where the under-drive is done. The damper, the important part in this discussion is the big part that mounts to the front of the hub and actually dampens the harmonics transmitted through the crankshaft.

The under-drive amount has nothing to do with the dampers ability to do its job.

http://www.atiracing.com/products/da...hubs/index.htm

Having said that,

that there are manufactures who make "dampers" which have resulted in failures of timing chains and other parts because they don't work. Just my 2 cents

that there are manufactures who make "dampers" which have resulted in failures of timing chains and other parts because they don't work. Just my 2 cents

#16

That damper will not work with a standard corvette accessory drive, and the steering rack is in it's way.

FWIW, I have an ATI 10% under and it seems to do the job. No need for marking or balancing. I've taken it on/off a couple times and it is stupid simple.

FWIW, I have an ATI 10% under and it seems to do the job. No need for marking or balancing. I've taken it on/off a couple times and it is stupid simple.

#17

Safety Car

Hmmmmmmm! IMHO Me thinks you misunderstand.

ATI makes a damper for the ASA LS1 motors and it has a 60% under-drive. The "hub" which is the pulley part of the damper assembly is where the under-drive is done. The damper, the important part in this discussion is the big part that mounts to the front of the hub and actually dampens the harmonics transmitted through the crankshaft.

The under-drive amount has nothing to do with the dampers ability to do its job.

ATI makes a damper for the ASA LS1 motors and it has a 60% under-drive. The "hub" which is the pulley part of the damper assembly is where the under-drive is done. The damper, the important part in this discussion is the big part that mounts to the front of the hub and actually dampens the harmonics transmitted through the crankshaft.

The under-drive amount has nothing to do with the dampers ability to do its job.

When you take it apart the "balancer" is the serpentine belt pulley and the hub installs on the crank snout. The more underdrive you want the smaller the pulley/balancer must be so a 25% UD pulley is only 5.5" vs the 10% I have being 6.78"

Exploded view of a non-serpentine super damper. The outer shell is the serpentine pulley on a Serpentine damper version.

Here's what one looks like taken apart

#18

Drifting

Member Since: Dec 2005

Location: Dayton, OH

Posts: 1,822

Likes: 0

Received 0 Likes

on

0 Posts

As a sidebar, LPE when doing testing of the ASA motor package found that they didn't even need a damper on the crank to stay within the GM spec for torsional flex of the crankshaft. Mind you, they were using a 5.5" clutch on that motor.

Last edited by geerookie; 11-11-2011 at 07:53 PM.

#20

Race Director

Thread Starter

I wish the FSM gave the weight of the short/medium/long weights. My old damper had one short & one medium. I assume they are lead?

Do you thing the safety wire idea is ok? Alignment with other pullies seems perfect.

Last edited by froggy47; 11-12-2011 at 03:11 PM.