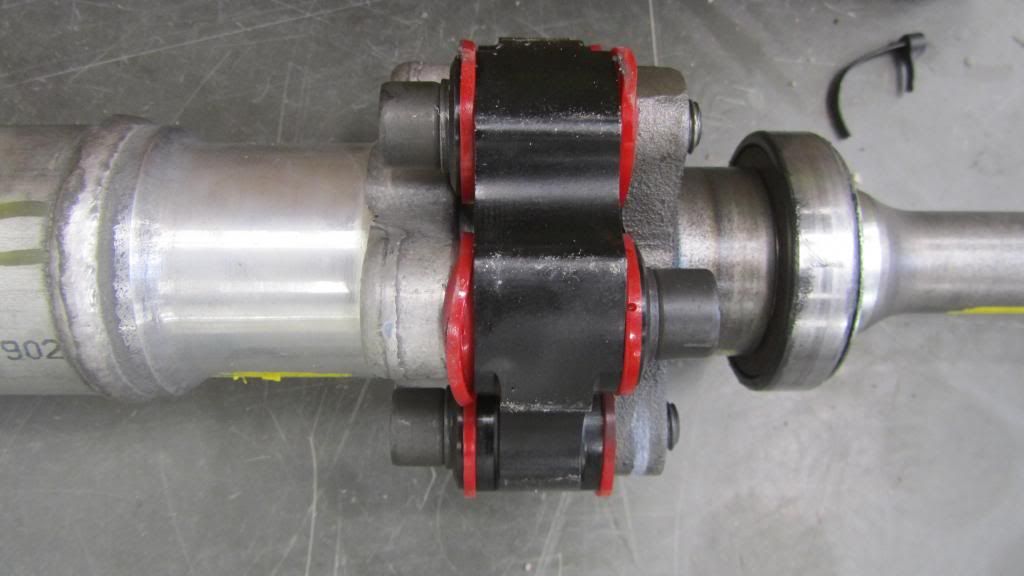

Prothane couplers: What went wrong, rear exploded!!

#2

Drifting

Thread Starter

Threads in aluminium driveshaft on rear side has broke up.. Reason, dont' know.

DSS couplers and new housing ordered.. New DSS driveshaft arrived few days ago.

DSS couplers and new housing ordered.. New DSS driveshaft arrived few days ago.

#5

Melting Slicks

For high power, track oriented applications, I would get rid of the couplers altogether. You can either choose a DSS carbon fiber driveshaft or Pfadt carbon fiber.

I chose the DSS and will never have to change couplers again.

I chose the DSS and will never have to change couplers again.

#6

If I am looking at that correctly the urethane is clamped by the bolt? Do you have some detailed pictures of one in good condition? In a sheer situation the bolt has to be torqued against and through a solid surface. Any lash hugely compromises the integrity.

#7

Melting Slicks

I would guess a cyclical fatigue failure. It looks like you were using a stock driveshaft, but I'm not sure how much power you are making. At high sustained engine rpms, the shaft has a small whipping motion or "jump rope" effect. This is transferred through the couplers. In this case, it looks like the repeated cyclical load caused the polyurthane to break down. This caused the internal clearances to increase in the bolted connection which allowed even more movement until the failure occured.

As mentioned before, there are a few different solutions. A driveshaft with a larger moment of inertia via increased diameter may reduce the harmonic oscillations to a point that is manageable with stock couplers. Many people see the couplers as a wear item. When you look at the amount of work involved to change them out and the cost to buy new ones a few times, it made more sense for me to go ahead and purchase a carbon fiber driveshaft and do away with the couplers completely.

As mentioned before, there are a few different solutions. A driveshaft with a larger moment of inertia via increased diameter may reduce the harmonic oscillations to a point that is manageable with stock couplers. Many people see the couplers as a wear item. When you look at the amount of work involved to change them out and the cost to buy new ones a few times, it made more sense for me to go ahead and purchase a carbon fiber driveshaft and do away with the couplers completely.

#8

Drifting

Thread Starter

I would guess a cyclical fatigue failure. It looks like you were using a stock driveshaft, but I'm not sure how much power you are making. At high sustained engine rpms, the shaft has a small whipping motion or "jump rope" effect. This is transferred through the couplers. In this case, it looks like the repeated cyclical load caused the polyurthane to break down. This caused the internal clearances to increase in the bolted connection which allowed even more movement until the failure occured.

As mentioned before, there are a few different solutions. A driveshaft with a larger moment of inertia via increased diameter may reduce the harmonic oscillations to a point that is manageable with stock couplers. Many people see the couplers as a wear item. When you look at the amount of work involved to change them out and the cost to buy new ones a few times, it made more sense for me to go ahead and purchase a carbon fiber driveshaft and do away with the couplers completely.

As mentioned before, there are a few different solutions. A driveshaft with a larger moment of inertia via increased diameter may reduce the harmonic oscillations to a point that is manageable with stock couplers. Many people see the couplers as a wear item. When you look at the amount of work involved to change them out and the cost to buy new ones a few times, it made more sense for me to go ahead and purchase a carbon fiber driveshaft and do away with the couplers completely.

I'm trying to brake after will get new long block 1 K rwhp and don't know power rating of carbon drive shaft.. Now moving to 3,5" DSS shaft and DSS couplers.

#11

Platinum Supporting Vendor

I've run these on several high power boosted vettes and they work great, unless the car does road course track days. ie- 25+ min sessions and the heat inside the torque tube will cause it to melt and scatter just like that. None of the street cars, drag cars, roll race, standing mile cars ever melted one, just the road course cars.

I prefer the GM/BMW rubber coupler up front and a billet alum rear for my personal setup.

I prefer the GM/BMW rubber coupler up front and a billet alum rear for my personal setup.

__________________

Thanks, Josh Dodson

PLEASE TAKE A MOMENT TO VISIT OUR NEW WEBSITE AT WWW.AACORVETTE.COM

NOW PARTNERING WITH AFFIRM TO OFFER INTEREST FREE FINANCING!

A&A CORVETTE PERFORMANCE

477 LAMBERT ST Ste A

OXNARD CA 93036

(805) 278-4107

Instagram @aacorvettesuperchargers

• Facebook.com/AACorvette •

Thanks, Josh Dodson

PLEASE TAKE A MOMENT TO VISIT OUR NEW WEBSITE AT WWW.AACORVETTE.COM

NOW PARTNERING WITH AFFIRM TO OFFER INTEREST FREE FINANCING!

A&A CORVETTE PERFORMANCE

477 LAMBERT ST Ste A

OXNARD CA 93036

(805) 278-4107

Instagram @aacorvettesuperchargers

• Facebook.com/AACorvette •

#12

Hello Over there !

We had close the same problems with the Couplers.

I would say . heat is one problem for shure.

Otherproblems are :

The contakt face ( Outside diameter ) of the aluminim Bushings to the shaftside and the driveflanshes is to small .( look on the shaft where the treats are in..you will see a compressed aira from the old oem coupler as well from the Prothane sleeves )

The commpressing reduces the stretch of the bolt..the bolt gets loose and so on..

I also would say there is also a steel shim missing between the shaft and the

Poly-bushing...so the Bushing is not able to sit real flat against the ears

of the shaft and is able to walk out to the outside....

I mashined the shaft some tens o a millimeter to have a clean surface...

I will shorting the Aluminium Coupler Ring to allow the use 2 halfes

of selfbuild mushroom bushings build from 42 CrNiMo 6

I also will use different bolts with a shaft what has on 32mm from the head-side no tread to aligne the bushings better and to protect the inside of the bushings better from the sharp treads

We test that this Month in SPA Belgium

Hope this was interesting for you !

By

Rainer @Heavy Dutys Germany

We had close the same problems with the Couplers.

I would say . heat is one problem for shure.

Otherproblems are :

The contakt face ( Outside diameter ) of the aluminim Bushings to the shaftside and the driveflanshes is to small .( look on the shaft where the treats are in..you will see a compressed aira from the old oem coupler as well from the Prothane sleeves )

The commpressing reduces the stretch of the bolt..the bolt gets loose and so on..

I also would say there is also a steel shim missing between the shaft and the

Poly-bushing...so the Bushing is not able to sit real flat against the ears

of the shaft and is able to walk out to the outside....

I mashined the shaft some tens o a millimeter to have a clean surface...

I will shorting the Aluminium Coupler Ring to allow the use 2 halfes

of selfbuild mushroom bushings build from 42 CrNiMo 6

I also will use different bolts with a shaft what has on 32mm from the head-side no tread to aligne the bushings better and to protect the inside of the bushings better from the sharp treads

We test that this Month in SPA Belgium

Hope this was interesting for you !

By

Rainer @Heavy Dutys Germany