New rebuild won't start up

#1

I just rebuilt a 1996 LT1 383 engine and it won't start. The car cranks and putts and backfires a bit, but won't go any farther. I've got the EASE computer-based scan tool and no codes are showing.

When I pulled the plugs, I'm seeing that they are blackened pretty bad. They are brand new plugs - Bosch Platinum +4's that don't require gapping.

I have verified that all plugs are firing by pulling them one by one, replacing with a new, unblackened plug, and seeing spark during the cranking.

I did a compression test and found good compression in all cylinders (around 200 psi).

I checked the fuel pressure and its around 45 psi. The injectors are new and a noid light shows that they are all activating.

A friend of mine told me that my timing might be off 180 degrees, with the spark firing on cylinder 1 when it should be firing on cylinder 6. How can I even verify that the timing is off by 180 degrees? I thought about doing a quick check with a timing light, but in thinking about it, since the cylinders travel up and down twice per cam revolution, the timing light would still show the correct timing, but on the wrong stroke if things were off 180 degrees. I could turn the engine by hand with spark plug #1 out and I could probably determine if I'm on a compression stroke. Then what?

Is it even possible to get the timing out 180 degrees? In thinking through this, it seems like all of the timing components are keyed and can only be assembled in one way. If, for example, I set up cylinder 1 at TDC on the wrong stroke, and assembled the timing sprockets, then this would put the cam's pin for the OptiSpark positioned for the #6 setup. So the OptiSpark wouldn't fit on unless the rotor was rotated for the #6 position rather than the #1, and all should be fine. I think...

I'm beginning to think that the problem may lie elsewhere? Any ideas?

Ron

When I pulled the plugs, I'm seeing that they are blackened pretty bad. They are brand new plugs - Bosch Platinum +4's that don't require gapping.

I have verified that all plugs are firing by pulling them one by one, replacing with a new, unblackened plug, and seeing spark during the cranking.

I did a compression test and found good compression in all cylinders (around 200 psi).

I checked the fuel pressure and its around 45 psi. The injectors are new and a noid light shows that they are all activating.

A friend of mine told me that my timing might be off 180 degrees, with the spark firing on cylinder 1 when it should be firing on cylinder 6. How can I even verify that the timing is off by 180 degrees? I thought about doing a quick check with a timing light, but in thinking about it, since the cylinders travel up and down twice per cam revolution, the timing light would still show the correct timing, but on the wrong stroke if things were off 180 degrees. I could turn the engine by hand with spark plug #1 out and I could probably determine if I'm on a compression stroke. Then what?

Is it even possible to get the timing out 180 degrees? In thinking through this, it seems like all of the timing components are keyed and can only be assembled in one way. If, for example, I set up cylinder 1 at TDC on the wrong stroke, and assembled the timing sprockets, then this would put the cam's pin for the OptiSpark positioned for the #6 setup. So the OptiSpark wouldn't fit on unless the rotor was rotated for the #6 position rather than the #1, and all should be fine. I think...

I'm beginning to think that the problem may lie elsewhere? Any ideas?

Ron

#3

Team Owner

Member Since: Aug 2005

Location: Riverside County Southern California

Posts: 34,988

Received 501 Likes

on

342 Posts

Co-winner 2020 C4 of the Year - Modified

2018 Corvette of Year Finalist

2017 C4 of Year

2016 C7 of Year Finalist

St. Jude Donor '09-'10-'11-'12-'13-'14-'15-'16-'17-'18-'19-'20

I cant wait for Wayne, Sweet, Jon, Randy, Bob, Bart and Friz to see this one. Oh boy

Rottenbind, do you have pictures of your build up?

BTW Is your MAF connected?

#4

Am I sure that the Opti is installed correctly? No. Ha! I think it is, but who knows? If it were quick and easy, I'd pull it and see. Pulling the damper off looks like a major headache, not to mention getting the water pump out. Is there a way that I can easily verify things before going through all of this? I'd hate to do this only to find that it's something completely different.

Yep, the MAF is connected. I briefly disconnected it at one point to try starting up in speed density mode just to see what would happen. No change really, so I connected it back up.

Pictures? Yep, I have hundreds of them! Let me see what I can dig up that would be useful or at least give you guys something fun to laugh at!

Yep, the MAF is connected. I briefly disconnected it at one point to try starting up in speed density mode just to see what would happen. No change really, so I connected it back up.

Pictures? Yep, I have hundreds of them! Let me see what I can dig up that would be useful or at least give you guys something fun to laugh at!

#6

I did a complete rebuild. Everything was disassembled completely, so yes, I did set the rockers. I've never done any of this before, by the way, so I got a real education going through this and it is extremely likely that I've done something silly.

When I adjusted the rockers, I remember thinking how "fiddly" the process was. I adjusted them by spinning the push rods and turning the nut until the rods started to grab. Then I gave the nuts a half-turn of pre-load. It was kind of a judgement call as to when the grabbing on the push rods really started to happen, particularly because the ends were covered with grease. All of this was done on the engine stand. I've also read about techniques where people adjust the push rod lash while the engine is running with the valve covers off. Right now, I can't even get it running!

When I adjusted the rockers, I remember thinking how "fiddly" the process was. I adjusted them by spinning the push rods and turning the nut until the rods started to grab. Then I gave the nuts a half-turn of pre-load. It was kind of a judgement call as to when the grabbing on the push rods really started to happen, particularly because the ends were covered with grease. All of this was done on the engine stand. I've also read about techniques where people adjust the push rod lash while the engine is running with the valve covers off. Right now, I can't even get it running!

#8

Drifting

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

Turn the motor over manually with the crank bolt (5/8") till the timing mark is at 0 degrees (after removing all the plugs). Have a look inside cylinder 1 and see if the piston is up the top and both valves are closed (may need to take valve cover off) . If not the timing is your issue.

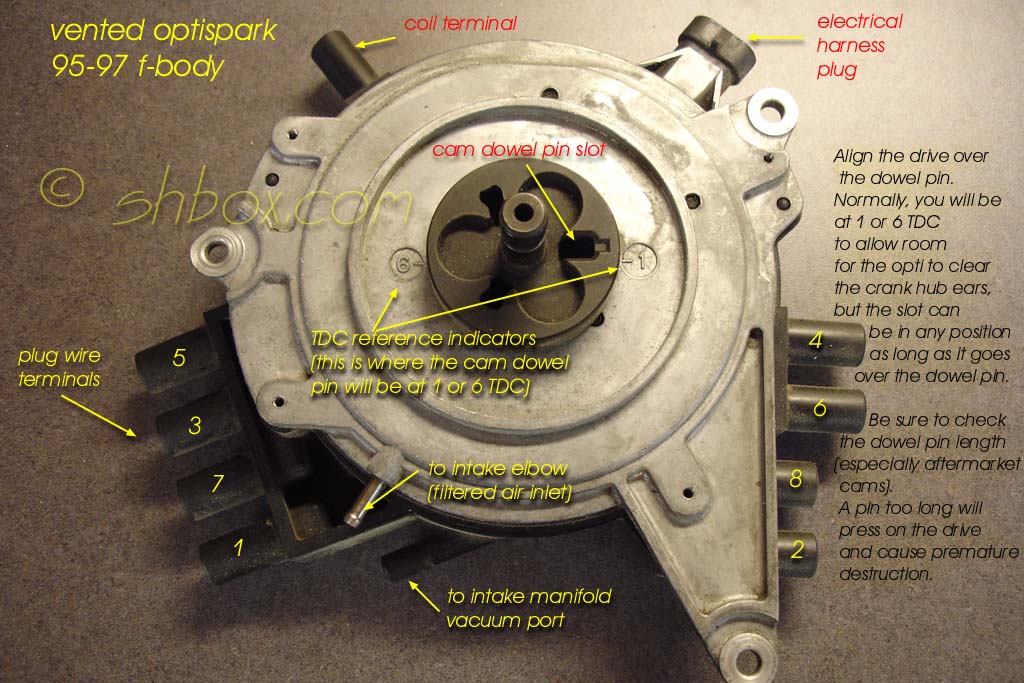

Check your firing order first by making sure the plugs leads are in the right positions as per the opti picture above. Engine firing order is 18436572.

Check your firing order first by making sure the plugs leads are in the right positions as per the opti picture above. Engine firing order is 18436572.

Last edited by Lemme; 08-24-2011 at 08:41 PM.

#9

Tech Contributor

The opti is installed wrong. I'll bet that in order to seat it against the timing chain cover, you snugged the bolts down instead of seating it by hand. Forcing the Opti in place means it was mispositioned.

The beauty about the LTx engines is that when you install the Opti, the Opti doesn't care where in the firing order the pistons are sitting....hence the reason it's so important to install the Opti correctly.

You will also note from the picture posted above, that the wires are not installed in the same order as a traditional distributor as suggested by Lemme. Even if you had a couple wires crossed, the engine would still run...albeit rough.

All the above says you need to pull the Opti off and reinstall it correctly.

The beauty about the LTx engines is that when you install the Opti, the Opti doesn't care where in the firing order the pistons are sitting....hence the reason it's so important to install the Opti correctly.

You will also note from the picture posted above, that the wires are not installed in the same order as a traditional distributor as suggested by Lemme. Even if you had a couple wires crossed, the engine would still run...albeit rough.

All the above says you need to pull the Opti off and reinstall it correctly.

#10

Le Mans Master

I put mine on once before in the wrong tab. It did exactly what you are describing. I don't think it's that hard to pull a opti and check just a few hour job if that.

I put mine on once before in the wrong tab. It did exactly what you are describing. I don't think it's that hard to pull a opti and check just a few hour job if that.

#11

Burning Brakes

3 ideas that come to mind...

-bent pushrods

-broken wire / disconnected MAP sensor (had your exact symptoms on my LS1)

-loose / disconnected engine ground

-bent pushrods

-broken wire / disconnected MAP sensor (had your exact symptoms on my LS1)

-loose / disconnected engine ground

#12

Drifting

My 383 wouldn't start also. It would crank and putt and it was just enough where I wanted to keep trying. I had 5 and 7 plug wires reversed. That's all it took.

#13

based on the way you described some of the things you did, you need to go back and check everything, that includes the opti, actually , have someone who knows what they're doing check it, fiddly and 200 lbs compression dont make sense. seems like for just rebuilding it , you dont know much about it, and it being a 383

Last edited by oldalaskaman; 09-13-2011 at 12:11 PM.

#14

Pro

Member Since: Apr 2008

Location: middle of Illinois

Posts: 542

Likes: 0

Received 0 Likes

on

0 Posts

It could be the timing, but it might be worth the time it takes to back off your rockers a little bit and see if it'll stay running.

When I finished rebuilding my engine and tried to start it the first time, it wouldn't run either. It would sometimes fire a couple of times and then pop and shoot flames out the headers. After a few days of wondering I discovered that what I did wrong was set the valve lash with no oil in the lifters. Compression looked good on the stand, but once I primed the oil pump and the lifters filled with oil, they were holding the valves open. Silly mistake, but it had been a few years since I rebuilt an engine and I hadn't even considered that the hydraulic lifters would need to fill before I adjusted the rockers.

When I finished rebuilding my engine and tried to start it the first time, it wouldn't run either. It would sometimes fire a couple of times and then pop and shoot flames out the headers. After a few days of wondering I discovered that what I did wrong was set the valve lash with no oil in the lifters. Compression looked good on the stand, but once I primed the oil pump and the lifters filled with oil, they were holding the valves open. Silly mistake, but it had been a few years since I rebuilt an engine and I hadn't even considered that the hydraulic lifters would need to fill before I adjusted the rockers.

#15

I just wanted to follow up and let you guys know how I've made out. I've been doing this project in my very limited spare time so it took me a while to get through things.

I've disassembled the front of the engine to get to the OptiSpark and found no issue. I'm not sure as to whether the pin of the cam shaft was seated correctly or not, but I'm sure that I got it right this time around. I also went further and removed the timing gear cover and verified that the timing is in good shape.

Finding nothing that looked unusual or wrong, I put things back together and guess what? The engine started up immediately without any hesitation whatsoever! WoooHooo!!!!! I don't know what the problem was but I apparently fixed something in the rebuild. Probably the camshaft pin engagement in the Opti was the issue, but who knows.

Thanks for the help guys!

I've disassembled the front of the engine to get to the OptiSpark and found no issue. I'm not sure as to whether the pin of the cam shaft was seated correctly or not, but I'm sure that I got it right this time around. I also went further and removed the timing gear cover and verified that the timing is in good shape.

Finding nothing that looked unusual or wrong, I put things back together and guess what? The engine started up immediately without any hesitation whatsoever! WoooHooo!!!!! I don't know what the problem was but I apparently fixed something in the rebuild. Probably the camshaft pin engagement in the Opti was the issue, but who knows.

Thanks for the help guys!

#16

Here is a write up that was given to me and helped me out. This will be a little diffrent due to your car having opti. It is a great check list given to me by the late forum member Jake. God rest his soul.

Here are my thoughts and how I do mine:

First off, of course, the lifter preload has to be properly set. I strongly recommend the IC/EO method. If the preload isn't right the engine will have a really hard time running, that is if it'll run at all. So that's crucial.

Many guys don't prime the oiling system well enough. You should use an oil priming tool attached to a 1/2" drive electric drill and prime the system until oil comes for all 16 rocker arms.

This will take some time and will also require you to manually turn over the engine many times in order for oil pressure to reach all the lifters, then pushrods and finally rocker arms. As it does that the priming will force all the air out of the oil galleries.

Prime, prime, prime and when oil is seen coming from a rocker arm keep priming until not air comes out along with that oil. You want to force out all the air.

Then turn the engine over - manually - a very little, maybe 1/8th turn - and begin priming some more. Keep repeating that until all the rockers are flowing oil with no air bubbles.

While priming, have someone keep a look out for any oil leak.

A 1/2" drill will be needed because a 3/8" drill will over-heat. Also, don't use synthetic oil for the break-in. Rings seat quicker and better by using good old dyno oil.

Once the oil system is well primed, it's time to install the distributor which I always do as follows:

I remove the #1 spar plug, then either manually or with a bump starter turn over the engine while detecting when the #1 piston is on the compression stroke. If I'm alone, I stick a piece of toilet paper/paper towel in the #1 spark plug hole.

Using the starter, I bump the engine until the cylinder pressure forces out the paper/towel. With a helper, I let him/her turn the ignition key and do the bumping. While doing that I have my finger in the #1 hole and feel for compression building.

The ideal position is for the timing mark on the balancer/damper to stop somewhere between 4 and 10 degrees BTDC. Our engines need some amount of timing advance in order to start and run immediately.

So, now we have the timing mark aligned with between 4 and 10 BTDC on the COMPRESSION STROKE, time to drop in the distributor.

When you do align the rotor tip with the distributor cap's #1 terminal. As you probably know, the #1 terminal in the distributor cap can be anywhere - the engine doesn't know or even care. Just as long as all the other wires are in the proper sequence 1, 8, 4, 3, etc.

This most often requires aligning the distributor with the oil pump drive shaft.

Some guys use a long screwdriver to turn the oil pump drive rod so it properly aligns with the distributor. Others do as I do and just drop in the distributor to as far as it will go then just bump over the engine using the starter. At some point the distributor and oil pump drive rod will align with each other and the distributor will drop all the way down, flush with the intake.

Install the hold down clamp and make all the electrical connections to the distributor.

I prime the fuel system by turning the ignition key on, off - wait - on, off - wait - etc. I attach my fuel pressure gauge to the Schrader valve location so I can visually monitor the fuel pressure wile doing this.

Fill, top off the coolant; check for any tools, rags, etc. that may be in the way. I then look at all my connections, hoses, etc., to make sure none has been left disconnected.

I DON'T DISCONNECT THE BY-PASS WIRE. I leave it plugged in so the engine will get full timing once it starts. If the By-Pass is disconnected, the engine will only get a small amount of timing advance and will quickly overheat. If you're running headers they'll turn a new, cherry red too.

I DON'T DISCONNECT THE FPR VACUUM HOSE. Unless you have an adjustable FPR, there's no setting of the fuel pressure required or possible. Fuel pressure is automatically controlled by the regulator.

I DON'T DISCONNECT THE IAC.

If the lifter preload was set correctly and nothing was left disconnected, the engine should quickly fire and run.

FIRST THING TO CHECK IS OIL PRESSURE.

Immediately after seeing the reading check for any sign of a fuel leak. Now check OIL PRESSURE AGAIN. Then look for coolant temp and any sign of coolant leak.

Since you're running a roller cam, you can keep the engine RPMs on the low side - 1500/2000 - until you've verified no leak and good oil pressure. Vary the RPM to cause oil to be sprayed/splashed to all the internal parts of the engine.

WATCH OIL PRESSURE LIKE A HAWK!

IF YOU FIND ANYTHING AMISS, SHUT DOWN THE ENGINE TO ADDRESS IT. Don't try fixing it with the engine running. Shut down the engine, fix the problem, re-fire.

Once the engine will idle on it's own, shut it down, disconnect the by-pass wire and re-fire the engine. Set the base ignition timing to 6 degrees BTDC, which is the stock recommended setting. You can always play with that setting later once the engine is through with its teething-pains.

I always change my oil and filter right after the initial fire-up, timing setting, coolant top off, etc. If the engine's been run for, say, half an hour, that's long enough to me before putting in fresh oil and a new filter.

Once the engine has stabilized, has fresh oil, etc., I take it out for it's first drive. I find a roadway with minimal traffic and load and unload the engine to help seat the rings.

There are different opinions on break-in, here's how I do mine:

Half throttle in 2nd gear to 3500 or so, then release the pedal and let the engine pull down back to near idle speed, then I repeat that. I do that several times then increase my pedal pressure to, say 3/4 throttle to around 4000, always letting the engine pull down with no pedal pressure.

ALL THE WHILE WATCHING OIL PRESSURE LIKE A HAWK!

Hopefully everything will go smoothly, but don't be discouraged if there's hiccup or two. Newly built engines often go through their problems.

Let me know if I can help further. GOOD LUCK!

Jake

Here are my thoughts and how I do mine:

First off, of course, the lifter preload has to be properly set. I strongly recommend the IC/EO method. If the preload isn't right the engine will have a really hard time running, that is if it'll run at all. So that's crucial.

Many guys don't prime the oiling system well enough. You should use an oil priming tool attached to a 1/2" drive electric drill and prime the system until oil comes for all 16 rocker arms.

This will take some time and will also require you to manually turn over the engine many times in order for oil pressure to reach all the lifters, then pushrods and finally rocker arms. As it does that the priming will force all the air out of the oil galleries.

Prime, prime, prime and when oil is seen coming from a rocker arm keep priming until not air comes out along with that oil. You want to force out all the air.

Then turn the engine over - manually - a very little, maybe 1/8th turn - and begin priming some more. Keep repeating that until all the rockers are flowing oil with no air bubbles.

While priming, have someone keep a look out for any oil leak.

A 1/2" drill will be needed because a 3/8" drill will over-heat. Also, don't use synthetic oil for the break-in. Rings seat quicker and better by using good old dyno oil.

Once the oil system is well primed, it's time to install the distributor which I always do as follows:

I remove the #1 spar plug, then either manually or with a bump starter turn over the engine while detecting when the #1 piston is on the compression stroke. If I'm alone, I stick a piece of toilet paper/paper towel in the #1 spark plug hole.

Using the starter, I bump the engine until the cylinder pressure forces out the paper/towel. With a helper, I let him/her turn the ignition key and do the bumping. While doing that I have my finger in the #1 hole and feel for compression building.

The ideal position is for the timing mark on the balancer/damper to stop somewhere between 4 and 10 degrees BTDC. Our engines need some amount of timing advance in order to start and run immediately.

So, now we have the timing mark aligned with between 4 and 10 BTDC on the COMPRESSION STROKE, time to drop in the distributor.

When you do align the rotor tip with the distributor cap's #1 terminal. As you probably know, the #1 terminal in the distributor cap can be anywhere - the engine doesn't know or even care. Just as long as all the other wires are in the proper sequence 1, 8, 4, 3, etc.

This most often requires aligning the distributor with the oil pump drive shaft.

Some guys use a long screwdriver to turn the oil pump drive rod so it properly aligns with the distributor. Others do as I do and just drop in the distributor to as far as it will go then just bump over the engine using the starter. At some point the distributor and oil pump drive rod will align with each other and the distributor will drop all the way down, flush with the intake.

Install the hold down clamp and make all the electrical connections to the distributor.

I prime the fuel system by turning the ignition key on, off - wait - on, off - wait - etc. I attach my fuel pressure gauge to the Schrader valve location so I can visually monitor the fuel pressure wile doing this.

Fill, top off the coolant; check for any tools, rags, etc. that may be in the way. I then look at all my connections, hoses, etc., to make sure none has been left disconnected.

I DON'T DISCONNECT THE BY-PASS WIRE. I leave it plugged in so the engine will get full timing once it starts. If the By-Pass is disconnected, the engine will only get a small amount of timing advance and will quickly overheat. If you're running headers they'll turn a new, cherry red too.

I DON'T DISCONNECT THE FPR VACUUM HOSE. Unless you have an adjustable FPR, there's no setting of the fuel pressure required or possible. Fuel pressure is automatically controlled by the regulator.

I DON'T DISCONNECT THE IAC.

If the lifter preload was set correctly and nothing was left disconnected, the engine should quickly fire and run.

FIRST THING TO CHECK IS OIL PRESSURE.

Immediately after seeing the reading check for any sign of a fuel leak. Now check OIL PRESSURE AGAIN. Then look for coolant temp and any sign of coolant leak.

Since you're running a roller cam, you can keep the engine RPMs on the low side - 1500/2000 - until you've verified no leak and good oil pressure. Vary the RPM to cause oil to be sprayed/splashed to all the internal parts of the engine.

WATCH OIL PRESSURE LIKE A HAWK!

IF YOU FIND ANYTHING AMISS, SHUT DOWN THE ENGINE TO ADDRESS IT. Don't try fixing it with the engine running. Shut down the engine, fix the problem, re-fire.

Once the engine will idle on it's own, shut it down, disconnect the by-pass wire and re-fire the engine. Set the base ignition timing to 6 degrees BTDC, which is the stock recommended setting. You can always play with that setting later once the engine is through with its teething-pains.

I always change my oil and filter right after the initial fire-up, timing setting, coolant top off, etc. If the engine's been run for, say, half an hour, that's long enough to me before putting in fresh oil and a new filter.

Once the engine has stabilized, has fresh oil, etc., I take it out for it's first drive. I find a roadway with minimal traffic and load and unload the engine to help seat the rings.

There are different opinions on break-in, here's how I do mine:

Half throttle in 2nd gear to 3500 or so, then release the pedal and let the engine pull down back to near idle speed, then I repeat that. I do that several times then increase my pedal pressure to, say 3/4 throttle to around 4000, always letting the engine pull down with no pedal pressure.

ALL THE WHILE WATCHING OIL PRESSURE LIKE A HAWK!

Hopefully everything will go smoothly, but don't be discouraged if there's hiccup or two. Newly built engines often go through their problems.

Let me know if I can help further. GOOD LUCK!

Jake

#17

Question because I am having problems getting my 94 LT1 to run right, this pic of a 95-97 optispark, is the alignment of 1 and 6 the same on the older optispark?? because at 1 TDC, the indexed splines face 12 oclock not 3 oclock like this picture

SN i did find that the person who installed the spline in the cam prior to me was off by one tooth on the spline, i am going to put her back together but sum1 was saying the rotor is facing the wrong way, another note: the cam and crank dots are both 12, could they have put them on wrong also?

#18

I just rebuilt a 1996 LT1 383 engine and it won't start. The car cranks and putts and backfires a bit, but won't go any farther. I've got the EASE computer-based scan tool and no codes are showing.

When I pulled the plugs, I'm seeing that they are blackened pretty bad. They are brand new plugs - Bosch Platinum +4's that don't require gapping.

I have verified that all plugs are firing by pulling them one by one, replacing with a new, unblackened plug, and seeing spark during the cranking.

I did a compression test and found good compression in all cylinders (around 200 psi).

I checked the fuel pressure and its around 45 psi. The injectors are new and a noid light shows that they are all activating.

A friend of mine told me that my timing might be off 180 degrees, with the spark firing on cylinder 1 when it should be firing on cylinder 6. How can I even verify that the timing is off by 180 degrees? I thought about doing a quick check with a timing light, but in thinking about it, since the cylinders travel up and down twice per cam revolution, the timing light would still show the correct timing, but on the wrong stroke if things were off 180 degrees. I could turn the engine by hand with spark plug #1 out and I could probably determine if I'm on a compression stroke. Then what?

Is it even possible to get the timing out 180 degrees? In thinking through this, it seems like all of the timing components are keyed and can only be assembled in one way. If, for example, I set up cylinder 1 at TDC on the wrong stroke, and assembled the timing sprockets, then this would put the cam's pin for the OptiSpark positioned for the #6 setup. So the OptiSpark wouldn't fit on unless the rotor was rotated for the #6 position rather than the #1, and all should be fine. I think...

I'm beginning to think that the problem may lie elsewhere? Any ideas?

Ron

When I pulled the plugs, I'm seeing that they are blackened pretty bad. They are brand new plugs - Bosch Platinum +4's that don't require gapping.

I have verified that all plugs are firing by pulling them one by one, replacing with a new, unblackened plug, and seeing spark during the cranking.

I did a compression test and found good compression in all cylinders (around 200 psi).

I checked the fuel pressure and its around 45 psi. The injectors are new and a noid light shows that they are all activating.

A friend of mine told me that my timing might be off 180 degrees, with the spark firing on cylinder 1 when it should be firing on cylinder 6. How can I even verify that the timing is off by 180 degrees? I thought about doing a quick check with a timing light, but in thinking about it, since the cylinders travel up and down twice per cam revolution, the timing light would still show the correct timing, but on the wrong stroke if things were off 180 degrees. I could turn the engine by hand with spark plug #1 out and I could probably determine if I'm on a compression stroke. Then what?

Is it even possible to get the timing out 180 degrees? In thinking through this, it seems like all of the timing components are keyed and can only be assembled in one way. If, for example, I set up cylinder 1 at TDC on the wrong stroke, and assembled the timing sprockets, then this would put the cam's pin for the OptiSpark positioned for the #6 setup. So the OptiSpark wouldn't fit on unless the rotor was rotated for the #6 position rather than the #1, and all should be fine. I think...

I'm beginning to think that the problem may lie elsewhere? Any ideas?

Ron

I'm following in your footsteps and having exact same symptoms. Mine is a 96 and put a 383 kit in. I have no mechanical experience to speak of. I had a machine shop build the short block so all I had to get right were the heads/rockers and opti-spark.

I'm confident I have the rockers adjusted correctly but like you, I found the grab point a bit subjective.

As far as the opti-spark goes, I didn't know you could get it on wrong. I'll bet that's my issue.

How could you tell if you were in #1 firing position as opposed to #6 without valve cover off?

Thom

#19

Thom,

From what I remember, the optispark only can be assembled one way, the correct way. If you have it wrong, it just won't fit together.

I remember the time that I went through back then... I had my nifty new engine all assembled and installed, turned the key and it just wouldn't start. After a lot of diagnosis without finding any problem, I took the whole front off, including the optispark, water pump, damper pulley, and timing cover with the engine still in the car. Not fun.

All of that to verify that the timing chain was correct and to examine the optispark to see if there were any timing issues that I might have caused by improper assembly. I didn't find anything obviously wrong, and further, I found that there was little that you could get wrong - everything fits together just one way. I put everything back together and figured that I'd have a big mess on my hands. But after re-assembly, it started right up. I have no idea what was different. And despite all odds, my '96 is still running mean today.

As for verifying the firing position, I think that taking the valve cover off is probably your best bet. I can't think of any easier way. You certainly don't want to do what I did and take things apart to verify the timing marks on the gears. That was just no fun at all. I've heard of people determining the position of their cylinders by inspection through the spark plug holes, but taking the valve cover off is a far easier approach to me. Hopefully you can determine if the #1 cylinder spark plug is firing when the cylinder is in the correct position with a timing light.

Just remember the basics:

- Do you have spark? Are you absolutely sure all plugs are firing?

- Do you have fuel being delivered? Are you sure?

- Do you have compression in the cylinders? A compression test will verify a lot of mechanical issues.

If you have spark, fuel, and compression, then the only thing left is timing. Do they all happen at the right time? From what I can tell on the LT1, there are really only a couple of items that would affect timing:

- incorrect wiring from the optispark to the plugs

- misaligned timing marks on the timing chain sprockets.

- other things that a compression test would catch, like valves not operating

That's about all there is from a timing point of view - apart from tweaking in the PCM settings that can be done during a performance tuning with a dyno. Its likely that you don't need to get into that to at least get the engine running.

Post more on what you've found and what the car is and is not doing and hopefully we'll be able to help you more.

Good luck,

Ron

From what I remember, the optispark only can be assembled one way, the correct way. If you have it wrong, it just won't fit together.

I remember the time that I went through back then... I had my nifty new engine all assembled and installed, turned the key and it just wouldn't start. After a lot of diagnosis without finding any problem, I took the whole front off, including the optispark, water pump, damper pulley, and timing cover with the engine still in the car. Not fun.

All of that to verify that the timing chain was correct and to examine the optispark to see if there were any timing issues that I might have caused by improper assembly. I didn't find anything obviously wrong, and further, I found that there was little that you could get wrong - everything fits together just one way. I put everything back together and figured that I'd have a big mess on my hands. But after re-assembly, it started right up. I have no idea what was different. And despite all odds, my '96 is still running mean today.

As for verifying the firing position, I think that taking the valve cover off is probably your best bet. I can't think of any easier way. You certainly don't want to do what I did and take things apart to verify the timing marks on the gears. That was just no fun at all. I've heard of people determining the position of their cylinders by inspection through the spark plug holes, but taking the valve cover off is a far easier approach to me. Hopefully you can determine if the #1 cylinder spark plug is firing when the cylinder is in the correct position with a timing light.

Just remember the basics:

- Do you have spark? Are you absolutely sure all plugs are firing?

- Do you have fuel being delivered? Are you sure?

- Do you have compression in the cylinders? A compression test will verify a lot of mechanical issues.

If you have spark, fuel, and compression, then the only thing left is timing. Do they all happen at the right time? From what I can tell on the LT1, there are really only a couple of items that would affect timing:

- incorrect wiring from the optispark to the plugs

- misaligned timing marks on the timing chain sprockets.

- other things that a compression test would catch, like valves not operating

That's about all there is from a timing point of view - apart from tweaking in the PCM settings that can be done during a performance tuning with a dyno. Its likely that you don't need to get into that to at least get the engine running.

Post more on what you've found and what the car is and is not doing and hopefully we'll be able to help you more.

Good luck,

Ron