Pounds per Pound-Foot

#21

Safety Car

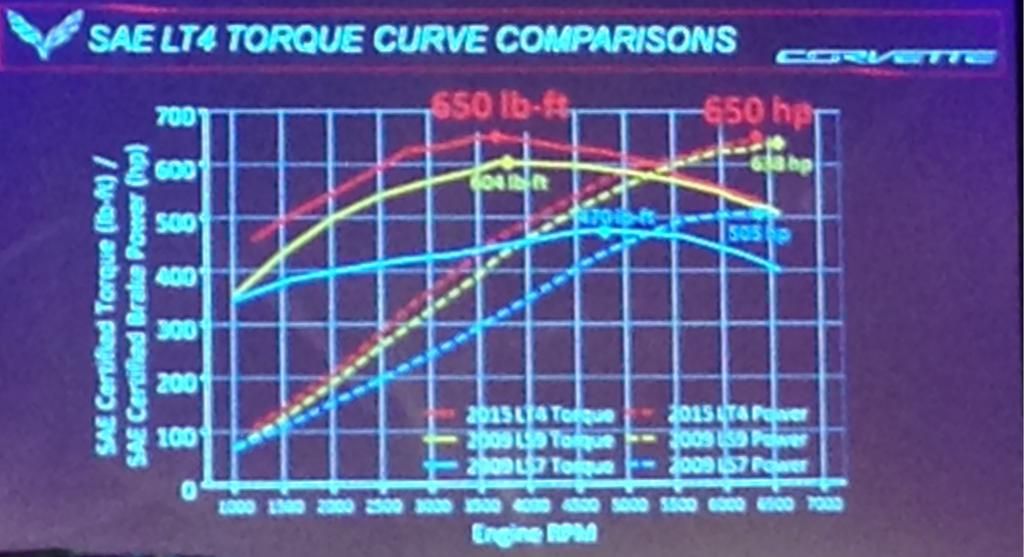

The TVS 1740 builds boost linearly from 2500rpm to about 4000rpm, and then increases boost about one PSI fairly gradually on this platform. Unlike the TVS2300 on the ZR1 this is a far better boost curve. It peaks at high rpm instead of mid rpm and it produces more boost around 6000rpm than the ZR1 blower. In effect, the supercharger should produce a steeper, more naturally aspired like power curve than the old ZR1 blower. Furthermore, we know it's more efficient by 10%. An additional benefit for those who tune their cars is that you can maintain lower boost at low rpm so there is less chance of detonation on extreme tunes. Rev high only on high octane and you are good. Ok, so it's not the blower.

If it's not the blower than it has to be the head. Two things going on, both of which impede the ability of the valves. The introduction of direct injection meant that the fuel inectors needed to be directly coupled for injection. The optimum location required a lower diameter intake valve than that in the LS9. There is your first factor. The introduction of AFM required AFM capable lifters. These lifters don't like a lot of lift. GM engineers specified lift at the max AFM lifters can tolerate, which unfortunately is less than that of the LS9. There is your second factor.

The single largest factor torque drops at high rpm has to be AFM, indirectly by restricting maximum lift on the exhaust valve. I don't think the intake valve limitations matter as much given there is boost.

#22

Instructor

Those guys are Formula One commentators, so for that conversation you can change "never being below 4,000 rpm" to "never being below 6,000 rpm" because F1 cars idle at 6k and will stall at anything below that (at least that was the case before this year when they went turbo - not sure of the exact idle speed now, but sure it's at least 4k rpm).

#23

Drifting

The AFM explanation makes sense. Looks like the peak output could easily have been 35-50hp higher if not for the drop.

#24

Those guys are Formula One commentators, so for that conversation you can change "never being below 4,000 rpm" to "never being below 6,000 rpm" because F1 cars idle at 6k and will stall at anything below that (at least that was the case before this year when they went turbo - not sure of the exact idle speed now, but sure it's at least 4k rpm).

Went to Austin last year for the race and the sound was glorious.

This year's 1.6L Turbos rev to 11K, with much higher torque than the 2.4L NAs.

They can rev higher, but because the cars are restricted to 100kgs of fuel per race they don't.

Hopefully next year they will loosen the fuel usage rule and the engine revs will climb back up where they should be.

#25

Safety Car

I would have preferred a non DI non AFM LT4 engine. Compared to the actual LT4 produced: lower weight, similar torque, lower noise, cheaper, a lot more power.

#26

Looks like Autoblog & Motortrend may have borrowed their idea from our thread on Corvette Forum. Funny how so many posters discounted torque to weight as a legitimate metric until the major car media started using it.

https://www.corvetteforum.com/forums...-in-class.html

https://www.corvetteforum.com/forums...-in-class.html

#27

On a DynoJet chassis dyno, HP is measured and torque is calculated. On the DDG51 Arleigh Burke class of US Navy destroyers, they have 4 jet engines with a measured output of 25,000 HP each for a total of 100,000 shaft HP. On some ships, I've been able to coax 104,000 HP from the engines...overachievers. Lol

HP is a real entity, you feel it as it adds kinetic energy to the car. The more HP an engine has, the higher the rate of kinetic energy added to the car and the higher the rate of acceleration...that is what you feel. One HP equals 746 Watts, grab a 60 watt light bulb to get an idea of how real HP is...you'll never say HP is nothing more than a computed number.

HP is a real entity, you feel it as it adds kinetic energy to the car. The more HP an engine has, the higher the rate of kinetic energy added to the car and the higher the rate of acceleration...that is what you feel. One HP equals 746 Watts, grab a 60 watt light bulb to get an idea of how real HP is...you'll never say HP is nothing more than a computed number.

One horsepower is defined as 550 foot-pounds per second. Foot-pounds? Kind of sounds familiar, doesn't it? Like the way we measure torque?

If you go to the farm and grab a couple of horses to see how they rate against this standard, some will probably do it easily, maybe some will have trouble or can't do it at all. It's an arbitrary number made up by some human engineers so that ordinary people transitioning from real horses can relate.

I know that a lot of turbines are rated by horsepower. I used to fly helicopters and they were all rated by horsepower, and turboprop airplanes, as well. None of them made 100,000 hp, though! I was talking about jets that fly from thrust instead of going through a gearbox and driving a propeller, although most, if not all, commercial jets these days produce most of their thrust from a geared fan. If you use the correct formula for calculating horsepower that it takes to get a Boeing 777 to fly at 540 knots, I'm pretty sure it would come out well above 100,000 horsepower because of the speed component.

I'll do some research.

#28

Safety Car

Looks like Autoblog & Motortrend may have borrowed their idea from our thread on Corvette Forum. Funny how so many posters discounted torque to weight as a legitimate metric until the major car media started using it.

https://www.corvetteforum.com/forums...-in-class.html

https://www.corvetteforum.com/forums...-in-class.html

So facts are decided by a popular vote nowadays?

So facts are decided by a popular vote nowadays? If that were true, and scientific reason did not exist, an LT4 would be nothing more than a bottle opener.

#29

Agreed. However, within any gear, the peak acceleration occurs at the torque peak and not at the horsepower peak. Even that statement isn't entirely correct if you include frictional and drag losses in the equation of motion (a ~ T - Lf - Ld) but, to a first order, peak acceleration in any given gear will occur at (or very near) the RPM where torque peaks, and not where HP peaks. HP is still the only metric you need to determine the acceleration capability since it already includes the torque multiplication through gearing.

Having said all of the above, max acceleration does not occur at peak torque because torque is just a force which is linear or 1st order, you have no way of resolving all of the 2nd order influences unless you include the time factor. Before you get ahead of me here, I'm not saying peak acceleration occurs at peak HP. Since KE is a 2nd order equation, the amount of KE added to the car to accelerate from 30- 40 MPH is ¼ of the amount of KE added to the car to accelerate from 60-70 MPH even though both are 10 MPH increments. It takes the same amount of HP to add a certain amount of KE (let's say 1000 units) to the car no matter what speed you're going, therefore the higher your speed, the slower you accelerate with the same HP. I haven't run any numbers but it's obvious peak acceleration is past peak torque but before peak HP if the HP curve is flattening out as it reaches peak HP. In the case of the LT4/LS9 where the HP curve climbs at a steep rate up to peak HP, peak acceleration will occur closer to peak HP.

The main reason I investigated this is because I have a DOHC engine in my C4 ZR-1 that has an almost flat HP curve from ~5600-7000 RPM, it only varies about 20 HP through the whole range. On the other hand, torque peaks at ~4800 RPM and continues to drop out to 7000 RPM where it's ~65 LB-FT less than peak torque yet I don't feel acceleration dropping off. The first time I raced the car, I hit the 7100 RPM rev limiter hard in 1st gear because it just didn't experience any decrease in acceleration that I came to expect with a pushrod engine. I was used to holding a gear until I felt acceleration drop off and then shift...it just doesn't happen with this DOHC engine.

Road racers use a program where they load the HP curve and the speeds on track into it and the program tells them the optimum gears and shift points on track to use. Notice it doesn't use the torque curve, torque is a 1st order force that is really meaningless in the overall scheme of things. One day I'll sit down and run the numbers to see where peak acceleration occurs.

#30

Looks like Autoblog & Motortrend may have borrowed their idea from our thread on Corvette Forum. Funny how so many posters discounted torque to weight as a legitimate metric until the major car media started using it.

https://www.corvetteforum.com/forums...-in-class.html

https://www.corvetteforum.com/forums...-in-class.html

#31

Burning Brakes

Here, let me try one more time for you; it's a simple-enough concept that most first-year engineering students and even internet bench racers get it first-try. I think we're saying the same thing - that from a roll, horsepower determines acceleration.

Take 2 identical cars.....same weight, same aero and drivetrain losses, but car #1 makes 400hp, and car #2 makes 600hp.

Pick a speed....say, 60mph for example. At 60mph (or any other given speed), the 600hp car can generate more forward acceleration than the 400hp car, assuming both cars are optimally geared.

The 600hp car generates more forward acceleration since it is able to develop more torque at the rear wheels at a given speed, through gearing.

Take 2 identical cars.....same weight, same aero and drivetrain losses, but car #1 makes 400hp, and car #2 makes 600hp.

Pick a speed....say, 60mph for example. At 60mph (or any other given speed), the 600hp car can generate more forward acceleration than the 400hp car, assuming both cars are optimally geared.

The 600hp car generates more forward acceleration since it is able to develop more torque at the rear wheels at a given speed, through gearing.

for those that want to argue,

defn of kinetic energy: T = 1/2*m*v^2

defn of power: P = dE/dt (where E is energy; can also use W for work. same thing. J)

so some quick calculus to illustrate my point:

dE/dt = dT/dt = d(1/2*m*v^2) = 1/2*m*2*v*dv/dt = m*v*dv/dt = m*v*a, where a is acceleration.

therefore

P = m*v*a -> (P/m)/v = a. at a given speed, the power to weight ratio determines acceleration. for spherical corvettes in an intertial frame, in a vacuum, and with frictionless tires of course.

#32

Burning Brakes

his R^2s were very poor (weak, weak correlation) and driven by three outlier points, two of which were corvette and one viper.

#33

Not being an expert in DynoJet dynos, I'm going to go out on a limb and say that I think you have it backwards. Horsepower was just a way for people to connect to new contraptions like the automobile.

One horsepower is defined as 550 foot-pounds per second. Foot-pounds? Kind of sounds familiar, doesn't it? Like the way we measure torque?

If you go to the farm and grab a couple of horses to see how they rate against this standard, some will probably do it easily, maybe some will have trouble or can't do it at all. It's an arbitrary number made up by some human engineers so that ordinary people transitioning from real horses can relate.

I know that a lot of turbines are rated by horsepower. I used to fly helicopters and they were all rated by horsepower, and turboprop airplanes, as well. None of them made 100,000 hp, though! I was talking about jets that fly from thrust instead of going through a gearbox and driving a propeller, although most, if not all, commercial jets these days produce most of their thrust from a geared fan. If you use the correct formula for calculating horsepower that it takes to get a Boeing 777 to fly at 540 knots, I'm pretty sure it would come out well above 100,000 horsepower because of the speed component.

I'll do some research.

One horsepower is defined as 550 foot-pounds per second. Foot-pounds? Kind of sounds familiar, doesn't it? Like the way we measure torque?

If you go to the farm and grab a couple of horses to see how they rate against this standard, some will probably do it easily, maybe some will have trouble or can't do it at all. It's an arbitrary number made up by some human engineers so that ordinary people transitioning from real horses can relate.

I know that a lot of turbines are rated by horsepower. I used to fly helicopters and they were all rated by horsepower, and turboprop airplanes, as well. None of them made 100,000 hp, though! I was talking about jets that fly from thrust instead of going through a gearbox and driving a propeller, although most, if not all, commercial jets these days produce most of their thrust from a geared fan. If you use the correct formula for calculating horsepower that it takes to get a Boeing 777 to fly at 540 knots, I'm pretty sure it would come out well above 100,000 horsepower because of the speed component.

I'll do some research.

A DynoJet inertia type chassis dyno measures HP by measuring the change in RPM of the roller drum to determine the Kinetic Energy added to the drum of a known mass/moment of inertia and then dividing that amount by the time it took to increase the KE to determine HP. From that, torque is calculated...there are no strain gages to measure torque.

Yes, HP=550 ft-lb/sec...as in 550 pounds lifted one foot in one second. The "ft-lb" term is not torque, it's a unit of work...HP is the rate work is done therefore the units are ft-lb/sec where the "lb" term is a pound mass. Torque is lb-ft which is a unit force where the "lb" term is a pound force. They are two different units of measure. Torque is a cross product of two vectors resulting in a vector with magnitude and direction while energy is a dot product of two vectors resulting in a scalar that has magnitude but no direction. The unit of HP was defined before cars came along.

The 550 ft-lb/sec was a measured number from watching the average work a horse could do, there was nothing arbitrary about it. However, the two terms in torque, foot and pound-force, are very arbitrary. The foot is based on the length of an average man's foot which of course varies. Over the years, depending on the location and time, the length of a foot has varied arbitrarily. The foot was defined in the US in 1893 and then internationally in 1959. It appears the foot is not only arbitrary but a moving target. The pound was initially as 7000 grains of wheat or barley and has experienced the same arbitrary changes into modern times as the foot.

#34

Burning Brakes

to get work (energy), torque also needs to be multiplied (actually, dotted) by an angle, given in radians (dimensionless, which doesn't add another unit so it stays ft*lbs) to convert it to a unit of work (a scalar) as opposed to a unit of torque (a vector). also, you missed the important point: per second. energy (work) per second is power.

nope. the concept of energy and power is very fundamental in physics, came waaaay before the car, and has an incredible number of well understood uses.

Last edited by nitrojunky; 10-15-2014 at 11:35 PM.

#35

Melting Slicks

You need to do a lot of research...I don't have anything backwards. I was in charge of the internal combustion engine lab my senior year at Georgia Tech and it had every kind of dyno you could imagine, I think I know how different dynos work.

A DynoJet inertia type chassis dyno measures HP by measuring the change in RPM of the roller drum to determine the Kinetic Energy added to the drum of a known mass/moment of inertia and then dividing that amount by the time it took to increase the KE to determine HP. From that, torque is calculated...there are no strain gages to measure torque.

Yes, HP=550 ft-lb/sec...as in 550 pounds lifted one foot in one second. The "ft-lb" term is not torque, it's a unit of work...HP is the rate work is done therefore the units are ft-lb/sec where the "lb" term is a pound mass. Torque is lb-ft which is a unit force where the "lb" term is a pound force. They are two different units of measure. Torque is a cross product of two vectors resulting in a vector with magnitude and direction while energy is a dot product of two vectors resulting in a scalar that has magnitude but no direction. The unit of HP was defined before cars came along.

The 550 ft-lb/sec was a measured number from watching the average work a horse could do, there was nothing arbitrary about it. However, the two terms in torque, foot and pound-force, are very arbitrary. The foot is based on the length of an average man's foot which of course varies. Over the years, depending on the location and time, the length of a foot has varied arbitrarily. The foot was defined in the US in 1893 and then internationally in 1959. It appears the foot is not only arbitrary but a moving target. The pound was initially as 7000 grains of wheat or barley and has experienced the same arbitrary changes into modern times as the foot.

A DynoJet inertia type chassis dyno measures HP by measuring the change in RPM of the roller drum to determine the Kinetic Energy added to the drum of a known mass/moment of inertia and then dividing that amount by the time it took to increase the KE to determine HP. From that, torque is calculated...there are no strain gages to measure torque.

Yes, HP=550 ft-lb/sec...as in 550 pounds lifted one foot in one second. The "ft-lb" term is not torque, it's a unit of work...HP is the rate work is done therefore the units are ft-lb/sec where the "lb" term is a pound mass. Torque is lb-ft which is a unit force where the "lb" term is a pound force. They are two different units of measure. Torque is a cross product of two vectors resulting in a vector with magnitude and direction while energy is a dot product of two vectors resulting in a scalar that has magnitude but no direction. The unit of HP was defined before cars came along.

The 550 ft-lb/sec was a measured number from watching the average work a horse could do, there was nothing arbitrary about it. However, the two terms in torque, foot and pound-force, are very arbitrary. The foot is based on the length of an average man's foot which of course varies. Over the years, depending on the location and time, the length of a foot has varied arbitrarily. The foot was defined in the US in 1893 and then internationally in 1959. It appears the foot is not only arbitrary but a moving target. The pound was initially as 7000 grains of wheat or barley and has experienced the same arbitrary changes into modern times as the foot.

#36

Burning Brakes

So I’m guessing you didn’t have an Eddy current dyno there in your lab did you? Because they DO measure torque and then calculate HP as a result. And NO, even a dyno jet does NOT measure HP directly; it measures acceleration of the drum and acceleration of the vehicle and relates the 2 to calculate HP. But, as I’m sure you already know, the units of acceleration are distance/ time^2. So again, it uses a calculation to figure out HP. And it’s very convenient in the imperial system that 1 pound of force equals 1 pound of mass (on earth at least). Bottom line is, no matter how you slice it, horsepower is a CALCULATED value. There is absolutely zero way to measure it directly. We CAN measure force, mass, distance, and time and then calculate a slew of things from there.

bottom line: at a given speed and all other factors being the same and allowing for proper gear selection, the car with more (horse)power will be able to produce a larger acceleration. period.

speed is a function of energy and power is how fast you can change the energy level. it's very basic physics, and torque at the flywheel is nowhere to be found.

#37

So I’m guessing you didn’t have an Eddy current dyno there in your lab did you? Because they DO measure torque and then calculate HP as a result. And NO, even a dyno jet does NOT measure HP directly; it measures acceleration of the drum and acceleration of the vehicle and relates the 2 to calculate HP. But, as I’m sure you already know, the units of acceleration are distance/ time^2. So again, it uses a calculation to figure out HP. And it’s very convenient in the imperial system that 1 pound of force equals 1 pound of mass (on earth at least). Bottom line is, no matter how you slice it, horsepower is a CALCULATED value. There is absolutely zero way to measure it directly. We CAN measure force, mass, distance, and time and then calculate a slew of things from there.

You continue by splitting hairs about measuring HP...by your reasoning, torque isn't measured either. The strain gage measures the strain in the shaft and correlates it to torque based on the diameter, material, and temperature of the shaft. Or, after the lever arm is measured and the force applied is measured, torque is calculated. Splitting hairs works both ways but what he was really saying was torque has to be measured first before you could calculate HP and he was wrong, your weak attempt to defend his position makes you just as wrong. The bottom line is you can't directly measure torque transmitted though a spinning shaft, you can directly measure the work done by a spinning shaft and divide it by the time it took to measure HP or HP=dW/dT. By measuring the rate at which the roller drum is accelerated, there is a direct correlation to HP so the output is just given in HP, not α. Therefore, we just measured HP with torque calculated...again, this is on a DynoJet inertia type chassis dyno.

FYI, one pound of force/weight does not have the same units of one pound of mass.

#38

Drifting

Member Since: Jun 1999

Location: Colorado Springs CO

Posts: 1,580

Likes: 0

Received 0 Likes

on

0 Posts

Having said all of the above, max acceleration does not occur at peak torque because torque is just a force which is linear or 1st order, you have no way of resolving all of the 2nd order influences unless you include the time factor. Before you get ahead of me here, I'm not saying peak acceleration occurs at peak HP. Since KE is a 2nd order equation, the amount of KE added to the car to accelerate from 30- 40 MPH is ¼ of the amount of KE added to the car to accelerate from 60-70 MPH even though both are 10 MPH increments. It takes the same amount of HP to add a certain amount of KE (let's say 1000 units) to the car no matter what speed you're going, therefore the higher your speed, the slower you accelerate with the same HP. I haven't run any numbers but it's obvious peak acceleration is past peak torque but before peak HP if the HP curve is flattening out as it reaches peak HP. In the case of the LT4/LS9 where the HP curve climbs at a steep rate up to peak HP, peak acceleration will occur closer to peak HP.

We could keep things closer to a first order by limiting ourselves to first gear acceleration runs (both drag loss and frictional loss should be negligible). I would imagine in this scenario, that peak acceleration would be close to the torque peak and, if anything, it should occur slightly lower than the torque peak due to increased drivetrain loss at higher rpms. If you do run some simulations, I'd be very curious to see how this plays out.

#39

Burning Brakes

In your example, the KE increase in going from 30-40 should be a bit over one-half (~0.54) the KE increase in going from 60-70, not 1/4 - what am I missing here?

We could keep things closer to a first order by limiting ourselves to first gear acceleration runs (both drag loss and frictional loss should be negligible). I would imagine in this scenario, that peak acceleration would be close to the torque peak and, if anything, it should occur slightly lower than the torque peak due to increased drivetrain loss at higher rpms. If you do run some simulations, I'd be very curious to see how this plays out.

We could keep things closer to a first order by limiting ourselves to first gear acceleration runs (both drag loss and frictional loss should be negligible). I would imagine in this scenario, that peak acceleration would be close to the torque peak and, if anything, it should occur slightly lower than the torque peak due to increased drivetrain loss at higher rpms. If you do run some simulations, I'd be very curious to see how this plays out.

#40

Melting Slicks

Actually, I did run an Eddy current dyno at Georgia Tech but you have failed to make a point. Read my post again, I was talking specifically about a DynoJet inertia type chassis dyno which does measure HP. He stated HP is calculated from torque which is measured first before HP can be calculated...all I had to do was show one instance where that isn't true and I did exactly that, try to keep up.

You continue by splitting hairs about measuring HP...by your reasoning, torque isn't measured either. The strain gage measures the strain in the shaft and correlates it to torque based on the diameter, material, and temperature of the shaft. Or, after the lever arm is measured and the force applied is measured, torque is calculated. Splitting hairs works both ways but what he was really saying was torque has to be measured first before you could calculate HP and he was wrong, your weak attempt to defend his position makes you just as wrong. The bottom line is you can't directly measure torque transmitted though a spinning shaft, you can directly measure the work done by a spinning shaft and divide it by the time it took to measure HP or HP=dW/dT. By measuring the rate at which the roller drum is accelerated, there is a direct correlation to HP so the output is just given in HP, not α. Therefore, we just measured HP with torque calculated...again, this is on a DynoJet inertia type chassis dyno.

FYI, one pound of force/weight does not have the same units of one pound of mass.

You continue by splitting hairs about measuring HP...by your reasoning, torque isn't measured either. The strain gage measures the strain in the shaft and correlates it to torque based on the diameter, material, and temperature of the shaft. Or, after the lever arm is measured and the force applied is measured, torque is calculated. Splitting hairs works both ways but what he was really saying was torque has to be measured first before you could calculate HP and he was wrong, your weak attempt to defend his position makes you just as wrong. The bottom line is you can't directly measure torque transmitted though a spinning shaft, you can directly measure the work done by a spinning shaft and divide it by the time it took to measure HP or HP=dW/dT. By measuring the rate at which the roller drum is accelerated, there is a direct correlation to HP so the output is just given in HP, not α. Therefore, we just measured HP with torque calculated...again, this is on a DynoJet inertia type chassis dyno.

FYI, one pound of force/weight does not have the same units of one pound of mass.

And an Eddy current dyno does indeed calculate HP based on its derrived torque measurement. The conversation was not limited to dynojets until you said it was just now.

And yes I know one pound of force does not have the same units as one pound of mass. However, one pound of mass creates one pound of force on earth.