[Z06] LS7 Engine Failures On CF....The Breakdown

#441

Le Mans Master

It really would depend on where you are measuring the reduced pressure and how the flow was affected. I donít believe the oil between bearing surfaces even realized the pulse do to the volume of oil present in front of the pump. That mechanical interface has a term call histeresis or a lagging behind along with the film of oil that is still present on the bearing surface. Iím now leaning toward the pickup being starved intermittently and that is exaggerated with insufficent oil in reserve. I think that with the development of the engine over the previous years before release had to have been vetted thoroughly. That I would have to rely on the integrity of the design Engineers. I can assure you with my experience with Engineering that for one to wake in the morning with the intention to do a bad or dumb thing is not possible. Unless there were outright saboteurs in play of which I seriously doubt. Most all Engineers I know have a big ego and to be embarrassed by their peers is totally alien to the profession. That said can you do it again but suck out two quarts to 6 and try again, just joking, my lame sense of humor.

#442

Those tires are not availible through Discount Tire...I'm sure they could special order them if you pressed them...but they are not in their warehouses.

#443

#444

Melting Slicks

It really would depend on where you are measuring the reduced pressure and how the flow was affected. I don’t believe the oil between bearing surfaces even realized the pulse do to the volume of oil present in front of the pump. That mechanical interface has a term call histeresis or a lagging behind along with the film of oil that is still present on the bearing surface. I’m now leaning toward the pickup being starved intermittently and that is exaggerated with insufficent oil in reserve. I think that with the development of the engine over the previous years before release had to have been vetted thoroughly. That I would have to rely on the integrity of the design Engineers. I can assure you with my experience with Engineering that for one to wake in the morning with the intention to do a bad or dumb thing is not possible. Unless there were outright saboteurs in play of which I seriously doubt. Most all Engineers I know have a big ego and to be embarrassed by their peers is totally alien to the profession. That said can you do it again but suck out two quarts to 6 and try again, just joking, my lame sense of humor.

From this point, I *believe* the next stop for the oil is downward to the bearings (Maybe someone can confirm this??)...

I purposely did not plumb it close to the oil pan/pump nor sump tank. I'm definitely not measuring oil pickup starvation.

I concluded that bearing damage occurred using basic calculations:

The "pulses" (oil pressure drops) last 100-200ms. And 5000 rev/min = 83 rev/sec = 8.3 rev/100ms

So on average the engine spins 12 revs / pulse... The graph shows 3 pulses plus some 'jaggies' around 30psi... Let's say 50 revs.

50 revolutions without oil if 100% of the pulse gets to the bearing

25 revolutions without oil if 50% of the pulse gets to the bearing

12 revolutions if 25% of the pulse gets thru.

And that's PER LAP.

I'm still confident some bearing damage occurred

On your point about the GM engineers... I 100% agree. IMHO, I do not believe they released this car knowing that this problem exists... or even that the oil system was "marginal" or "maxed" out.

I believe they tested the crap out of the car, but in 100% stock form and obviously not on a banked track... and they did not see any oil pressure problems. I mean either you see a pressure drop or you don't... it's a "binary" result.

...but perhaps i'm being naive...

#445

Team Owner

Thread Starter

Beaverun.

Before that I primarily drag raced my Vettes.

My interest in something other than straight line performance started with my first C6 Corvette, a 2005 with Z51. I held onto that car for a short while before buying the Z06 a little over 2yrs ago.

With the Z06 I pretty much migrated from drag racing altogether.

I also don't believe that they "knew" of any shortcomings in the oiling system when the car was released.

Before that I primarily drag raced my Vettes.

My interest in something other than straight line performance started with my first C6 Corvette, a 2005 with Z51. I held onto that car for a short while before buying the Z06 a little over 2yrs ago.

With the Z06 I pretty much migrated from drag racing altogether.

....On your point about the GM engineers... I 100% agree. IMHO, I do not believe they released this car knowing that this problem exists... or even that the oil system was "marginal" or "maxed" out.

I believe they tested the crap out of the car, but in 100% stock form and obviously not on a banked track... and they did not see any oil pressure problems. I mean either you see a pressure drop or you don't... it's a "binary" result.

...but perhaps i'm being naive...

I believe they tested the crap out of the car, but in 100% stock form and obviously not on a banked track... and they did not see any oil pressure problems. I mean either you see a pressure drop or you don't... it's a "binary" result.

...but perhaps i'm being naive...

Last edited by '06 Quicksilver Z06; 08-06-2009 at 08:43 AM.

#446

As an engineer for a heavy duty truck OEM that worked on their race team I'm curious what the time scale is on your graph. How long are the pulses? Are you thinking this is caused by air bubbles? Can you zoom into that part of the graph?

#447

Team Owner

How can you know this for sure. You are relying on indirect data and not even positive of the oil flow route ????

Has your normal oil pressure changed?

Have you done an oil analysis?

Short-Throw new he had a problem/damage .... he could tell.

I hope you are wrong

*****Do you have a set of street tires for ACS******

DH

Has your normal oil pressure changed?

Have you done an oil analysis?

Short-Throw new he had a problem/damage .... he could tell.

I hope you are wrong

*****Do you have a set of street tires for ACS******

DH

Last edited by Dirty Howie; 08-06-2009 at 01:32 AM.

#448

Melting Slicks

How can you know this for sure. You are relying on indirect data and not even positive of the oil flow route ????

Has your normal oil pressure changed?

Have you done an oil analysis?

Short-Throw new he had a problem/damage .... he could tell.

I hope you are wrong

*****Do you have a set of street tires for ACS******

DH

Has your normal oil pressure changed?

Have you done an oil analysis?

Short-Throw new he had a problem/damage .... he could tell.

I hope you are wrong

*****Do you have a set of street tires for ACS******

DH

Metal to bearing contact is avoided by a thin layer of oil, which if under constant pressure, cannot be compressed. It is when there is a loss of pressure, even for a moment that bearings lose it like these did, since that oil barrier is replaced by air.

Will PM you about street tires...

#449

Le Mans Master

You're right Howie... "Confident" may be too strong... how about "strongly believe". This is based on the 'rule of thumb' that you need 10psi of pressure per 1000rpms... and Jim (Halltech) summarized it well, referring to Painrace's bearing damage:

And i hope i'm wrong too

Will PM you about street tires...

And i hope i'm wrong too

Will PM you about street tires...

#450

Racer

Wow ! I'm impressed...........so many experts on this thread. Hey guys, stay by the phone, GM will be calling you shortly to assist in future Corvette development

The Z06 is the first production car Chevy has every built that you could track right off the showroom floor and whip most every car out there. Its so good, in fact, that when fitted with special racing tires, the engine may possibly run out of oil for a small brief moment, and in those cases, engine failure may occur. Instead of celebrating the release of this magnificent car, you Midol-needing Prozac-begging depressing geniuses are bitchin all the way to the shrink's couch. OK, I give in. I agree with the negative pundits..........this car is a real piece of crap. Tell you what I'll do for you. Contact me and I'll come over and take that crappy Z06 off your hands, and I won't even charge you a disposal fee.

The Z06 is the first production car Chevy has every built that you could track right off the showroom floor and whip most every car out there. Its so good, in fact, that when fitted with special racing tires, the engine may possibly run out of oil for a small brief moment, and in those cases, engine failure may occur. Instead of celebrating the release of this magnificent car, you Midol-needing Prozac-begging depressing geniuses are bitchin all the way to the shrink's couch. OK, I give in. I agree with the negative pundits..........this car is a real piece of crap. Tell you what I'll do for you. Contact me and I'll come over and take that crappy Z06 off your hands, and I won't even charge you a disposal fee.

#451

Melting Slicks

Never mentioned Hoosiers. ronsc1985 is making it sound that the Z06 shouldnt be tracked because its a street car and I am saying GM sells the ZO6 option as a weekend track/HPDE car so the oil system should be more then up to the task, not barely good enouph with stock tire.

When someone presents facts that show problems with the oiling system under any street driven condition i.e. canyons, off ramps etc. then you have a legitimate complaint. If not then understand, as anyone who has ever raced eventually understands, when you run at the track expect to have to change something.

For some reason people will spend all kinds of money on increasing performance and not even think about reliability until something breaks. The old saying that in order to finish first you first have to finish seems appropriate to this discussion.

#452

Melting Slicks

My experience after building and racing quite a few race engines, from rotaries to 1000+ hp big block Chevy's, is that a small time duration, down to 20 psi oil pressure spike, is unlikely to cause any noticeable bearing damage.

Many times while drag racing a hard tail RED , especially during severe tire shake or excursions to the center line or wall due to excessive tire spin, the data recorder indicated less then 10 psi oil pressure for short time durations. In no case did this ever cause any significant bearing damage since the oil pressure always returned to normal. Yearly tear downs to freshen the motor usually resulted in putting the same rod and mail bearings back in the motor unless some failure in the fuel system had resulted in periods of detonation. The measurement points were the factory drilled passages from the main oil galleries to the main bearing oil holes.

Most times the oil was 15-50 synthetic so it was a little thicker then the 5-30 recommended for a Vette, however in recent years people drag racing have been using 0w oil with no apparent problems.

This was drag racing so the times between laps are not similar to road racing but these engines are produce higher bearing loads since they put out a lot more power.

If you have significant bearing damage you can usually tell by cutting open the oil filter. If you get through the bearing babbitt and into the underlying metal you should be able to see fine metal flakes all over the place. When this happens you will also see some blackening and/or scoring on the crank main and rod journals.

Many times while drag racing a hard tail RED , especially during severe tire shake or excursions to the center line or wall due to excessive tire spin, the data recorder indicated less then 10 psi oil pressure for short time durations. In no case did this ever cause any significant bearing damage since the oil pressure always returned to normal. Yearly tear downs to freshen the motor usually resulted in putting the same rod and mail bearings back in the motor unless some failure in the fuel system had resulted in periods of detonation. The measurement points were the factory drilled passages from the main oil galleries to the main bearing oil holes.

Most times the oil was 15-50 synthetic so it was a little thicker then the 5-30 recommended for a Vette, however in recent years people drag racing have been using 0w oil with no apparent problems.

This was drag racing so the times between laps are not similar to road racing but these engines are produce higher bearing loads since they put out a lot more power.

If you have significant bearing damage you can usually tell by cutting open the oil filter. If you get through the bearing babbitt and into the underlying metal you should be able to see fine metal flakes all over the place. When this happens you will also see some blackening and/or scoring on the crank main and rod journals.

#453

Le Mans Master

This thread has kept me entertained. An now, thanks to you, I am going to be going slow and saving $$!

Jim

#454

Le Mans Master

My experience after building and racing quite a few race engines, from rotaries to 1000+ hp big block Chevy's, is that a small time duration, down to 20 psi oil pressure spike, is unlikely to cause any noticeable bearing damage.

Many times while drag racing a hard tail RED , especially during severe tire shake or excursions to the center line or wall due to excessive tire spin, the data recorder indicated less then 10 psi oil pressure for short time durations. In no case did this ever cause any significant bearing damage since the oil pressure always returned to normal. Yearly tear downs to freshen the motor usually resulted in putting the same rod and mail bearings back in the motor unless some failure in the fuel system had resulted in periods of detonation. The measurement points were the factory drilled passages from the main oil galleries to the main bearing oil holes.

Most times the oil was 15-50 synthetic so it was a little thicker then the 5-30 recommended for a Vette, however in recent years people drag racing have been using 0w oil with no apparent problems.

This was drag racing so the times between laps are not similar to road racing but these engines are produce higher bearing loads since they put out a lot more power.

If you have significant bearing damage you can usually tell by cutting open the oil filter. If you get through the bearing babbitt and into the underlying metal you should be able to see fine metal flakes all over the place. When this happens you will also see some blackening and/or scoring on the crank main and rod journals.

Many times while drag racing a hard tail RED , especially during severe tire shake or excursions to the center line or wall due to excessive tire spin, the data recorder indicated less then 10 psi oil pressure for short time durations. In no case did this ever cause any significant bearing damage since the oil pressure always returned to normal. Yearly tear downs to freshen the motor usually resulted in putting the same rod and mail bearings back in the motor unless some failure in the fuel system had resulted in periods of detonation. The measurement points were the factory drilled passages from the main oil galleries to the main bearing oil holes.

Most times the oil was 15-50 synthetic so it was a little thicker then the 5-30 recommended for a Vette, however in recent years people drag racing have been using 0w oil with no apparent problems.

This was drag racing so the times between laps are not similar to road racing but these engines are produce higher bearing loads since they put out a lot more power.

If you have significant bearing damage you can usually tell by cutting open the oil filter. If you get through the bearing babbitt and into the underlying metal you should be able to see fine metal flakes all over the place. When this happens you will also see some blackening and/or scoring on the crank main and rod journals.

#456

Le Mans Master

My experience after building and racing quite a few race engines, from rotaries to 1000+ hp big block Chevy's, is that a small time duration, down to 20 psi oil pressure spike, is unlikely to cause any noticeable bearing damage.

Many times while drag racing a hard tail RED , especially during severe tire shake or excursions to the center line or wall due to excessive tire spin, the data recorder indicated less then 10 psi oil pressure for short time durations. In no case did this ever cause any significant bearing damage since the oil pressure always returned to normal. Yearly tear downs to freshen the motor usually resulted in putting the same rod and mail bearings back in the motor unless some failure in the fuel system had resulted in periods of detonation. The measurement points were the factory drilled passages from the main oil galleries to the main bearing oil holes.

Most times the oil was 15-50 synthetic so it was a little thicker then the 5-30 recommended for a Vette, however in recent years people drag racing have been using 0w oil with no apparent problems.

This was drag racing so the times between laps are not similar to road racing but these engines are produce higher bearing loads since they put out a lot more power.

If you have significant bearing damage you can usually tell by cutting open the oil filter. If you get through the bearing babbitt and into the underlying metal you should be able to see fine metal flakes all over the place. When this happens you will also see some blackening and/or scoring on the crank main and rod journals.

Many times while drag racing a hard tail RED , especially during severe tire shake or excursions to the center line or wall due to excessive tire spin, the data recorder indicated less then 10 psi oil pressure for short time durations. In no case did this ever cause any significant bearing damage since the oil pressure always returned to normal. Yearly tear downs to freshen the motor usually resulted in putting the same rod and mail bearings back in the motor unless some failure in the fuel system had resulted in periods of detonation. The measurement points were the factory drilled passages from the main oil galleries to the main bearing oil holes.

Most times the oil was 15-50 synthetic so it was a little thicker then the 5-30 recommended for a Vette, however in recent years people drag racing have been using 0w oil with no apparent problems.

This was drag racing so the times between laps are not similar to road racing but these engines are produce higher bearing loads since they put out a lot more power.

If you have significant bearing damage you can usually tell by cutting open the oil filter. If you get through the bearing babbitt and into the underlying metal you should be able to see fine metal flakes all over the place. When this happens you will also see some blackening and/or scoring on the crank main and rod journals.

Jim

#457

Le Mans Master

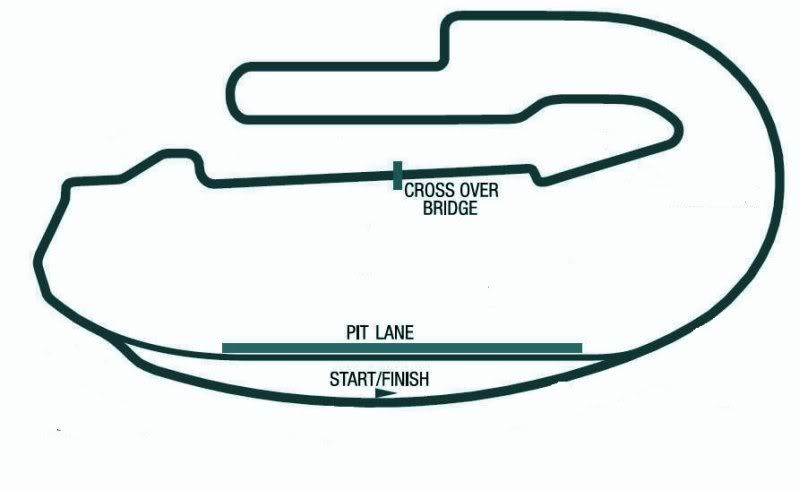

You're fine. I checked the track map, not a sweeper in sight. Feel free to run NT01's, RII's at Beaverun also.

Now, here is bad news:

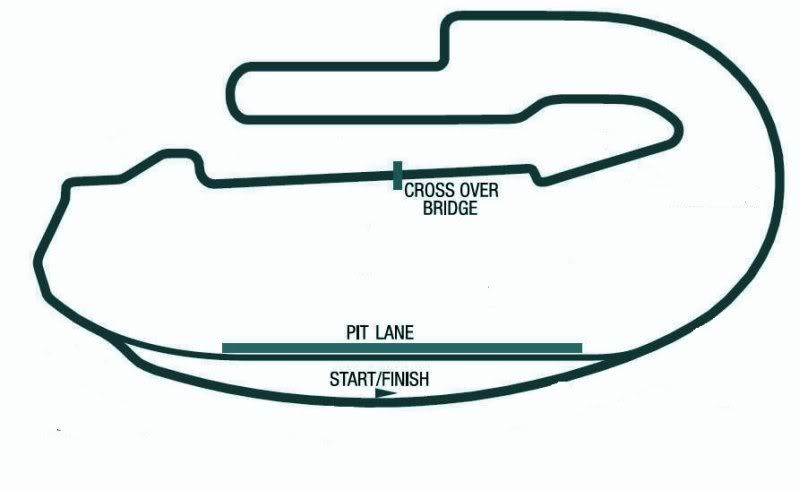

This is ACS - Auto Club Speedway (Fontana) in the Roval configuration, run CCW. The rounded stuff you see to the right is Exhibit "A" in what one needs to be careful with.

Now, here is bad news:

This is ACS - Auto Club Speedway (Fontana) in the Roval configuration, run CCW. The rounded stuff you see to the right is Exhibit "A" in what one needs to be careful with.

#458

Le Mans Master

Question to you, when the pressure drops do to increased temp does not the oil flow increase to do lower viscosity or am I looking in the wrong area? Just having a hard time with explaining bearing stress at those psi levels if the flow increases.

#460

Melting Slicks

If oil temperature caused decreased viscosity is a problem either use higher viscosity oil or get a bigger oil cooler.

Last edited by ronsc1985; 08-06-2009 at 05:26 PM.

He finally admits it.

He finally admits it.