strut brace question

#1

Drifting

Thread Starter

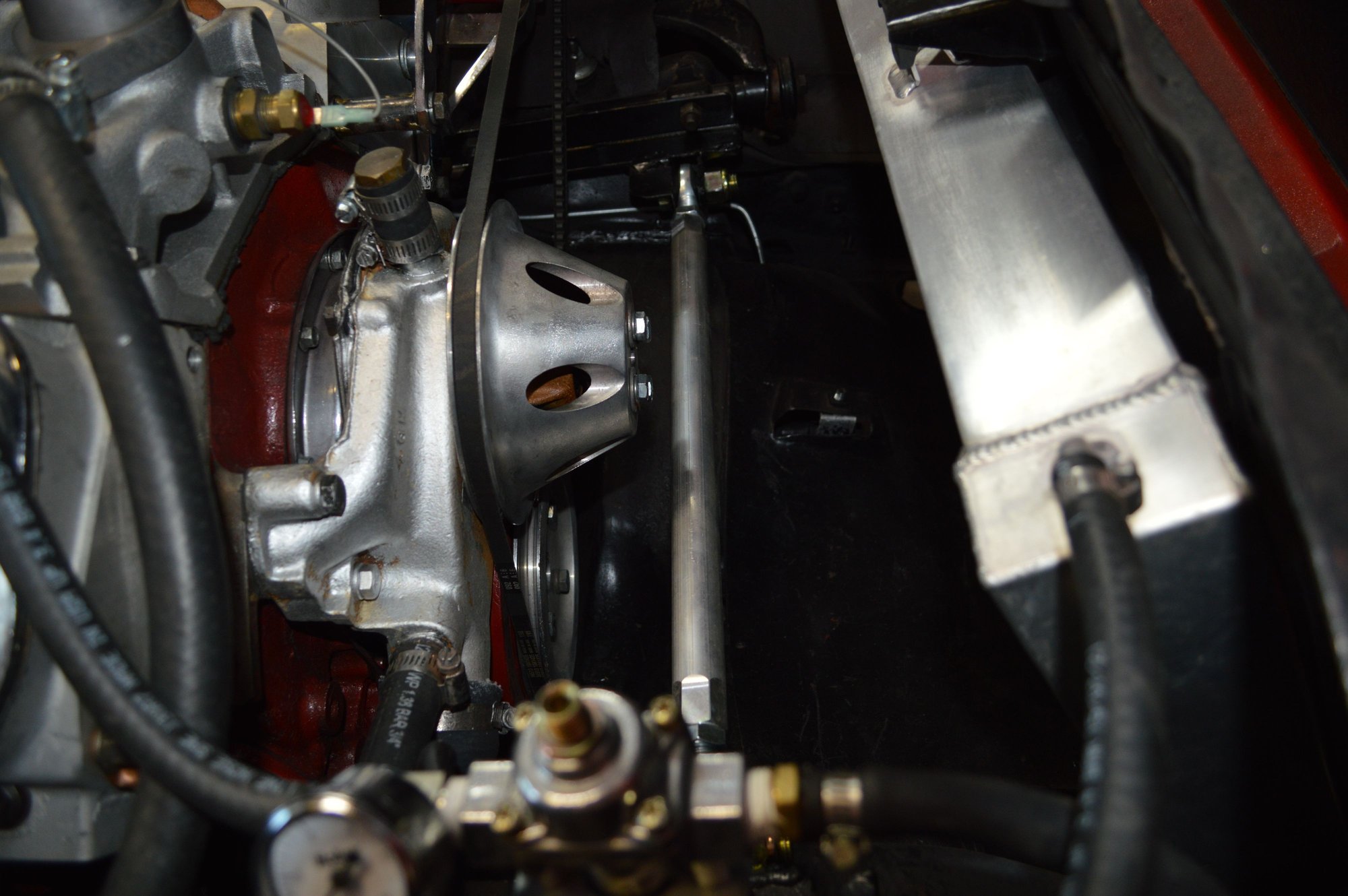

tie rod end of strut brace. one amateur weld- others are better

strut brace on 68 convert with 454 and electric fan

I just finished installing a strut brace on my 68 convert with NOM 454. Fan is removed and space allowed using a strut brace I fabricated using the shark type as a model. Right and left hand threaded tie rod at 16 inch was used with the corresponding rod ends. Brackets use the A arm bolts as attachment points.

Question: I pre-loaded the tension to push (extend) the tie rod against the shock towers. Since there is a slight play in the tie rod ends, is this the correct pre-load? Or would pulling (decreasing the length) give the most stability to the brace?

#2

Race Director

The engine cradle is trying to collapse inwards to each other...so...apply slight tension outwards is how I would do it. I would not force it outwards.

DUB

DUB

Last edited by DUB; 08-24-2017 at 07:13 PM.

#3

Race Director

Member Since: Mar 2003

Location: Eustis ( Area 51 Bat Cave ) Fl

Posts: 11,608

Received 772 Likes

on

645 Posts

I have seen a lot of long posts about this but cutting to it from my understanding you did it correctly, its how i will do mine...

Last edited by The13Bats; 08-24-2017 at 07:01 PM.

The following users liked this post:

ronarndt (08-24-2017)

#4

Drifting

Thread Starter

Thanks, that's what I did. Just enough pressure to take up the 1/32 inch of play in the rod ends. I figured when the car goes over a hard bump, the upper A arm is forced inward against the frame member, so bracing against that force should help. One more piece of high performance equipment on my car that has never gone over 70 mph!

The following users liked this post:

BV85 (08-25-2017)

#5

Le Mans Master

When I installed mine I rotated the bar by hand to remove as much slack as I could, then put a wrench on it and added 3/4 of a turn.

No alignment issues since.

No alignment issues since.

#6

Drifting

Thread Starter

#7

Race Director

A spreader bar is a definite improvement and worth its weight in gold in my opinion.

Even though you do not take your Corvette over 70 MPH...that spreader bar is doing a lot for you when you are turning the car and going over bumps,etc. It was a great investment. Hopefully you are aware of what problems you stopped by installing that spreader bar. Mainly the cradle collapse which can cause the Corvette to eventually have to go onto a frame machine and get the cradle stretched back out to specifications again.

DUB

Last edited by DUB; 08-25-2017 at 06:40 PM.

#8

Race Director

I looked into spreader bars and only found them for sale for small block set ups. I was told that they are not necessary for a corvette set up with a big block and that they could not fit.

Call me dumb, but exactly what does the spreader bar do, and if you know, where can I purchase one for my 73 BB???

Call me dumb, but exactly what does the spreader bar do, and if you know, where can I purchase one for my 73 BB???

#9

Melting Slicks

Member Since: Jul 2010

Location: perth western australia

Posts: 3,101

Received 599 Likes

on

533 Posts

I looked into spreader bars and only found them for sale for small block set ups. I was told that they are not necessary for a corvette set up with a big block and that they could not fit.

Call me dumb, but exactly what does the spreader bar do, and if you know, where can I purchase one for my 73 BB???

Call me dumb, but exactly what does the spreader bar do, and if you know, where can I purchase one for my 73 BB???

I just bought a weld up style from VB&P for my 77

https://www.vbandp.com/auto-parts/c2...it-detail.html

Last edited by bazza77; 08-25-2017 at 08:46 PM. Reason: add link

#10

Drifting

Nice job Ronarndt!!!!! Looks very professionally done!

Can I ask how long of a torque tube you used and what size Heims?

Also, any info on the bracket design?

Thanks!

Can I ask how long of a torque tube you used and what size Heims?

Also, any info on the bracket design?

Thanks!

#11

Drifting

Thread Starter

It is obvious the great minds think a like.

A spreader bar is a definite improvement and worth its weight in gold in my opinion.

Even though you do not take your Corvette over 70 MPH...that spreader bar is doing a lot for you when you are turning the car and going over bumps,etc. It was a great investment. Hopefully you are aware of what problems you stopped by installing that spreader bar. Mainly the cradle collapse which can cause the Corvette to eventually have to go onto a frame machine and get the cradle stretched back out to specifications again.

DUB

A spreader bar is a definite improvement and worth its weight in gold in my opinion.

Even though you do not take your Corvette over 70 MPH...that spreader bar is doing a lot for you when you are turning the car and going over bumps,etc. It was a great investment. Hopefully you are aware of what problems you stopped by installing that spreader bar. Mainly the cradle collapse which can cause the Corvette to eventually have to go onto a frame machine and get the cradle stretched back out to specifications again.

DUB

"Hopefully you are aware of what problems you stopped " I figure I have a fifty-year-old frame with the A arms fastened to a stub on the old frame. Sooner or later something is going to crack or bend. Sort of like I feel getting up in the morning.

#12

Drifting

Thread Starter

it has RH and LH threads

RH Heim rod end from JEGS #555-64106 ($8.99)

LH Heim rod end #555-64116 ($6.99)

Fastening bolts for rod ends are 5/8 x 2 inch grade 8 bolts with Nylock nuts. about $5 from hardware store.

Bracket is cut from 1 1/4 inch angle iron. Main piece is 9 inches long. Make sure it is not too long or it will rub on the A arm bushing. The tabs are also cut from 1 1/4 inch angle iron and are 3 inches long.

I pre-fit everything before drilling holes and tack welded to check fit.

The front tab has one side of the angle iron removed to allow better access to tighten the large Nylock nut. Lots of grinding done to round off sharp corners.

Installation tip: Jack up the car to take the pressure off the A arm before loosening the caster/camber adjusting nuts, otherwise the bolts may pull through the frame mounting point.

Last edited by ronarndt; 08-26-2017 at 01:22 PM. Reason: typo

#13

Drifting

Member Since: Oct 2001

Location: Halifax, Nova Scotia, Canada

Posts: 1,879

Received 875 Likes

on

252 Posts

#14

Drifting

Thread Starter

I looked into spreader bars and only found them for sale for small block set ups. I was told that they are not necessary for a corvette set up with a big block and that they could not fit.

Call me dumb, but exactly what does the spreader bar do, and if you know, where can I purchase one for my 73 BB???

Call me dumb, but exactly what does the spreader bar do, and if you know, where can I purchase one for my 73 BB???

As bazza77 said, the engine driven fan gets in the way of the bar. My car came with both an engine driven fan and an electric fan for the aftermarket aluminum radiator. Much of the fan shrouding was for a small block and did not fit well, so I removed it and also the engine driven fan. No overheating problems and now lots of room for the strut brace.

On your BB car, you might be able to fit a brace that clears the fan, but I suspect you would need to put a bend in it to get the mid section closer to the engine block to miss the fan blades.

#15

Race Director

It is only common sense ( in my opinion) that a metal frame that is as old as these frames are getting are not as fatigued-free as they were when they were built. Thus one should not expect it to react the same to forces as it did 40 years ago....especially if it has been subjected to previous damage, rust and other factors.

DUB

#16

Race Director

If I am planning to remove the engine driven fan and run electric fans, can I purchase a strut brace for a small block? Or will I need to make something custom?

#17

Le Mans Master

#18

Team Owner

but I didn't go 3/4. I went just enough to take up all the slack.

but I didn't go 3/4. I went just enough to take up all the slack.I didn't really notice a big difference going over bumps but my car is a flexible convertible but I'm sure it helps. I did notice a huge difference in steering response.

#19

Race Director

Ok, you convinced me, I just ordered a kit from Van Steel.

Nice job.

Nice job.