[Z06] OEM LS7 Exhaust Valves Dissection

#82

Burning Brakes

Yes, I think it would be more prone unless the tuner is someone like Ricardo or AVL. I think a fundamental tuning assumption is that there is a safety factor built into stock tunes that can be reasonably safely exceeded. Perhaps by chance what is done will exactly counteract what is causing the failures. I am speaking of a stock car that is being tuned with the expectation that the tune will not seriously diminish the lifespan of the engine.

There exists the possibility that GM can provide a new safe tune but in that case it would likely be a detune. This is why I was curious as to whether programming updates for any/all of the drive train are available.

There exists the possibility that GM can provide a new safe tune but in that case it would likely be a detune. This is why I was curious as to whether programming updates for any/all of the drive train are available.

Alternatively, it could shed light on the criticism that after 8 model years, Chevy never increased the power output of the Z06. Which is seemingly rare in this present golden age of horsepower.

Again, that is all speculation and musings on my part, so I'm not trying to make any real claims here.

#83

http://www.autofieldguide.com/articl...arkable-engine

And they retained use of the sodium exhaust valve. Interesting, eh?

Aside: Another idea you should keep in mind is that huge numbers of analysis time do not surmount fundamental issues in logic, mathematics and information theory. This will become a bigger and bigger issue if modeling is blindly trusted to replicate reality.

Edit: Another article mentions changes from the LS7 exhaust valve architecture to the LT1...

http://gmauthority.com/blog/2012/10/...ylinder-heads/

Hmmm. I calculated 12.25 degrees on the Hot Rod CAD slice. Well, that suggests that .25 degrees is significant (John, hope you are reading this) and that production tolerances need to be held to this. With newer laser CMM techniques that should be practical to monitor. It also points to the close analysis of the exhaust valve issue. Surprise? Again, even within LS7 production, the castings for the exhaust rocker arms were altered at least three times. Quick, that also reinforces your concern about QC control of exhaust valve mass.

There was a comprehensive computer-aided and physical testing regimen for the Gen 5 engine development. This included steady-state airflow assessments, 3D computation fluid dynamics, airflow bench testing, one dimensional, engine cycle simulation, geometric flame propagation analysis, 3D mixing and combustion analysis, single and multi-cylinder combustion testing, and vehicle-level performance and fuel economy analysis. Thirty analysts worked digitally on the engine development program, literally years before the first physical model was produced. They used both commercially available CAE/CAD software as well as specially developed code. It is estimated that there were more than 10-million hours of computational analysis for the engine development.

Aside: Another idea you should keep in mind is that huge numbers of analysis time do not surmount fundamental issues in logic, mathematics and information theory. This will become a bigger and bigger issue if modeling is blindly trusted to replicate reality.

Edit: Another article mentions changes from the LS7 exhaust valve architecture to the LT1...

http://gmauthority.com/blog/2012/10/...ylinder-heads/

The intake valves remain huge, at 2.13 inches (54mm) in diameter, which is actually one millimeter smaller than the LS3 intake valves. The intake ports have also been raised to make room for the direct injection system. After combustion occurs, the exhaust exits through 1.59-inch (40.4mm) hollow sodium exhaust valves. And based on their findings through millions of simulation hours of computational fluid dynamics testing , the valves are held at new, 12.5-degree intake/12-degree exhaust angles, vs. the Gen 4’s 15-degree angle setup, and as we covered in part one, are splayed slightly to reduce shrouding and enable greater airflow. The valve springs are also 2mm taller than the outgoing LS3, and the 8.7mm wide pushrods are stiffened. Additionally, deactivation lifters are applied on the pushrods dedicated to cylinders 1, 7, 6 and 4, to allow the engine to operate in V4 thanks to active fuel management (AFM).

Last edited by KLJ; 02-20-2013 at 06:05 AM.

#84

Nicely done KLJ, where did you get that cross sectional view??

Anyone else feel as though GM is asking quite a bit trying to maintain .25 degrees of tolerance on a production head with semi-automated equipment?? .25 degrees of maximum deviation with manufacturable statistical confidence would have to be .08 degrees of standard deviation. Seems like they may have tried to cut it a bit thin on this one.

Anyone else feel as though GM is asking quite a bit trying to maintain .25 degrees of tolerance on a production head with semi-automated equipment?? .25 degrees of maximum deviation with manufacturable statistical confidence would have to be .08 degrees of standard deviation. Seems like they may have tried to cut it a bit thin on this one.

#85

Nicely done KLJ, where did you get that cross sectional view??

Anyone else feel as though GM is asking quite a bit trying to maintain .25 degrees of tolerance on a production head with semi-automated equipment?? .25 degrees of maximum deviation with manufacturable statistical confidence would have to be .08 degrees of standard deviation. Seems like they may have tried to cut it a bit thin on this one.

Anyone else feel as though GM is asking quite a bit trying to maintain .25 degrees of tolerance on a production head with semi-automated equipment?? .25 degrees of maximum deviation with manufacturable statistical confidence would have to be .08 degrees of standard deviation. Seems like they may have tried to cut it a bit thin on this one.

2006 article in Hot Rod.

#86

Safety Car

Thread Starter

Observations, as these questions were not directed at me:

The problem has yet to be specifically identified by anyone.

Broken valves are not the problem; they are a symptom.

Excessively worn valve guides are not the problem; they are a symptom.

"Error in machining the valve guide" is not the problem; it is a vague statement.

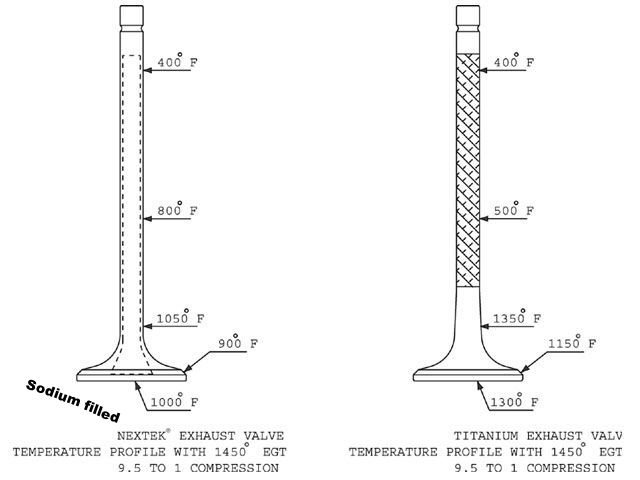

Given that GM engineers were concerned about heat in the combustion chamber (otherwise they surely would not have specified a sodium valve), it seems that any change which would increase heat in the combustion chamber would exacerbate what the engineers were concerned about (heat in the combustion chamber). And of course heat is a prime suspect in the current OEM exhaust valve guide situation.

My opinion is that no changes should be done to the LS7 stock tune unless EGT's are monitored (and there is really no way to monitor EGT beyond drilling a hole in exhaust header runner and inserting a thermocouple). In fact it would appear that any changes to the stock induction/exhaust system (airflow) could affect EGT's, so I would say an EGT gauge would be a very wise investment for anyone modifying their LS7.

[...] Do you think the current fix offered by WCCH that many of the forum members are going with will solve the issue long term, 30k, 40k, 50,000 miles later, or do you think it just slows down the process or worst yet, just simply a bandaid fix and the person will end up with the same problem after 10,000, 20,000 miles?

Broken valves are not the problem; they are a symptom.

Excessively worn valve guides are not the problem; they are a symptom.

"Error in machining the valve guide" is not the problem; it is a vague statement.

KLJ,

Do you buy into the theory that a stock Z is more prone to the issue with a dyno tune on it versus a stock tune? My buddy out of warranty is considering doing this until I told him that many feel it may be an issue, but wanted to get your opinion from your engineering perspective.

Do you buy into the theory that a stock Z is more prone to the issue with a dyno tune on it versus a stock tune? My buddy out of warranty is considering doing this until I told him that many feel it may be an issue, but wanted to get your opinion from your engineering perspective.

My opinion is that no changes should be done to the LS7 stock tune unless EGT's are monitored (and there is really no way to monitor EGT beyond drilling a hole in exhaust header runner and inserting a thermocouple). In fact it would appear that any changes to the stock induction/exhaust system (airflow) could affect EGT's, so I would say an EGT gauge would be a very wise investment for anyone modifying their LS7.

#87

Safety Car

My opinion is that no changes should be done to the LS7 stock tune unless EGT's are monitored (and there is really no way to monitor EGT beyond drilling a hole in exhaust header runner and inserting a thermocouple). In fact it would appear that any changes to the stock induction/exhaust system (airflow) could affect EGT's, so I would say an EGT gauge would be a very wise investment for anyone modifying their LS7.

So if you maintain that HEAT is the primary culprit (and monitoring EGT's on a cylinder-by-cylinder basis is so impractical as to be a non-solution); then the obvious choice becomes:

if you modify, take steps to mitigate heat. That means either solid - or inconel if you're really hardcore - valves and appropriate guides with appropriate clearances (and good oil selection).

I'm not agreeing with your theory completely, but just playing Devil's Advocate that if you believe in heat as the primary etiology, then professionally installed guides/solid valves are an obvious choice, right?

#88

Safety Car

Thread Starter

I think you're also neglecting to go that one step further: what is the biggest downfall of heat? Guide wear and potentially worn valves. Maybe burnt pistons/pins and other nasty things potentially.

So if you maintain that HEAT is the primary culprit (and monitoring EGT's on a cylinder-by-cylinder basis is so impractical as to be a non-solution); then the obvious choice becomes:

if you modify, take steps to mitigate heat. That means either solid - or inconel if you're really hardcore - valves and appropriate guides with appropriate clearances (and good oil selection).

I'm not agreeing with your theory completely, but just playing Devil's Advocate that if you believe in heat as the primary etiology, then professionally installed guides/solid valves are an obvious choice, right?

So if you maintain that HEAT is the primary culprit (and monitoring EGT's on a cylinder-by-cylinder basis is so impractical as to be a non-solution); then the obvious choice becomes:

if you modify, take steps to mitigate heat. That means either solid - or inconel if you're really hardcore - valves and appropriate guides with appropriate clearances (and good oil selection).

I'm not agreeing with your theory completely, but just playing Devil's Advocate that if you believe in heat as the primary etiology, then professionally installed guides/solid valves are an obvious choice, right?

From here we can go two paths:

1. You modify the car (extra power) and increase the combustion chamber temps. Or you can simply play with spark timing and increase EGT's. If the exhaust valve was dealing with 1400F EGT's originally, and the EGT's go up to 1600F, you're nearing the design limit of the sodium valve (as I read it -- 1600F at the valve). Now you've got a problem... too much heat, things break down (lubrication, sodium, etc) and things go bad.

2. You replace the sodium valve with a solid valve. It is not designed to pull that extra heat out of the combustion chamber. Therefore combustion chamber temps go up, and chances of pre-ignition and detonation go up. If you modify the car (increase power) and increase the combustion chamber temps even further, you probably won't burn up the guide or the valve but you may burn up a valve seat or break a piston.

I think you can monitor one cylinder for EGT and get a good overall feel for what's going on inside the engine. Unless there is a problem the various cylinders should be roughly the same (I dunno, surely within 100F or so).

#89

It would be interesting to know how valve composition could directly affect emissions.

#90

Burning Brakes

I think you're also neglecting to go that one step further: what is the biggest downfall of heat? Guide wear and potentially worn valves. Maybe burnt pistons/pins and other nasty things potentially.

So if you maintain that HEAT is the primary culprit (and monitoring EGT's on a cylinder-by-cylinder basis is so impractical as to be a non-solution); then the obvious choice becomes:

if you modify, take steps to mitigate heat. That means either solid - or inconel if you're really hardcore - valves and appropriate guides with appropriate clearances (and good oil selection).

I'm not agreeing with your theory completely, but just playing Devil's Advocate that if you believe in heat as the primary etiology, then professionally installed guides/solid valves are an obvious choice, right?

So if you maintain that HEAT is the primary culprit (and monitoring EGT's on a cylinder-by-cylinder basis is so impractical as to be a non-solution); then the obvious choice becomes:

if you modify, take steps to mitigate heat. That means either solid - or inconel if you're really hardcore - valves and appropriate guides with appropriate clearances (and good oil selection).

I'm not agreeing with your theory completely, but just playing Devil's Advocate that if you believe in heat as the primary etiology, then professionally installed guides/solid valves are an obvious choice, right?

To your point on inconel, I would like to highlight the following from none other than the infamous spintron study:

The benefit of the solid Inconel valve being able to sustain high temperature is restraining the valvetrain from running at high speed.

In this application we need the high-temperature benefits of Inconel, so a lighter valve is not an option.

I also point to the fact that inconel is the valve of choice for their Air Attack TT package. A package that probably produces an enormous amount of heat as it is a boosted application advertised to produce up to 1000hp.

http://www.katechengines.com/perform...hicles/c6-z06/

Furthermore, if one is concerned about resonance issues with sloshing dynamics of the NaK, a solid valve eliminates those variables as well. The rub being that you are assuming that the heavier valve is properly controlled after the fact.

Last edited by Rock36; 02-20-2013 at 03:49 PM.

#91

Burning Brakes

Just curious as to how the various govt agencies view switching valves/springs -- California has always seemed to be the worst. Is there an exemption for this? Tunes are above and beyond that, of course.

It would be interesting to know how valve composition could directly affect emissions.

It would be interesting to know how valve composition could directly affect emissions.

#92

Safety Car

Thread Starter

I don't think I would posit that

#93

Safety Car

Thread Starter

It should also be pointed out that a custom camshaft was designed for that package which, among other things, takes into consideration the heavier weight of that valve (likely via lobe ramp design). In fact, if I were to run the heavy valves I'd be talking to them about using that particular camshaft.... surely it is a well tested package (cam/valve/springs), as opposed to throwing different valves and springs on a cam designed for something quite different.

#94

Burning Brakes

wow this does get better and better i always wondered WTF a sodium filled valve was now i know

what it is

and what it is suppose to do damm u guys r smart!lol

what it is

and what it is suppose to do damm u guys r smart!lol

#95

http://books.google.com/books?id=Rue...ssions&f=false

Well, yes it will affect emissions. Be sure to get your engines recertified.

Be sure to get your engines recertified.

I am wondering if GM did not use the sodium filled valves whether they would be able to meet ever more stringent requirements at the performance and durability levels they are/were aiming for. That would be related to your speculation as to whether they seriously considered other combinations of parts, like stainless steel or superalloy exhaust valves.

Well, yes it will affect emissions.

Be sure to get your engines recertified.

Be sure to get your engines recertified.I am wondering if GM did not use the sodium filled valves whether they would be able to meet ever more stringent requirements at the performance and durability levels they are/were aiming for. That would be related to your speculation as to whether they seriously considered other combinations of parts, like stainless steel or superalloy exhaust valves.

#96

Burning Brakes

http://books.google.com/books?id=Rue...ssions&f=false

Well, yes it will affect emissions. Be sure to get your engines recertified.

Be sure to get your engines recertified.

I am wondering if GM did not use the sodium filled valves whether they would be able to meet ever more stringent requirements at the performance and durability levels they are/were aiming for. That would be related to your speculation as to whether they seriously considered other combinations of parts, like stainless steel or superalloy exhaust valves.

Well, yes it will affect emissions.

Be sure to get your engines recertified.

Be sure to get your engines recertified.I am wondering if GM did not use the sodium filled valves whether they would be able to meet ever more stringent requirements at the performance and durability levels they are/were aiming for. That would be related to your speculation as to whether they seriously considered other combinations of parts, like stainless steel or superalloy exhaust valves.

The redline in the new GEN V LT1 is 6600 rpm as you know, and the LS3 with solid exhaust valves has the same redline. So that rpm especially doesn't strike me as lofty enough that a light weight sodium-filled exhaust valve is absolutely necessary from a stability standpoint, but add to that the 11.5:1 compression ratio, direct injection, engine knock avoidance, and ever tightening emissions requirements and it might become more necessary to use sodium-filled valves for other reasons perhaps..

#97

Safety Car

Thread Starter

Thanks for the link, and the read. Now that you have brought up emissions, I wonder to what extent sodium filled valves are also used due to their effects on emissions, and their ability to aid in running higher compression ratios.

The redline in the new GEN V LT1 is 6600 rpm as you know, and the LS3 with solid exhaust valves has the same redline. So that rpm especially doesn't strike me as lofty enough that a light weight sodium-filled exhaust valve is absolutely necessary from a stability standpoint, but add to that the 11.5:1 compression ratio, direct injection, engine knock avoidance, and ever tightening emissions requirements and it might become more necessary to use sodium-filled valves for other reasons perhaps.

The redline in the new GEN V LT1 is 6600 rpm as you know, and the LS3 with solid exhaust valves has the same redline. So that rpm especially doesn't strike me as lofty enough that a light weight sodium-filled exhaust valve is absolutely necessary from a stability standpoint, but add to that the 11.5:1 compression ratio, direct injection, engine knock avoidance, and ever tightening emissions requirements and it might become more necessary to use sodium-filled valves for other reasons perhaps.

#98

Safety Car

Thread Starter

Came into possession of some components and thought some might find the info useful or interesting:

8 new OEM exhaust valves from a vendor's current inventory. These valves carry a part number marking (12618110), a stylized "M" logo (Mahle, I presume), and what I assume is a date code of 07-12. My guess is that this is the 7th week of 2012, which I find somewhat interesting (indicating that these valves are late production). I did not dissect any of these valves, but they weighed from 73.87 to 74.60 grams and had a stem diameter in the .3137 range.

Some new CHE valve guides that are supposedly what is in current use for The Fix. Overall Length (OAL) 2.201 inches.

Some new OEM valve guides (that's what the man said). OAL 2.112 inches.

As is typical for the LS7 (and not for others), the valve guide O.D. is 0.500. The OEM guide is a straight tube. The CHE guide has a .0529 'lip' at .700 (approx) from the top (this is install height) and a 0.499 'threaded' portion atop that. It appears from observation and actual fitment that an OEM LS7 valve seal (with the integral seat/locator) will fit over this guide. However, from actual measurement I'm pretty sure that a PSI 1511 spring will not fit over that seal, so if using that spring the separate seal/seat-locator arrangement will have to be used.

Didn't have camera available, but here are some stock photos:

8 new OEM exhaust valves from a vendor's current inventory. These valves carry a part number marking (12618110), a stylized "M" logo (Mahle, I presume), and what I assume is a date code of 07-12. My guess is that this is the 7th week of 2012, which I find somewhat interesting (indicating that these valves are late production). I did not dissect any of these valves, but they weighed from 73.87 to 74.60 grams and had a stem diameter in the .3137 range.

Some new CHE valve guides that are supposedly what is in current use for The Fix. Overall Length (OAL) 2.201 inches.

Some new OEM valve guides (that's what the man said). OAL 2.112 inches.

As is typical for the LS7 (and not for others), the valve guide O.D. is 0.500. The OEM guide is a straight tube. The CHE guide has a .0529 'lip' at .700 (approx) from the top (this is install height) and a 0.499 'threaded' portion atop that. It appears from observation and actual fitment that an OEM LS7 valve seal (with the integral seat/locator) will fit over this guide. However, from actual measurement I'm pretty sure that a PSI 1511 spring will not fit over that seal, so if using that spring the separate seal/seat-locator arrangement will have to be used.

Didn't have camera available, but here are some stock photos:

CHE (typical):

________________________________________ _

OEM (typical):

________________________________________ _

LS7 OEM Valve Stem Seal w/integral Locator:

________________________________________ _

'Short' Valve Stem Seal:

________________________________________ _

OEM (typical):

________________________________________ _

LS7 OEM Valve Stem Seal w/integral Locator:

________________________________________ _

'Short' Valve Stem Seal:

Last edited by Mark2009; 03-22-2013 at 09:17 PM. Reason: Added Seal Photos

#99

Came into possession of some components and thought some might find the info useful or interesting:

8 new OEM exhaust valves from a vendor's current inventory. These valves carry a part number marking (12618110), a stylized "M" logo (Mahle, I presume), and what I assume is a date code of 07-12. My guess is that this is the 7th week of 2012, which I find somewhat interesting (indicating that these valves are late production). I did not dissect any of these valves, but they weighed from 73.87 to 74.60 grams and had a stem diameter in the .3137 range.

Some new CHE valve guides that are supposedly what is in current use for The Fix. Overall Length (OAL) 2.201 inches.

Some new OEM valve guides (that's what the man said). OAL 2.112 inches.

As is typical for the LS7 (and not for others), the valve guide O.D. is 0.500. The OEM guide is a straight tube. The CHE guide has a .0529 'lip' at .700 (approx) from the top (this is install height) and a 0.499 'threaded' portion atop that. It appears from observation and actual fitment that an OEM LS7 valve seal (with the integral seat/locator) will fit over this guide. However, from actual measurement I'm pretty sure that a PSI 1511 spring will not fit over that seal, so if using that spring the separate seal/seat-locator arrangement will have to be used.

Didn't have camera available, but here are some stock photos:

8 new OEM exhaust valves from a vendor's current inventory. These valves carry a part number marking (12618110), a stylized "M" logo (Mahle, I presume), and what I assume is a date code of 07-12. My guess is that this is the 7th week of 2012, which I find somewhat interesting (indicating that these valves are late production). I did not dissect any of these valves, but they weighed from 73.87 to 74.60 grams and had a stem diameter in the .3137 range.

Some new CHE valve guides that are supposedly what is in current use for The Fix. Overall Length (OAL) 2.201 inches.

Some new OEM valve guides (that's what the man said). OAL 2.112 inches.

As is typical for the LS7 (and not for others), the valve guide O.D. is 0.500. The OEM guide is a straight tube. The CHE guide has a .0529 'lip' at .700 (approx) from the top (this is install height) and a 0.499 'threaded' portion atop that. It appears from observation and actual fitment that an OEM LS7 valve seal (with the integral seat/locator) will fit over this guide. However, from actual measurement I'm pretty sure that a PSI 1511 spring will not fit over that seal, so if using that spring the separate seal/seat-locator arrangement will have to be used.

Didn't have camera available, but here are some stock photos:

CHE (typical):

________________________________________ _

OEM (typical):

________________________________________ _

LS7 OEM Valve Stem Seal w/integral Locator:

________________________________________ _

'Short' Valve Stem Seal:

________________________________________ _

OEM (typical):

________________________________________ _

LS7 OEM Valve Stem Seal w/integral Locator:

________________________________________ _

'Short' Valve Stem Seal:

The guides used in "The Fix" are not always C.H.E. guides.

Si Valves, made the guides in mine and in at least one other set of heads that I know about.

http://www.sivalves.com/ocantique_vguides.html

#100

Safety Car

Thread Starter

I'm sorry that you wound up with an inferior substitute

Do you have dimensions for your product that differ from those I posted? If not, what is your point?

Do you have dimensions for your product that differ from those I posted? If not, what is your point?