[Z06] Who's running Ferrea hollow stemmed exhaust valves? F2042P

#121

Safety Car

Not really. Just because that piece stays together doesn't mean the whole system will last. Simply moving the point of failure to the next weakest link doesn't solve the problem. I'd actually like to know not how many people have been fine after the fix but how many have lost a lifter, a cam lobe, etc after the fix.

This always brings me back to the very early LS1 days when guys in M6's were bending pushrods. So the vendors "fix" was to sell these guys hardened aftermarket pushrods. The vendors "fix" never broke again (the pushrod) but as you can imagine, lots of guys started to bend valves, break springs, etc. So then the "fix" became to fly cut the LS1 flat top pistons and vendors were able to do it in car. Another fix, another story. Someone will always have THE "fix."

There will always be guys that will want to have it done right an precise as a system. And there will always be guys that 80% is good enough for the time being. Those guys get all bent, rant and move on to something else when the next part breaks on them anyways.

At the end of the day, the only waste is the time everyone spends here bickering about it on the net instead of enjoying the Z!

This always brings me back to the very early LS1 days when guys in M6's were bending pushrods. So the vendors "fix" was to sell these guys hardened aftermarket pushrods. The vendors "fix" never broke again (the pushrod) but as you can imagine, lots of guys started to bend valves, break springs, etc. So then the "fix" became to fly cut the LS1 flat top pistons and vendors were able to do it in car. Another fix, another story. Someone will always have THE "fix."

There will always be guys that will want to have it done right an precise as a system. And there will always be guys that 80% is good enough for the time being. Those guys get all bent, rant and move on to something else when the next part breaks on them anyways.

At the end of the day, the only waste is the time everyone spends here bickering about it on the net instead of enjoying the Z!

#122

Drifting

- Manley Nextek .700" Dual Spring Kit w/ Ti Retainers, Hardened Locators, Precision Locks

so that what we used.

#123

Melting Slicks

Hmmmm... those springs didn't test well with the SS valves. I wonder how they will do with the Ferra's. Thats a lot of spring for a light valve. What are the cam specs?

Last edited by propain; 04-29-2014 at 11:17 AM.

#124

Drifting

I wondered about that and at first we were going with SS valves but I wanted the Ferra's and guess I should have asked if the springs were ok.

I was getting ready to post my complete build and results and I am not good at understanding the cam specs but will give you some and maybe you can figure it out.

Lift at valves---.615 in.---.626 ex.

Rocker ratio---1.700 in.---1.700 ex.

Duration at .050 tappet lift---223 in.---235 ex.

Advertised duration---273 in.---285 ex.

All I can say is the car runs great and the 2 k to 5 k torque is insane. Just got the car back so still getting used to the power.

Thanks for the interest.

I was getting ready to post my complete build and results and I am not good at understanding the cam specs but will give you some and maybe you can figure it out.

Lift at valves---.615 in.---.626 ex.

Rocker ratio---1.700 in.---1.700 ex.

Duration at .050 tappet lift---223 in.---235 ex.

Advertised duration---273 in.---285 ex.

All I can say is the car runs great and the 2 k to 5 k torque is insane. Just got the car back so still getting used to the power.

Thanks for the interest.

#125

I wondered about that and at first we were going with SS valves but I wanted the Ferra's and guess I should have asked if the springs were ok.

I was getting ready to post my complete build and results and I am not good at understanding the cam specs but will give you some and maybe you can figure it out.

Lift at valves---.615 in.---.626 ex.

Rocker ratio---1.700 in.---1.700 ex.

Duration at .050 tappet lift---223 in.---235 ex.

Advertised duration---273 in.---285 ex.

All I can say is the car runs great and the 2 k to 5 k torque is insane. Just got the car back so still getting used to the power.

Thanks for the interest.

I was getting ready to post my complete build and results and I am not good at understanding the cam specs but will give you some and maybe you can figure it out.

Lift at valves---.615 in.---.626 ex.

Rocker ratio---1.700 in.---1.700 ex.

Duration at .050 tappet lift---223 in.---235 ex.

Advertised duration---273 in.---285 ex.

All I can say is the car runs great and the 2 k to 5 k torque is insane. Just got the car back so still getting used to the power.

Thanks for the interest.

Congrats

#126

Hey guys,

I have to ask again, please keep the conversation about the Hollow stem valves. The thread isn't even about the solid SS valves so let's not keep discussing them here. How about we argue the merits or cons of the hollow stem valves?

Thanks everyone,

Joshua

I have to ask again, please keep the conversation about the Hollow stem valves. The thread isn't even about the solid SS valves so let's not keep discussing them here. How about we argue the merits or cons of the hollow stem valves?

Thanks everyone,

Joshua

Those are the "cons" that come to mind.

The positives are weight reduction. The weight advantages are many, and have a progressive path from the seat to the crank gear. Too many to go into, and to discuss them is wasted effort and time on this forum. If you can not tell by some of the responses already, there is little desire to understand theory of operation on this forum by most.

As far as this particular hollow stemmed valve from Ferrea, I have no reason to believe it is not a very good option. Ferrea makes a great product. I've used their stuff in many engines over the years.

The single concern I would have, is the removal of sodium from the stem. Without knowing exactly why the head design engineers felt this particular seat/port needed more flux transfer to the guide, I would be a bit hesitant to remove that transfer path, unless I could enhance heat transfer to the seat. The only way to effectively do that, is to change seat material, or seat angle, or a combination of both. Changing angle will hinder flow, so I'd lean toward seat material. But, that also might cause issues with these heads, as the seats are siamesed, so cooling water does not remove heat uniformly around the seat circumference. This could result in warped seats. That in itself could be why the engineers selected the sodium stems.

The problem with modifying an engineered design, is not knowing what you don't know. Without a structured management of change process, you are shooting from the hip. Sometimes you get lucky. Sometimes you get shot.

#127

Safety Car

Member Since: Dec 1999

Location: Virginia Beach, VA & Port Charlotte, FL (snowbird)

Posts: 4,404

Received 1,092 Likes

on

576 Posts

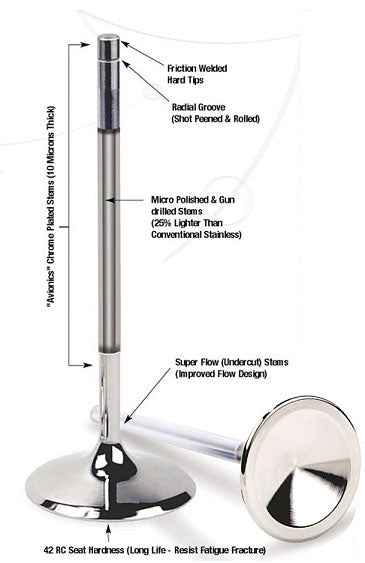

A hollow stemmed valve will not withstand the same degree of abuse that a solid stemmed valve will, such as PTVC. Hollow stemmed valves are generally gun drilled, so the wall thickness will vary to some degree. There may be some new processes other than gun drilling that I am not aware of. What they are, and if they are reliable is not something I know. A hollow stemmed valve will also tend to 'flex' if it is opened earlier with the presence of cylinder pressure, such as with a more aggressive (than OE) cam profile.

Those are the "cons" that come to mind.

The positives are weight reduction. The weight advantages are many, and have a progressive path from the seat to the crank gear. Too many to go into, and to discuss them is wasted effort and time on this forum. If you can not tell by some of the responses already, there is little desire to understand theory of operation on this forum by most.

As far as this particular hollow stemmed valve from Ferrea, I have no reason to believe it is not a very good option. Ferrea makes a great product. I've used their stuff in many engines over the years.

The single concern I would have, is the removal of sodium from the stem. Without knowing exactly why the head design engineers felt this particular seat/port needed more flux transfer to the guide, I would be a bit hesitant to remove that transfer path, unless I could enhance heat transfer to the seat. The only way to effectively do that, is to change seat material, or seat angle, or a combination of both. Changing angle will hinder flow, so I'd lean toward seat material. But, that also might cause issues with these heads, as the seats are siamesed, so cooling water does not remove heat uniformly around the seat circumference. This could result in warped seats. That in itself could be why the engineers selected the sodium stems.

The problem with modifying an engineered design, is not knowing what you don't know. Without a structured management of change process, you are shooting from the hip. Sometimes you get lucky. Sometimes you get shot.

Those are the "cons" that come to mind.

The positives are weight reduction. The weight advantages are many, and have a progressive path from the seat to the crank gear. Too many to go into, and to discuss them is wasted effort and time on this forum. If you can not tell by some of the responses already, there is little desire to understand theory of operation on this forum by most.

As far as this particular hollow stemmed valve from Ferrea, I have no reason to believe it is not a very good option. Ferrea makes a great product. I've used their stuff in many engines over the years.

The single concern I would have, is the removal of sodium from the stem. Without knowing exactly why the head design engineers felt this particular seat/port needed more flux transfer to the guide, I would be a bit hesitant to remove that transfer path, unless I could enhance heat transfer to the seat. The only way to effectively do that, is to change seat material, or seat angle, or a combination of both. Changing angle will hinder flow, so I'd lean toward seat material. But, that also might cause issues with these heads, as the seats are siamesed, so cooling water does not remove heat uniformly around the seat circumference. This could result in warped seats. That in itself could be why the engineers selected the sodium stems.

The problem with modifying an engineered design, is not knowing what you don't know. Without a structured management of change process, you are shooting from the hip. Sometimes you get lucky. Sometimes you get shot.

#130

Burning Brakes

I don't think this matters, it's secondary job is to conduct heat up the stem to the guide to the water jacket. As soon as the heat hits the hollow part of the stem, heat conduction will slow down. Sodium has 4-5x the thermal conductivity of (generic) SS. Once the heat gets up into the guide it should flow into the cooling system.

#131

Safety Car

Member Since: Dec 1999

Location: Virginia Beach, VA & Port Charlotte, FL (snowbird)

Posts: 4,404

Received 1,092 Likes

on

576 Posts

I don't think this matters, it's secondary job is to conduct heat up the stem to the guide to the water jacket. As soon as the heat hits the hollow part of the stem, heat conduction will slow down. Sodium has 4-5x the thermal conductivity of (generic) SS. Once the heat gets up into the guide it should flow into the cooling system.

I agree with its reduction in heat transfer. The jury is still out as to its long term effects

#132

Melting Slicks

Do you believe the hollow portion of the valve protruding into the combustion chamber reduces its strength?

#133

Melting Slicks

A hollow stemmed valve will not withstand the same degree of abuse that a solid stemmed valve will, such as PTVC. Hollow stemmed valves are generally gun drilled, so the wall thickness will vary to some degree. There may be some new processes other than gun drilling that I am not aware of. What they are, and if they are reliable is not something I know. A hollow stemmed valve will also tend to 'flex' if it is opened earlier with the presence of cylinder pressure, such as with a more aggressive (than OE) cam profile.

Those are the "cons" that come to mind.

The positives are weight reduction. The weight advantages are many, and have a progressive path from the seat to the crank gear. Too many to go into, and to discuss them is wasted effort and time on this forum. If you can not tell by some of the responses already, there is little desire to understand theory of operation on this forum by most.

As far as this particular hollow stemmed valve from Ferrea, I have no reason to believe it is not a very good option. Ferrea makes a great product. I've used their stuff in many engines over the years.

The single concern I would have, is the removal of sodium from the stem. Without knowing exactly why the head design engineers felt this particular seat/port needed more flux transfer to the guide, I would be a bit hesitant to remove that transfer path, unless I could enhance heat transfer to the seat. The only way to effectively do that, is to change seat material, or seat angle, or a combination of both. Changing angle will hinder flow, so I'd lean toward seat material. But, that also might cause issues with these heads, as the seats are siamesed, so cooling water does not remove heat uniformly around the seat circumference. This could result in warped seats. That in itself could be why the engineers selected the sodium stems.

The problem with modifying an engineered design, is not knowing what you don't know. Without a structured management of change process, you are shooting from the hip. Sometimes you get lucky. Sometimes you get shot.

Those are the "cons" that come to mind.

The positives are weight reduction. The weight advantages are many, and have a progressive path from the seat to the crank gear. Too many to go into, and to discuss them is wasted effort and time on this forum. If you can not tell by some of the responses already, there is little desire to understand theory of operation on this forum by most.

As far as this particular hollow stemmed valve from Ferrea, I have no reason to believe it is not a very good option. Ferrea makes a great product. I've used their stuff in many engines over the years.

The single concern I would have, is the removal of sodium from the stem. Without knowing exactly why the head design engineers felt this particular seat/port needed more flux transfer to the guide, I would be a bit hesitant to remove that transfer path, unless I could enhance heat transfer to the seat. The only way to effectively do that, is to change seat material, or seat angle, or a combination of both. Changing angle will hinder flow, so I'd lean toward seat material. But, that also might cause issues with these heads, as the seats are siamesed, so cooling water does not remove heat uniformly around the seat circumference. This could result in warped seats. That in itself could be why the engineers selected the sodium stems.

The problem with modifying an engineered design, is not knowing what you don't know. Without a structured management of change process, you are shooting from the hip. Sometimes you get lucky. Sometimes you get shot.

My only quibble is that apparently you missed the memo about GM having lousy engineers, I mean aren't all those pictures of holed blocks floating around the forum not proof enough that a head rebuilder should be doing your engineering for you

Cheers, Paul.

#134

Safety Car

Member Since: Dec 1999

Location: Virginia Beach, VA & Port Charlotte, FL (snowbird)

Posts: 4,404

Received 1,092 Likes

on

576 Posts

If it does protrude, the 0.080" wall thickness should be more than adequate for its intended use. Ferrea states that it's the strongest hollow stem valve on the market today. I've no reason to doubt their claim.

When my PRC265s come off in the future for a bottom end build the heads will be R&R'd with a new set of these valves and a set of PSI springs.

The car has right at 100K on it now and doesn't use a drop of oil. I wiggle tested my PRCs @ 10K miles use and the valve guide wear was negligible. The car seldom sees north of 6K rpm anyway as it's 99.9% street only. No track and only once to the strip. That's why I'm really not too concerned about the heavy stainless valve issue. Not an ounce of bounce...

#136

Melting Slicks

I don't think it protrudes into the combustion chamber. I believe it's contained by the guide at all times, as I stated in my previous post.

If it does protrude, the 0.080" wall thickness should be more than adequate for its intended use. Ferrea states that it's the strongest hollow stem valve on the market today. I've no reason to doubt their claim.

When my PRC265s come off in the future for a bottom end build the heads will be R&R'd with a new set of these valves and a set of PSI springs.

The car has right at 100K on it now and doesn't use a drop of oil. I wiggle tested my PRCs @ 10K miles use and the valve guide wear was negligible. The car seldom sees north of 6K rpm anyway as it's 99.9% street only. No track and only once to the strip. That's why I'm really not too concerned about the heavy stainless valve issue. Not an ounce of bounce...

If it does protrude, the 0.080" wall thickness should be more than adequate for its intended use. Ferrea states that it's the strongest hollow stem valve on the market today. I've no reason to doubt their claim.

When my PRC265s come off in the future for a bottom end build the heads will be R&R'd with a new set of these valves and a set of PSI springs.

The car has right at 100K on it now and doesn't use a drop of oil. I wiggle tested my PRCs @ 10K miles use and the valve guide wear was negligible. The car seldom sees north of 6K rpm anyway as it's 99.9% street only. No track and only once to the strip. That's why I'm really not too concerned about the heavy stainless valve issue. Not an ounce of bounce...

One thing you didn't factor in with these valves is the gun drilled portion of the stem never protrudes into the combustion chamber, even at full lift. This is unlike the OEM valves.

I guess I read it wrong? How so?

#137

Melting Slicks

#138

Advanced

Thread Starter

Member Since: Mar 2014

Location: ausitn TX - Texas

Posts: 69

Likes: 0

Received 0 Likes

on

0 Posts

#139

One thing you didn't factor in with these valves is the gun drilled portion of the stem never protrudes into the combustion chamber, even at full lift. This is unlike the OEM valves. That being said, it would negate the reduced strength concerns since the "weaker" portion of the valve would be contained within the guide at all times.

And a solid stemmed valve is even thicker yet!!! So what's your point?? You seamed to forget the rational behind why the stem is hollow. There is a point when 'thicker' is not necessary, and simply increases weight.

#140

Safety Car

Member Since: Dec 1999

Location: Virginia Beach, VA & Port Charlotte, FL (snowbird)

Posts: 4,404

Received 1,092 Likes

on

576 Posts

A hollow stemmed valve will not withstand the same degree of abuse that a solid stemmed valve will, such as PTVC. Hollow stemmed valves are generally gun drilled, so the wall thickness will vary to some degree. There may be some new processes other than gun drilling that I am not aware of. What they are, and if they are reliable is not something I know. A hollow stemmed valve will also tend to 'flex' if it is opened earlier with the presence of cylinder pressure, such as with a more aggressive (than OE) cam profile.

Those are the "cons" that come to mind.

The positives are weight reduction. The weight advantages are many, and have a progressive path from the seat to the crank gear. Too many to go into, and to discuss them is wasted effort and time on this forum. If you can not tell by some of the responses already, there is little desire to understand theory of operation on this forum by most.

As far as this particular hollow stemmed valve from Ferrea, I have no reason to believe it is not a very good option. Ferrea makes a great product. I've used their stuff in many engines over the years.

The single concern I would have, is the removal of sodium from the stem. Without knowing exactly why the head design engineers felt this particular seat/port needed more flux transfer to the guide, I would be a bit hesitant to remove that transfer path, unless I could enhance heat transfer to the seat. The only way to effectively do that, is to change seat material, or seat angle, or a combination of both. Changing angle will hinder flow, so I'd lean toward seat material. But, that also might cause issues with these heads, as the seats are siamesed, so cooling water does not remove heat uniformly around the seat circumference. This could result in warped seats. That in itself could be why the engineers selected the sodium stems.

The problem with modifying an engineered design, is not knowing what you don't know. Without a structured management of change process, you are shooting from the hip. Sometimes you get lucky. Sometimes you get shot.

Those are the "cons" that come to mind.

The positives are weight reduction. The weight advantages are many, and have a progressive path from the seat to the crank gear. Too many to go into, and to discuss them is wasted effort and time on this forum. If you can not tell by some of the responses already, there is little desire to understand theory of operation on this forum by most.

As far as this particular hollow stemmed valve from Ferrea, I have no reason to believe it is not a very good option. Ferrea makes a great product. I've used their stuff in many engines over the years.

The single concern I would have, is the removal of sodium from the stem. Without knowing exactly why the head design engineers felt this particular seat/port needed more flux transfer to the guide, I would be a bit hesitant to remove that transfer path, unless I could enhance heat transfer to the seat. The only way to effectively do that, is to change seat material, or seat angle, or a combination of both. Changing angle will hinder flow, so I'd lean toward seat material. But, that also might cause issues with these heads, as the seats are siamesed, so cooling water does not remove heat uniformly around the seat circumference. This could result in warped seats. That in itself could be why the engineers selected the sodium stems.

The problem with modifying an engineered design, is not knowing what you don't know. Without a structured management of change process, you are shooting from the hip. Sometimes you get lucky. Sometimes you get shot.