LT7 confirmed

#141

It is absolutely a limitation with the current block. Sealing off each pair of cylinders with the firing order of a CPC will create massive air pressure differences, both vacuum and high pressure, as the pistons move up and down in their "mini block." It works in an FPC because while one of each pair of cylinders is moving up, the other is moving down, maintaining a constant volume in the chamber. With a CPC, you'd have both pistons moving up or down at the same time in some of the chambers. Firing order is everything.

The following users liked this post:

GM Bureaucrat (05-05-2023)

#143

Drifting

It is absolutely a limitation with the current block. Sealing off each pair of cylinders with the firing order of a CPC will create massive air pressure differences, both vacuum and high pressure, as the pistons move up and down in their "mini block." It works in an FPC because while one of each pair of cylinders is moving up, the other is moving down, maintaining a constant volume in the chamber. With a CPC, you'd have both pistons moving up or down at the same time in some of the chambers. Firing order is everything.

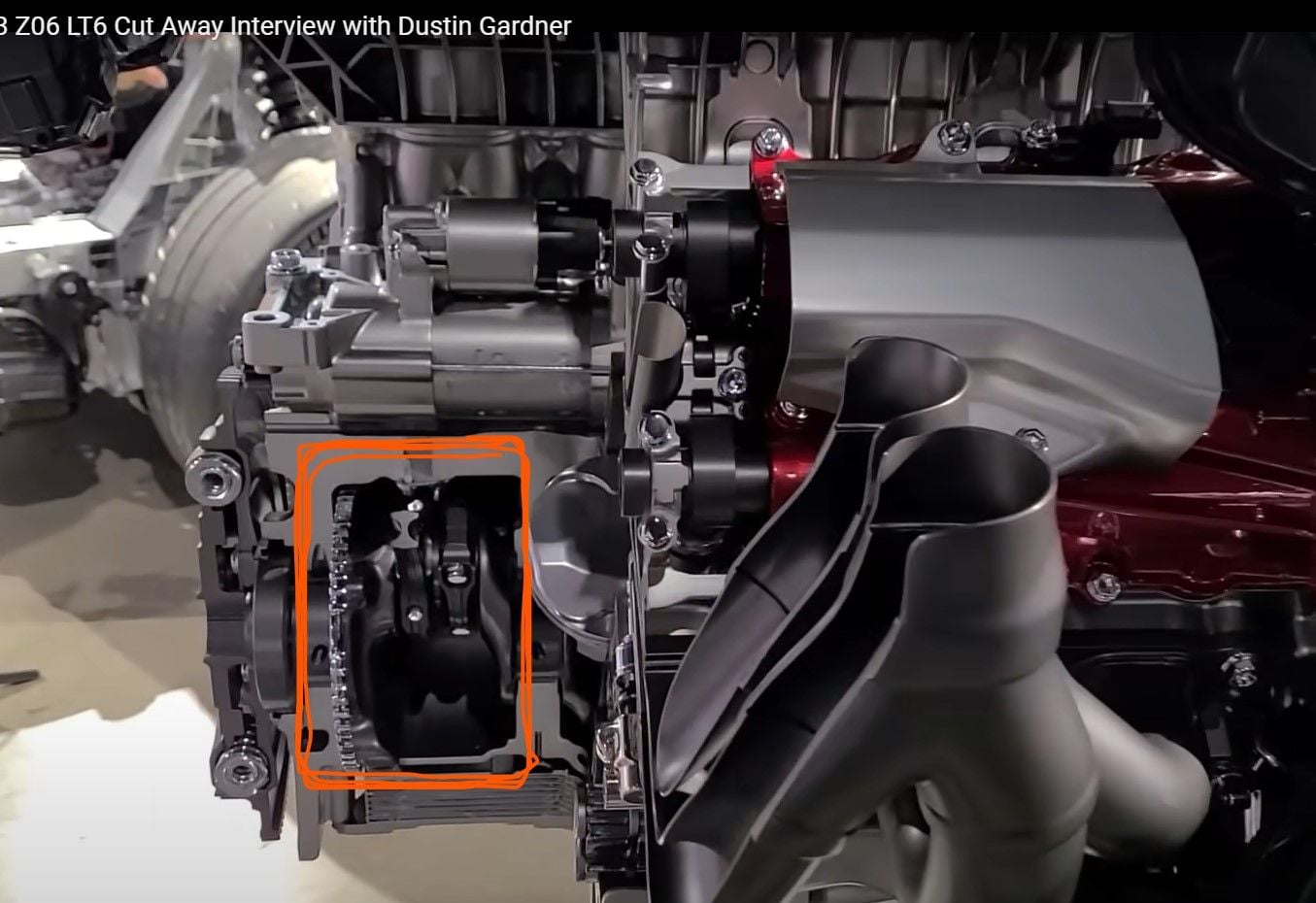

In the FPC, each of the two pistons that occupy any given sealed bay, share a common crankpin; this means that their mechanical motion relative to one another, up or down, is phased 90 degrees apart. You can see this in the figure below; shown is the front of the LT6 FPC, with pistons 1 and 2 in the front; these pistons share the same crankpin, and occupy the same sealed bay. Similarly, 3&4 occupy the next sealed bay; 5&6 the next; 7&8 the next.

Now, in a CPC, cylinders 1 & 2 would also share a common crankpin, and a common sealed bay. They would also be phased 90 degrees apart, and would experience the same mechanical motion relative to one another as in a FPC. The difference is in the FPC, all crankpins are in the same plane, whereas in the CPC, crankpins occupy 2 planes.

In both a FPC and CPC, pistons 1&2 (and all other pairs) experience identical relative mechanical motion. The vacuum pump pulls such a high vacuum in these bays though, that the air mass being pumped back and forth is largely reduced.

The firing order has no impact on the sealed bay operation for either.

Here's an animation that shows the "groups of 2" pistons in the sealed bays have the same mechanical motion relative to one another in both a FPC and CPC;

LT6 FPC ; note cylinders 1&2, in the front, have the big end of their rod sharing the same crankpin. Same as in a CPC.

LT6 cutaway showing cylinder 1&2 sealed bay circled in orange; In a CPC, cylinders 1&2 would occupy the same sealed bay, share the same crankpin, and have the same relative piston motion.

The following 8 users liked this post by RedLS6:

416vette (05-05-2023),

CPhelps (02-07-2023),

Kodiak Bear (05-05-2023),

skank (02-09-2023),

smoove7410 (02-07-2023),

and 3 others liked this post.

#144

Pro

It is absolutely a limitation with the current block. Sealing off each pair of cylinders with the firing order of a CPC will create massive air pressure differences, both vacuum and high pressure, as the pistons move up and down in their "mini block." It works in an FPC because while one of each pair of cylinders is moving up, the other is moving down, maintaining a constant volume in the chamber. With a CPC, you'd have both pistons moving up or down at the same time in some of the chambers. Firing order is everything.

But I'd expect the LT7 will have a different block, but for other reasons, like a smaller bore among other things.

In any case the LT6 and LT7 are both part of the larger Gen6 family.

The following 7 users liked this post by GrandSport 2017:

2cnd Chance (05-05-2023),

416vette (05-05-2023),

CorvettoBrando (05-05-2023),

Latterlon (02-08-2023),

smoove7410 (02-08-2023),

and 2 others liked this post.

#145

Pro

That would probably drop the redline if flat plane, but they could still build a heck of a crossplane. Move the wristpin down, strengthen the piston and shorten the rod, keep the stroke, could still spin it well over 7000 in crossplane config with a little less primary than the LT6. The 12% heavier crank is still ~18% lighter than an LT2. Ti rods? The LT6 crank main journal bores are around 3mm larger in diameter versus the LT2 so they have provided for strength there. The 3-valve tuned intake will be gone, replaced by intercoolers so why not. Everything is better with boost.

Keep your eyes open, data collection is underway.

Keep your eyes open, data collection is underway.

The following 13 users liked this post by GrandSport 2017:

2cnd Chance (05-05-2023),

416vette (05-05-2023),

CorvettoBrando (05-05-2023),

GM Bureaucrat (05-07-2023),

JockItch (05-05-2023),

and 8 others liked this post.

#146

#147

Pro

Please explain exactly why it would "be a disaster" to put a cross plane crank in the Gen6 block?

The following 10 users liked this post by GrandSport 2017:

CorvettoBrando (05-08-2023),

GM Bureaucrat (05-07-2023),

Latterlon (05-08-2023),

Lavender (09-14-2023),

OnPoint (05-09-2023),

and 5 others liked this post.

#148

The Consigliere

Member Since: May 2006

Location: 2023 Z06 & 2010 ZR1

Posts: 22,257

Received 5,450 Likes

on

2,273 Posts

The following 3 users liked this post by OnPoint:

#149

Drifting

The following 4 users liked this post by RedLS6:

#150

Le Mans Master

#151

Drifting

But vaulting over onto your subject, the vibration and airflow solutions for both CPC and FPC architectures are well known. My position has always been that they'll push for a FPC TT solution, with a CPC as a strong alternate.

The following users liked this post:

CorvettoBrando (05-08-2023)

#153

Drifting

Also, Grandsport2017 always contributes very good technical insight here, along with a few others.

The following 6 users liked this post by RedLS6:

CDNZR (05-13-2023),

CPhelps (05-10-2023),

RapidC84B (05-09-2023),

smoove7410 (05-10-2023),

vettesweetnos (05-10-2023),

and 1 others liked this post.

#155

Le Mans Master

After skimming through this old thread I disagree with half the stuff

I posted!

I posted!

#156

but you can’t replace the displaced displacement.

said differently, you can’t compare a 6.2 vs. 4.8 boosted car. The 6.2 takes the 4.8.

so technically yes you can replace displacement. But what still holds true is that “there is no replacement for displacement”.

#157

If scaled up to 5.5L, that's 875 lb-ft!

Last edited by glass slipper; 05-14-2023 at 07:24 AM.

#158

Pro

Chevrolet's past history is full of first innovations, and the "906" is one of them for sure, as was their "D" OHV V8 105 years ago, the SBC 68 years ago, LT5 34 years ago, LS-1 26 years ago and now the LT6.

Its not what can be done, think of it as whats allowed to be done.

Its not what can be done, think of it as whats allowed to be done.

The following 6 users liked this post by GrandSport 2017:

CorvettoBrando (05-18-2023),

GM Bureaucrat (05-18-2023),

JG853 (05-14-2023),

Latterlon (05-15-2023),

Lavender (09-14-2023),

and 1 others liked this post.

#159

Le Mans Master

The 2.7L turbo 4-cylinder GM uses in their full size trucks makes 430 lb-ft of torque from 1500-4000 RPM, scaling that up to 4.4L gives 700 lb-ft. The 2.7L uses a 4.01" stroke, shorten that to the 3.15" stroke of the LT6 and that alone will get you to 720 lb-ft. If we didn't tell you the engine displacement but just told you it makes 720 lb-ft of torque from 2000-5000 RPM, would you be happy? Would you even care about engine displacement at that point?

If scaled up to 5.5L, that's 875 lb-ft!

If scaled up to 5.5L, that's 875 lb-ft!

#160

Frankly, I don't care if you believe me or not. Believe Tadge, who is the one who described how and why the crankcase seals off each pair of cylinders.