Crank pulley backed out- need help

#1

Burning Brakes

Thread Starter

Member Since: Aug 2009

Location: Virginia Beach Virginia

Posts: 816

Received 0 Likes

on

0 Posts

2000 FRC H/C/I/full exhaust. The other day I was driving my Vette and when I looked in the mirror I noticed a cloud about 250 yards behind me. I thought "Thats not from me",.LOL famous last words right? Well when I got home I popped the hood and noticed the ac belt was shredded, serp belp was in between belt seats on the crank pulley, and a serous ammount of oil on the ground. Then I noticed that the Crank pulley bolt was completly loose and would have fallen out were it not for the steering rack and the pulley was no longer seated where it should be. Soooooo, with all that said I wanted to ensure this does not happen again.

I bought the following items:

1. Summit 25% underdriven crank pulley

2. both belts (AC and the accesory belt for the underdrive pulley application)

3. Heavy Duty Loctite

4. ARP crank pulley bolt (damn thing was 28 bucks)

5. Timing cover replacement gasket kit from felpro

If anyone has any tips or gained experience for removal of the pulley and timing cover and re installation I would really appreciate it.. Thanks guys

I bought the following items:

1. Summit 25% underdriven crank pulley

2. both belts (AC and the accesory belt for the underdrive pulley application)

3. Heavy Duty Loctite

4. ARP crank pulley bolt (damn thing was 28 bucks)

5. Timing cover replacement gasket kit from felpro

If anyone has any tips or gained experience for removal of the pulley and timing cover and re installation I would really appreciate it.. Thanks guys

Last edited by deadcafe; 09-23-2009 at 09:46 PM.

#3

Burning Brakes

Thread Starter

Member Since: Aug 2009

Location: Virginia Beach Virginia

Posts: 816

Received 0 Likes

on

0 Posts

#4

Tech Contributor

Member Since: Dec 2006

Location: Van Buren Arkansas

Posts: 10,962

Likes: 0

Received 26 Likes

on

25 Posts

Wounded Warrior Escort '11

Where did the oil come from? The front seal shouldn't have come out too but the balancer will trash the steering rack and badly. Hope not for your sake.

#5

Team Owner

No, line must be disconnected.

You need the correct installation and removal tools as well. The loctite won't do anything for this but cause headaches later, I wouldn't use it. The pulley depends on an interference fit and preload into the crank. Since the existing pulley spun on the crank so bad, the OD of the crank may be out of spec. You should measure it and you need to do this to 0.0001" accuracy as the interference fit is less than 0.001". I would suggest pinning the new pulley. Not sure what the summit pulley is but the ATI and Powerbond have keyways for pinning the crank (SLP does too but it is essentially a Powerbond) with the ATI kit.

You need the correct installation and removal tools as well. The loctite won't do anything for this but cause headaches later, I wouldn't use it. The pulley depends on an interference fit and preload into the crank. Since the existing pulley spun on the crank so bad, the OD of the crank may be out of spec. You should measure it and you need to do this to 0.0001" accuracy as the interference fit is less than 0.001". I would suggest pinning the new pulley. Not sure what the summit pulley is but the ATI and Powerbond have keyways for pinning the crank (SLP does too but it is essentially a Powerbond) with the ATI kit.

#6

Burning Brakes

Thread Starter

Member Since: Aug 2009

Location: Virginia Beach Virginia

Posts: 816

Received 0 Likes

on

0 Posts

It came close but it never hit the rack except for the bolt but the rack was all that was holding it in at the time. The oil is comming from the front seal, I guess it could have cause the pulley to back off. I am at a loss.

#8

Burning Brakes

Thread Starter

Member Since: Aug 2009

Location: Virginia Beach Virginia

Posts: 816

Received 0 Likes

on

0 Posts

No, line must be disconnected.

You need the correct installation and removal tools as well. The loctite won't do anything for this but cause headaches later, I wouldn't use it. The pulley depends on an interference fit and preload into the crank. Since the existing pulley spun on the crank so bad, the OD of the crank may be out of spec. You should measure it and you need to do this to 0.0001" accuracy as the interference fit is less than 0.001". I would suggest pinning the new pulley. Not sure what the summit pulley is but the ATI and Powerbond have keyways for pinning the crank (SLP does too but it is essentially a Powerbond) with the ATI kit.

You need the correct installation and removal tools as well. The loctite won't do anything for this but cause headaches later, I wouldn't use it. The pulley depends on an interference fit and preload into the crank. Since the existing pulley spun on the crank so bad, the OD of the crank may be out of spec. You should measure it and you need to do this to 0.0001" accuracy as the interference fit is less than 0.001". I would suggest pinning the new pulley. Not sure what the summit pulley is but the ATI and Powerbond have keyways for pinning the crank (SLP does too but it is essentially a Powerbond) with the ATI kit.

Please let me know if I have forgotten anything, i am going in a Virgin.

#9

Burning Brakes

Thread Starter

Member Since: Aug 2009

Location: Virginia Beach Virginia

Posts: 816

Received 0 Likes

on

0 Posts

#10

Racer

Member Since: Oct 2007

Location: Knoxville Tennessee

Posts: 380

Likes: 0

Received 0 Likes

on

0 Posts

Remove the water pump, alt bracket, power steering and ABS stuff first. Be sure you buy an 18mm fairnut wrench, the only real way the PS lines will come off.

#11

Burning Brakes

Thread Starter

Member Since: Aug 2009

Location: Virginia Beach Virginia

Posts: 816

Received 0 Likes

on

0 Posts

Are there any other special tools I will need aside from a torque wrench, pulley puller, 18mm fairnut wrench, impact wrench, a pipe for reach on the T wrench? Why should I not use the loctite???

#12

Burning Brakes

Thread Starter

Member Since: Aug 2009

Location: Virginia Beach Virginia

Posts: 816

Received 0 Likes

on

0 Posts

No, line must be disconnected.

You need the correct installation and removal tools as well. The loctite won't do anything for this but cause headaches later, I wouldn't use it. The pulley depends on an interference fit and preload into the crank. Since the existing pulley spun on the crank so bad, the OD of the crank may be out of spec. You should measure it and you need to do this to 0.0001" accuracy as the interference fit is less than 0.001". I would suggest pinning the new pulley. Not sure what the summit pulley is but the ATI and Powerbond have keyways for pinning the crank (SLP does too but it is essentially a Powerbond) with the ATI kit.

You need the correct installation and removal tools as well. The loctite won't do anything for this but cause headaches later, I wouldn't use it. The pulley depends on an interference fit and preload into the crank. Since the existing pulley spun on the crank so bad, the OD of the crank may be out of spec. You should measure it and you need to do this to 0.0001" accuracy as the interference fit is less than 0.001". I would suggest pinning the new pulley. Not sure what the summit pulley is but the ATI and Powerbond have keyways for pinning the crank (SLP does too but it is essentially a Powerbond) with the ATI kit.

#13

Tech Contributor

#14

Racer

Member Since: Oct 2007

Location: Knoxville Tennessee

Posts: 380

Likes: 0

Received 0 Likes

on

0 Posts

#16

Team Owner

I plan on removing the steering rack and then using a puller for the pulley, I will then remove the water pump and then the timing chain cover. I will then clean it up and add the new gaskets and front seal, I will then install the cover the water pump and then do my best to get the new pulley on the key way and add up too 240 lbs of torque to the ARP (re-usable) crank bolt.

Please let me know if I have forgotten anything, i am going in a Virgin.

Please let me know if I have forgotten anything, i am going in a Virgin.

As for pinning, there are two types of kits. One, shown by Patches in the above thread, drills the crank end on and the pin is inserted endwise into the crane with half into the crank and half into the pulley hub. The ATI kit drills the crank from the side so the pin is 90 degrees to the crank snout. Then the pulley must have a keyway milled into it. I used the ATI kit.

Here is the drilled hole, into which the pin is inserted. It is the one near the end of the crank. The key in the crank will be covered, this photo was taken prior to installation of the oil drive sprocket onto the crank which will cover the key.

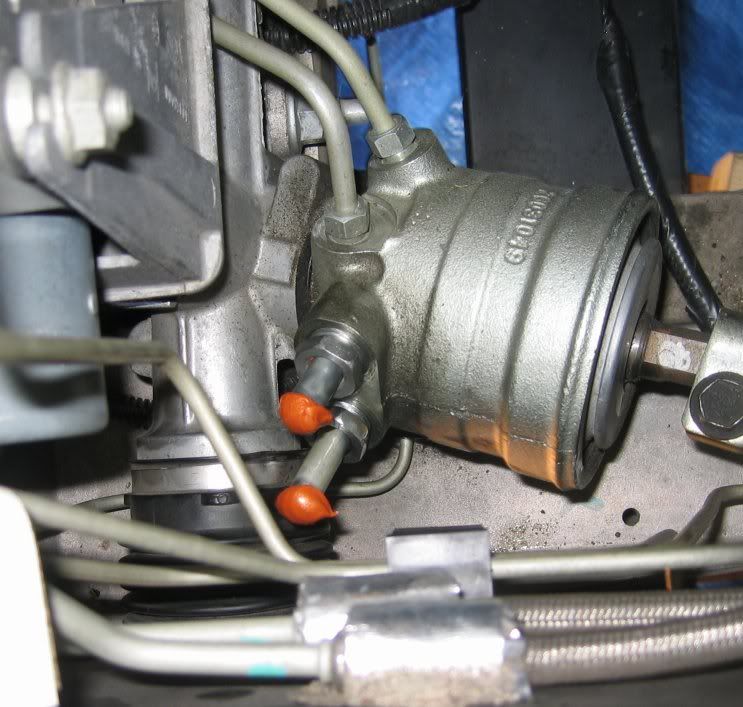

Here are the lines, use a toothbrush or something to clean the area prior to removal. You can access from the wheel well, which can be easier then from the top.

I made caps to prevent fluid loss while the rack was out and used 3/8" rubber vacuum caps on the hoses. I don't think I lost more than a few drops of fluid.

Last edited by vettenuts; 09-24-2009 at 07:05 AM.

#17

Burning Brakes

Member Since: Aug 2006

Location: Stark County Ohio

Posts: 1,217

Likes: 0

Received 5 Likes

on

5 Posts

2000 FRC H/C/I/full exhaust. The other day I was driving my Vette and when I looked in the mirror I noticed a cloud about 250 yards behind me. I thought "Thats not from me",.LOL famous last words right? Well when I got home I popped the hood and noticed the ac belt was shredded, serp belp was in between belt seats on the crank pulley, and a serous ammount of oil on the ground. Then I noticed that the Crank pulley bolt was completly loose and would have fallen out were it not for the steering rack and the pulley was no longer seated where it should be. Soooooo, with all that said I wanted to ensure this does not happen again.

I bought the following items:

1. Summit 25% underdriven crank pulley2. both belts (AC and the accesory belt for the underdrive pulley application)

3. Heavy Duty Loctite

4. ARP crank pulley bolt (damn thing was 28 bucks)

5. Timing cover replacement gasket kit from felpro

If anyone has any tips or gained experience for removal of the pulley and timing cover and re installation I would really appreciate it.. Thanks guys

I bought the following items:

1. Summit 25% underdriven crank pulley2. both belts (AC and the accesory belt for the underdrive pulley application)

3. Heavy Duty Loctite

4. ARP crank pulley bolt (damn thing was 28 bucks)

5. Timing cover replacement gasket kit from felpro

If anyone has any tips or gained experience for removal of the pulley and timing cover and re installation I would really appreciate it.. Thanks guys

The Summit pulley has a keyway. ATI is the pinning method that is best and is made to use the keyway slot in the new pulley’s hub.

Use red lock-tight on that ARP bolt and torque it down to 240 ft lbs AFTER the balancer is properly seated.

#18

You dont need to pin it unless you have supercharger running off the pulley, If you use the old bolt to install the pulley and tighen up hard, then take it out and install the new bolt. Put locktight on the threads. Inspect the end of the crank nose well, You also torque it then you have to use the torque turn method.

#19

Tech Contributor

Member Since: May 2008

Location: Howell Michigan

Posts: 2,844

Likes: 0

Received 15 Likes

on

15 Posts

St. Jude Donor '09-'10-'11

I learned something new last week.  You can teach an old dog a new trick now and then.

You can teach an old dog a new trick now and then. To help reduce the risk of the harmonic balancer rotating, pining might be the best choice. Short of pinning, there is a diamond powered washer that comes standard on the LS2, LS3, LS7 and LS9 even though it is keyed as well. It is part number 12600525 that fits between the balancer and the oil pump drive. The washer allow the joint to withstand higher torsional loads.

To help reduce the risk of the harmonic balancer rotating, pining might be the best choice. Short of pinning, there is a diamond powered washer that comes standard on the LS2, LS3, LS7 and LS9 even though it is keyed as well. It is part number 12600525 that fits between the balancer and the oil pump drive. The washer allow the joint to withstand higher torsional loads.

You can teach an old dog a new trick now and then.

You can teach an old dog a new trick now and then. To help reduce the risk of the harmonic balancer rotating, pining might be the best choice. Short of pinning, there is a diamond powered washer that comes standard on the LS2, LS3, LS7 and LS9 even though it is keyed as well. It is part number 12600525 that fits between the balancer and the oil pump drive. The washer allow the joint to withstand higher torsional loads.

To help reduce the risk of the harmonic balancer rotating, pining might be the best choice. Short of pinning, there is a diamond powered washer that comes standard on the LS2, LS3, LS7 and LS9 even though it is keyed as well. It is part number 12600525 that fits between the balancer and the oil pump drive. The washer allow the joint to withstand higher torsional loads.

Last edited by Eric D; 09-24-2009 at 02:32 PM. Reason: can't spell today!!

#20

Team Owner

Why in the world is everyone recommending loctite? The last time I spoke to ARP engineering, they told me that I wouldn't believe how many people call up complaining that they have broken bolts using loctite when trying to remove. ARP doesn't recommend using Loctite on this bolt. Do so at your own risk.

The OP spun the hub on the crank. If it has lost any of the interference capability then pinning the crank is good insurance.

The OP spun the hub on the crank. If it has lost any of the interference capability then pinning the crank is good insurance.