[Z06] Dirty Howie Goes To WCCH: Pictorial !!

#1

Team Owner

Thread Starter

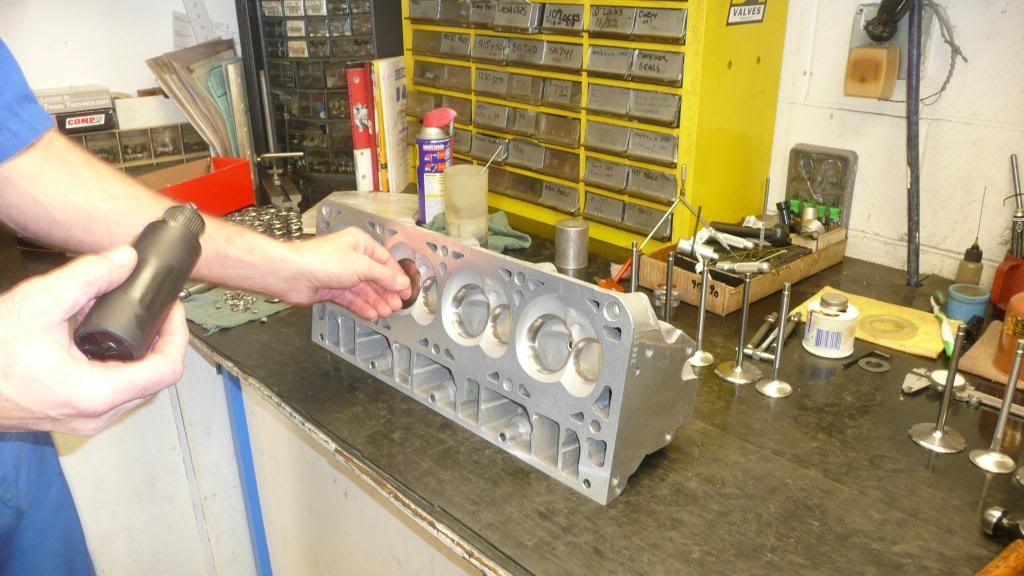

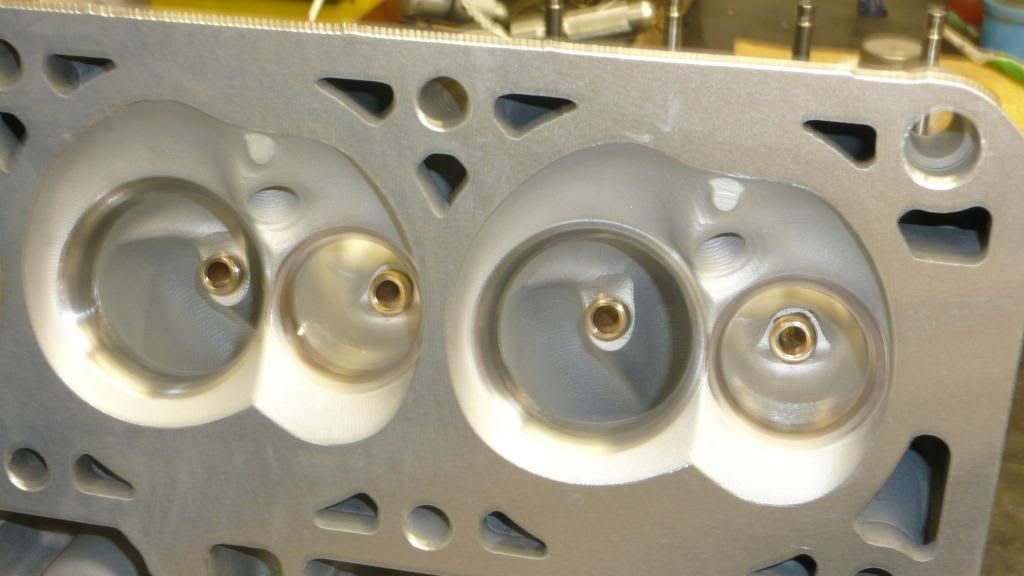

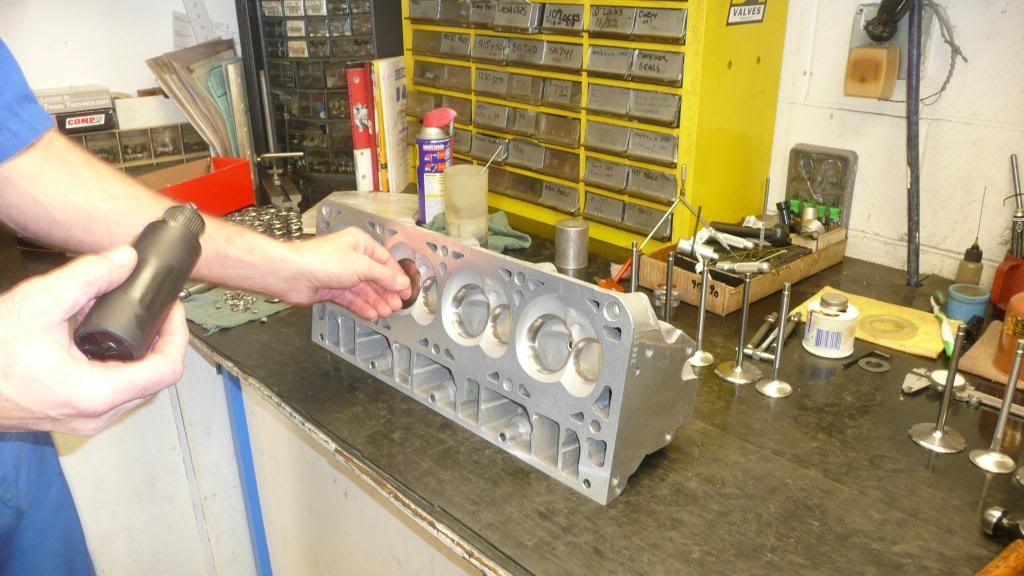

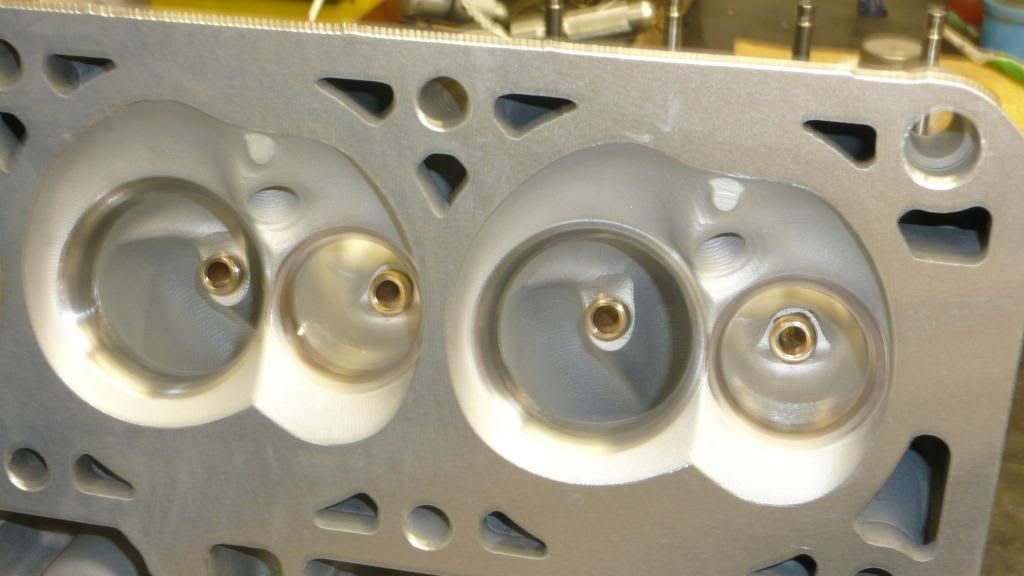

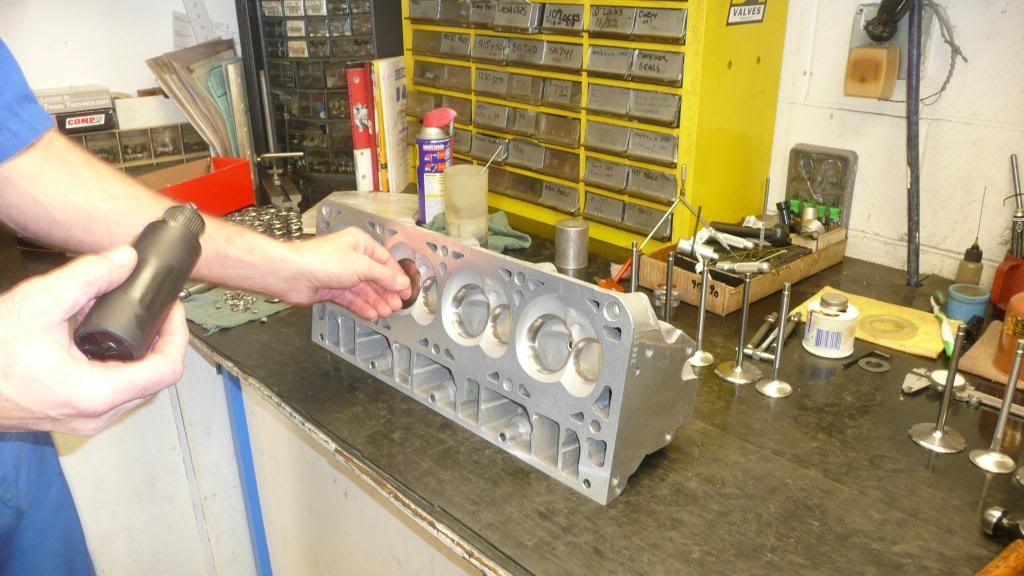

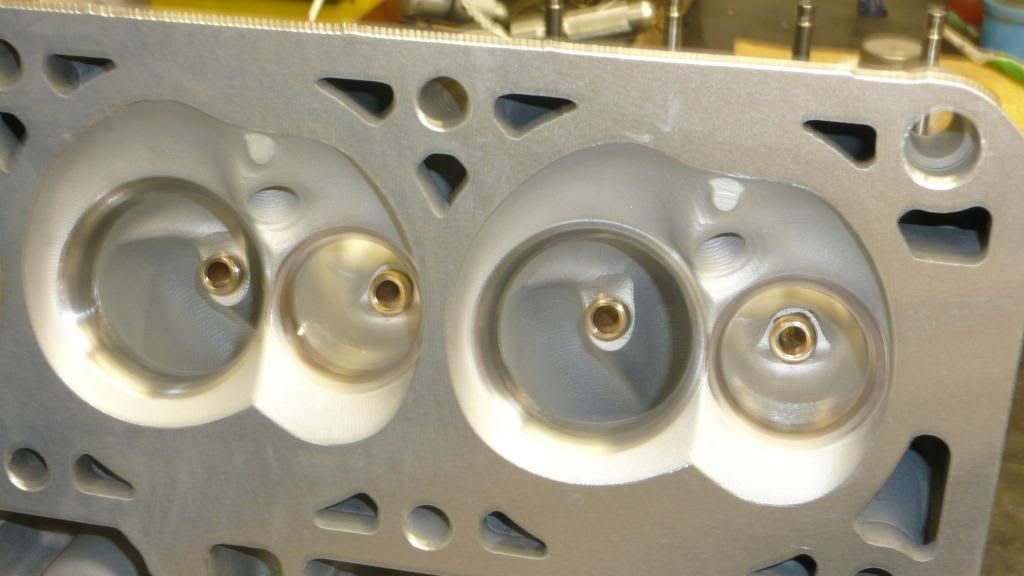

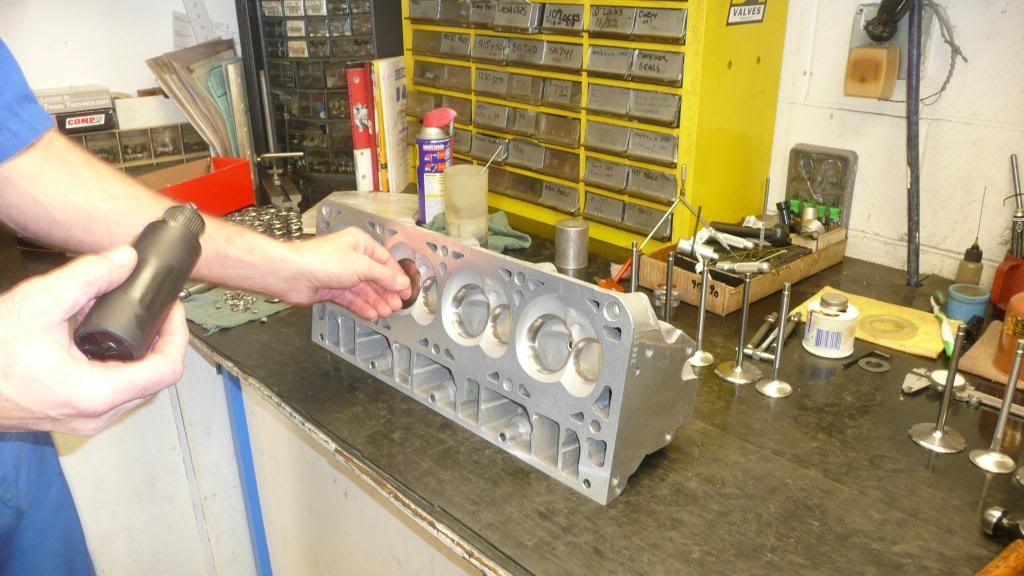

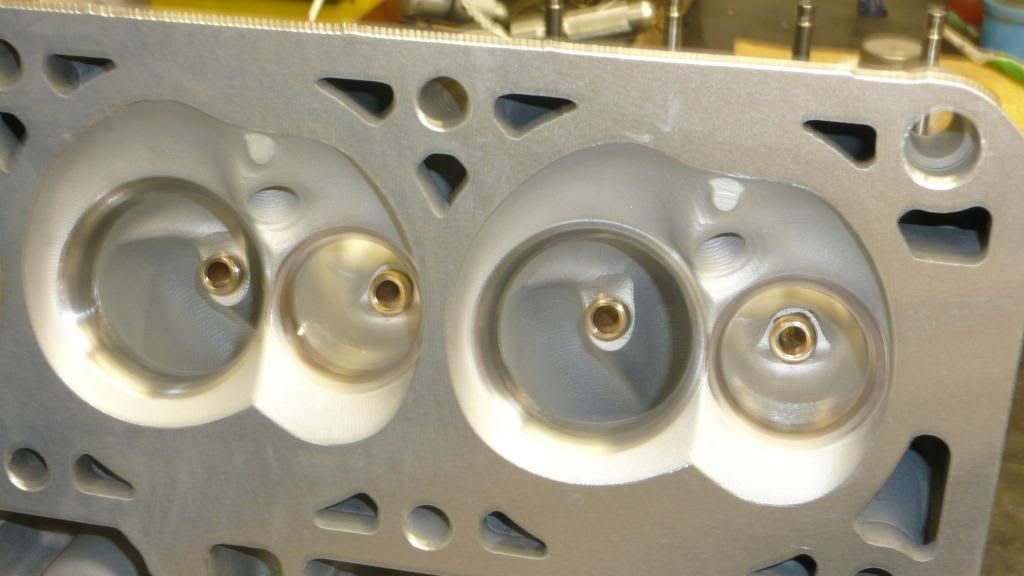

Well I went to WCCH today. I hung out with Richard and watched him install the valves and springs on my reworked LS7 cylinder heads. He took a lot of time and educated me very well. I now know what burnt valves and over heated guides look like. I know there are different valve seals for intake or exhaust valves. Finally saw how valve seals, seats springs, retainers and keepers are put together.

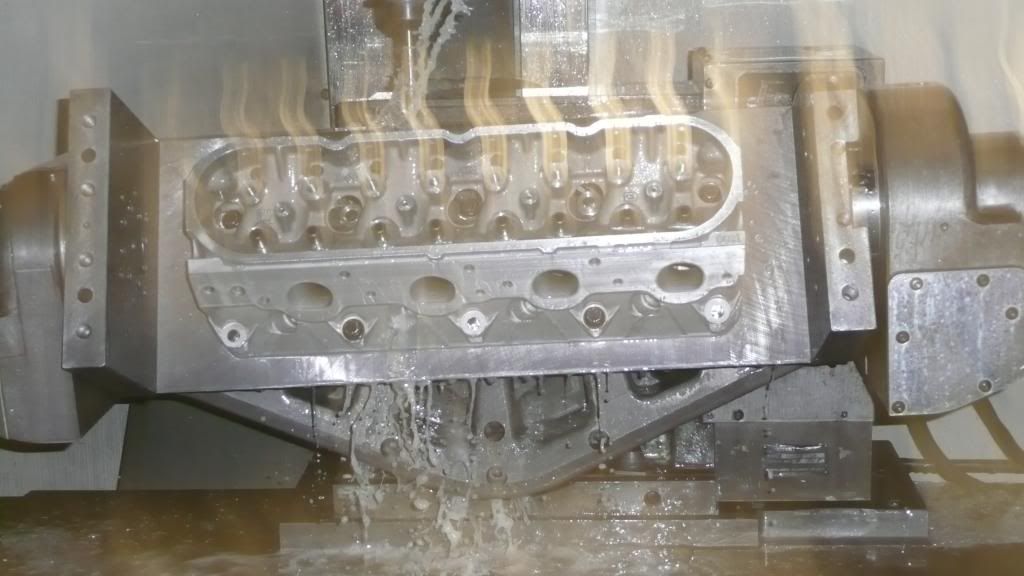

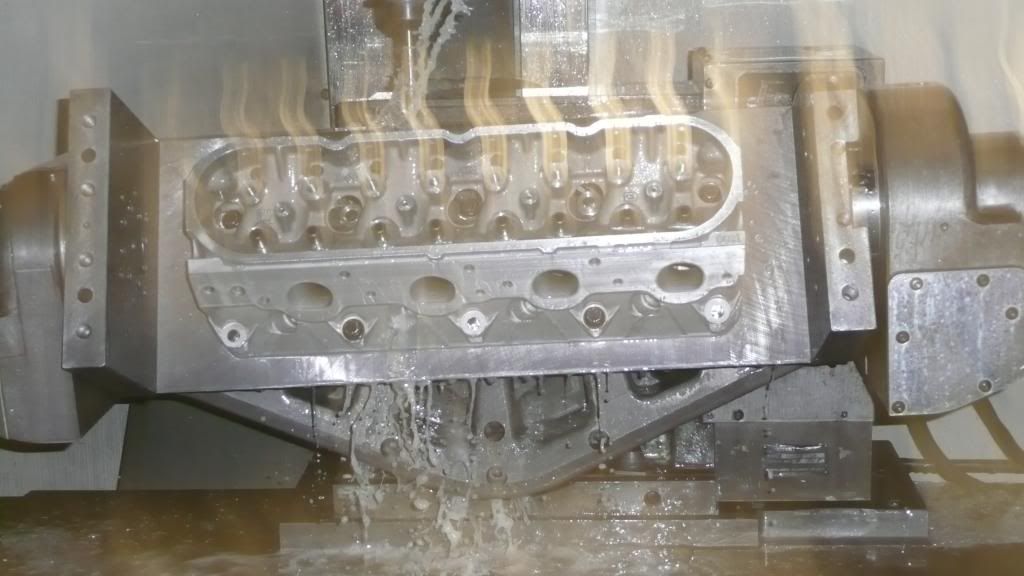

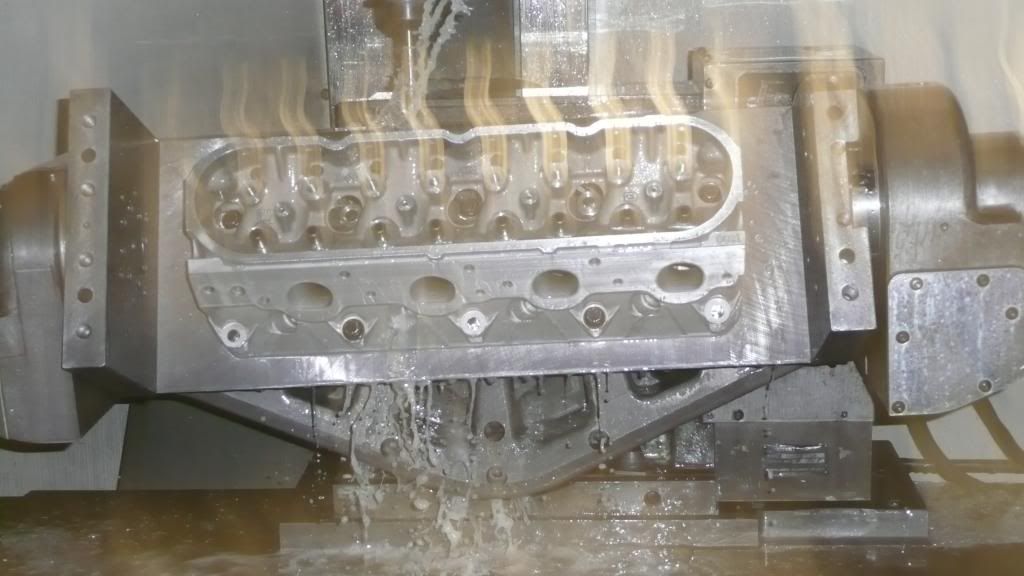

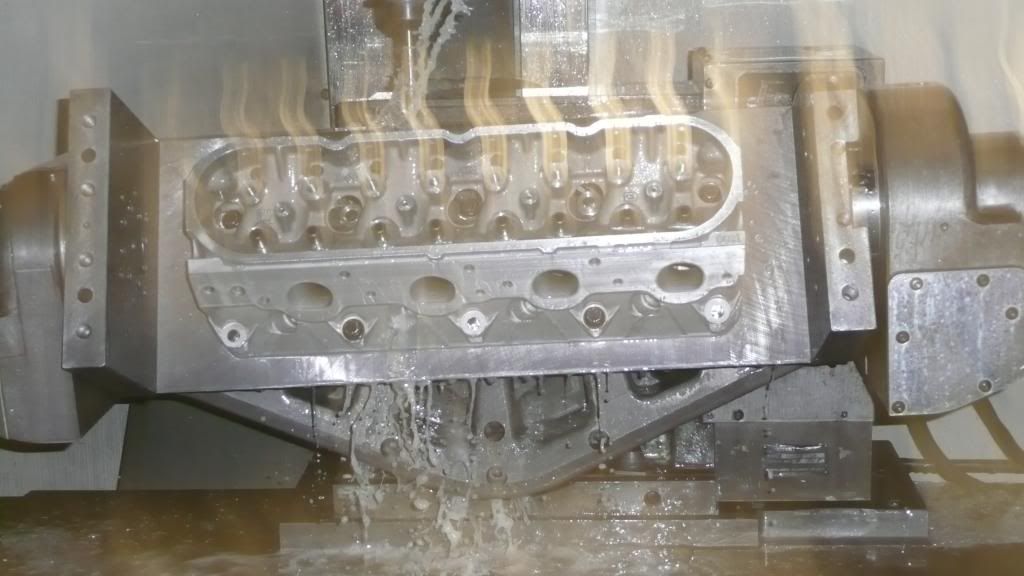

Below you will see many pictures I took today. My car in front of their shop. Some pictures of the different equipment, Sunnen, CNC etc. A few of the cylinder heads ..... there were tons of LS7 heads in there . A few pics of the my heads being assembled. Pictures of burnt valves, guides showing excess heat have been included. Some pictures of measurements being taken of the guide bore. Also pics of my new CHE rockers.

. A few pics of the my heads being assembled. Pictures of burnt valves, guides showing excess heat have been included. Some pictures of measurements being taken of the guide bore. Also pics of my new CHE rockers.

First here is a video of what a worn guide looks like

And here pictures from my visit:

[IMG]http://i20.photobucket.com/albums/b219/DirtyHowie/P1020130_zps6a5fa062.jpg[/IMG

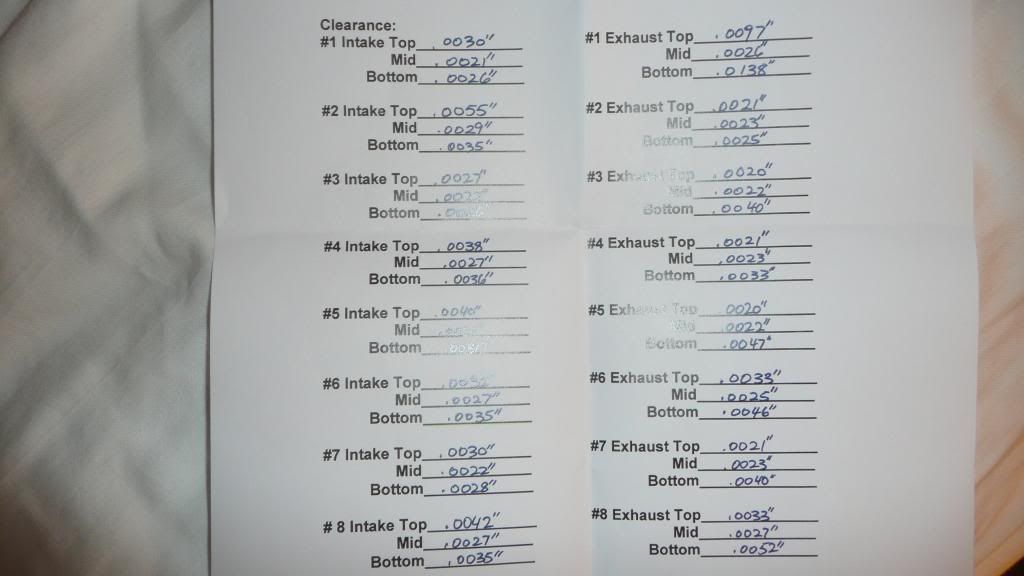

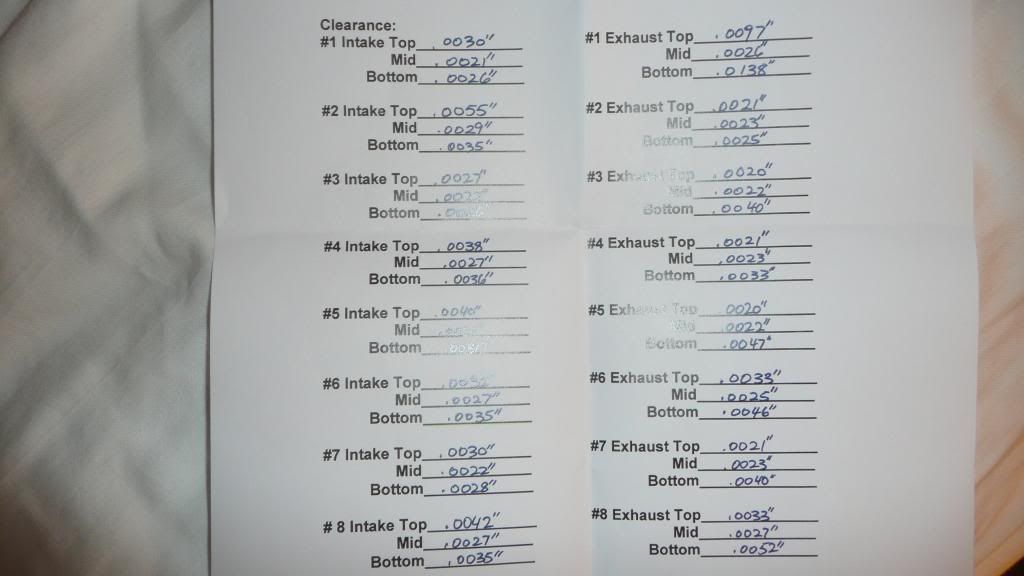

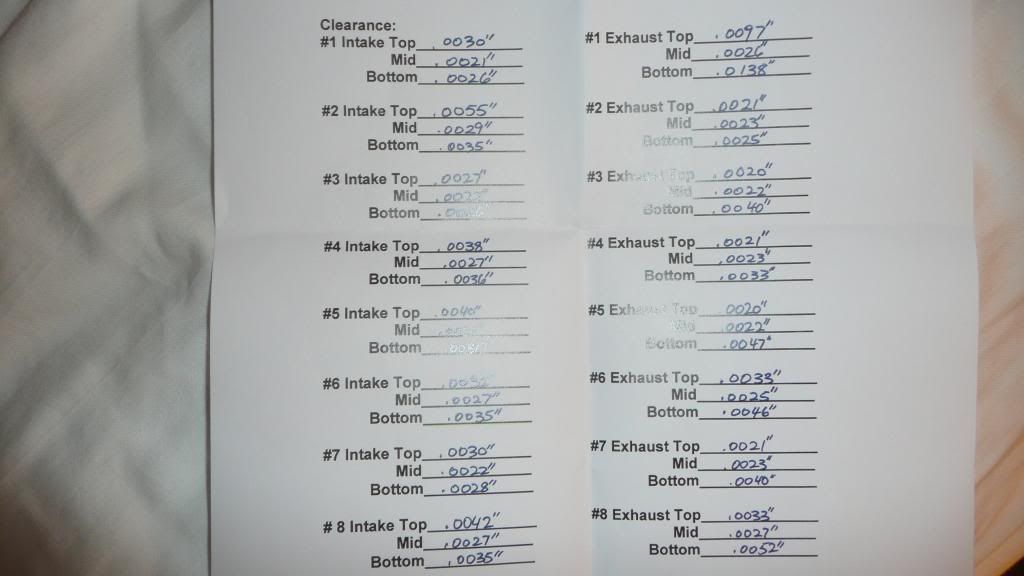

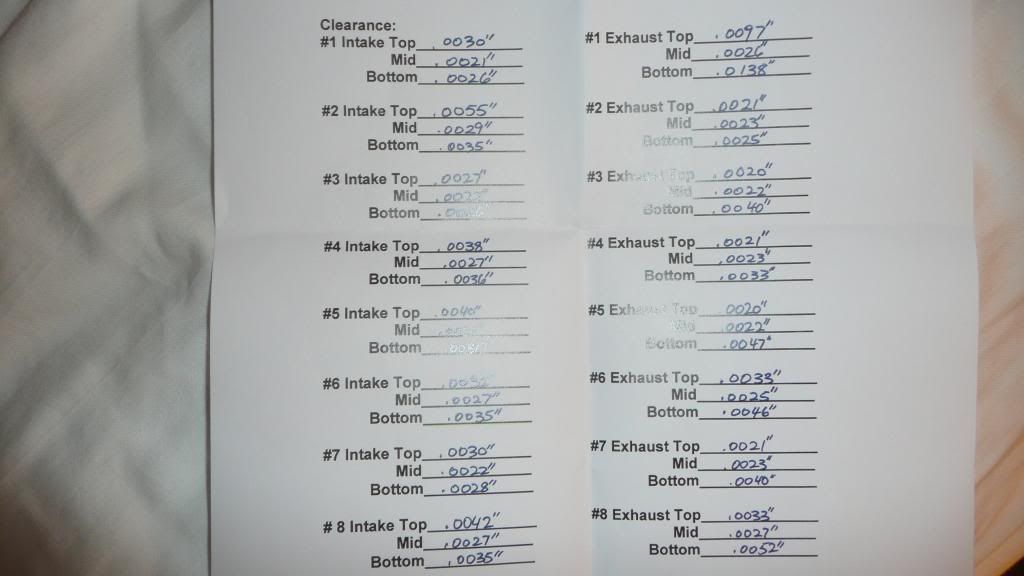

Here is the spec sheet on the heads before they were reworked:

My current heads and rockers which checked out with good geometry, compression and no oil on the plugs will be available on Feb 1. I can deliver these to WCCH to save buyer shipping costs. The guide wear will be measured incase they are in spec and someone just wants to slap them on. I will sell the heads and rockers separately. Here is the link:

http://forums.corvetteforum.com/c6-p...d-rockers.html

DH

Below you will see many pictures I took today. My car in front of their shop. Some pictures of the different equipment, Sunnen, CNC etc. A few of the cylinder heads ..... there were tons of LS7 heads in there

. A few pics of the my heads being assembled. Pictures of burnt valves, guides showing excess heat have been included. Some pictures of measurements being taken of the guide bore. Also pics of my new CHE rockers.

. A few pics of the my heads being assembled. Pictures of burnt valves, guides showing excess heat have been included. Some pictures of measurements being taken of the guide bore. Also pics of my new CHE rockers.First here is a video of what a worn guide looks like

And here pictures from my visit:

[IMG]http://i20.photobucket.com/albums/b219/DirtyHowie/P1020130_zps6a5fa062.jpg[/IMG

Here is the spec sheet on the heads before they were reworked:

My current heads and rockers which checked out with good geometry, compression and no oil on the plugs will be available on Feb 1. I can deliver these to WCCH to save buyer shipping costs. The guide wear will be measured incase they are in spec and someone just wants to slap them on. I will sell the heads and rockers separately. Here is the link:

http://forums.corvetteforum.com/c6-p...d-rockers.html

DH

Last edited by Dirty Howie; 01-14-2013 at 04:13 PM.

#2

Le Mans Master

Niiiiiiiiice!

Thanks for taking pics!

Thanks for taking pics!

#7

Safety Car

"sending you forget me nots... to help me to remember - baby, please forget me not..."

ETA: can you specifically point out the "excess heat" or "burnt" markings on valves? I think it would be cool to see but based on your current photos I'm not sure if that's obvious?

Is this the guide w/ excessive heat that you also mentioned?

ETA: can you specifically point out the "excess heat" or "burnt" markings on valves? I think it would be cool to see but based on your current photos I'm not sure if that's obvious?

Is this the guide w/ excessive heat that you also mentioned?

Last edited by Random84; 01-12-2013 at 09:19 AM.

#8

Safety Car

Excellent thread Howie! Thanks for taking the time to do this and post the pictures.

#9

Nicely done Howie, and congrats on the new cylinder heads.

With so many pics, and such a glowing testimonial, you'd better be careful that people don't wisecrack that you should be on their payroll.

But on a more serious note:

Theirs is a top notch shop, and having had them do my own cylinder heads a few months ago, I can tell anyone considering this option, that there is a lot to be said in knowing that your cylinder heads were done by one of the best, if not the best, in the cylinder head business.

You know that you got top notch heads, top notch work, using top notch machinery and parts.

Now you can drive that car as hard as you want, and with rock solid confidence that it won't fail due to a broken off hollow stemmed exhaust valve head.

Howie your pics speak volumes. And Richard is indeed that type of person who will answer your questions if you just call him up and ask. So anyone wanting to know about guide length, and why, or any other questions, I can say that in talking to him, he has never failed to answer a question I asked him, to my satisfaction. You have questions, call him and ask him or Dave.

I also see, in your pics, the Sunnen valve guide and seat machine which MichaelD refers to below:

Small wonder why Katech uses WCCH for their cylinder head work, and has enough confidence in them to build the cylinder heads for their packages.

And when you say that there were several LS7 cylinder heads there, I can certainly believe you. They apparently see a lot of LS7 heads, certainly more than any of us do, and this is again why I know that when they tell me what they believe the cause and cure of this issue is, I believe them.

Good job with the post and pics Howie, and best of luck with the install.

I also see that several guides were out of spec in this set of heads.

BTW, I sent them my rockers for the CHE upgrade and will be getting them back in a few days.

Good to see a few more pics of what they will look like, when they come back.

With so many pics, and such a glowing testimonial, you'd better be careful that people don't wisecrack that you should be on their payroll.

But on a more serious note:

Theirs is a top notch shop, and having had them do my own cylinder heads a few months ago, I can tell anyone considering this option, that there is a lot to be said in knowing that your cylinder heads were done by one of the best, if not the best, in the cylinder head business.

You know that you got top notch heads, top notch work, using top notch machinery and parts.

Now you can drive that car as hard as you want, and with rock solid confidence that it won't fail due to a broken off hollow stemmed exhaust valve head.

Howie your pics speak volumes. And Richard is indeed that type of person who will answer your questions if you just call him up and ask. So anyone wanting to know about guide length, and why, or any other questions, I can say that in talking to him, he has never failed to answer a question I asked him, to my satisfaction. You have questions, call him and ask him or Dave.

I also see, in your pics, the Sunnen valve guide and seat machine which MichaelD refers to below:

Seats SHOULD be cut/ground AFTER the guide is complete. Preferably, on a robust seat and guide machine with a dead pilot and floating head. Some machines are better than others. I had a Serdi 100 that was a POS. I never could get the damn thing to cut right, so I sold it. I think they made improvements with the 100 HD, but not sure… Life changes redirected what I do with my spare time, so I never did buy another and sold off the bulk of my other engine building tools / equipment a few years ago. I’d probably get a Rotler SG8 if I were in the market for a new one. The Sunnen VGS 20 is another good option, but I do not believe they make them any more. At any rate, it’s a good idea to ask the head builder what machinery they use and if they do in fact check post machining run out. By simply asking the question, they will know that you are not completely ignorant of the process and will most likely ensure that the work is done with a wee bit more attention to detail....

And when you say that there were several LS7 cylinder heads there, I can certainly believe you. They apparently see a lot of LS7 heads, certainly more than any of us do, and this is again why I know that when they tell me what they believe the cause and cure of this issue is, I believe them.

Good job with the post and pics Howie, and best of luck with the install.

I also see that several guides were out of spec in this set of heads.

BTW, I sent them my rockers for the CHE upgrade and will be getting them back in a few days.

Good to see a few more pics of what they will look like, when they come back.

Well I went to WCCH today. I hung out with Richard and watched him install the valves and springs on my reworked LS7 cylinder heads. He took a lot of time and educated me very well. I now know what burnt valves and over heated guides look like. I know there are different valve seals for intake or exhaust valves. Finally saw how valve seals, seats springs, retainers and keepers are put together.

Below you will see many pictures I took today. My car in front of their shop. Some pictures of the different equipment, Sunnen, CNC etc. A few of the cylinder heads ..... there were tons of LS7 heads in there . A few pics of the my heads being assembled. Pictures of burnt valves, guides showing excess heat have been included. Some pictures of measurements being taken of the guide bore. Also pics of my new CHE rockers.

. A few pics of the my heads being assembled. Pictures of burnt valves, guides showing excess heat have been included. Some pictures of measurements being taken of the guide bore. Also pics of my new CHE rockers.

First here is a video of what a worn guide looks like

And here pictures from my visit:

[IMG]http://i20.photobucket.com/albums/b219/DirtyHowie/P1020130_zps6a5fa062.jpg[/IMG

Here is the spec sheet on the heads before they were reworked:

My current heads and rockers which checked out with good geometry, compression and no oil on the plugs will be available on Feb 1. I can deliver these to WCCH to save buyer shipping costs. The guide wear will be measured incase they are in spec and someone just wants to slap them on. I will sell the heads and rockers separately. Here is the link:

http://forums.corvetteforum.com/c6-p...d-rockers.html

DH

Below you will see many pictures I took today. My car in front of their shop. Some pictures of the different equipment, Sunnen, CNC etc. A few of the cylinder heads ..... there were tons of LS7 heads in there

. A few pics of the my heads being assembled. Pictures of burnt valves, guides showing excess heat have been included. Some pictures of measurements being taken of the guide bore. Also pics of my new CHE rockers.

. A few pics of the my heads being assembled. Pictures of burnt valves, guides showing excess heat have been included. Some pictures of measurements being taken of the guide bore. Also pics of my new CHE rockers.First here is a video of what a worn guide looks like

And here pictures from my visit:

[IMG]http://i20.photobucket.com/albums/b219/DirtyHowie/P1020130_zps6a5fa062.jpg[/IMG

Here is the spec sheet on the heads before they were reworked:

My current heads and rockers which checked out with good geometry, compression and no oil on the plugs will be available on Feb 1. I can deliver these to WCCH to save buyer shipping costs. The guide wear will be measured incase they are in spec and someone just wants to slap them on. I will sell the heads and rockers separately. Here is the link:

http://forums.corvetteforum.com/c6-p...d-rockers.html

DH

Last edited by '06 Quicksilver Z06; 01-12-2013 at 09:32 AM.

#14

Safety Car

#16

Tech Contributor

Member Since: Oct 1999

Location: Charlotte, NC (formerly Endicott, NY)

Posts: 40,089

Received 8,928 Likes

on

5,333 Posts

Bill

#17

Team Owner

Thread Starter

"sending you forget me nots... to help me to remember - baby, please forget me not..."

ETA: can you specifically point out the "excess heat" or "burnt" markings on valves? I think it would be cool to see but based on your current photos I'm not sure if that's obvious?

Is this the guide w/ excessive heat that you also mentioned?

ETA: can you specifically point out the "excess heat" or "burnt" markings on valves? I think it would be cool to see but based on your current photos I'm not sure if that's obvious?

Is this the guide w/ excessive heat that you also mentioned?

And yes, this was a random guide he was trying to demonstrate how there is a rainbow affect from excess heat.

DH

#19

Race Director

DH, who will be installing your "new" heads for you?

Thanks for the pictures and I look forward to the guide measurements on your current heads from your replacement engine. It's great info for us forum members.

Thanks for the pictures and I look forward to the guide measurements on your current heads from your replacement engine. It's great info for us forum members.

#20

Team Owner

Thread Starter

Nicely done Howie, and congrats on the new cylinder heads.

With so many pics, and such a glowing testimonial, you'd better be careful that people don't wisecrack that you should be on their payroll.

But on a more serious note:

Theirs is a top notch shop, and having had them do my own cylinder heads a few months ago, I can tell anyone considering this option, that there is a lot to be said in knowing that your cylinder heads were done by one of the best, if not the best, in the cylinder head business.

You know that you got top notch heads, top notch work, using top notch machinery and parts.

Now you can drive that car as hard as you want, and with rock solid confidence that it won't fail due to a broken off hollow stemmed exhaust valve head.

Howie your pics speak volumes. And Richard is indeed that type of person who will answer your questions if you just call him up and ask. So anyone wanting to know about guide length, and why, or any other questions, I can say that in talking to him, he has never failed to answer a question I asked him, to my satisfaction. You have questions, call him and ask him or Dave.

I also see, in your pics, the Sunnen valve guide and seat machine which MichaelD refers to below:

Small wonder why Katech uses WCCH for their cylinder head work, and has enough confidence in them to build the cylinder heads for their packages.

And when you say that there were several LS7 cylinder heads there, I can certainly believe you. They apparently see a lot of LS7 heads, certainly more than any of us do, and this is again why I know that when they tell me what they believe the cause and cure of this issue is, I believe them.

Good job with the post and pics Howie, and best of luck with the install.

I also see that several guides were out of spec in this set of heads.

BTW, I sent them my rockers for the CHE upgrade and will be getting them back in a few days.

Good to see a few more pics of what they will look like, when they come back.

With so many pics, and such a glowing testimonial, you'd better be careful that people don't wisecrack that you should be on their payroll.

But on a more serious note:

Theirs is a top notch shop, and having had them do my own cylinder heads a few months ago, I can tell anyone considering this option, that there is a lot to be said in knowing that your cylinder heads were done by one of the best, if not the best, in the cylinder head business.

You know that you got top notch heads, top notch work, using top notch machinery and parts.

Now you can drive that car as hard as you want, and with rock solid confidence that it won't fail due to a broken off hollow stemmed exhaust valve head.

Howie your pics speak volumes. And Richard is indeed that type of person who will answer your questions if you just call him up and ask. So anyone wanting to know about guide length, and why, or any other questions, I can say that in talking to him, he has never failed to answer a question I asked him, to my satisfaction. You have questions, call him and ask him or Dave.

I also see, in your pics, the Sunnen valve guide and seat machine which MichaelD refers to below:

Small wonder why Katech uses WCCH for their cylinder head work, and has enough confidence in them to build the cylinder heads for their packages.

And when you say that there were several LS7 cylinder heads there, I can certainly believe you. They apparently see a lot of LS7 heads, certainly more than any of us do, and this is again why I know that when they tell me what they believe the cause and cure of this issue is, I believe them.

Good job with the post and pics Howie, and best of luck with the install.

I also see that several guides were out of spec in this set of heads.

BTW, I sent them my rockers for the CHE upgrade and will be getting them back in a few days.

Good to see a few more pics of what they will look like, when they come back.

I don't mind promoting people who demonstrate expertise and do it in a friendly and professional manner.

Richard exudes with confidence in his product and workmanship. I brought up the question of when I should start checking my springs for loss of tension. He said probably NEVER. He just thinks this setup is bullet proof and again said no issues with 100K miles and my continued track use.

He did discuss how his valve guides are longer and feels this is one of the contributing factors involved in the failures we see. He specifically said that GM screwed up hear.

He also doesn't believe there is a geometry problem with the heads. He has checked this out in some way with his CNC or other machinery on several heads.

I saw at least 10 sets of LS7 heads in there. Dave was machining another set while Richard was assembling mine. I saw work sheets from other companies like Cunningham Motorsports. And he received a call from Eddlebrock (spelling) while I was there. So he certainly seems to be the go to guy !!!!!!

I'm hoping who ever buys my heads will use WCCH so I can bring my heads down there and hang out some more

DH