1988 coupe keeps cutting out

#1

I've owned my car for over 20 years and haven't had any complaints up until this last year and aside from the regular replacements - fuel pump, steering rack, plugs, belts, alternator...etc. it's been great.

Last year I started experiencing some hesitation when pushing on the gas and it just spiraled from there. After spending most of the summer at the mechanics (ouch!) it's still a mystery and no better. Replaced a pile of things including my mass air flow, plugs, several leaks...on and on...and nothing if not worse. Happens mostly in the a.m. but can be anytime I've stopped at a light then press on the gas - sometimes it's there, sometimes it sputters until it kicks in. A real pain.

The only thing I've read that may make sense at this point is my K&N air filter that I installed shortly before putting it away 2 years ago. Have heard they may cause issues. Open to any suggestions or thoughts...desperate actually since I'm at my limit with this car and can't even sell it while it's not running right!

Last year I started experiencing some hesitation when pushing on the gas and it just spiraled from there. After spending most of the summer at the mechanics (ouch!) it's still a mystery and no better. Replaced a pile of things including my mass air flow, plugs, several leaks...on and on...and nothing if not worse. Happens mostly in the a.m. but can be anytime I've stopped at a light then press on the gas - sometimes it's there, sometimes it sputters until it kicks in. A real pain.

The only thing I've read that may make sense at this point is my K&N air filter that I installed shortly before putting it away 2 years ago. Have heard they may cause issues. Open to any suggestions or thoughts...desperate actually since I'm at my limit with this car and can't even sell it while it's not running right!

#2

Instructor

Check your TPS - Throttle Position Sensor.

I just got my 88, but was having similar issues - not to the point of stalling out, but rough idle & hesitation as I got on the gas.

I adjusted the TPS this weekend & it made a world of difference.

The setting is supposed to be .54 volts - and while mine wasnt far off at .51 - it made a huge improvement in low throttle response.

I just got my 88, but was having similar issues - not to the point of stalling out, but rough idle & hesitation as I got on the gas.

I adjusted the TPS this weekend & it made a world of difference.

The setting is supposed to be .54 volts - and while mine wasnt far off at .51 - it made a huge improvement in low throttle response.

#3

Drifting

Ohm the injectors, check fuelrail pressure, and pull and inspect all plug wires. Having a scanner capable of watching devices like suggested above is a great help too.

#4

Racer

Check ignition too, pull the cap and inspect the rotor, leads and the wires traveling into the cap for breaks in the wires.

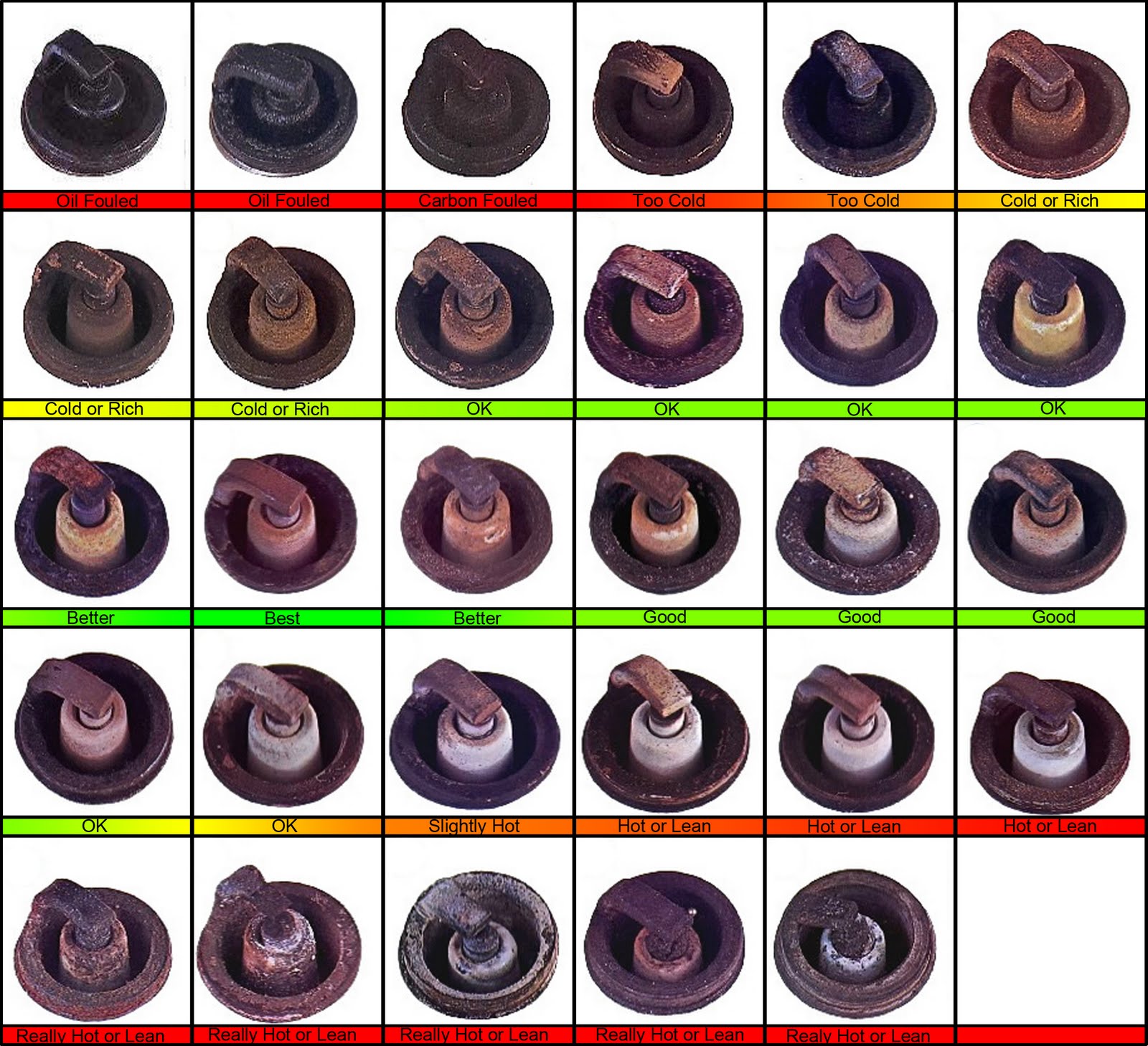

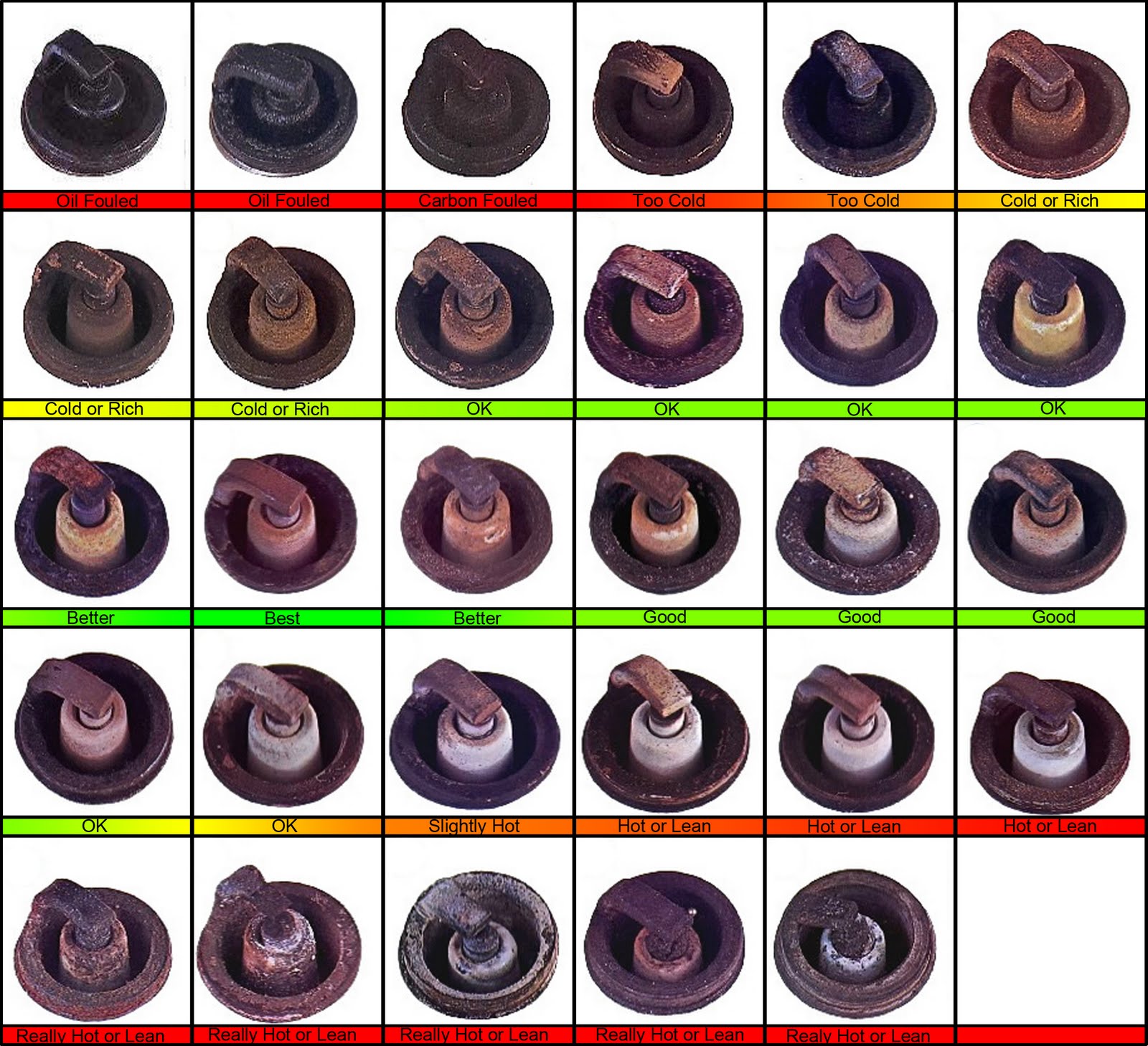

In replacing plugs, you should notice a plug that has more deposit on it then the others, this could indicate a bad valve or a bad injector.

As stated above by MrWilly, Ohm test the injectors, check fuel pressure. After that, check the TPC/IAC.

If you do not have a code reader, try looking for a code stored in the diagnostic log:

http://www.corvettephotographs.com/c4vettes/codes.htm

In replacing plugs, you should notice a plug that has more deposit on it then the others, this could indicate a bad valve or a bad injector.

As stated above by MrWilly, Ohm test the injectors, check fuel pressure. After that, check the TPC/IAC.

If you do not have a code reader, try looking for a code stored in the diagnostic log:

http://www.corvettephotographs.com/c4vettes/codes.htm

#5

Race Director

Many times a hesitation off idle is caused by a vacuum leak. They can be sneaky and in really non-obvious places, like an EGR valve that is stuck in the open position or a vacuum hose that is cracked.

You might have a bad MAF burnoff circuit (most likely the relay, but could be a connector or wiring problem). This can be amplified by the K&N because the MAF wire can get coated with oil from the filter.

You might have a bad MAF burnoff circuit (most likely the relay, but could be a connector or wiring problem). This can be amplified by the K&N because the MAF wire can get coated with oil from the filter.

Last edited by Cliff Harris; 05-06-2014 at 03:39 AM.

#6

Team Owner

Member Since: Dec 2000

Location: SE NY

Posts: 90,675

Likes: 0

Received 300 Likes

on

274 Posts

Cruise-In II Veteran

The setting is supposed to be .54 volts - and while mine wasnt far off at .51 - it made a huge improvement in low throttle response.

I prefer to run the TPS at ~.75 Vdc for a little better throttle response off idle.

#7

Racer

General:

Idle speed and off-idle response on the early TPI systems is determined by correct adjustment of the minimum idle speed screw combined with a correct setting of the TPS. I've seen many of these cars that have had their idle speed "corrected" by well-intentioned mechanice and owners by simply screwing the minimum idle speed screw in a few turns. This really messes up the settings, and will not make your car perform properly. Doing a correct setup of the TPS is one of the easiest ways make your car feel and respond better. To maximize the benefit of this procedure, I recommend that you first remove your Throttle Body (TB), disassemble it (it's incredible easy - there are a total of about 5 pieces in it...), clean the TB up really good with some spray carb cleaner, and put it back together. A nice clean TB will really put an edge on the performance improvement you will get by doing this procedure.

The Service Manual has instructions for doing these operations, but the directions are scattered through several sections of the Manual. Here is the complete, step-by-step process for doing this (not including TB rebuild). All specs and steps are taken directly from the Manual (all 3 different sections), and this process is absolutely correct.

Tools and Equipment

You will need the following tools and equipment:

1. A set of Torx wrenches. You can buy a complete set in a nice, genuine plastic pouch at Sears

2. A good digital voltmeter that will read voltages less than 1 volt

3. A paper clip

4. A small screwdriver

Procedure

There are two electrical components on the TB that you will be working with: The TPS and the Idle Air Control Valve (IAC). Make sure that the connectors for these two components are easily accessible and that you can easily disconnect the IAC. You will also be playing with the diagnostic connector under the dash. Remove the cover (if it’s still in place). Bend your paper clip into a “u” shape. You will be playing with the two top right hand terminals (“A” to “B”) in the connector.

1. First step is to set the minimum idle speed. If nobody has messed with this on your car before, the set screw will be covered by a pressed-in plug. It’s located on the driver’s side of the TB. Remove this plug if it’s there.

2. With the IAC connected and the ignition “OFF,” stick the paper clip into the diagnostic connector from “A” to “B.” This grounds the diagnostic lead.

3. Turn the ignition to the “ON” position without starting the engine. Wait 30 seconds.

4. Now, with the ignition still in the “ON” position, disconnect the IAC connector at the IAC.

5. Remove the paper clip from the diagnostic connector.

6. Start the engine and allow it to reach normal operation temperature. The idle speed will probably be really low, and you may have to coax the engine a bit with the gas pedal to keep it running for a while.

7. If your car is an automatic, set the parking brake and put the transmission in “DRIVE.” If your car is a manual, leave it in neutral.

8. Adjust the idle speed screw to obtain 400 rpm in drive or 450 in neutral.

9. Shut off the engine and reconnect the IAC.

That’s it for idle speed. Now on to the TPS.

There are 3 wires stacked vertically on the TPS. You will need to be able to measure the voltage between the two top wires. You can either buy a special harness connector that breaks these wires out (from Min America), or gently pierce the insulation of the wires with the pointy prongs on your volt meter. You can also stick a paper clip into each of the two top locations of the connector and clamp onto the paper clips to measure the voltage. Whatever is easiest for you.

1. Turn the ignition to the “ON” position without starting the engine.

2. Loosen the TPS Torx adjustment screws.

3. Set your volt meter to the low scale DC volt setting that will accurately read less than 1 volt.

4. Measure the voltage between the two top TPS wires.

5. Adjust the TPS by rotating its position until you get a reading of .54 volts.

6. Tighten the Torx screws and recheck the voltage. Readjust if necessary to make sure voltage is right at .54

7. Turn the ignition “OFF.”

#8

Racer

If I am reading the procedure correctly, the pin has been removed from the diagnostic connection upon completing the idle adjustment. This means the idle would be 700 or so rpm's when starting the TPS adjustment.