87 Corvette Brake Failure

#42

Pro

Thread Starter

Nice looking RAS and I like the 12-inch blade -- my little 10-inch barely gets through a 4"x4".

Race Prepared: Your comment made me go back and add up the receipts. I hate doing that but it looks like I've spent around $1,100 on parts and another $155 on tools. My projects are escalating in price. I think my exhaust system on the 72 is about $1,000 in parts and another $1,500 in tools (MIG and TIG welders add up). Maybe I should just spend $51,000 on a new C7 and get rid of these two old Vettes. Then what would I do with all my free time....

RossyHusker: I appreciate the compliment. I like working on my cars and the documentation others have provided has helped me so many times I feel obligated to pay it forward. Hopefully something I've shown or done will help another forum member.

#43

Pro

Thread Starter

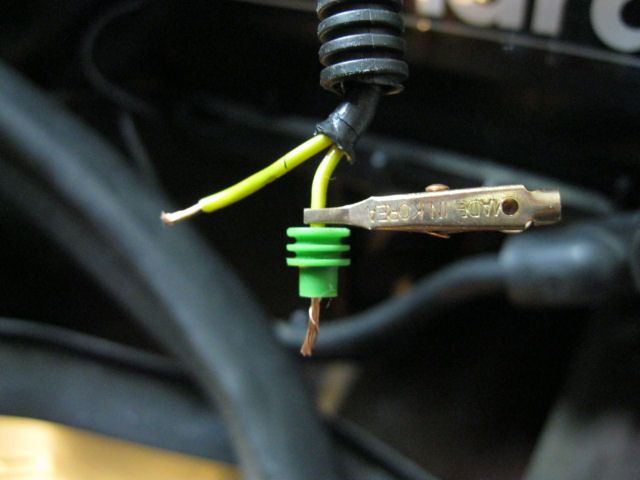

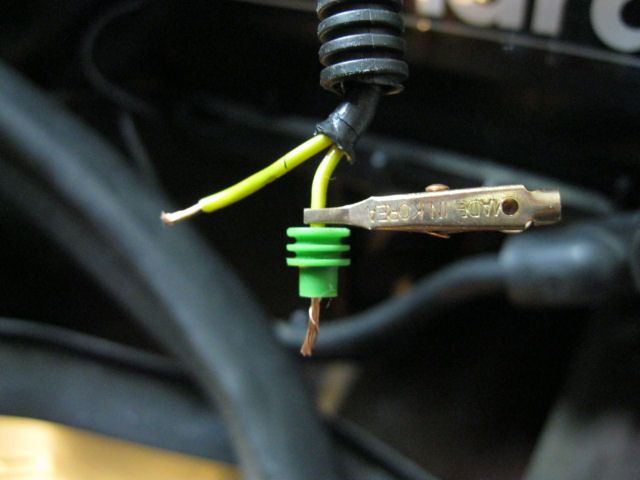

I was able to install the final four terminals without too much drama. Because of my earlier experience pushing the insulation too far into the terminal, I dug up a tool to help with the seal alignment. It’s a miniature alligator clip left over from another project. It holds onto the wire pretty tightly but has no teeth to puncture the insulation. This is both good and bad. Good that I had the leftover clip but bad that it reinforces my hoarding tendencies.

I have some 1” diameter shrink tubing that covers the weatherpack connectors and I gave them a trial fit. I routed the wire under the car and made up the connections and I’m having second thoughts about hitting these giant tubes with the heat gun. The ends will be open and water is sure to get in there, held in place right at the weatherpack connection. I’ll save the pieces just in case I end up needing to do something about the somewhat exposed connectors. Two more pieces to add to my hoard...

With the wiring out of the way I re-installed the steering shaft. There should be a better name for the coupler since the joint no longer has any rag or fabric in it. Before I removed it the steering shaft a while back I used a center-punch to put three small marks in in the shafts on both sides of the rag joint coupling. I could see myself re-attaching it 180-degrees out of alignment. I would, of course, remove the steering wheel, turn it 180-degrees and re-mount it. I would then be shocked that the turn signal no longer cancels normally or some other such nonsense.

I couldn’t put the dull aluminum shaft with a rusty steel column clamp back in so I spent a few minutes at the buffer, followed by a few moments with a rattle can. Few will ever see the inside of the engine compartment but I just can’t help myself.

The driver side rear was next. I checked my rubber hose supply and found several pieces of ľ” hose. Unfortunately none of the pieces appeared to be fuel line so I improvised. Someone is going to laugh their *** off when they see my stupid little piece of braided line clamped to the vent line.

Put the shock and sway bar back on, with a little Loctite on the bolts. I think I’m done dropping the ABS lower cover so I re-connected the e-brake cable system. I then started the tightening process on all the brake line fittings in this corner.

Before moving to the passenger side, I tightened all the fittings on the ABS Unit, made up the electrical connections and clamped down the main harness.

I repeated the process on the passenger side rear, followed by a re-check of the driver side and then one more time on the passenger side. I know I’m going to have a leak but I’m hoping it will only be one or two out of the 20 connections.

4 – Caliper fittings

4 – Flex line fittings

3 – Rear T-fitting

5 – ABS fittings

2 – Front crossover line fittings

2 – Master cylinder line fittings

A little work up front and it should be time to bleed this puppy.

I have some 1” diameter shrink tubing that covers the weatherpack connectors and I gave them a trial fit. I routed the wire under the car and made up the connections and I’m having second thoughts about hitting these giant tubes with the heat gun. The ends will be open and water is sure to get in there, held in place right at the weatherpack connection. I’ll save the pieces just in case I end up needing to do something about the somewhat exposed connectors. Two more pieces to add to my hoard...

With the wiring out of the way I re-installed the steering shaft. There should be a better name for the coupler since the joint no longer has any rag or fabric in it. Before I removed it the steering shaft a while back I used a center-punch to put three small marks in in the shafts on both sides of the rag joint coupling. I could see myself re-attaching it 180-degrees out of alignment. I would, of course, remove the steering wheel, turn it 180-degrees and re-mount it. I would then be shocked that the turn signal no longer cancels normally or some other such nonsense.

I couldn’t put the dull aluminum shaft with a rusty steel column clamp back in so I spent a few minutes at the buffer, followed by a few moments with a rattle can. Few will ever see the inside of the engine compartment but I just can’t help myself.

The driver side rear was next. I checked my rubber hose supply and found several pieces of ľ” hose. Unfortunately none of the pieces appeared to be fuel line so I improvised. Someone is going to laugh their *** off when they see my stupid little piece of braided line clamped to the vent line.

Put the shock and sway bar back on, with a little Loctite on the bolts. I think I’m done dropping the ABS lower cover so I re-connected the e-brake cable system. I then started the tightening process on all the brake line fittings in this corner.

Before moving to the passenger side, I tightened all the fittings on the ABS Unit, made up the electrical connections and clamped down the main harness.

I repeated the process on the passenger side rear, followed by a re-check of the driver side and then one more time on the passenger side. I know I’m going to have a leak but I’m hoping it will only be one or two out of the 20 connections.

4 – Caliper fittings

4 – Flex line fittings

3 – Rear T-fitting

5 – ABS fittings

2 – Front crossover line fittings

2 – Master cylinder line fittings

A little work up front and it should be time to bleed this puppy.

Last edited by Bob Heine; 02-06-2014 at 01:29 PM. Reason: Inability to Count

#44

Race Director

I was looking at a used sensor assembly and I have concluded that the wires are NOT covered by sleeving but rather are embedded in rubber that is molded onto the wires (I wonder how they do that). The rubber gets old, hard and brittle and crumbles into chunks. I would think Bosch could do better than that, but it is what it is. I've been trying to figure out a way to somehow mold/coat the wires with RTV, which will stay flexible and will resist the heat. My car is strictly street driven now so I assume the heat isn't as intense as it was when I was racing...

#45

Burning Brakes

Member Since: Jul 2009

Location: Ashland PA

Posts: 1,247

Received 95 Likes

on

80 Posts

2021 C4 of the Year - Modified Finalist

I'm currently looking at replacing my ABS sensor connectors (they're in multiple pieces right now). I've bought some used sensors just to get the connectors. I'm planning on a visit to a BMW or Mercedes Benz dealer to see if the parts guys recognize these connectors.

I was looking at a used sensor assembly and I have concluded that the wires are NOT covered by sleeving but rather are embedded in rubber that is molded onto the wires (I wonder how they do that). The rubber gets old, hard and brittle and crumbles into chunks. I would think Bosch could do better than that, but it is what it is. I've been trying to figure out a way to somehow mold/coat the wires with RTV, which will stay flexible and will resist the heat. My car is strictly street driven now so I assume the heat isn't as intense as it was when I was racing...

I was looking at a used sensor assembly and I have concluded that the wires are NOT covered by sleeving but rather are embedded in rubber that is molded onto the wires (I wonder how they do that). The rubber gets old, hard and brittle and crumbles into chunks. I would think Bosch could do better than that, but it is what it is. I've been trying to figure out a way to somehow mold/coat the wires with RTV, which will stay flexible and will resist the heat. My car is strictly street driven now so I assume the heat isn't as intense as it was when I was racing...

Last edited by eutu1984; 04-12-2014 at 12:33 PM.

#46

Burning Brakes

Bob, Thank you for the fantastic write-up and pictures. You did an excellent job on the car, and also presenting it on this forum.

One thing you forgot though....

One thing you forgot though....

#47

Pro

Thread Starter

I'm currently looking at replacing my ABS sensor connectors (they're in multiple pieces right now). I've bought some used sensors just to get the connectors. I'm planning on a visit to a BMW or Mercedes Benz dealer to see if the parts guys recognize these connectors.

I was looking at a used sensor assembly and I have concluded that the wires are NOT covered by sleeving but rather are embedded in rubber that is molded onto the wires (I wonder how they do that). The rubber gets old, hard and brittle and crumbles into chunks. I would think Bosch could do better than that, but it is what it is. I've been trying to figure out a way to somehow mold/coat the wires with RTV, which will stay flexible and will resist the heat. My car is strictly street driven now so I assume the heat isn't as intense as it was when I was racing...

I was looking at a used sensor assembly and I have concluded that the wires are NOT covered by sleeving but rather are embedded in rubber that is molded onto the wires (I wonder how they do that). The rubber gets old, hard and brittle and crumbles into chunks. I would think Bosch could do better than that, but it is what it is. I've been trying to figure out a way to somehow mold/coat the wires with RTV, which will stay flexible and will resist the heat. My car is strictly street driven now so I assume the heat isn't as intense as it was when I was racing...

I found new front sensor cables at Rock Auto but for around $100 each for the ones with no o-ring and $120 for the ones with o-rings.

Almost sprang for them but couldn't find the harness cable to mate up to it so I gave up and used the weatherpack connectors. I came across quite a few used sensor cables in worse shape than mine and they are asking $25 and up. None of them had intact original connectors. If you find those connectors, please let us know.

Sounds like a good solution. The insulation on the wires isn't the best either, but the silicone should give them some protection.

Thanks for the positive feedback. It's funny you mention the line lock because I was thinking of adding one. In my younger days I laughed at the old guys driving Corvettes and as I hit 70 later this year I realize I is one of them. Three of my grandchildren are over 20 and they would have a field day if I got a ticket for doing burnouts. The other six younger ones would probably love it but have no idea what is going on with the tires spinning and the car going nowhere.

#48

Race Director

Just a suggestion for shrink tubing, try the marine shrink tubing as it contains a glue that when you heat it it melts to seal the tubing to the wire..

#49

Race Director

I did some searching online and found that BMW ABS sensors use the same connectors. I also found some European truck ABS sensors with those connectors, so they seem to be fairly common.

I did a lot of searching for Bosch connectors but couldn't find any like the ones on the ABS sensors. It occurred to me that they might be made by Siemens. Haven't looked into that yet.

I was looking at a Corvette ABS sensor I just bought on eBay. It almost looks like the connector was molded on. From what I could tell, it appears that these connectors are similar to the Bosch fuel injector connectors. You have to put the wire through the connector shell from the back and then crimp on the pin. Then you pull the wire and pin back into the connector shell. Stupid design in my opinion because you can't pull the wires and pins out the back of the connector shell and replace just the shell. You have to cut off the pins to get the wires out of the shell. Even breaking the old shell doesn't help because the pins go in from the front of the new connector shell, so the pins have to come off the wires to get the wires into the shell. The only redeeming feature of this design is that you can't accidentally push the pins out of the shell when plugging in the connector.

I did find these ABS sensors manufactured by Raybestos (I don't remember where -- I think it was on O'Reilly's web site):

ABS530017 - Left front, without O-ring

ABS530018 - Right front, without O-ring

ABS530019 - Left front

ABS530020 - Right front

I did a lot of searching for Bosch connectors but couldn't find any like the ones on the ABS sensors. It occurred to me that they might be made by Siemens. Haven't looked into that yet.

I was looking at a Corvette ABS sensor I just bought on eBay. It almost looks like the connector was molded on. From what I could tell, it appears that these connectors are similar to the Bosch fuel injector connectors. You have to put the wire through the connector shell from the back and then crimp on the pin. Then you pull the wire and pin back into the connector shell. Stupid design in my opinion because you can't pull the wires and pins out the back of the connector shell and replace just the shell. You have to cut off the pins to get the wires out of the shell. Even breaking the old shell doesn't help because the pins go in from the front of the new connector shell, so the pins have to come off the wires to get the wires into the shell. The only redeeming feature of this design is that you can't accidentally push the pins out of the shell when plugging in the connector.

I did find these ABS sensors manufactured by Raybestos (I don't remember where -- I think it was on O'Reilly's web site):

ABS530017 - Left front, without O-ring

ABS530018 - Right front, without O-ring

ABS530019 - Left front

ABS530020 - Right front

Last edited by Cliff Harris; 01-07-2016 at 02:25 AM. Reason: Added missing word.

#50

Pro

Thread Starter

Thanks for that advice. I didn't know that was available so I did some searching. Most of the sites had short pieces (3"and 6") but I did find bulk (4-foot) adhesive shrink tubing at Buy Heat Shrink (http://www.buyheatshrink.com/).

I did some searching online and found that BMW ABS sensors use the same connectors. I also found some European truck ABS sensors with those connectors, so they seem to be fairly common.

I did a lot of searching for Bosch connectors but couldn't find any like the ones on the ABS sensors. It occurred to me that they might be made by Siemens. Haven't looked into that yet.

I was looking at a Corvette ABS sensor I just bought on eBay. It almost looks like the connector was molded on. From what I could tell, it appears that these connectors are similar to the Bosch fuel injector connectors. You have to put the wire through the connector shell from the back and then crimp on the pin. Then you pull the wire and pin back into the connector shell. Stupid design in my opinion because you can't pull the wires and pins out the back of the connector shell and replace just the shell. You have to cut off the pins to get the wires out of the shell. Even breaking the old shell doesn't help because the pins go in from the front of the new connector shell, so the pins have to off the wires to get the wires into the shell. The only redeeming feature of this design is that you can't accidentally push the pins out of the shell when plugging in the connector.

I did find these ABS sensors manufactured by Raybestos (I don't remember where -- I think it was on O'Reilly's web site):

ABS530017 - Left front, without O-ring

ABS530018 - Right front, without O-ring

ABS530019 - Left front

ABS530020 - Right front

I did a lot of searching for Bosch connectors but couldn't find any like the ones on the ABS sensors. It occurred to me that they might be made by Siemens. Haven't looked into that yet.

I was looking at a Corvette ABS sensor I just bought on eBay. It almost looks like the connector was molded on. From what I could tell, it appears that these connectors are similar to the Bosch fuel injector connectors. You have to put the wire through the connector shell from the back and then crimp on the pin. Then you pull the wire and pin back into the connector shell. Stupid design in my opinion because you can't pull the wires and pins out the back of the connector shell and replace just the shell. You have to cut off the pins to get the wires out of the shell. Even breaking the old shell doesn't help because the pins go in from the front of the new connector shell, so the pins have to off the wires to get the wires into the shell. The only redeeming feature of this design is that you can't accidentally push the pins out of the shell when plugging in the connector.

I did find these ABS sensors manufactured by Raybestos (I don't remember where -- I think it was on O'Reilly's web site):

ABS530017 - Left front, without O-ring

ABS530018 - Right front, without O-ring

ABS530019 - Left front

ABS530020 - Right front

Those are the part numbers I found at Rock Auto. Since I looked at 1:00 this morning the first two items have disappeared but the front O-ring ones are still there, along with this Wagner one:

AB130653 {#F130653} - Rear left (no mention of O-ring)

#51

Pro

Thread Starter

Sorry about the two month delay in posting the final steps in the process. I left off with Ďjustí needing to bleed the brakes.

I did find four fittings that needed a little extra tightening (expected that with stainless lines). I checked for leaks by putting sheets of newspaper under the car at all four corners. Two of the leaks were in the rear of the car and were just a drop or two. The other two were the master cylinder fittings (I was being gentle when I tightened those).

Once the fittings were tightened I wiped off the brake fluid, replaced the newspaper and pumped the brakes a few times. Everything was sealed up and there were no leaks. I left it overnight and there were still no leaks in the morning.

I have a few tools for bleeding brakes:

1. Vacuum hose and olive jar.

2. Harbor Freight brake bleeder and vacuum pump kit.

3. Motive pressure bleeder.

4. Old old metal tank pressure bleeder.

I decided to skip the first option and pull the brake fluid though the lines using the HF vacuum pump.

It worked fine on the front brakes, which have new calipers. When I started the process on the rear brakes things did not go well. I was rushing so I pumped the tool hard and fast giving me 10 inches of vacuum and lots of air coming out. I refilled the reservoir and sucked air from the second side. After I re-filled the reservoir again, I pumped the brake pedal with the engine off and then with the engine running. When I maintained pressure on the brake pedal, it was slowly going to the floorÖ.

I checked the rear brakes and there were big puddles of brake fluid on the fresh newspaper under both rear calipers. It was coming from the calipers themselves. These are the original calipers with new seals from 2008. Obviously there is something wrong with both of them. I thought about rebuilding them but decided to replace them.

After the new calipers arrived, I gave them a quick polish and swapped them into the car. I hooked up the Motive pressure bleeder, added a fresh quart of DOT 3&4 synthetic fluid into the tank and pumped the tank to about 5 psi. After a few cycles on each rear caliper there was no fluid leak and the brake pedal was solid.

I decided to do a postmortem on the old rear calipers. When I removed the caliper piston, I could see no obvious failure but there was a deposit on the piston that looked like the seal had left something behind. When I removed the O-ring seal, there was some aluminum corrosion in the caliper bore under the seal.

Iím no expert and this is the only C4 Iíve done brake work on so I could be completely off base. I think the 10-inches of vacuum I created with the vacuum pump pulled the piston seal to the back of the O-ring bore. When I then pumped the brakes the pressure pushed the seals back toward the front of the bore and the corrosion or crud in that bore prevented the O-ring from sealing properly.

I chose to use the vacuum pump first because the last time I used the Motive pressure bleeder, the adapter loosened up during the bleeding process (I think the chain was twisted and popped loose) and I ended up with a big section of paint removed from the frame. The vacuum pump bleeder worked on the new front calipers but didnít work on the old rear calipers. My conclusion is that the Motive bleeder does a better job overall and I would avoid using the vacuum pump if you are just flushing old fluid from your brake system. If you do use the vacuum pump, take it slow and gentle. Seeing how much vacuum you can pull might just backfire.

Iím calling it done. The brakes are working better than ever. The car seems to do a 4-wheel squat rather than a nose dive when I brake. The car also starts instantly and runs a little smoother (that little piece of vacuum hose I replaced might be responsible). The only glitch is the ABS light in the message panel is now on. Iím going to take the car out on a rainy day and see if I can set the ABS off. Thatís how I reset it last time. If not, I have two known good relays I can swap into the ABS unit.

I did find four fittings that needed a little extra tightening (expected that with stainless lines). I checked for leaks by putting sheets of newspaper under the car at all four corners. Two of the leaks were in the rear of the car and were just a drop or two. The other two were the master cylinder fittings (I was being gentle when I tightened those).

Once the fittings were tightened I wiped off the brake fluid, replaced the newspaper and pumped the brakes a few times. Everything was sealed up and there were no leaks. I left it overnight and there were still no leaks in the morning.

I have a few tools for bleeding brakes:

1. Vacuum hose and olive jar.

2. Harbor Freight brake bleeder and vacuum pump kit.

3. Motive pressure bleeder.

4. Old old metal tank pressure bleeder.

I decided to skip the first option and pull the brake fluid though the lines using the HF vacuum pump.

It worked fine on the front brakes, which have new calipers. When I started the process on the rear brakes things did not go well. I was rushing so I pumped the tool hard and fast giving me 10 inches of vacuum and lots of air coming out. I refilled the reservoir and sucked air from the second side. After I re-filled the reservoir again, I pumped the brake pedal with the engine off and then with the engine running. When I maintained pressure on the brake pedal, it was slowly going to the floorÖ.

I checked the rear brakes and there were big puddles of brake fluid on the fresh newspaper under both rear calipers. It was coming from the calipers themselves. These are the original calipers with new seals from 2008. Obviously there is something wrong with both of them. I thought about rebuilding them but decided to replace them.

After the new calipers arrived, I gave them a quick polish and swapped them into the car. I hooked up the Motive pressure bleeder, added a fresh quart of DOT 3&4 synthetic fluid into the tank and pumped the tank to about 5 psi. After a few cycles on each rear caliper there was no fluid leak and the brake pedal was solid.

I decided to do a postmortem on the old rear calipers. When I removed the caliper piston, I could see no obvious failure but there was a deposit on the piston that looked like the seal had left something behind. When I removed the O-ring seal, there was some aluminum corrosion in the caliper bore under the seal.

Iím no expert and this is the only C4 Iíve done brake work on so I could be completely off base. I think the 10-inches of vacuum I created with the vacuum pump pulled the piston seal to the back of the O-ring bore. When I then pumped the brakes the pressure pushed the seals back toward the front of the bore and the corrosion or crud in that bore prevented the O-ring from sealing properly.

I chose to use the vacuum pump first because the last time I used the Motive pressure bleeder, the adapter loosened up during the bleeding process (I think the chain was twisted and popped loose) and I ended up with a big section of paint removed from the frame. The vacuum pump bleeder worked on the new front calipers but didnít work on the old rear calipers. My conclusion is that the Motive bleeder does a better job overall and I would avoid using the vacuum pump if you are just flushing old fluid from your brake system. If you do use the vacuum pump, take it slow and gentle. Seeing how much vacuum you can pull might just backfire.

Iím calling it done. The brakes are working better than ever. The car seems to do a 4-wheel squat rather than a nose dive when I brake. The car also starts instantly and runs a little smoother (that little piece of vacuum hose I replaced might be responsible). The only glitch is the ABS light in the message panel is now on. Iím going to take the car out on a rainy day and see if I can set the ABS off. Thatís how I reset it last time. If not, I have two known good relays I can swap into the ABS unit.

#52

Race Director

I bought a used ABS sensor from eBay. I thought this one would really help me out because it came with both connectors and the retainer/mounting bracket (wrong!):

As you can see the rubber coating is completely gone on the sensor side. The retainer is locked on and there doesn't seem to be enough movement to allow it to "unhook". More investigation is required there.

I have been doing some research on the Bimmer forums because '80s BMWs use the same style ABS sensors with the same connectors. They have exactly the same problems we do -- the connectors just fall apart for no apparent reason. Age, I guess.

Now here is where it gets weird. The '90s BMWs use a different style of connector, which is blue. IT HAS EXACTLY THE SAME PROBLEMS. Namely, being very brittle and falling to pieces when you try to take it apart. They have another problem, because BMWs use the right rear ABS sensor for their speedometer so they see it right away when it goes bad.

I wanted to keep my car "stock" so that there would be no problems with interchanging parts. I have decided, based on the above, that it's hopeless and the only way to get a reliable connection is to switch to the weatherpack connectors as described in posts #30, #36 and #37.

As you can see the rubber coating is completely gone on the sensor side. The retainer is locked on and there doesn't seem to be enough movement to allow it to "unhook". More investigation is required there.

I have been doing some research on the Bimmer forums because '80s BMWs use the same style ABS sensors with the same connectors. They have exactly the same problems we do -- the connectors just fall apart for no apparent reason. Age, I guess.

Now here is where it gets weird. The '90s BMWs use a different style of connector, which is blue. IT HAS EXACTLY THE SAME PROBLEMS. Namely, being very brittle and falling to pieces when you try to take it apart. They have another problem, because BMWs use the right rear ABS sensor for their speedometer so they see it right away when it goes bad.

I wanted to keep my car "stock" so that there would be no problems with interchanging parts. I have decided, based on the above, that it's hopeless and the only way to get a reliable connection is to switch to the weatherpack connectors as described in posts #30, #36 and #37.

Last edited by Cliff Harris; 04-24-2014 at 11:55 PM.

#53

Pro

Thread Starter

I have been doing some research on the Bimmer forums because '80s BMWs use the same style ABS sensors with the same connectors. They have exactly the same problems we do -- the connectors just fall apart for no apparent reason. Age, I guess.

Now here is where it gets weird. The '90s BMWs use a different style of connector, which is blue. IT HAS EXACTLY THE SAME PROBLEMS. Namely, being very brittle and falling to pieces when you try to take it apart. They have another problem, because BMWs use the right rear ABS sensor for their speedometer so they see it right away when it goes bad.

I wanted to keep my car "stock" so that there would be no problems with interchanging parts. I have decided, based on the above, that it's hopeless and the only way to get a reliable connection is to switch to the weatherpack connectors as described in posts #30, #36 and #37.

Now here is where it gets weird. The '90s BMWs use a different style of connector, which is blue. IT HAS EXACTLY THE SAME PROBLEMS. Namely, being very brittle and falling to pieces when you try to take it apart. They have another problem, because BMWs use the right rear ABS sensor for their speedometer so they see it right away when it goes bad.

I wanted to keep my car "stock" so that there would be no problems with interchanging parts. I have decided, based on the above, that it's hopeless and the only way to get a reliable connection is to switch to the weatherpack connectors as described in posts #30, #36 and #37.

I almost spent the $200+ on new sensor cable assemblies but realized they wouldn't have anything to connect to when the mating cable connectors crumbled to dust as well.

Thanks for the information. I don't understand the thought process that led to this design. Even brand new these connector housings require you to cut the cable or unsolder the terminal just to take them apart. Then they select a cable cover that disintegrates in less than 20 years. At least the connector material holds up for a year or two longer. The aftermarket suppliers seem to have given up as well. You'd think a key component like this that sells for a hundred or more dollars would have a fix. The 'hate C4s' crowd has another talking point.