Pressure build up in gas tank---normal?

#42

Advanced

Thread Starter

Whether it changes the pressure build up or not, I still feel my car was worth spending $125 on to allow the evap system to function again.

#43

Le Mans Master

Think of it this way: It takes pressure to move what's in the tank to the Canister. Look at the size of the hose that carries the vapor to the Canister. Look at the size of the hole you've just made by removing the gas gap - whoosh - particularly if it's full of vapors (and usually it is since the tank is empty).

At shut down, evaporation (and pressure), due to heat soak increases. It's one the parameters (heat soak) covered by the Fed Standard. In the old days, particularly in the summer, this led to the malady known as vapor lock. EVAP emissions systems has eliminated it. Of all the emission controls, this is a good one - except for the fact that if you want to fill it to the gas cap these days (2000 and newer) you will: A). Find it incredibly hard to do; and B). Probably ruin it if you make a habit of doing so because the design now sends vapors to the canister as you fill it up - the canister is meant for vapors only, not liquid.

Non-operational systems have several symptoms (none of them a whoosh): 1. odor - step away and keep away from any flames or sources of ignition. 2. Dieseling or run on at shutdown. The IAC has been pulled back to allow plenty of air for a restart. Add a little vapor and it'll keep running for a second or two, even without a spark from the spark plug. 3. Hard start. It's only programmed to provide extra fuel from the injectors 4. All of the things that an overly rich mixture does to performance/driveability - fouled plugs, rotten egg exhaust and so on an so forth.

At shut down, evaporation (and pressure), due to heat soak increases. It's one the parameters (heat soak) covered by the Fed Standard. In the old days, particularly in the summer, this led to the malady known as vapor lock. EVAP emissions systems has eliminated it. Of all the emission controls, this is a good one - except for the fact that if you want to fill it to the gas cap these days (2000 and newer) you will: A). Find it incredibly hard to do; and B). Probably ruin it if you make a habit of doing so because the design now sends vapors to the canister as you fill it up - the canister is meant for vapors only, not liquid.

Non-operational systems have several symptoms (none of them a whoosh): 1. odor - step away and keep away from any flames or sources of ignition. 2. Dieseling or run on at shutdown. The IAC has been pulled back to allow plenty of air for a restart. Add a little vapor and it'll keep running for a second or two, even without a spark from the spark plug. 3. Hard start. It's only programmed to provide extra fuel from the injectors 4. All of the things that an overly rich mixture does to performance/driveability - fouled plugs, rotten egg exhaust and so on an so forth.

#44

Race Director

That's the whole point of the charcoal canister -- it collects and filters the fuel vapors so they DON'T get vented to the atmosphere.

#45

Race Director

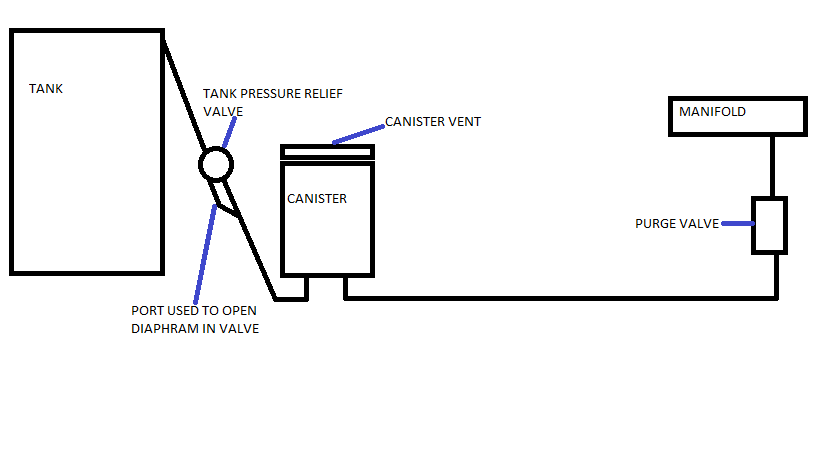

I removed my tank pressure control valve to check it out. It has two large ports, labeled TANK and CAN.

I blew and sucked on the CAN port and got no flow.

I sucked on the TANK port and got no flow.

I blew on the TANK port and the flow started slowly and gradually built up. I got the impression that a diaphragm was opening. I did this several times and the behavior was the same, so apparently there is a spring inside that closes the port.

I applied vacuum to the vacuum port and then the TANK port flowed freely.

I conclude from this that the fuel tank is vented through the charcoal canister, even when the engine is off.

Apparently the system is limited in its flow capacity which means that pressure can build up in the tank. I assume the pressure would gradually diminish if the car is allowed to sit.

I blew and sucked on the CAN port and got no flow.

I sucked on the TANK port and got no flow.

I blew on the TANK port and the flow started slowly and gradually built up. I got the impression that a diaphragm was opening. I did this several times and the behavior was the same, so apparently there is a spring inside that closes the port.

I applied vacuum to the vacuum port and then the TANK port flowed freely.

I conclude from this that the fuel tank is vented through the charcoal canister, even when the engine is off.

Apparently the system is limited in its flow capacity which means that pressure can build up in the tank. I assume the pressure would gradually diminish if the car is allowed to sit.

#46

Le Mans Master

That's pretty much the way it works - there's a small restriction in the tank valve that allows a minute amount to flow to the canister when the engine is off. When the pressure equalizes; ie, after it's sat a bit, nothing goes anywhere (which is what it's going to have to do to pass CA emissions testing - which by the way is now the Fed standard for Evap Emissions). That doesn't mean you won't get a whoosh - even if it's sat overnight - though you may hardly notice it. It all depends on system pressure which is going to be determined by the temperature and volume of the gas. The fact of the matter is that most drive into the station and immediately remove the cap. Heat soak has set in and it's reaching it max evaporatation rate so there's more pressure - all of which is trying to squeeze through that tiny hose through an even smaller restriction in the tank valve (the purge solenoid should have shut off the canister at 25% throttle). Bigger hole - bigger whoosh.

#47

Race Director

On my car (1986) the canister is connected to the intake manifold through the same pipe as the PCV valve, so there's vacuum there all the time the engine is running. You can see that connection on the YDF emission hose diagram that Agent86 posted earlier in this thread.

I know that later cars have the canister connected to the ported vacuum port on the throttle body, but I don't know when that change was made.

I know that later cars have the canister connected to the ported vacuum port on the throttle body, but I don't know when that change was made.

#48

Advanced

Thread Starter

I know with my evap there was no way the engine vacuum was going to aid in removing any pressure from the tank, the plastic tube and rubber hoses were packed full of charcoal. I would guess there was at least 6 feet of blockage.

#49

Race Director

Member Since: Jan 2003

Location: Summerland B.C. Canada

Posts: 19,667

Likes: 0

Received 36 Likes

on

32 Posts

the Pressure Relief or Tank Valve or whatever you want to call it only bleeds a minute amount of vapor to the canister when it's off. There's a very small restriction that allows this - but it reduces pressure flowing to the canister, it doesn't reduce pressure at the tank. at least not as long as there's gasoline in it and it's cooking up vapors. Pressure at the source remains proportional to temperature and volume.

I don't get what the big deal is. If you live in CA where gas hot water heaters are common to every garage, why in the world would you want gasoline vapors venting from your gas tank??? If that's the case with your car, please park it in the street and stay away from my house!

Since there is some confusion in the other thread about gas tank venting I thought I would bump this to the top. You need only turn your gas cap over and look at the valve there to know it's vented.

--------

Motor vehicles are subjected to wide variations in temperature and air pressure, both while in use and when parked. Elevated temperatures and reduced air pressures, in particular, result in the generation of hydrocarbon vapors within the vapor space of the vehicle's fuel tank. Modern motor vehicles include a gas cap adapted to seal the open end of the tank filler neck, to prevent atmospheric venting of these polluting vapors. Such vehicles also are equipped with a charcoal canister, having an inlet interconnected to the vapor space in the upper portion of the fuel tank, by means of a vapor vent line. The outlet of the canister is interconnected to the engine's air/fuel intake system, such as the intake manifold, or the like.

The function of the charcoal canister is to absorb excessive gasoline vapors generated during high temperature and/or low ambient pressure conditions, while simultaneously avoiding a dangerous vapor pressure buildup in the fuel tank. Thus, in a proper functioning evaporative system, when pressure in the vapor space exceeds atmospheric pressure, fuel vapors migrate through the vapor vent line into the vehicle's canister, where the hydrocarbons are absorbed by the charcoal. If vapor pressure is sufficient, the filtered vapor is safely exhausted to the atmosphere through an air vent in bottom of the canister.

Then, during driving, the vacuum existing in the intake manifold draws fresh air in through the same vent, vaporizing the hydrocarbons. The gas vapor is drawn by vacuum through the purge line, and introduced into the intake manifold for combustion. In this manner, the gasoline is fully utilized, and the charcoal canister is fully purged of vapors, restoring its hydrocarbon storage capacity for the next cycle.

If the charcoal canister is not regularly purged while the vehicle is driven, the charcoal will eventually become saturated and the trapped hydrocarbons will escape directly into the atmosphere through the canister's air vent. When this occurs, the major advantages provided by the evaporative system are defeated. The negative environmental impact of uncontrolled vapor discharge through the canister rivals that of the vehicle's exhaust emissions. Moreover, this vapor emission also decreases the overall fuel economy of the vehicle, by venting hydrocarbons which would otherwise be burned in the engine. Consequently, proper purging of the canister has significance both for the environment and for the conservation of energy.

In recognition of these facts, the Federal Environmental Agency (EPA), has mandated the testing of this canister purging function, in the context of a more comprehensive vehicle inspection and maintenance testing procedure, known as the "I/M 240" test. In the course of this 240 second test, a vehicle is put through a predetermined driving cycle on a dynamometer, simulating vehicle performance at various speeds and during acceleration/deceleration conditions. While being so tested, the purge line leading from the canister to the engine is constantly monitored, using a sensor and a recording instrument. This confirms that at some point during the predetermined driving test cycle, an adequate purging event has occurred.

---------

Vented Gas Cap Function

# The vented gas cap is designed to vent small amounts of air into the car gas tank line. The vented gas cap has a one-way release valve that is pressure-activated. When the pressure reaches a certain point (defined by so many pounds per square inch) the valve opens by a very small amount, relieving some of the pressure. In this case, the pressure is formed on the outside of the tank, due to the vacuum formed from the displacement of fuel on the inside. After the pressure inside the line equalizes, the pressure valve closes. The valve is set to balance the pressure with the surrounding atmosphere. Air is allowed in, but no fumes are allowed out of the gas cap, because of environmental concerns.

Inner Parts

# The vented gas cap has a chamber under the plastic cap handle that inserts into the fuel fill line. The cap screws shut, and this chamber fits relatively close inside the intake tube of the fuel line running to the tank. On each side of the chamber are small openings where air is able to enter. These chambers lead to the pressure valve, which, as the level in the tank decreases, allows air inside to remove any possibility of a vacuum forming.

---------

Fuel cap venting

Actual fuel cap venting is (+/- 1psia) - 1psia = 2"HG vacuum, so your fuel cap will vent at (rounding Barometric pressure to 15psia) 16psia overpressure, also at 14psia under pressure.

When tank is full of fuel, little free-air volume remains between the surface of the fuel and the top of the tank, so any hiss will be small - as fuel level drops, free-air volume above the fuel increases, so the hiss will be greater - this indicates greater volume of air in the tank, not greater pressure or vacuum.

The tank and cap was designed to also maintain ~2"HG vacuum, intended to reduce aerated fuel, which is foaming you cannot see, the bubbles being too small to break threw fuel surface tension - since each bubble below the surface of the fuel is a tiny microcosm of atmospheric pressure, any reduction in BP above the surface will reduce surface tension, allowing the smaller bubbles to break threw, thereby reducing aeration.

The fuel cap should be checked regularly to ensure it meets correct pressure\vacuum venting specs - use a radiator-pressure hand pump or a vacuum hand pump.

--------

Motor vehicles are subjected to wide variations in temperature and air pressure, both while in use and when parked. Elevated temperatures and reduced air pressures, in particular, result in the generation of hydrocarbon vapors within the vapor space of the vehicle's fuel tank. Modern motor vehicles include a gas cap adapted to seal the open end of the tank filler neck, to prevent atmospheric venting of these polluting vapors. Such vehicles also are equipped with a charcoal canister, having an inlet interconnected to the vapor space in the upper portion of the fuel tank, by means of a vapor vent line. The outlet of the canister is interconnected to the engine's air/fuel intake system, such as the intake manifold, or the like.

The function of the charcoal canister is to absorb excessive gasoline vapors generated during high temperature and/or low ambient pressure conditions, while simultaneously avoiding a dangerous vapor pressure buildup in the fuel tank. Thus, in a proper functioning evaporative system, when pressure in the vapor space exceeds atmospheric pressure, fuel vapors migrate through the vapor vent line into the vehicle's canister, where the hydrocarbons are absorbed by the charcoal. If vapor pressure is sufficient, the filtered vapor is safely exhausted to the atmosphere through an air vent in bottom of the canister.

Then, during driving, the vacuum existing in the intake manifold draws fresh air in through the same vent, vaporizing the hydrocarbons. The gas vapor is drawn by vacuum through the purge line, and introduced into the intake manifold for combustion. In this manner, the gasoline is fully utilized, and the charcoal canister is fully purged of vapors, restoring its hydrocarbon storage capacity for the next cycle.

If the charcoal canister is not regularly purged while the vehicle is driven, the charcoal will eventually become saturated and the trapped hydrocarbons will escape directly into the atmosphere through the canister's air vent. When this occurs, the major advantages provided by the evaporative system are defeated. The negative environmental impact of uncontrolled vapor discharge through the canister rivals that of the vehicle's exhaust emissions. Moreover, this vapor emission also decreases the overall fuel economy of the vehicle, by venting hydrocarbons which would otherwise be burned in the engine. Consequently, proper purging of the canister has significance both for the environment and for the conservation of energy.

In recognition of these facts, the Federal Environmental Agency (EPA), has mandated the testing of this canister purging function, in the context of a more comprehensive vehicle inspection and maintenance testing procedure, known as the "I/M 240" test. In the course of this 240 second test, a vehicle is put through a predetermined driving cycle on a dynamometer, simulating vehicle performance at various speeds and during acceleration/deceleration conditions. While being so tested, the purge line leading from the canister to the engine is constantly monitored, using a sensor and a recording instrument. This confirms that at some point during the predetermined driving test cycle, an adequate purging event has occurred.

---------

Vented Gas Cap Function

# The vented gas cap is designed to vent small amounts of air into the car gas tank line. The vented gas cap has a one-way release valve that is pressure-activated. When the pressure reaches a certain point (defined by so many pounds per square inch) the valve opens by a very small amount, relieving some of the pressure. In this case, the pressure is formed on the outside of the tank, due to the vacuum formed from the displacement of fuel on the inside. After the pressure inside the line equalizes, the pressure valve closes. The valve is set to balance the pressure with the surrounding atmosphere. Air is allowed in, but no fumes are allowed out of the gas cap, because of environmental concerns.

Inner Parts

# The vented gas cap has a chamber under the plastic cap handle that inserts into the fuel fill line. The cap screws shut, and this chamber fits relatively close inside the intake tube of the fuel line running to the tank. On each side of the chamber are small openings where air is able to enter. These chambers lead to the pressure valve, which, as the level in the tank decreases, allows air inside to remove any possibility of a vacuum forming.

---------

Fuel cap venting

Actual fuel cap venting is (+/- 1psia) - 1psia = 2"HG vacuum, so your fuel cap will vent at (rounding Barometric pressure to 15psia) 16psia overpressure, also at 14psia under pressure.

When tank is full of fuel, little free-air volume remains between the surface of the fuel and the top of the tank, so any hiss will be small - as fuel level drops, free-air volume above the fuel increases, so the hiss will be greater - this indicates greater volume of air in the tank, not greater pressure or vacuum.

The tank and cap was designed to also maintain ~2"HG vacuum, intended to reduce aerated fuel, which is foaming you cannot see, the bubbles being too small to break threw fuel surface tension - since each bubble below the surface of the fuel is a tiny microcosm of atmospheric pressure, any reduction in BP above the surface will reduce surface tension, allowing the smaller bubbles to break threw, thereby reducing aeration.

The fuel cap should be checked regularly to ensure it meets correct pressure\vacuum venting specs - use a radiator-pressure hand pump or a vacuum hand pump.

The only pressurization of the fuel tank is due to the vaporization of the fuel as the tank heats up. This vapor is dealt with by the Evaporative Emission control system. This method transfers fuel vapor from the fuel tank to an activated carbon (charcoal) storage canister to hold the vapors when the engine is not operating. My 96 has this canister in the area behind the right rear wheel. Earlier models have it by the left headlight. When the engine is running, the fuel vapor is purged from the carbon element by intake airflow and consumed in the normal combustion process.

When gasoline vapor builds enough to overcome the spring tension of the Evap pressure control valve, the vapor will flow to the canister where it is absorbed and stored by the charcoal.

The system uses an in-line EVAP pressure control valve as a pressure relief valve. On my 96, when the pressure in the tank exceeds 0.7 PSI the diaphragm valve opens, allowing vapors to vent to the canister. Yes folks, that is 7 tenths of a pound. Hardly enough to cause much of a sound or blow the cap out of your hand. Now if the car has been sitting a long time, the canister can become saturated and press could build. The cap should relieve this press. Don't know the value.

If you have been driving the car for awhile and stop for gas, there should be very little press in the tank.

The vent line from the tank to the canister is partially made of steel and for the cars with the canister in the front is pretty long. It has been known to rust up and clog.

BOTTOM LINE: If you find a great deal of press in the tank, something is not working right.

When gasoline vapor builds enough to overcome the spring tension of the Evap pressure control valve, the vapor will flow to the canister where it is absorbed and stored by the charcoal.

The system uses an in-line EVAP pressure control valve as a pressure relief valve. On my 96, when the pressure in the tank exceeds 0.7 PSI the diaphragm valve opens, allowing vapors to vent to the canister. Yes folks, that is 7 tenths of a pound. Hardly enough to cause much of a sound or blow the cap out of your hand. Now if the car has been sitting a long time, the canister can become saturated and press could build. The cap should relieve this press. Don't know the value.

If you have been driving the car for awhile and stop for gas, there should be very little press in the tank.

The vent line from the tank to the canister is partially made of steel and for the cars with the canister in the front is pretty long. It has been known to rust up and clog.

BOTTOM LINE: If you find a great deal of press in the tank, something is not working right.

Instead of "Huh ? " and "I beg to differ", why don't you go and test your own .

Last edited by AGENT 86; 08-07-2012 at 12:15 AM.

The following users liked this post:

cardo0 (08-04-2018)

#51

Le Mans Master

"Instead of "Huh ? " and "I beg to differ", why don't you go and test your own ."

Every 2 years whether I want to or not - the real bitch being that the testing process releases more HC's into the atmosphere than would otherwise be released if they didn't test. Broken systems don't run (or burn to the ground). Green for the sake of green gone bad.

Every 2 years whether I want to or not - the real bitch being that the testing process releases more HC's into the atmosphere than would otherwise be released if they didn't test. Broken systems don't run (or burn to the ground). Green for the sake of green gone bad.

#52

Drifting

If some folks are running their fuel tanks down to 1/8 of a tank or less before filling up: the fuel pump may fail prematurely.

The fuel pump is cooled by the gasoline in the tank. Upon acceleration, the fuel will slosh a bit (even though there is a bladder) and if the tank is close to empty, the fuel pump will not run as cool as designed. Eventually there will be a fuel pump failure.

The fuel pump is cooled by the gasoline in the tank. Upon acceleration, the fuel will slosh a bit (even though there is a bladder) and if the tank is close to empty, the fuel pump will not run as cool as designed. Eventually there will be a fuel pump failure.

#53

Race Director

No, the pump can be externally mounted without heat issues. It is cooled by fuel going through it, not by surrounding fuel. I made a garden sprayer out of an old one. I also had Racetronix comment about the issue in a thread a long time back. That is totally off topic though!

#54

Le Mans Master

The Rocket Scientists out there allready know the Perfect Gas Equation (the only one I know owns a C5); but for the rest of us, it's PV = MRT. That's Absolute Pressure (atmospheric plus gage) times Volume (cubic inches) equals Mass (weight) times Gas Constant (for the Hydrocarbon Blend you're using) times Absolute Temperature (Kelvin). So, if you want to know the System Pressure created by the Vapor in your Tank, get the weight and volume (include the Canister and Lines), R Value (kinda difficult to come by and it's different for ethanol) and convert F to C to Kelvin: 5/9(F-32) + 273. All of this was (hopefully) calculated across the whole range of temps and blends for system design (integrity). I know that early testing of EVAP controls in CA led to some busted systems. The tank is pressurized rather quickly and there were a few posts around here (and at the CARB site of overpressurization leading to system failure - allmost hate to go back, but I have no choice.

Cliff: you're system isn't venting full time into the Manifold - the Bell Shape cover above the Canister with the hoses is the solenoid driven by the ECM which will flow fumes at something like 25% throttle, closed loop.

Basic, critical dates for EVAP systems in the US were 1971 - introduction; 1996 OBD2 Monitoring; and 2000 vapor capture at fillup. Designs vary according to Law and Tech but pretty much accomplish the same stuff.

Cliff: you're system isn't venting full time into the Manifold - the Bell Shape cover above the Canister with the hoses is the solenoid driven by the ECM which will flow fumes at something like 25% throttle, closed loop.

Basic, critical dates for EVAP systems in the US were 1971 - introduction; 1996 OBD2 Monitoring; and 2000 vapor capture at fillup. Designs vary according to Law and Tech but pretty much accomplish the same stuff.

#55

Race Director

Member Since: Jan 2003

Location: Summerland B.C. Canada

Posts: 19,667

Likes: 0

Received 36 Likes

on

32 Posts

#56

Le Mans Master

It's going to go through the restriction to the Canister until Pressure is equalized - which is what Mr. Harris did for us. If it goes anywhere else, you blew too hard and broke it or it's allready broken. Anyway, I'm satisfied with what the State does for me. Accept the fact that your system is either broken or your test is invalid. Holding out a 20 plus year old system (I presume untouched) as a perfect example of how it works might be a tad unreasonable or I don't get what you're trying to say. The science and Fed Law speaks for itself - I didn't make it up.

#57

Le Mans Master

PS - for those of you who own '96 and newer with OBD2 monitoring, you may be keenly aware of tank pressure. Some, Toyota for example, mount a strain like gage above the tank or between the tank and the canister. One side goes to atmosphere, the other to vapor. If the Vapor side isn't above atmospheric, you get a Check Engine Light and the P0440 code - allmost always a loose gas cap! Others, use a pump that builds pressure and shuts off if the system is sealed. It it doesn't seal off; ie, build pressure, the PCM knows there's a leak and you get the same code. It can throw you for a loop, because the test can be a 2 trip strategy meaning you leave the station with the cap loose, but you don't get the code until you start it up the next morning - after you've forgotten that you just filled it up! That sends you to the Dealer. Good Dealers, at least in the early days, kept a code reader handy and simply tightened the cap and cleared the code so that you didn't have to leave your vehicle, but it still happens - my son left his '05 Mustang in my driveway with a Check Engine Light about a month back and was a little embarrassed to find out it was a loose cap.

#58

Race Director

Member Since: Jan 2003

Location: Summerland B.C. Canada

Posts: 19,667

Likes: 0

Received 36 Likes

on

32 Posts

Why is Mr Harris's test a pass and mine is invalid and broken ?

Looks like the same test was done ??

Peace--Out

#59

Le Mans Master

Oh my - I think you guys are as bad as we are: http://www.ic.gc.ca/eic/site/auto-au...g/am01205.html

It's all in there somewhere - interesting that you're going after lawnmowers now too!

It's all in there somewhere - interesting that you're going after lawnmowers now too!

#60

Advanced

Thread Starter

PS - for those of you who own '96 and newer with OBD2 monitoring, you may be keenly aware of tank pressure. Some, Toyota for example, mount a strain like gage above the tank or between the tank and the canister. One side goes to atmosphere, the other to vapor. If the Vapor side isn't above atmospheric, you get a Check Engine Light and the P0440 code - allmost always a loose gas cap! Others, use a pump that builds pressure and shuts off if the system is sealed. It it doesn't seal off; ie, build pressure, the PCM knows there's a leak and you get the same code. It can throw you for a loop, because the test can be a 2 trip strategy meaning you leave the station with the cap loose, but you don't get the code until you start it up the next morning - after you've forgotten that you just filled it up! That sends you to the Dealer. Good Dealers, at least in the early days, kept a code reader handy and simply tightened the cap and cleared the code so that you didn't have to leave your vehicle, but it still happens - my son left his '05 Mustang in my driveway with a Check Engine Light about a month back and was a little embarrassed to find out it was a loose cap.

That seems to be the attitude of most mechanics when it comes to evap systems..."if it doesn't make the car run bad, then don't worry about it".

As for what you said about the evap using a pump to test the system, that is completely false. Unless you are refering to the engine as a pump?....and a vacuum pump at that.

The PCM tests the evap by closing the vent valve and opening the purge valve. This, in turn, builds a vacuum in the tank. From there, both valves close and the tank pressure sensor moniters the vacuum and relays the data to the PCM. If the vacuum drops below a certan threshold, then the PCM will set a code for a system leak.

This is how the newer systems (1996+) work. The older systems did not "watch" the evap as closely because it was not yet mandated by the FEDS or the EPA.

Loose gas caps are seldom the cause of evap codes, but is the most common blame by "mechanics".