Question about DYNO results

#1

Melting Slicks

Thread Starter

Member Since: Dec 2009

Location: Smallingerland Friesland, Netherlands

Posts: 3,421

Received 39 Likes

on

27 Posts

Hi all,

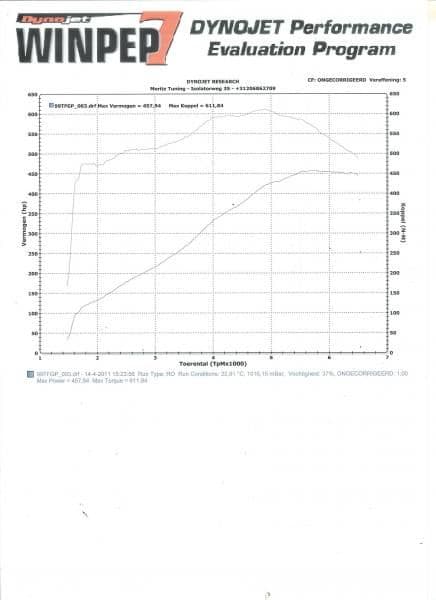

Below is a DYNO sheet of my Z06, and I would like to invite you to comment on the results (be they disappointing or encouraging)...

Because the picture was resized and is rather small (it's in My Garage), I include a link to a slightly larger picture on my Facebook account (should work, my albums are public ).

).

I have a question to the experts, here on the forum. How do these results, which were gathered while the car was in 5th gear, translate to the way that measurements are taken in the US? It's commonplace to dyno cars in 4th gear, I believe?

Is it as simple as applying a correction factor of .74 (4th gear ratio of 1:1, 5th gear ratio of 1:0.74), or is physics more complicated than that?

Thanks in advance everyone!

Ronald

Ronald

Legend:

(Max) Vermogen = (Max) HP

(Max) Koppel = (Max) Torque (expressed in Nm)

Toerental (TpM) = rpm

Vochtigheid = Humidity

ONGECORRIGEERD = UNCORRECTED

Note: data represent measurements in 5th gear

Below is a DYNO sheet of my Z06, and I would like to invite you to comment on the results (be they disappointing or encouraging)...

Because the picture was resized and is rather small (it's in My Garage), I include a link to a slightly larger picture on my Facebook account (should work, my albums are public

).

).I have a question to the experts, here on the forum. How do these results, which were gathered while the car was in 5th gear, translate to the way that measurements are taken in the US? It's commonplace to dyno cars in 4th gear, I believe?

Is it as simple as applying a correction factor of .74 (4th gear ratio of 1:1, 5th gear ratio of 1:0.74), or is physics more complicated than that?

Thanks in advance everyone!

Ronald

RonaldLegend:

(Max) Vermogen = (Max) HP

(Max) Koppel = (Max) Torque (expressed in Nm)

Toerental (TpM) = rpm

Vochtigheid = Humidity

ONGECORRIGEERD = UNCORRECTED

Note: data represent measurements in 5th gear

#3

Safety Car

It's hard to comment when you don't know how that correlates to how most folks post their results. I can say that you shouldn't change the numbers based on gear ratios, torque and horsepower are what they are. BUT, it would be best if you dyno'd in fourth gear and posted SAE corrected numbers.

I'll bet there aren't that many Z's where you are, enjoy the ride!

I'll bet there aren't that many Z's where you are, enjoy the ride!

#10

Hi all,

Below is a DYNO sheet of my Z06, and I would like to invite you to comment on the results (be they disappointing or encouraging)...

Because the picture was resized and is rather small (it's in My Garage), I include a link to a slightly larger picture on my Facebook account (should work, my albums are public ).

).

I have a question to the experts, here on the forum. How do these results, which were gathered while the car was in 5th gear, translate to the way that measurements are taken in the US? It's commonplace to dyno cars in 4th gear, I believe?

Is it as simple as applying a correction factor of .74 (4th gear ratio of 1:1, 5th gear ratio of 1:0.74), or is physics more complicated than that?

Thanks in advance everyone!

Ronald

Ronald

Legend:

(Max) Vermogen = (Max) HP

(Max) Koppel = (Max) Torque (expressed in Nm)

Toerental (TpM) = rpm

Vochtigheid = Humidity

ONGECORRIGEERD = UNCORRECTED

Note: data represent measurements in 5th gear

Below is a DYNO sheet of my Z06, and I would like to invite you to comment on the results (be they disappointing or encouraging)...

Because the picture was resized and is rather small (it's in My Garage), I include a link to a slightly larger picture on my Facebook account (should work, my albums are public

).

).I have a question to the experts, here on the forum. How do these results, which were gathered while the car was in 5th gear, translate to the way that measurements are taken in the US? It's commonplace to dyno cars in 4th gear, I believe?

Is it as simple as applying a correction factor of .74 (4th gear ratio of 1:1, 5th gear ratio of 1:0.74), or is physics more complicated than that?

Thanks in advance everyone!

Ronald

RonaldLegend:

(Max) Vermogen = (Max) HP

(Max) Koppel = (Max) Torque (expressed in Nm)

Toerental (TpM) = rpm

Vochtigheid = Humidity

ONGECORRIGEERD = UNCORRECTED

Note: data represent measurements in 5th gear

Chris

#11

Melting Slicks

Thread Starter

Member Since: Dec 2009

Location: Smallingerland Friesland, Netherlands

Posts: 3,421

Received 39 Likes

on

27 Posts

It is best to measure in a direct (1:1) gear, rather than an overdrive gear. That said, Dynojet's are roller dynos that have a lot of inconsistencies built into them, such as tire pressure, camber setting, type of wheel, type of tire, strap tension, etc. Plus, they have that famous "correction factor", which is an arbitrary number chosen to convert measured torque to wheel horsepower. I've seen rather large (10% or more) differences between one roller dyno and another, and large differences on the same dyno on different days or with different operators. If you are really concerned about the accuracy of a chassis dyno result, find a nearby hub dyno (like a Dynapack) and give it a try. Expect to pay a little more as those are more expensive pieces of equipment, but they are worth it, in my opinion.

Chris

Chris

Very useful comment, thanks!

I did not know that the differences between the various roller dynos had such a huge variation; 10% or more, wow!

BTW, I am not concerned, just very curious if my modifications thus far (CAI, LT headers, intake manifold, mufflers) pay off. I am not dissatisfied or disappointed about my Z06 either. On the contrary, I LOVE my baby!

Ronald

#12

It is best to measure in a direct (1:1) gear, rather than an overdrive gear. That said, Dynojet's are roller dynos that have a lot of inconsistencies built into them, such as tire pressure, camber setting, type of wheel, type of tire, strap tension, etc. Plus, they have that famous "correction factor", which is an arbitrary number chosen to convert measured torque to wheel horsepower. I've seen rather large (10% or more) differences between one roller dyno and another, and large differences on the same dyno on different days or with different operators. If you are really concerned about the accuracy of a chassis dyno result, find a nearby hub dyno (like a Dynapack) and give it a try. Expect to pay a little more as those are more expensive pieces of equipment, but they are worth it, in my opinion.

Chris

Chris

It might interest you to know the Dynapack is probably the least accurate chassis dyno made. Yes, it eliminates differences in air pressure and tires/wheels but those are variables that can be controlled by you the owner. Unfortunately, the Dynapack introduces constantly changing unknown inaccuracies. When the hub gets bolted to the Dynapack, it drives a hydraulic pump. The pump RPM and pressure are used to calculate HP which is pretty simple on the surface but much more complicated once you start digging a little. Dynapack sources the pump from Eaton and the first thing they do is tear the brand new pump down to be "blueprinted". That alone tells you how inconsistent hydraulic pumps are...every pump has a different amount of internal leakage/friction. The blueprinting process makes them close initially but then wear takes its toll from day one causing internal friction/leakage to increase as time goes forward. I'm a mechanical engineer who specializes in hydraulics and I calculate hydraulic HP using the formula HP=GPM*PSI*.0007...it's a very rough estimate at best and I'd never present it as the most accurate. There's really no way to accurately measure HP using hydraulics but it certainly is easier. Chassis dyno numbers should never be touted as accurate, they're just a tool to measure increases (or decreases) after mods or as a tuning/trouble shooting aid.

Last edited by glass slipper; 06-11-2011 at 11:24 PM.

#14

Quite frankly, it doesn't matter what gear you use as long as you use the same one everytime. The DynoJet pure inertia chassis dyno is the most consistant and accurate chassis dyno out there because they use a constant weight roller drum to measure HP. While it's true that different tire pressure, tires, and/or wheels will have an impact on the HP reading, that's true of all roller type chassis dynos. As for the "arbitrary" correction factor, that's far from the truth...STD and SAE correction factors use an exponential equation involving temperature, absolute air pressure, and humidity to arrive at the proper CF. I'm not sure where you got the "arbitrary" term from.

It might interest you to know the Dynapack is probably the least accurate chassis dyno made. Yes, it eliminates differences in air pressure and tires/wheels but those are variables that can be controlled by you the owner. Unfortunately, the Dynapack introduces constantly changing unknown inaccuracies. When the hub gets bolted to the Dynapack, it drives a hydraulic pump. The pump RPM and pressure are used to calculate HP which is pretty simple on the surface but much more complicated once you start digging a little. Dynapack sources the pump from Eaton and the first thing they do is tear the brand new pump down to be "blueprinted". That alone tells you how inconsistant hydraulic pumps are...every pump has a different amount of internal leakage/friction. The blueprinting process makes them close initially but then wear takes its toll from day one causing internal friction/leakage to increase as time goes forward. I'm a mechanical engineer who specializes in hydraulics and I calculate hydraulic HP using the formula HP=GPM*PSI*.0007...it's a very rough estimate at best and I'd never present it as the most accurate. There's really no way to accurately measure HP using hydraulics but it certainly is easier. Chassis dyno numbers should never be touted as accurate, they're just a tool to measure increases (or decreases) after mods or as a tuning/trouble shooting aid.

It might interest you to know the Dynapack is probably the least accurate chassis dyno made. Yes, it eliminates differences in air pressure and tires/wheels but those are variables that can be controlled by you the owner. Unfortunately, the Dynapack introduces constantly changing unknown inaccuracies. When the hub gets bolted to the Dynapack, it drives a hydraulic pump. The pump RPM and pressure are used to calculate HP which is pretty simple on the surface but much more complicated once you start digging a little. Dynapack sources the pump from Eaton and the first thing they do is tear the brand new pump down to be "blueprinted". That alone tells you how inconsistant hydraulic pumps are...every pump has a different amount of internal leakage/friction. The blueprinting process makes them close initially but then wear takes its toll from day one causing internal friction/leakage to increase as time goes forward. I'm a mechanical engineer who specializes in hydraulics and I calculate hydraulic HP using the formula HP=GPM*PSI*.0007...it's a very rough estimate at best and I'd never present it as the most accurate. There's really no way to accurately measure HP using hydraulics but it certainly is easier. Chassis dyno numbers should never be touted as accurate, they're just a tool to measure increases (or decreases) after mods or as a tuning/trouble shooting aid.

Also, I was not referring to SAE or STD corrections. What is more interesting is how Dynojet converts from measured torque to horsepower. The factor that manufacturer has chosen was, indeed, arbitrarily selected based on some empirical data. That factor has a known error that grows with horsepower, meaning that the more power the engine/chassis combo being testing produces, the more off the results are. Also, I've seen plenty of pulls on a roller dyno. I'm not sure how anyone can say that the way each vehicle is strapped down is in any way repeatable. In practice, it is far from it. Try changing camber a degree or two and watch the numbers move. Heck, the roller dynos around here vary over 50HP from place to place and operator to operator just in the 450-550 WHP range alone.

Chris

#15

Last edited by glass slipper; 06-11-2011 at 11:26 PM.

#16

I'm an engineer as well who has researched the issues you present. The Dynapack is consistently within 0.3%, which is much better than any roller dyno I've studied (so far). Yes, they do a lot to get it that way. The whole reason they even exist was to get past the inherent inaccuracies that are part of the roller dyno approach. While there may be plenty of argument on which type of induced load is best, the Dynapack has proven in the field to have very good repeatability, which is far more important to a tuner than absolute accuracy anyway (as you have alluded to).

Also, I was not referring to SAE or STD corrections. What is more interesting is how Dynojet converts from measured torque to horsepower. The factor that manufacturer has chosen was, indeed, arbitrarily selected based on some empirical data. That factor has a known error that grows with horsepower, meaning that the more power the engine/chassis combo being testing produces, the more off the results are. Also, I've seen plenty of pulls on a roller dyno. I'm not sure how anyone can say that the way each vehicle is strapped down is in any way repeatable. In practice, it is far from it. Try changing camber a degree or two and watch the numbers move. Heck, the roller dynos around here vary over 50HP from place to place and operator to operator just in the 450-550 WHP range alone.

Chris

Also, I was not referring to SAE or STD corrections. What is more interesting is how Dynojet converts from measured torque to horsepower. The factor that manufacturer has chosen was, indeed, arbitrarily selected based on some empirical data. That factor has a known error that grows with horsepower, meaning that the more power the engine/chassis combo being testing produces, the more off the results are. Also, I've seen plenty of pulls on a roller dyno. I'm not sure how anyone can say that the way each vehicle is strapped down is in any way repeatable. In practice, it is far from it. Try changing camber a degree or two and watch the numbers move. Heck, the roller dynos around here vary over 50HP from place to place and operator to operator just in the 450-550 WHP range alone.

Chris

I not only bolded a sentence in your second paragraph, but I made it red to point out a glaring error in your understanding of how a DynoJet dyno works. On a DynoJet, HP is measured and Torque is calculated...maybe you would like to "research the issues I presented" a little more. Please tell us what the "arbitrarily selected based on some empirical data" factor is. Since there is no calculation of torque to HP, that makes your claim of a "factor" pure BS.

I'd also like an explanation of how differences in strapping the car down makes a difference. And while I can see how more toe-in or toe-out will eat up some HP, give us a good explanation on how camber affects HP.

#17

Burning Brakes

#18

The very idea of consistency on a chassis dyno is laughable at best. SAE engine dyno tests specify a particular intake air temperature, coolant temperature, humidity, absolute air pressure, and oil temperature...basically the tests are done in a climate controlled setting. There's no way you can repeat any of the above to an accuracy of .3% on a chassis dyno making your claim pretty silly. While the Dynapack may be repeatable with a given input within .3% on runs back to back, the absolute accuracy of the Dynapack is very questionable due to the use of hydraulics to "calculate" HP. A run done a year later with the same input will definitely result in an error of more than .3%...that's the way hydraulic pumps are, constantly changing internal friction/leakage. And we all know hydraulic oil viscosity changes with temperature, there's even a correction factor in the Dynapack to account for that too. Anybody can be consistently wrong.

I not only bolded a sentence in your second paragraph, but I made it red to point out a glaring error in your understanding of how a DynoJet dyno works. On a DynoJet, HP is measured and Torque is calculated...maybe you would like to "research the issues I presented" a little more. Please tell us what the "arbitrarily selected based on some empirical data" factor is. Since there is no calculation of torque to HP, that makes your claim of a "factor" pure BS.

I'd also like an explanation of how differences in strapping the car down makes a difference. And while I can see how more toe-in or toe-out will eat up some HP, give us a good explanation on how camber affects HP.

I not only bolded a sentence in your second paragraph, but I made it red to point out a glaring error in your understanding of how a DynoJet dyno works. On a DynoJet, HP is measured and Torque is calculated...maybe you would like to "research the issues I presented" a little more. Please tell us what the "arbitrarily selected based on some empirical data" factor is. Since there is no calculation of torque to HP, that makes your claim of a "factor" pure BS.

I'd also like an explanation of how differences in strapping the car down makes a difference. And while I can see how more toe-in or toe-out will eat up some HP, give us a good explanation on how camber affects HP.

However, regarding strapping down and camber settings, one who has studied and tested tires can easily see how horsepower consumption through tire deflection is not a trivial issue. The harder the car is strapped down, the more load the tire sees. More vertical load --> more deflection --> more horsepower loss. It's a lot like suffering a reduction in fuel mileage due to under-inflated tires.

Camber has a similar effect, but it is closer to a zero sum game. The more negative camber, the more the inside tire sidewall is loaded, but also the less the outside is loaded. Does one sidewall's increase power consumption equal the other's decrease? Maybe, or maybe not. Depends on the tire construction, air pressure, air temperature and other factors. Not so easy and repeatable, is it?

And before anyone dismisses tire deflection losses, consider one case that I'm familiar with, even though I'll admit it is a bit extreme. Some years ago, I was communicating closely with an very bright and highly experience tire engineer over at Goodyear. He had been developing top fuel and funny car drag racing slicks. From their testing, they had discovered the dragsters were losing 550HP (peak) PER TIRE during the 1/4 mile run. That's 1100HP being sucked up!

OK, so most street tires do not deflect anywhere near those levels, but we can say that the losses are certainly not trivial. And if we are willing wave off differences in alignment settings, tire pressures, tire temperatures or vertical loads due to the straps, we can't expect to be dealing with repeatable dyno results. Let's face it, the better engine dynos are far better for accuracy, but as long as we have resolved to measuring horsepower while the engine is still in the car, we ought to at least remove one of the biggest and least consistent variables from the equation -- the tires.

Chris

#19

However, regarding strapping down and camber settings, one who has studied and tested tires can easily see how horsepower consumption through tire deflection is not a trivial issue. The harder the car is strapped down, the more load the tire sees. More vertical load --> more deflection --> more horsepower loss. It's a lot like suffering a reduction in fuel mileage due to under-inflated tires.

Camber has a similar effect, but it is closer to a zero sum game. The more negative camber, the more the inside tire sidewall is loaded, but also the less the outside is loaded. Does one sidewall's increase power consumption equal the other's decrease? Maybe, or maybe not. Depends on the tire construction, air pressure, air temperature and other factors. Not so easy and repeatable, is it?

And before anyone dismisses tire deflection losses, consider one case that I'm familiar with, even though I'll admit it is a bit extreme. Some years ago, I was communicating closely with an very bright and highly experience tire engineer over at Goodyear. He had been developing top fuel and funny car drag racing slicks. From their testing, they had discovered the dragsters were losing 550HP (peak) PER TIRE during the 1/4 mile run. That's 1100HP being sucked up!

OK, so most street tires do not deflect anywhere near those levels, but we can say that the losses are certainly not trivial. And if we are willing wave off differences in alignment settings, tire pressures, tire temperatures or vertical loads due to the straps, we can't expect to be dealing with repeatable dyno results. Let's face it, the better engine dynos are far better for accuracy, but as long as we have resolved to measuring horsepower while the engine is still in the car, we ought to at least remove one of the biggest and least consistent variables from the equation -- the tires.

Chris

Chris

#20

Most of the load from the straps is horizontal, the vertical portion is a small amount. If the tires are in the correct range of proper tire pressure, there will not be a sufficient amount of tire sidewall deflection to make a measurable difference. The amount of HP loss due to tire deflection is a very small amount...a very small percentage of a very small number is insignificant in the overall scheme of things as you'll see below.

On a 12" wide 26.8" tall tire, the vertical change at each sidewall due to a 1° change in camber from an initial setting of 0° is very small. Again, a very small percentage of a very small number is insignificant in the overall scheme of things. When the decrease in HP loss from the other sidewall is taken into account, it takes you to zero. If camber caused excessive HP loss, you wouldn't see racers running around with 3° negative camber.

You do realize HP is heat so HP going to tire deflection creates heat in the tire according to the 1st Law of Thermodynamics which you should be aware of as an engineer. Also, 550 HP is ~410300 Watts...if you've ever grabbed a 60 Watt incandescent light bulb, common sense would tell you 410300 Watts going to overcome tire deflection would render that drag slick a molten pile of rubber. I wasn't there for your conversation with that tire engineer so I don't know who is BSing who. Please try to verify info before posting so I'm not put in this position.

The C6 platform with a manual transmission loses about 50-60 HP on a chassis dyno due to drivetrain losses that consists of oil windage in the transmission/differential, gear tooth friction at the ring and pinion, seal drag in the transmission/differential/wheel hubs, brake drag, bearing friction in the transmission/differential/wheel hubs/CV joints, inertia of all the rotating components from the clutch to the tire, and tire sidewall deflection (feel free to add any places I missed). HP loss to tire/wheel inertia and sidewall deflection is only about 10-15 HP of the 50-60 HP total. Even a large 10% increase in HP loss to tire/wheel inertia and tire deflection will only give a 1.5 HP increase worse case scenario. Small changes in wheel/tire weights, tire pressure (within the correct range of proper tire pressure), or sidewall deflection have a very small impact on the total losses. So we remove the tires and hook up to a pair of hydraulic pumps that have no consistency from one year to the next and a HP calculation that is a guess at best...good move. The Dynapack is a great tool for tuning a car or troubleshooting a problem but so is a Mustang or DynoJet (with power absorption feature) and you don't have to go through the cumbersome task of taking the wheels off and bolting the hubs to a machine. If you like the Dynapack better, rock on...just don't think you're getting something any better than the others. All chassis dynos are a tool to be used for measuring changes due to mods, tuning, or trouble shooting...accuracy and consistency are not their forte. Having said that, a pure inertia chassis dyno will be the most accurate and consistent all other things held constant however it's not the best for tuning or trouble shooting since you can't control the rate of engine acceleration.

Arguing about accuracy, while a little bit entertaining, is not what really concerns me. I'm far more interested in repeatability, which is why I look at all roller dyno results with a jaundiced eye. Both the stopwatch and the butt dyno are very sensitive to actual, measurable changes, not overall accuracy.

Chris