Next R&D "bullet" about to hit the dyno....

#1

Former Vendor

Thread Starter

Im sure most the guys on this forum followed the last engine I built for Steve Smith which at the time debuted the release of our new 215 cc head....It was a 407 CID stroker built around an LS2 OEM block.

In case your new or somehow overlooked it feel free to review it now....its a good read with solid tech, good pics, and an overall engaging thread IMO. When the smoke cleared we managed to meet our peak torque figures....meet our peak HP figures, but completely obliterate anything I expected to produce below 4000 RPM. This engine started the pull at 490 ft/lbs and cleared 500 as early as 3800 RPM's never dipping below that figure till 6500 RPM's. Peak power occured at 6300 coming in at 618 HP.....peak torque at 5100 reaching 564 ft/lbs. Numbers a larger and much heavier 460 CID BBC would have been proud of not that long ago but I'm dating myself a little....LOL

Here is the thread covering that build....

http://forums.corvetteforum.com/c5-t...-complete.html

Of course I usually leave the dyno with more questions than the number I actually had answered during the test session.

In this case I left the test above thinking what if I wouldnt have advanced the cam as much.....what if I would have went with a little more cam....etc. etc.....you see where Im going here. Had I had the opportunity to see the results ahead of time I would have secretly installed a slightly larger cam and not even have told Steve....LOL (Well....I fantasized about that scenario after the fact!) Now dont get me wrong.....we nailed ALL the parameters of the build Steve and I set forth to accomplish....I just felt we had so much torque down low we could actually afford to lose some in swap of more power upstairs. In an acceleration contest horsepower is king, but alot of low RPM torque is a blast to drive around town....no denying that. Ultimately the results were just what Steve was looking for and the car is a blast to drive with insane snap in the throttle and a peak output of 540/500 at the tire, but I left that test session with the nagging "what if" in the back of my mind.

Enter Jeremy Wendling....a guy I have been speaking to on and off about a build for the better part of two years. Steve's 407 build was right up his alley as he also cares about the area under the curve and a package that is still a pleasure to drive with good part throttle grunt and "crispness" but while Steve's Vette is more his daily, this project with Jeremy is more of a Friday night or weekend street toy....not to mention the guy lives in Canada where you only have a few months out of the year to really enjoy this stuff. Bottom line is while he still wanted a very tractable package, seeing as he puts a couple of thousand miles a year on the car, I was willing to get a tad more aggressive than I did for Steve's 407 build and he gave me the carte blanche to do so.

I opted for a little more cubes on this one starting with an LS3 block and overboring it around .006 per side to get a perfectly straight and round cylinder (416.5 CID with a 4.071 final bore dimension).

Now dont assume more cubes equal more horsepower because thats a mistake even some of the people in the industry still adhere to. More cubes equals more low RPM and peak torque but they have more internal friction and a larger appetite for air. Given a similar (or the same) induction and exhaust system, they will simply have more area under the curve with better low/mid RPM torque figures....peak about the same power at a lower RPM, and fall off a little faster than a smaller motor with the same "lungs" (heads, cam, intake, exhaust system, etc.). All of this a good thing but be clear that none of the power gained in this build will really be attributed to the slight gain in displacement.....only the potential peak torque increase although this motor has less compression than the 407 I just built because its a 91 octane piece (11.4 to 1) so that will slightly hurt us in peak torque output but I hope for slightly more net than the 407 build with higher compression.

The BIG news of this build is it also features a little more cylinder head. While Steve's "Mamo romanced" 215's flowed about the same as our current 225 production heads, this 417 will feature AFR's all new "V2" 230 cc head.....and its a pretty nasty piece. Its all about area under the curve with explosive low and midlift flow significantly better than our 225, and about 8-10 more peak CFM as well. The cool thing is while the moniker looks 5cc larger, in the real world its only about 2cc's.....our former 225 ran a few cc's larger than advertised....the new head is right at 229-230 cc's so not only does it flow considerably better, it does it with even more velocity and a higher level of efficiency.

Trying once again to slightly one up the last build in an effort to make a few more ponies this build will also feature one of my ported 102mm FAST intakes (versus the 92mm version I ported for Steve).

A little more cam (dont forget this still needed to be friendly on the street) with a 243/247 custom cam I designed around the new Comp LSL lobes (.624 lift on both sides). That should help keep the slightly larger engine from falling off as quickly as it would have with the same size cam I installed in the 407 which was an XER lobed 242 single pattern grind. Once again a larger motor has a bigger appetite for air and can tolerate more overlap while retaining the same amount of "civility" on the street a smaller motor with less cam might have.

Thats about all the time I have at this moment....I will post flow figures on the new AFR 230 heads and a few pics of the build later or tomorrow at the latest.

We are also launching a new version of our 205 which has been mega successful for almost six years....that head will now displace 210 cc's but up's the ante on flow alot more than the marginal increase in volume. I expect that head to do extremely well out in the field also.

Lots of exciting stuff AFR related and of course Im excited to see how much power and torque the new 417 produces on the engine dyno as well as the shape of the power curve.

Our goal heading into this project (of course taking some of what we learned from the last one) was to try and keep the bottom of the curve at least close in torque output, while trying to improve the power output and still retain good driving manners with decent idle vacuum as well.

If all goes smoothly the answer to that question will be available to us by Friday....

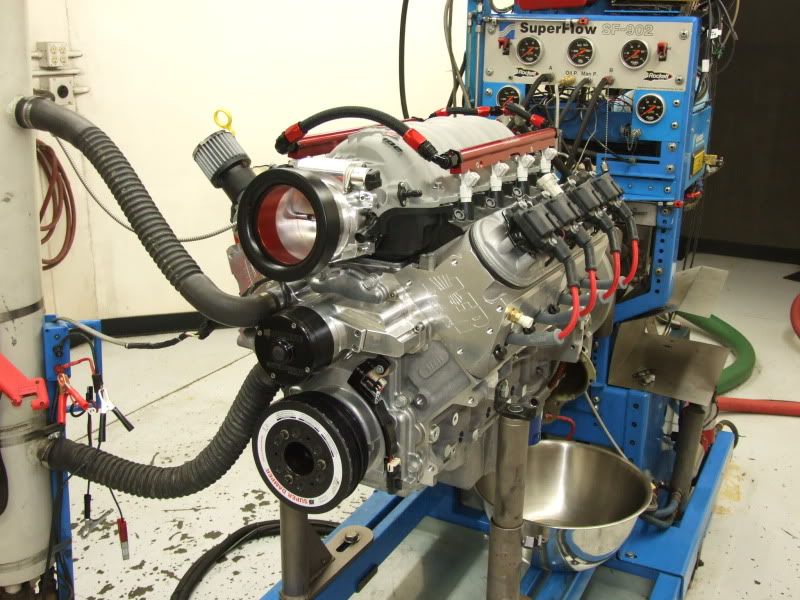

A pic of the latest creation

And while Im thinking about it, a heads up to all of you running the FAST 102.

I used the button head bolts supplied and noticed the 102 sits right on top of the even the low profile bolts before I was fully seated on the head. I decided to remove the valley plate and countersink the holes and then run conical stainless hardware that would lay flush with the plate when I was done. You only have to do nine of them....the two by the oil pressure sender clear the intake and you can use the button head bolts supplied by FAST. Now this could be different depending on your heads, but my guess is most people would experience the same or similar situation that I did because these are straight up 72 cc heads milled to 70 or so cc's to get my target CR.

Here is a pic of the finished install with the countersunk hardware....

Regards,

Tony

In case your new or somehow overlooked it feel free to review it now....its a good read with solid tech, good pics, and an overall engaging thread IMO. When the smoke cleared we managed to meet our peak torque figures....meet our peak HP figures, but completely obliterate anything I expected to produce below 4000 RPM. This engine started the pull at 490 ft/lbs and cleared 500 as early as 3800 RPM's never dipping below that figure till 6500 RPM's. Peak power occured at 6300 coming in at 618 HP.....peak torque at 5100 reaching 564 ft/lbs. Numbers a larger and much heavier 460 CID BBC would have been proud of not that long ago but I'm dating myself a little....LOL

Here is the thread covering that build....

http://forums.corvetteforum.com/c5-t...-complete.html

Of course I usually leave the dyno with more questions than the number I actually had answered during the test session.

In this case I left the test above thinking what if I wouldnt have advanced the cam as much.....what if I would have went with a little more cam....etc. etc.....you see where Im going here. Had I had the opportunity to see the results ahead of time I would have secretly installed a slightly larger cam and not even have told Steve....LOL (Well....I fantasized about that scenario after the fact!) Now dont get me wrong.....we nailed ALL the parameters of the build Steve and I set forth to accomplish....I just felt we had so much torque down low we could actually afford to lose some in swap of more power upstairs. In an acceleration contest horsepower is king, but alot of low RPM torque is a blast to drive around town....no denying that. Ultimately the results were just what Steve was looking for and the car is a blast to drive with insane snap in the throttle and a peak output of 540/500 at the tire, but I left that test session with the nagging "what if" in the back of my mind.

Enter Jeremy Wendling....a guy I have been speaking to on and off about a build for the better part of two years. Steve's 407 build was right up his alley as he also cares about the area under the curve and a package that is still a pleasure to drive with good part throttle grunt and "crispness" but while Steve's Vette is more his daily, this project with Jeremy is more of a Friday night or weekend street toy....not to mention the guy lives in Canada where you only have a few months out of the year to really enjoy this stuff. Bottom line is while he still wanted a very tractable package, seeing as he puts a couple of thousand miles a year on the car, I was willing to get a tad more aggressive than I did for Steve's 407 build and he gave me the carte blanche to do so.

I opted for a little more cubes on this one starting with an LS3 block and overboring it around .006 per side to get a perfectly straight and round cylinder (416.5 CID with a 4.071 final bore dimension).

Now dont assume more cubes equal more horsepower because thats a mistake even some of the people in the industry still adhere to. More cubes equals more low RPM and peak torque but they have more internal friction and a larger appetite for air. Given a similar (or the same) induction and exhaust system, they will simply have more area under the curve with better low/mid RPM torque figures....peak about the same power at a lower RPM, and fall off a little faster than a smaller motor with the same "lungs" (heads, cam, intake, exhaust system, etc.). All of this a good thing but be clear that none of the power gained in this build will really be attributed to the slight gain in displacement.....only the potential peak torque increase although this motor has less compression than the 407 I just built because its a 91 octane piece (11.4 to 1) so that will slightly hurt us in peak torque output but I hope for slightly more net than the 407 build with higher compression.

The BIG news of this build is it also features a little more cylinder head. While Steve's "Mamo romanced" 215's flowed about the same as our current 225 production heads, this 417 will feature AFR's all new "V2" 230 cc head.....and its a pretty nasty piece. Its all about area under the curve with explosive low and midlift flow significantly better than our 225, and about 8-10 more peak CFM as well. The cool thing is while the moniker looks 5cc larger, in the real world its only about 2cc's.....our former 225 ran a few cc's larger than advertised....the new head is right at 229-230 cc's so not only does it flow considerably better, it does it with even more velocity and a higher level of efficiency.

Trying once again to slightly one up the last build in an effort to make a few more ponies this build will also feature one of my ported 102mm FAST intakes (versus the 92mm version I ported for Steve).

A little more cam (dont forget this still needed to be friendly on the street) with a 243/247 custom cam I designed around the new Comp LSL lobes (.624 lift on both sides). That should help keep the slightly larger engine from falling off as quickly as it would have with the same size cam I installed in the 407 which was an XER lobed 242 single pattern grind. Once again a larger motor has a bigger appetite for air and can tolerate more overlap while retaining the same amount of "civility" on the street a smaller motor with less cam might have.

Thats about all the time I have at this moment....I will post flow figures on the new AFR 230 heads and a few pics of the build later or tomorrow at the latest.

We are also launching a new version of our 205 which has been mega successful for almost six years....that head will now displace 210 cc's but up's the ante on flow alot more than the marginal increase in volume. I expect that head to do extremely well out in the field also.

Lots of exciting stuff AFR related and of course Im excited to see how much power and torque the new 417 produces on the engine dyno as well as the shape of the power curve.

Our goal heading into this project (of course taking some of what we learned from the last one) was to try and keep the bottom of the curve at least close in torque output, while trying to improve the power output and still retain good driving manners with decent idle vacuum as well.

If all goes smoothly the answer to that question will be available to us by Friday....

A pic of the latest creation

And while Im thinking about it, a heads up to all of you running the FAST 102.

I used the button head bolts supplied and noticed the 102 sits right on top of the even the low profile bolts before I was fully seated on the head. I decided to remove the valley plate and countersink the holes and then run conical stainless hardware that would lay flush with the plate when I was done. You only have to do nine of them....the two by the oil pressure sender clear the intake and you can use the button head bolts supplied by FAST. Now this could be different depending on your heads, but my guess is most people would experience the same or similar situation that I did because these are straight up 72 cc heads milled to 70 or so cc's to get my target CR.

Here is a pic of the finished install with the countersunk hardware....

Regards,

Tony

#2

Melting Slicks

Member Since: Oct 2007

Location: It's true money can't buy happiness, but it is more comfortable crying in a Corvette than on a bicyc

Posts: 2,798

Likes: 0

Received 5 Likes

on

5 Posts

St. Jude Donor '13

I think I'm in love. Kind of a let down near the end though with no numbers, but I know you're dying to try this bad boy out and post up the numbers. What kind of peak HP and Torque are you shooting for?

#4

Former Vendor

Thread Starter

Number coming soon

Hoping for similar torque output to the last set-up I built and linked you to above (560-570 ft/lbs) and hopefully 20 more ponies (anything close to 640 would be sweet).

This wasn't a "numbers hunting" set on kill combo so thats pretty stout power for a 91 octane street friendly build. It is like most of my builds....a "devil is in the details" approach to extract all you can form a moderately aggressive user friendly combination.

The goal was to build an engine that would try to be the best of both worlds (which isn't easily accomplished because engines are always about compromise)....give up here to get more there....etc. etc.

The key here is Im taking what I learned from the last build (which was very successful) and tweaking the formula or recipe a bit to better dial in this one....although this build had a slightly more aggressive stance right from the start of our conversations being it is more the toy than a daily driver. Application is always key if helping to determine the optimal components for any build.

-Tony

#6

Team Owner

Tony,

How do the new AFR 210's compare with the 205's they are replacing? I am thinking that to re-tool and set up there must be more to the new design then just a few CFM.

How do the new AFR 210's compare with the 205's they are replacing? I am thinking that to re-tool and set up there must be more to the new design then just a few CFM.

#7

Former Vendor

Thread Starter

The castings needed the intake core modified which was handled by our foundry, but there was alot of time invested by myself and the Engineering team getting the most from the new design and optimizing the sizing and positioning of all the new toolpaths. The reality is it will take us awhile to get our money out of the time invested but the bottom line is the flow improvements were substantial and our customers are really the big winners here. IMO the gains more than justify the time but thats easy to say when my name isn't on the AFR electric bill and Im not the guy signing the checks!!

Here is the data on both heads (the new 210's and the new 230 cc heads)....don't forget the finished size of both new products is extremely close to the original and these are real world numbers that we stand behind off an SF600 bench. Also guys, please do NOT try and compare these numbers to other vendors "advertised" numbers....its a waste of time unless you have data off the same bench. Not to mention some of our competitors use a different style bench which can produce "generous" numbers when compared to the SuperFlow style bench (which IMO is still the industry standard).

What you need to keep in mind is we are comparing apples to apples here and at this point most everyone already knows how effective the 205 and the 225 has been over the years....we upped the ante with the V2 version of both.

INTAKE

Lift....AFR 205...AFR 210

.200......140.........153

.300......200.........214

.400......251.........262

.500......281.........293

.550......292.........300

.600......298.........302

EXHAUST

.200......112.........124

.300......170.........178

.400......203.........214

.500......221.........227

.600......230.........237

--------------------------------------------------------------

Now the 225/230 comparison....

Small bore (62 cc version)

INTAKE

Lift....AFR 225...AFR 230

.200......148.........157

.300......212.........224

.400......262.........272

.500......300.........311

.550......310.........320

.600......315.........324

Exhaust

.200......118.........129

.300......175.........183

.400......209.........225

.500......225.........244

.600......237.........252

Large bore (72 cc version)

INTAKE

Lift....AFR 225...AFR 230

.200......158.........158

.300......223.........230

.400......276.........282

.500......315.........320

.550......323.........325

.600......324.........328

EXHAUST

.200......120.........120

.300......178.........183

.400......220.........225

.500......241.........244

.600......250.........252

Thanks,

Tony

PS....Jeremy's "Mamofied" 230's went in the mid 330's on the intake and close to 260 on the exhaust! Big numbers thru a medium sized port!

#8

Former Vendor

Thread Starter

Well....

Last Thursday was one of those dyno days you dream about....

Besides the heat (it was over 100' most of the day), everything went fairly smooth and the engine slightly bested my higher hopes heading into the much anticipated day.

It certainly made more bottom end torque than I expected and a little more HP as well.....couple that with a table top torque curve that hung on extremely well and the end results were just pretty as a picture. It looks like the new "V2" AFR 230 is as effective as I hoped it would be because this 416.5 CID engine (4.071 bore / 4" stroke), seemed to make more torque and horsepower than its displacement might indicate or at the least a best case scenario for sure.

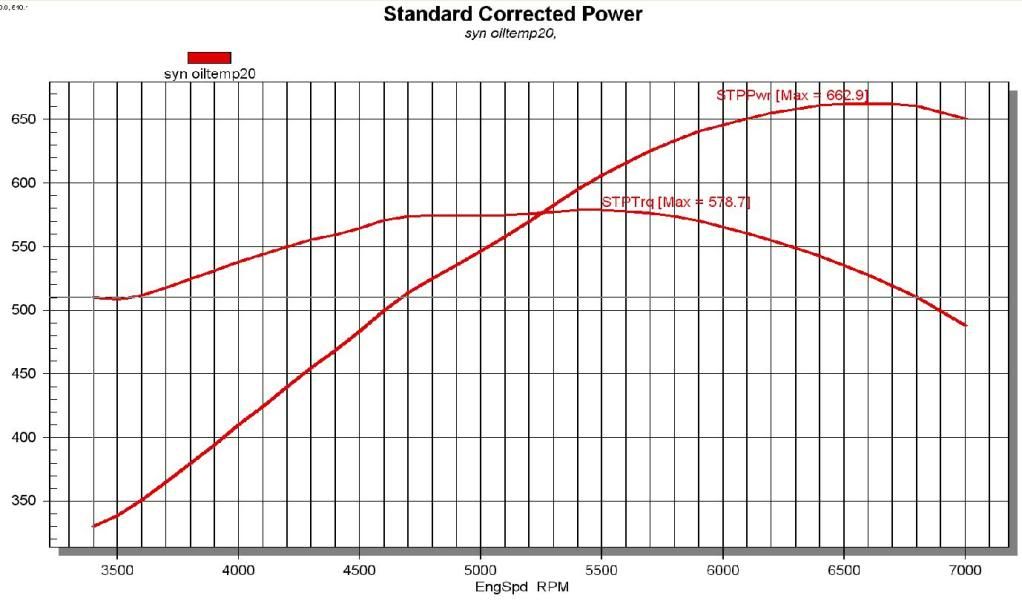

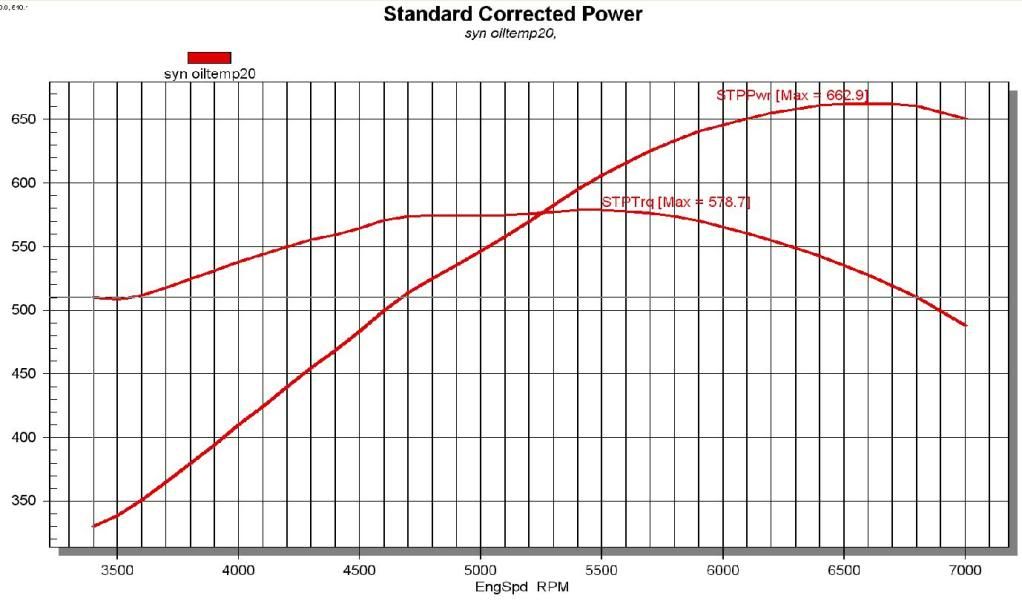

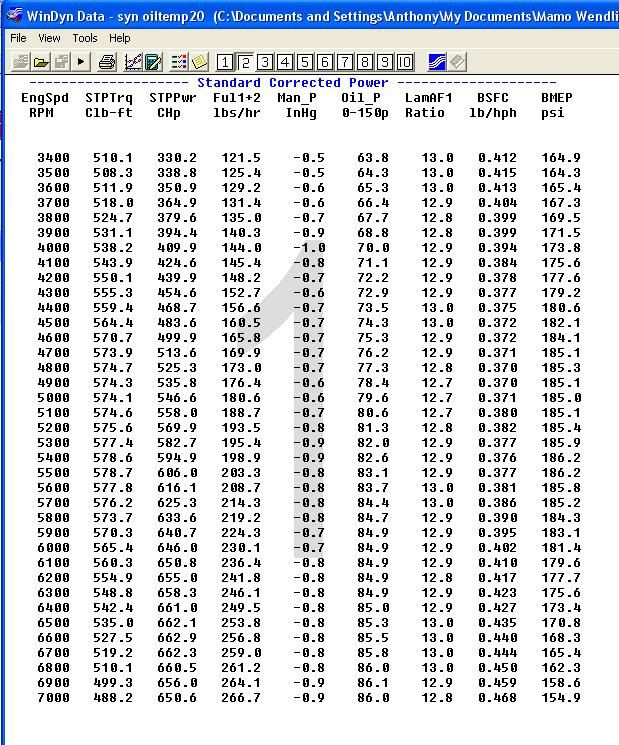

It made over 500 ft/lbs of torque from 3400 to 6900 RPM's (incredibly broad curve).....peaked at 579 but made over 570 (very close to it's peak output) for over 1300 RPM's! Peak power occurred at 6600 where it lopped up 663 HP (I was hoping for 650 ish) and it was still making 650 at 7000 RPM! With the bottom of the curve looking so good I just wouldn't have expected the top to be so strong or visa versa depending how you want to look at it.

Here is a picture of the power curve that really tells the story.....for the application we are discussing here it doesn't get much better, especially considering this is a hydraulic roller combination with zero maintenance or lash adjustment.

Believe it or not, Jeremy and I have been discussing this project for the better part of two years.....and while a few of the players changed along the way (different heads, intake, etc.) the end results most certainly justified the wait. This project is going in a cherry low mileage 2001 Firehawk (17K on the clock), and while F-Bodies generally aren't known for their hero dyno numbers (Vettes produce better results as a rule) I have a hunch this particular F-Body is going to lay down a fairly stout number. Having had multiple engine combo's on Westech's dyno and shortly after installed in my Vette, I can say confidently that with the right tune, this engine would have generated around 580 RWHP and close to 540 RWTQ in my personal vehicle. That's retarded power from a 91 octane build of moderate displacement that would also have brutal area under the curve in torque output, good throttle response and drivability, and a reasonable idle as well. In fact this engine made almost 12" of vacuum at 950-1000 RPM. While I can only speculate what this package will do in Jeremy's F-body, I feel confident its more of matter of how good it will look....LOL

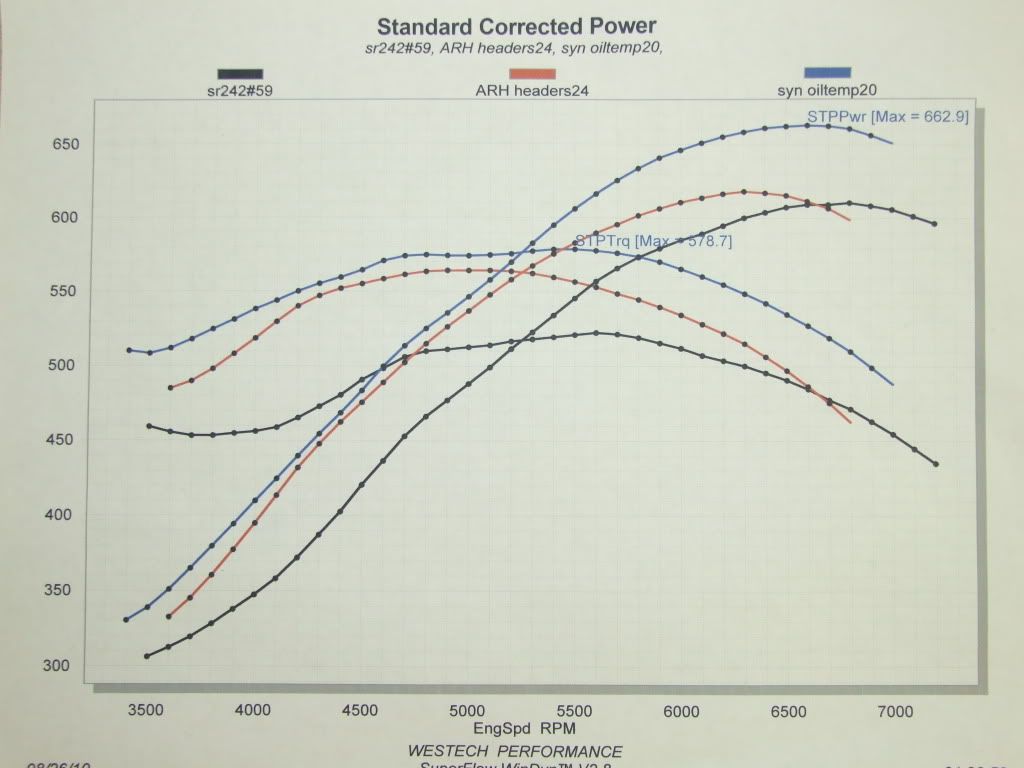

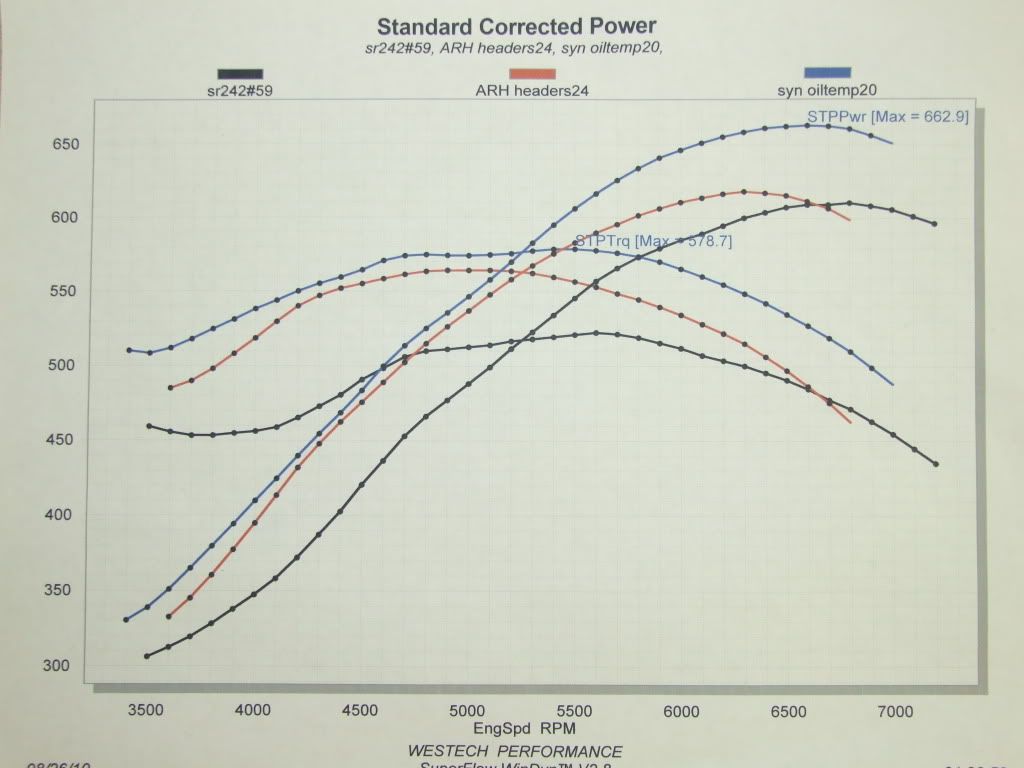

Look at the comparison below....

The black line is my former solid roller 383, which was a very stout combo that I cant emphasize enough how well that motor ran (130 trap in my 3400 lb C5). The red line is Steve Smith's engine I built and dyno'ed a couple of months ago which IMO was also very impressive with our new 215's and made 540/500 in his Corvette....and of course the blue line, Jeremy's 417 build which lays waste to my 383 at every RPM and puts a sizable lead on the 407 build as well (which of course wasn't quite as large or quite as aggressive as this build which I highlighted earlier in the thread). The bottom line here is this combination surprised me a little but these are the types of surprises that we all welcome.

So to wrap up I thought I would share a few pics and a couple of vids from the dyno day....

The first taken by Jeremy's wife (great gal) of the two of us off to the dyno as I pick up Jeremy in front of the hotel he was staying at the time.

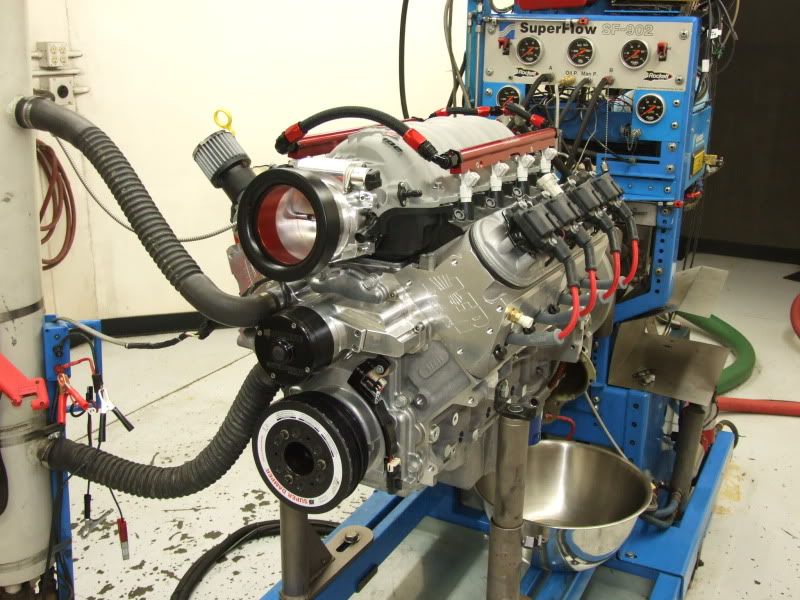

Next up a nice clean shot of the engine before it was covered in 100 miles of wiring and various sensors!

Steve Brule (this guy has pulled the handle on more engines than anyone in the country likely!) filling the block with water.....getting close!

Brule and I having a lighter moment before we light the engine and it's all business....

And at the end of the day (after all the smoke cleared from the twenty or so pulls), a "happily baffled" Mamo staring at the comparison of the three engines I shared with you above....LOL

Last but not least a couple of vids.....the first with the engine included in the cell.....the second just the dyno screen where its easier to see how stout this piece is and how quickly it ramps up into the fat part of the torque curve. Click on these two pics below to be linked to the video

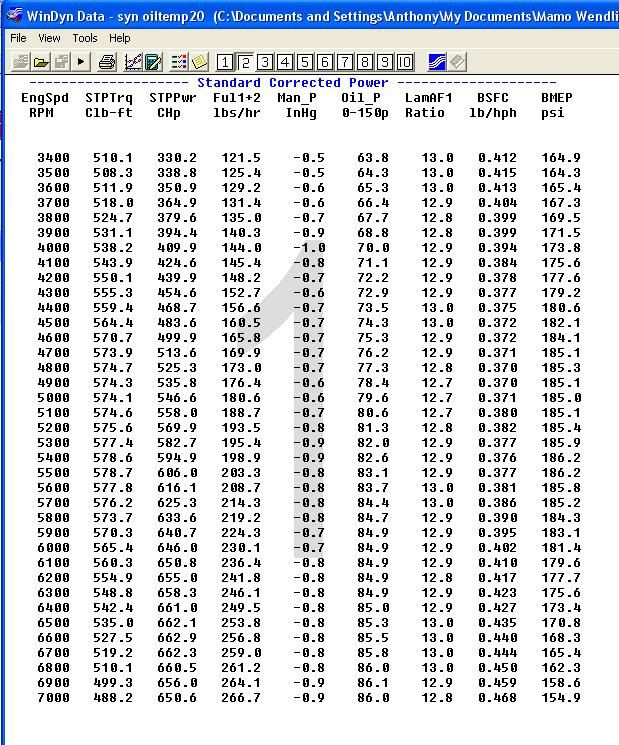

Here is the hard data from the best pull of the day....

And last but not least, Jeremy having an "intimate moment" with his new engine after we unloaded it from the dyno!

Hope you guys enjoyed the journey.....this engine gets shipped to Canada next week. Its going to take a little while, but hopefully we have some rear wheel numbers by early/mid October....

Cheers,

Tony

Last Thursday was one of those dyno days you dream about....

Besides the heat (it was over 100' most of the day), everything went fairly smooth and the engine slightly bested my higher hopes heading into the much anticipated day.

It certainly made more bottom end torque than I expected and a little more HP as well.....couple that with a table top torque curve that hung on extremely well and the end results were just pretty as a picture. It looks like the new "V2" AFR 230 is as effective as I hoped it would be because this 416.5 CID engine (4.071 bore / 4" stroke), seemed to make more torque and horsepower than its displacement might indicate or at the least a best case scenario for sure.

It made over 500 ft/lbs of torque from 3400 to 6900 RPM's (incredibly broad curve).....peaked at 579 but made over 570 (very close to it's peak output) for over 1300 RPM's! Peak power occurred at 6600 where it lopped up 663 HP (I was hoping for 650 ish) and it was still making 650 at 7000 RPM! With the bottom of the curve looking so good I just wouldn't have expected the top to be so strong or visa versa depending how you want to look at it.

Here is a picture of the power curve that really tells the story.....for the application we are discussing here it doesn't get much better, especially considering this is a hydraulic roller combination with zero maintenance or lash adjustment.

Believe it or not, Jeremy and I have been discussing this project for the better part of two years.....and while a few of the players changed along the way (different heads, intake, etc.) the end results most certainly justified the wait. This project is going in a cherry low mileage 2001 Firehawk (17K on the clock), and while F-Bodies generally aren't known for their hero dyno numbers (Vettes produce better results as a rule) I have a hunch this particular F-Body is going to lay down a fairly stout number. Having had multiple engine combo's on Westech's dyno and shortly after installed in my Vette, I can say confidently that with the right tune, this engine would have generated around 580 RWHP and close to 540 RWTQ in my personal vehicle. That's retarded power from a 91 octane build of moderate displacement that would also have brutal area under the curve in torque output, good throttle response and drivability, and a reasonable idle as well. In fact this engine made almost 12" of vacuum at 950-1000 RPM. While I can only speculate what this package will do in Jeremy's F-body, I feel confident its more of matter of how good it will look....LOL

Look at the comparison below....

The black line is my former solid roller 383, which was a very stout combo that I cant emphasize enough how well that motor ran (130 trap in my 3400 lb C5). The red line is Steve Smith's engine I built and dyno'ed a couple of months ago which IMO was also very impressive with our new 215's and made 540/500 in his Corvette....and of course the blue line, Jeremy's 417 build which lays waste to my 383 at every RPM and puts a sizable lead on the 407 build as well (which of course wasn't quite as large or quite as aggressive as this build which I highlighted earlier in the thread). The bottom line here is this combination surprised me a little but these are the types of surprises that we all welcome.

So to wrap up I thought I would share a few pics and a couple of vids from the dyno day....

The first taken by Jeremy's wife (great gal) of the two of us off to the dyno as I pick up Jeremy in front of the hotel he was staying at the time.

Next up a nice clean shot of the engine before it was covered in 100 miles of wiring and various sensors!

Steve Brule (this guy has pulled the handle on more engines than anyone in the country likely!) filling the block with water.....getting close!

Brule and I having a lighter moment before we light the engine and it's all business....

And at the end of the day (after all the smoke cleared from the twenty or so pulls), a "happily baffled" Mamo staring at the comparison of the three engines I shared with you above....LOL

Last but not least a couple of vids.....the first with the engine included in the cell.....the second just the dyno screen where its easier to see how stout this piece is and how quickly it ramps up into the fat part of the torque curve. Click on these two pics below to be linked to the video

Here is the hard data from the best pull of the day....

And last but not least, Jeremy having an "intimate moment" with his new engine after we unloaded it from the dyno!

Hope you guys enjoyed the journey.....this engine gets shipped to Canada next week. Its going to take a little while, but hopefully we have some rear wheel numbers by early/mid October....

Cheers,

Tony

#9

Le Mans Master

#10

Former Vendor

Thread Starter

Thats such a wide open question....obviously the potential is alot if you pay attention to all the details as witnessed here.

I think it would work better on a 383 than it would a stock displacement combo however.....a 215 is probably better sized for that.

I may be building a 383 with these in the future (spring of next year) so we will see what kind of power they can muster. My guess is low/mid 600's on the engine dyno.....mid 500's @ the tire.

-Tony

I think it would work better on a 383 than it would a stock displacement combo however.....a 215 is probably better sized for that.

I may be building a 383 with these in the future (spring of next year) so we will see what kind of power they can muster. My guess is low/mid 600's on the engine dyno.....mid 500's @ the tire.

-Tony

#11

Le Mans Master

Thats such a wide open question....obviously the potential is alot if you pay attention to all the details as witnessed here.

I think it would work better on a 383 than it would a stock displacement combo however.....a 215 is probably better sized for that.

I may be building a 383 with these in the future (spring of next year) so we will see what kind of power they can muster. My guess is low/mid 600's on the engine dyno.....mid 500's @ the tire.

-Tony

I think it would work better on a 383 than it would a stock displacement combo however.....a 215 is probably better sized for that.

I may be building a 383 with these in the future (spring of next year) so we will see what kind of power they can muster. My guess is low/mid 600's on the engine dyno.....mid 500's @ the tire.

-Tony

#12

Pro

I had the good fortune to be Tony's guest at both Steve & Jeremy's

dyno days. Wow!

To answer catsharks question if I may.

Steve's 407 made 618hp@crank & 540rwhp

Jeremy's 417 made 662hp@crank in a C5 my bet would be

at Least 560+ rwhp

dyno days. Wow!

To answer catsharks question if I may.

Steve's 407 made 618hp@crank & 540rwhp

Jeremy's 417 made 662hp@crank in a C5 my bet would be

at Least 560+ rwhp

#13

I just wanted to drop in here to thank Tony for an experience that I will always remember - and I haven't even experienced the engine in the car yet!

My first dealings with Tony were back in early 2006, when I had him port a FAST 90 to go along with the AFR 205's and the 224/228 cam that was installed in my 346. This was the same set-up that Tony first had in his vette. I enjoyed the stock like driveability and broad power curve that this set-up always delivered, but eventually as everyone does, you start to get used to the power.

One note that I think is important to mention, is that I was one of the few people who unfortunately ended up with a bad valve tip in 2007 due to the batch of bad valves AFR had received from a vendor. The way that AFR as a company stepped up, handled the entire situation and made sure I was "looked after" is part of the reason why I am a repeat AFR customer now. I figured if this is how the company stands behind their product, then they are a company that I want to continue to do business with.

Fast forward to June 2008 when I contacted Tony again with the thought that if I could replicate the characteristics of the 346 set-up with just more power everywhere and maybe throw in a little bit more of an aggressive flair to the set-up then I would be one happy camper... We kicked the idea around of going with more cubes and having Tony work my 205's on top of an LS3 stroker 416/418 for a couple of months. Then as we all know, the economic meltdown hit and I figured that now was not the time to be making a purchase of this nature at a time of such uncertainty. I told Tony that I was going to put the project on the back burner due to what was happening and he was completely professional about it and told me that he could appreciate my decision - which I respected again how he handled this.

On to August 2009 and with things starting to look like the world really may not be ending I contacted Tony again regarding a build. I certainly (as Tony can attest to) was not one to jump into something like this without thinking about it and talking it through over and over again!! What a patient guy Tony is. By the end of 2009 we had a plan (hell even a camshaft picked out). I knew Tony was going to dyno Steve Smith's 407 shortly, so wanting to be sure of what I was getting into, I waited until Steve's 407 was dyno'd with the outstanding results that it provided. Two days later I wired Tony the deposit for the build....

I went into this build knowing that this will very likely be the only chance that I get to do something like this, so I wanted it to be something that I would always remember. I knew there were several positives in my favor, one was that Tony had real skin in the game so to speak. He was putting his reputation on the line with the build and the fact that the guy who designed the heads was the one "romancing" them and building the entire engine to showcase them was nothing but a winner in my books. In my opinion what more could I ask for?

What Tony basically did throughout the build (even though I was 2000 miles away), is he took me along for the ride. We kept in close contact and when certain decisions had to be made we discussed it and then moved forward. Tony provided regular updates of the progress he was making along with an explanation of the complete and total attention to detail that he was putting into the build along with pictures, which I always looked forward to receiving. With the engine coming together in its final stages our dyno date was booked and we were ready to go.

The day at Westech was simply all I hoped it would be and more. Steve Brule and Ernie were both great guys and made me feel right at home with them in the Polygraph Room. It sure was neat being in the dyno cell that you regularly see in the magazines. The results have spoken for themselves and were more than I had hoped Tony could possibly pull off. Watching the rpm sweep with the numbers climbing higher and higher on the screen and the engine screaming at you is something almost surreal and really has to be experienced in person.

The entire build process with Tony was a life experience that I really will always treasure. We spent the rest of the weekend hanging with Tony, shared some great meals and had a pile of laughs (oh yah). I am happy to call Tony a friend and he is also the guy who built a kick *** engine that I feel very lucky to be able to call mine.

Hopefully this has provided some food for thought for any of you guys who are contemplating a build down the road. I know that this isn't the type of "deal" that everyone is looking for, but if it does look like it might be a fit, I suggest you get in touch with Tony and tell him what you are looking for, because he sure can deliver.

Jeremy.

My first dealings with Tony were back in early 2006, when I had him port a FAST 90 to go along with the AFR 205's and the 224/228 cam that was installed in my 346. This was the same set-up that Tony first had in his vette. I enjoyed the stock like driveability and broad power curve that this set-up always delivered, but eventually as everyone does, you start to get used to the power.

One note that I think is important to mention, is that I was one of the few people who unfortunately ended up with a bad valve tip in 2007 due to the batch of bad valves AFR had received from a vendor. The way that AFR as a company stepped up, handled the entire situation and made sure I was "looked after" is part of the reason why I am a repeat AFR customer now. I figured if this is how the company stands behind their product, then they are a company that I want to continue to do business with.

Fast forward to June 2008 when I contacted Tony again with the thought that if I could replicate the characteristics of the 346 set-up with just more power everywhere and maybe throw in a little bit more of an aggressive flair to the set-up then I would be one happy camper... We kicked the idea around of going with more cubes and having Tony work my 205's on top of an LS3 stroker 416/418 for a couple of months. Then as we all know, the economic meltdown hit and I figured that now was not the time to be making a purchase of this nature at a time of such uncertainty. I told Tony that I was going to put the project on the back burner due to what was happening and he was completely professional about it and told me that he could appreciate my decision - which I respected again how he handled this.

On to August 2009 and with things starting to look like the world really may not be ending I contacted Tony again regarding a build. I certainly (as Tony can attest to) was not one to jump into something like this without thinking about it and talking it through over and over again!! What a patient guy Tony is. By the end of 2009 we had a plan (hell even a camshaft picked out). I knew Tony was going to dyno Steve Smith's 407 shortly, so wanting to be sure of what I was getting into, I waited until Steve's 407 was dyno'd with the outstanding results that it provided. Two days later I wired Tony the deposit for the build....

I went into this build knowing that this will very likely be the only chance that I get to do something like this, so I wanted it to be something that I would always remember. I knew there were several positives in my favor, one was that Tony had real skin in the game so to speak. He was putting his reputation on the line with the build and the fact that the guy who designed the heads was the one "romancing" them and building the entire engine to showcase them was nothing but a winner in my books. In my opinion what more could I ask for?

What Tony basically did throughout the build (even though I was 2000 miles away), is he took me along for the ride. We kept in close contact and when certain decisions had to be made we discussed it and then moved forward. Tony provided regular updates of the progress he was making along with an explanation of the complete and total attention to detail that he was putting into the build along with pictures, which I always looked forward to receiving. With the engine coming together in its final stages our dyno date was booked and we were ready to go.

The day at Westech was simply all I hoped it would be and more. Steve Brule and Ernie were both great guys and made me feel right at home with them in the Polygraph Room. It sure was neat being in the dyno cell that you regularly see in the magazines. The results have spoken for themselves and were more than I had hoped Tony could possibly pull off. Watching the rpm sweep with the numbers climbing higher and higher on the screen and the engine screaming at you is something almost surreal and really has to be experienced in person.

The entire build process with Tony was a life experience that I really will always treasure. We spent the rest of the weekend hanging with Tony, shared some great meals and had a pile of laughs (oh yah). I am happy to call Tony a friend and he is also the guy who built a kick *** engine that I feel very lucky to be able to call mine.

Hopefully this has provided some food for thought for any of you guys who are contemplating a build down the road. I know that this isn't the type of "deal" that everyone is looking for, but if it does look like it might be a fit, I suggest you get in touch with Tony and tell him what you are looking for, because he sure can deliver.

Jeremy.

#16

Former Vendor

Member Since: Apr 2006

Location: Portland OR

Posts: 2,470

Likes: 0

Received 1 Like

on

1 Post

St. Jude Donor '10-'11-'12

Thats such a wide open question....obviously the potential is alot if you pay attention to all the details as witnessed here.

I think it would work better on a 383 than it would a stock displacement combo however.....a 215 is probably better sized for that.

I may be building a 383 with these in the future (spring of next year) so we will see what kind of power they can muster. My guess is low/mid 600's on the engine dyno.....mid 500's @ the tire.

-Tony

I think it would work better on a 383 than it would a stock displacement combo however.....a 215 is probably better sized for that.

I may be building a 383 with these in the future (spring of next year) so we will see what kind of power they can muster. My guess is low/mid 600's on the engine dyno.....mid 500's @ the tire.

-Tony

#18

Former Vendor

Thread Starter

It looks like all the "testing" is done....LOL

Take the plunge on a set and dont worry about the grenade.....Im sure your engine and your customer will thank you for it!