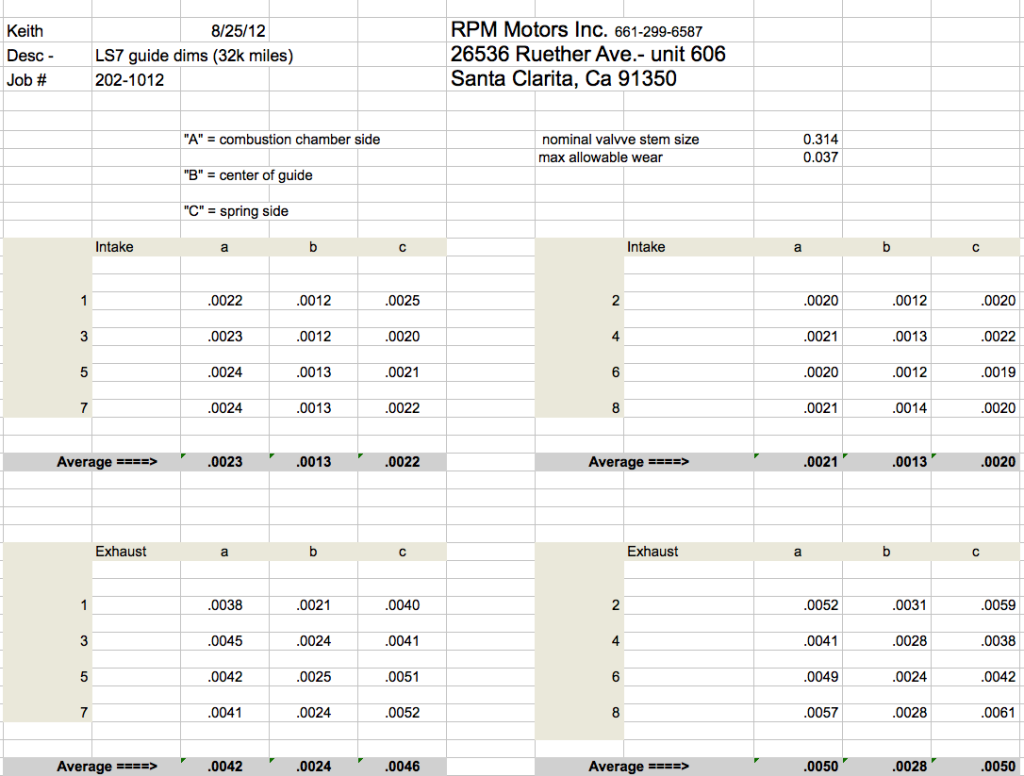

[Z06] 8 exhaust valves out, 8 new ones in PICS

#41

Le Mans Master

Thanks!

#42

Former Vendor

Speaking of geometry, one of the potential causes that was thrown around was that the guide and seat might not be "lined up" properly - I think it was referred to as valve seat concentricity. If that was off from the factory, does your step of machining the seat correct that? What kind of tolerance is there for that process? Sorry of this is a dumb question, I'm not a machinist.

Thanks!

Thanks!

it's when the guide wears that valve face to valve seat geometry goes awry.

#43

#44

Le Mans Master

#45

Safety Car

Member Since: Nov 1999

Location: S.E. WI.

Posts: 4,243

Received 69 Likes

on

50 Posts

St. Jude Donor '08-'09-'10

Nice work. Just curious but based on this statement, are you inclined to believe this is a stock guide issue with the LS7 or a combination issue with guide and exhaust valve?

#46

Former Vendor

The obvious differences with the LS7, as I'm sure you know, is the implementation of the 1.8:1 ratio rockers arms and rev limiter moved to 7100 RPM. So, at least in my mind, unless there has been a material or tolerance change in the guide/valve combination, the increased rocker ratio or increased red line (or combination thereof) are likely at the root of the issue.

#47

Safety Car

$2,695 ...car will be in the shop for 3-5 working days

Parts Include

CHE Valve Guides

SS exhaust Valves

Dual Springs, ti Retainers, Steel Spring Bases

Stem Seals

Head Bolts

Head Gaskets

Comp Trunnion Kit

Machining & Labor

Install guides and hone to size

Comp Valve Job

Light "bowl porting"

Mill & CC

Clean & Assemble

Upgrade Rocker Arms

R&R Heads

__________________

Parts Include

CHE Valve Guides

SS exhaust Valves

Dual Springs, ti Retainers, Steel Spring Bases

Stem Seals

Head Bolts

Head Gaskets

Comp Trunnion Kit

Machining & Labor

Install guides and hone to size

Comp Valve Job

Light "bowl porting"

Mill & CC

Clean & Assemble

Upgrade Rocker Arms

R&R Heads

__________________

#48

That's the 64,000 dollar question..up until the LS7 we just didn't see this type of wear - in fact, it was rare to find a guide issue on a LS1, LS2, LS3, etc. - and in the LS6, GM opted for sodium filled exhaust valves.

The obvious differences with the LS7, as I'm sure you know, is the implementation of the 1.8:1 ratio rockers arms and rev limiter moved to 7100 RPM. So, at least in my mind, unless there has been a material or tolerance change in the guide/valve combination, the increased rocker ratio or increased red line (or combination thereof) are likely at the root of the issue.

The obvious differences with the LS7, as I'm sure you know, is the implementation of the 1.8:1 ratio rockers arms and rev limiter moved to 7100 RPM. So, at least in my mind, unless there has been a material or tolerance change in the guide/valve combination, the increased rocker ratio or increased red line (or combination thereof) are likely at the root of the issue.

#49

#54

Thanks.

I'll be doing my heads a week from Friday. When I changed plugs this past weekend, I noticed 6 and 8 were very wet with oil.

88,000 miles on the engine.

I'm convinced there is a geometry problem. You can't get excessive wear unless there is significant side force on the valve stem.

Among other things, I'm going with roller rockers...can't get side loads with rollers.

I'll be doing my heads a week from Friday. When I changed plugs this past weekend, I noticed 6 and 8 were very wet with oil.

88,000 miles on the engine.

I'm convinced there is a geometry problem. You can't get excessive wear unless there is significant side force on the valve stem.

Among other things, I'm going with roller rockers...can't get side loads with rollers.

#55

Curious of any theories on what step they may have screwed up from the factory?