[Z06] pushrod help

#1

Putting my new ai heads on in a few minutes with my rather large cam, from what I've read I'm looking for a .80-.90 preload is that my best option? I don't wanna hear a clackity motor lol

#4

Works for me

But, again just me, if the rods I had worked out to .100 or thereabouts I wouldn't sweat it. Under .080 it might get a little noisy, or so the experts say, but hey -- it's a built motor

But, again just me, if the rods I had worked out to .100 or thereabouts I wouldn't sweat it. Under .080 it might get a little noisy, or so the experts say, but hey -- it's a built motor

#6

Okay so it seems that with the lash caps on the intake valves that I need a 7.750 and on the Manley ss exhaust valves I need a 7.725? Do I run 2 different lengths due to different heights?

#7

#8

Team Owner

#12

If it was me and I could split the difference with the pushrods I have on hand then that's probably the way I would go. Based on the measurements it sounds like that's not going to be the case, so if I was ordering pushrods anyway then I might just order two different sizes if I really wanted to hit a specific number.

As long as you stay in the suggested ranges I don't think it makes a difference (one size or two sizes), but if noise is a concern then I'd err on the high side (more preload instead of less). Keep in mind that GM runs them real deep (.120 or better) even though most shops recommend less. I suspect GM does that because of potential noise as the OEM lifter bleeds down at idle RPM (I presume you are running the stock lifters).

#14

I'm no expert but I don't think a .025 difference in zero preload between intake and exhaust is particularly alarming. Hopefully the experts will chime in on that.

Most likely the design of the Manley exhaust valve simply makes it sit a little taller than the stock valve for whatever reason. Shouldn't be an issue as long as it is accounted for with respect to the rest of the valvetrain system.

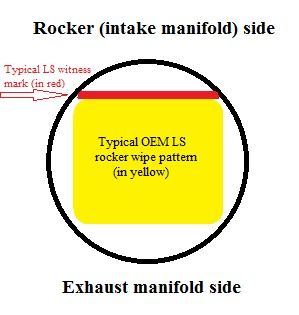

I would do a geometry 'witness mark' check on the exhaust side to make sure the rocker (I presume those are stock too) is not starting out on the very edge of the valve stem tip.

Most likely the design of the Manley exhaust valve simply makes it sit a little taller than the stock valve for whatever reason. Shouldn't be an issue as long as it is accounted for with respect to the rest of the valvetrain system.

I would do a geometry 'witness mark' check on the exhaust side to make sure the rocker (I presume those are stock too) is not starting out on the very edge of the valve stem tip.

#15

The OE valves were manufactured to locate the rocker pad at the same height, with the lash cap installed on the intake, and both springs installed at the same height.

Don't assume anything. Measure preload and wipe on both. This is just one of those things you have to go through when building an engine. Mock the top end up, take measurements, then order what you need. Sometimes the heads need to go back to the machine shop. Sometimes you get lucky.

#16

They did not return my stock valves or springs, after machine work plus sending them back isn't a option really after what I went through with them. I ran a rocker down all the way on exhaust and it stayed in middle of stem and I wasn't sure if the .025 was alarming or not I'm new to the ls world

#17

Supporting Vendor

Member Since: Sep 2013

Location: Harbor City California

Posts: 2,817

Received 1,012 Likes

on

533 Posts

Different base circles can result in different PR's for intake and exhaust.. different cam manufactures do this differently. Not unheard of at all to use different length PR's on the intake and exhaust.

#18

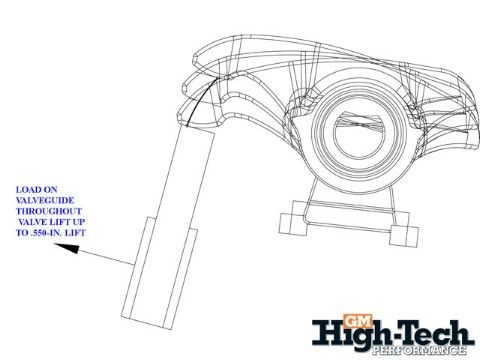

It will probably be difficult to get a good wipe mark with the engine assembled since, without oil pressure (if you are rotating the engine by hand), the lifter will probably compress in response to normal valve spring pressure.

However, you can get a fairly good witness mark by removing the pushrod, reinstalling the rocker, and holding up on the pushrod cup end while tapping the valve stem end. If the witness mark is in the vicinity of what is shown, then that would be the first step to confirming a good valve stem/rocker arm relationship. The main worry in your situation is if the valve stem is higher than normal, which would push the witness mark (point of first rocker contact) out to the actual edge of the valve stem (which would not be good).