My home alignment plan. Thoughts or Ideas?

#1

So I made a post earlier today about my basic plans for my alignment and thought I would post in detail what they are and get others thought about this.

I am close to finishing my 1979 Corvettes restoration and I do not want to use an alignment shop because in the 16 years that I have had the car I seem to always have issues with the alignments and the shops not knowing what to do with it or will not use other than stock alignment angles. My plan is to just do the alignment myself.

Here is a list of what has been modified on the car as far as the suspension.

Frame seams welded and braced per the Chevy power book including boxing in the frame horns.

Vette Brakes and products 550 ss springs and composite duel mount rear spring.

Van Steel Smart struts

Van Steel off set trailing arms

Van Steel tubular front upper control arms

Borgeson power steering box

1 1/4 front sway bar and 7/8 rear bar

all bushings are poly

Ok here is my step by step plan for my alignment.

1. Lay down plywood or masonite shims and level the area that the tires will sit. To do this I am thinking using 18 in squares and a long level.

2. Pull the car unto the level boards and then make sure the suspension height is where I want it.

3. Using string and plumb bobs I am going to attach the string to the front lower control arm at the bolt that holds the front bushing in and at the rear the trailing arm mounts. From this using the plumb bob I will mark the location on the ground at all 4 locations.

4. I will then measure from the marks I just made on the ground and mark the centerline between the marks and again use the plumb bob and string to mark the centerline of the car on the frame.

5. Next run a string from front to rear mounted on jack stands marking the exact center line of the car.

6. Set op a string on each side of the car on jack stands running parallel with the centering.

7. Next I will use a steel rule measuring from the string at the front of the rim and at the back to determine the toe, also I will be able to square up the front to the rear using this set up.

For Camber and caster I was looking at getting the Fast Track gage from Summit Racing. At first I am going to just turn the wheels complete from lock to lock to measure the caster. Eventfully if this all works well for setting my alignment I will invest in turn plates so that I can measure the 20 degrees turn in the steering that from what I have been reading is ideal for measuring caster.

Not sure what specs I am going to use but thinking about starting with this.

front

toe 1/32 in

camber -1/4

caster +4 3/4

rear

toe 1/8 in

camber - 1/2

Any thoughts or ideas are welcome.

Here is a photo of my frame.

I am close to finishing my 1979 Corvettes restoration and I do not want to use an alignment shop because in the 16 years that I have had the car I seem to always have issues with the alignments and the shops not knowing what to do with it or will not use other than stock alignment angles. My plan is to just do the alignment myself.

Here is a list of what has been modified on the car as far as the suspension.

Frame seams welded and braced per the Chevy power book including boxing in the frame horns.

Vette Brakes and products 550 ss springs and composite duel mount rear spring.

Van Steel Smart struts

Van Steel off set trailing arms

Van Steel tubular front upper control arms

Borgeson power steering box

1 1/4 front sway bar and 7/8 rear bar

all bushings are poly

Ok here is my step by step plan for my alignment.

1. Lay down plywood or masonite shims and level the area that the tires will sit. To do this I am thinking using 18 in squares and a long level.

2. Pull the car unto the level boards and then make sure the suspension height is where I want it.

3. Using string and plumb bobs I am going to attach the string to the front lower control arm at the bolt that holds the front bushing in and at the rear the trailing arm mounts. From this using the plumb bob I will mark the location on the ground at all 4 locations.

4. I will then measure from the marks I just made on the ground and mark the centerline between the marks and again use the plumb bob and string to mark the centerline of the car on the frame.

5. Next run a string from front to rear mounted on jack stands marking the exact center line of the car.

6. Set op a string on each side of the car on jack stands running parallel with the centering.

7. Next I will use a steel rule measuring from the string at the front of the rim and at the back to determine the toe, also I will be able to square up the front to the rear using this set up.

For Camber and caster I was looking at getting the Fast Track gage from Summit Racing. At first I am going to just turn the wheels complete from lock to lock to measure the caster. Eventfully if this all works well for setting my alignment I will invest in turn plates so that I can measure the 20 degrees turn in the steering that from what I have been reading is ideal for measuring caster.

Not sure what specs I am going to use but thinking about starting with this.

front

toe 1/32 in

camber -1/4

caster +4 3/4

rear

toe 1/8 in

camber - 1/2

Any thoughts or ideas are welcome.

Here is a photo of my frame.

#2

Racer

I think you are right on track with your plan. I didn't use a string on the centerline, but only on the outsides. I used magnetic dial indicator stands so I could move the string in very small increments until I had them parallel with the front to back of the rear rims. I used a 6" steel ruler to measure from the string to the rim. Then made adjustments based on the total distance between the strings in the rear and the ones in the front. Once that was done, then worked on getting the fronts the same distance on each side and finally to get the toe set.

The Fastrack works pretty well. Watch setting it up so you get it calibrated. I made turnstiles out of some 12 gage and used 12" lazy susan bearings you can get from HD or Lowes for about $10 each or less. I think they recommend you use 15 degrees in and out to read the castor settings. It helps to use a bungie cord to hold the gage on the wheel.

Your plan looks great, it will take a little time but it is worth the effort.

Unk

The Fastrack works pretty well. Watch setting it up so you get it calibrated. I made turnstiles out of some 12 gage and used 12" lazy susan bearings you can get from HD or Lowes for about $10 each or less. I think they recommend you use 15 degrees in and out to read the castor settings. It helps to use a bungie cord to hold the gage on the wheel.

Your plan looks great, it will take a little time but it is worth the effort.

Unk

#3

Le Mans Master

Member Since: Jul 2006

Location: charlotte north carolina

Posts: 8,117

Likes: 0

Received 100 Likes

on

92 Posts

I used a taut string coming from behind the rear tires to set the rear toe. A helper (wife) held the string so that it wrapped over the rear tire bulge and watched the string until it just made contact with the front bulge of the tire, and then measured to a set point on the frame. After a little practice, you can get it quite accurate. To set the front caster, I used a threaded rod connector to extend a bolt from a front wheel lug. A magnetic angle measuring instrument (Harbor freight) was suspended from the bolt. As the steering turns side to side, the caster angle can be read on the instrument. Use greased 12X12 floor tiles as "sliders" for the tire movement.

#4

Nam Labrat

Member Since: Sep 2013

Location: New Orleans Loo-z-anna

Posts: 33,899

Received 4,179 Likes

on

2,739 Posts

I also have had nightmare alignments done on my vehicles at one time or another!

But I remembered a family-operated alignment shop that my dad took the cars to when I was a kid...now the owners son inherited the shop and does great work. I will let him fine-tune my alignment once the car passes the State Safety Inspection.

Your method sounds more precise than my home-alignment---I measured from the outside of the frame and then set up the strings (taking into consideration the front and rear wheels Center to Center offset....(which worked well on my '34 street truck---as I have over 30,000 miles in the tires with a perfect wear pattern across the tread).

.

So.....your method should be even closer....(I'll doublecheck my alignment using the method that you researched....just to be sure because of the Vette 4-wheel alignment).

But I remembered a family-operated alignment shop that my dad took the cars to when I was a kid...now the owners son inherited the shop and does great work. I will let him fine-tune my alignment once the car passes the State Safety Inspection.

Your method sounds more precise than my home-alignment---I measured from the outside of the frame and then set up the strings (taking into consideration the front and rear wheels Center to Center offset....(which worked well on my '34 street truck---as I have over 30,000 miles in the tires with a perfect wear pattern across the tread).

.

So.....your method should be even closer....(I'll doublecheck my alignment using the method that you researched....just to be sure because of the Vette 4-wheel alignment).

Last edited by doorgunner; 06-09-2014 at 08:57 AM.

#5

So I made a post earlier today about my basic plans for my alignment and thought I would post in detail what they are and get others thought about this.

I am close to finishing my 1979 Corvettes restoration and I do not want to use an alignment shop because in the 16 years that I have had the car I seem to always have issues with the alignments and the shops not knowing what to do with it or will not use other than stock alignment angles. My plan is to just do the alignment myself.

Here is a list of what has been modified on the car as far as the suspension.

Frame seams welded and braced per the Chevy power book including boxing in the frame horns.

Vette Brakes and products 550 ss springs and composite duel mount rear spring.

Van Steel Smart struts

Van Steel off set trailing arms

Van Steel tubular front upper control arms

Borgeson power steering box

1 1/4 front sway bar and 7/8 rear bar

all bushings are poly

Ok here is my step by step plan for my alignment.

1. Lay down plywood or masonite shims and level the area that the tires will sit. To do this I am thinking using 18 in squares and a long level.

2. Pull the car unto the level boards and then make sure the suspension height is where I want it.

3. Using string and plumb bobs I am going to attach the string to the front lower control arm at the bolt that holds the front bushing in and at the rear the trailing arm mounts. From this using the plumb bob I will mark the location on the ground at all 4 locations.

4. I will then measure from the marks I just made on the ground and mark the centerline between the marks and again use the plumb bob and string to mark the centerline of the car on the frame.

5. Next run a string from front to rear mounted on jack stands marking the exact center line of the car.

6. Set op a string on each side of the car on jack stands running parallel with the centering.

7. Next I will use a steel rule measuring from the string at the front of the rim and at the back to determine the toe, also I will be able to square up the front to the rear using this set up.

For Camber and caster I was looking at getting the Fast Track gage from Summit Racing. At first I am going to just turn the wheels complete from lock to lock to measure the caster. Eventfully if this all works well for setting my alignment I will invest in turn plates so that I can measure the 20 degrees turn in the steering that from what I have been reading is ideal for measuring caster.

Not sure what specs I am going to use but thinking about starting with this.

front

toe 1/32 in

camber -1/4

caster +4 3/4

rear

toe 1/8 in

camber - 1/2

Any thoughts or ideas are welcome.

Here is a photo of my frame.

I am close to finishing my 1979 Corvettes restoration and I do not want to use an alignment shop because in the 16 years that I have had the car I seem to always have issues with the alignments and the shops not knowing what to do with it or will not use other than stock alignment angles. My plan is to just do the alignment myself.

Here is a list of what has been modified on the car as far as the suspension.

Frame seams welded and braced per the Chevy power book including boxing in the frame horns.

Vette Brakes and products 550 ss springs and composite duel mount rear spring.

Van Steel Smart struts

Van Steel off set trailing arms

Van Steel tubular front upper control arms

Borgeson power steering box

1 1/4 front sway bar and 7/8 rear bar

all bushings are poly

Ok here is my step by step plan for my alignment.

1. Lay down plywood or masonite shims and level the area that the tires will sit. To do this I am thinking using 18 in squares and a long level.

2. Pull the car unto the level boards and then make sure the suspension height is where I want it.

3. Using string and plumb bobs I am going to attach the string to the front lower control arm at the bolt that holds the front bushing in and at the rear the trailing arm mounts. From this using the plumb bob I will mark the location on the ground at all 4 locations.

4. I will then measure from the marks I just made on the ground and mark the centerline between the marks and again use the plumb bob and string to mark the centerline of the car on the frame.

5. Next run a string from front to rear mounted on jack stands marking the exact center line of the car.

6. Set op a string on each side of the car on jack stands running parallel with the centering.

7. Next I will use a steel rule measuring from the string at the front of the rim and at the back to determine the toe, also I will be able to square up the front to the rear using this set up.

For Camber and caster I was looking at getting the Fast Track gage from Summit Racing. At first I am going to just turn the wheels complete from lock to lock to measure the caster. Eventfully if this all works well for setting my alignment I will invest in turn plates so that I can measure the 20 degrees turn in the steering that from what I have been reading is ideal for measuring caster.

Not sure what specs I am going to use but thinking about starting with this.

front

toe 1/32 in

camber -1/4

caster +4 3/4

rear

toe 1/8 in

camber - 1/2

Any thoughts or ideas are welcome.

Here is a photo of my frame.

Similar to.

http://www.longacreracing.com/produc...%a2+LW+Adapter

This is quick and easy to use, works on non-level surfaces and auto calculates caster readings.

For the front center points I would try using the lower ball joints and for the rear your location is fine, but you may find that the wheels may no be centered from this location ?. Using strings on the wheels will take alot of patients making sure its square to all wheels. You should be able to measure equal distance from the string to the front center hub left and right side, and a equal distance from the string to the rear center hub left and right side. Front and rear will vary since the front and rear track is different on corvette's.

Also using strings its difficult to make consistent measurements. Do the complete setup 3 times and you wont get the same measurements each time. This is because its difficult to get the strings in the same location each time. You will be able to get a good setup for toe, but dont get hung up on being perfect. The alignment does have a wide tolerence for settings but I would make sure its balanced left side vs right side. If you have used rubber bushings things will be more difficult. Everything moves more. Then once you have the body on and the car fully loaded all the setup will need to be re-done. I prefer to use laser level units on the wheels and figure where they are pointing. This allows a larger measuring distance to improve accuracy of the measurements. I have used both and compared the process to an alignment shop measurements to determine my accuracy. Check out this post.

Corvette forum post my process in summary is post # 13 post # 19 is my result vs alignment shop results.

Last edited by cagotzmann; 06-09-2014 at 07:54 PM.

#6

Duntov Motor Company has a really neat rear suspension alignment procedure. Tells you how to accurately set track, toe and camber. After that the front ends a breeze. Check it out at http://www.duntovmotors.com

Good luck and hope this helps.

Good luck and hope this helps.

#7

WOW, lots of good information from every one, thank you. I think that I am about 3 to 5 weeks out from doing the alignment. Just trying to get as much information that I can and decide on what tools to order. The body is currently on the frame and the car should be coming home from the paint shop this week. I need to get everything else on the car to weight it down.

Here is a phone pic I took today at the paint shop.

Here is a phone pic I took today at the paint shop.

#8

If you long term goal is to do home alignments then I would invest in a digital caster camber guage.

Similar to.

http://www.longacreracing.com/produc...%a2+LW+Adapter

This is quick and easy to use, works on non-level surfaces and auto calculates caster readings.

For the front center points I would try using the lower ball joints and for the rear your location is fine, but you may find that the wheels may no be centered from this location ?. Using strings on the wheels will take alot of patients making sure its square to all wheels. You should be able to measure equal distance from the string to the front center hub left and right side, and a equal distance from the string to the rear center hub left and right side. Front and rear will vary since the front and rear track is different on corvette's.

Also using strings its difficult to make consistent measurements. Do the complete setup 3 times and you wont get the same measurements each time. This is because its difficult to get the strings in the same location each time. You will be able to get a good setup for toe, but dont get hung up on being perfect. The alignment does have a wide tolerence for settings but I would make sure its balanced left side vs right side. If you have used rubber bushings things will be more difficult. Everything moves more. Then once you have the body on and the car fully loaded all the setup will need to be re-done. I prefer to use laser level units on the wheels and figure where they are pointing. This allows a larger measuring distance to improve accuracy of the measurements. I have used both and compared the process to an alignment shop measurements to determine my accuracy. Check out this post.

Corvette forum post my process in summary is post # 13 post # 19 is my result vs alignment shop results.

Similar to.

http://www.longacreracing.com/produc...%a2+LW+Adapter

This is quick and easy to use, works on non-level surfaces and auto calculates caster readings.

For the front center points I would try using the lower ball joints and for the rear your location is fine, but you may find that the wheels may no be centered from this location ?. Using strings on the wheels will take alot of patients making sure its square to all wheels. You should be able to measure equal distance from the string to the front center hub left and right side, and a equal distance from the string to the rear center hub left and right side. Front and rear will vary since the front and rear track is different on corvette's.

Also using strings its difficult to make consistent measurements. Do the complete setup 3 times and you wont get the same measurements each time. This is because its difficult to get the strings in the same location each time. You will be able to get a good setup for toe, but dont get hung up on being perfect. The alignment does have a wide tolerence for settings but I would make sure its balanced left side vs right side. If you have used rubber bushings things will be more difficult. Everything moves more. Then once you have the body on and the car fully loaded all the setup will need to be re-done. I prefer to use laser level units on the wheels and figure where they are pointing. This allows a larger measuring distance to improve accuracy of the measurements. I have used both and compared the process to an alignment shop measurements to determine my accuracy. Check out this post.

Corvette forum post my process in summary is post # 13 post # 19 is my result vs alignment shop results.

This tool that you use looks good but expensive. Do you feel it is worth the money?

I am going to have to spend some time reading all the information that you posted on the other page, but scanning it looks like some really good information, thank you.

#9

If you have a good alignment shop to use then get it close and let them set it to your specs. If you wish to continue to do your own alignments then its best to get the easiest tool to use, or you will never really set out the time to do it correct.

There are other options,

http://www.smartracingproducts.com/smartcamber.html

not sure how well this works with caster, I think you read camber at 2 angles and use math to calculate caster. The longarc tools does this for you. But the main thing is a digital readout vs analog. I dont want to guess what the reading is, just read it.

#11

Le Mans Master

Member Since: Jul 2006

Location: charlotte north carolina

Posts: 8,117

Likes: 0

Received 100 Likes

on

92 Posts

I tried the laser pointer technique, but the problem is aligning the laser with the object being tested. I fastened a pointer to a carpenter's level with a screw that acted like a vernier. Clamped a metal plate in a bench vise and marked the laser point on the wall. Then I flipped it to the other side of the plate, adjusted for the distance from one side of the plate to the other and repeated until the two points were exactly the same distance apart as the distance from the laser beam on each side of the plate. Then I clamped it to the rotor. It resulted in the same rear toe alignment as the string technique!

#12

For a one time use its not worth spending the money. I drive my cars on the track and change alignment many times, so for me its worth it.

If you have a good alignment shop to use then get it close and let them set it to your specs. If you wish to continue to do your own alignments then its best to get the easiest tool to use, or you will never really set out the time to do it correct.

There are other options,

http://www.smartracingproducts.com/smartcamber.html

not sure how well this works with caster, I think you read camber at 2 angles and use math to calculate caster. The longarc tools does this for you. But the main thing is a digital readout vs analog. I dont want to guess what the reading is, just read it.

If you have a good alignment shop to use then get it close and let them set it to your specs. If you wish to continue to do your own alignments then its best to get the easiest tool to use, or you will never really set out the time to do it correct.

There are other options,

http://www.smartracingproducts.com/smartcamber.html

not sure how well this works with caster, I think you read camber at 2 angles and use math to calculate caster. The longarc tools does this for you. But the main thing is a digital readout vs analog. I dont want to guess what the reading is, just read it.

I plan to work with different alignment angles to see what is best with my car so I do want to get the digital gage as it looks like the best choice. But for right now I am going to keep reading and researching.

#13

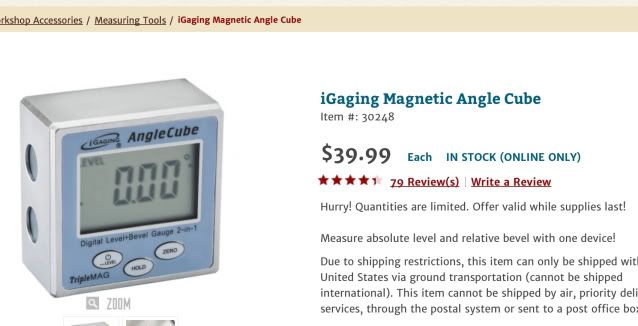

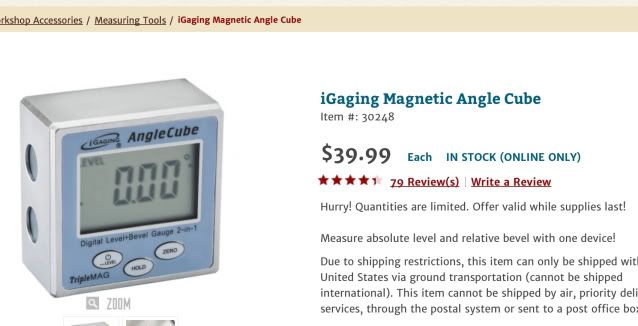

Rockier woodworking sells these magnetic base digital angle gauges. (see pics) I was thinking of using one of these to rig something up with some metal stock for a cheap homemade alignment device. What do you all think?

Last edited by C3Hawk; 06-14-2014 at 11:01 PM.

#15

I could only find this info. This is from the smart camber guage product.

subtract the difference camber1- camber2 and multiply by

for 20 degree wheel angles 1.5

for 15 degree wheel angles 2.0

for 10 degree wheel angles 3.0

I used my longarc camber caster guage which only works if you use 15 degree angles to read the numbers without calculations.

I measured -3.1 camber and + 3 camber @ 20 degrees, -2.5 and +2 at 15 degrees

Calculates to 6.1 * 1.5 = 9.15 and 4.5*2 = 9 and when using the gauge set for caster readings I get 9 - 9.1

So the above numbers seem to be correct or match what I get.

Compared to an alignment machine the actual caster they measured is 7.2

As for the rig to attach the level too, look at the commerical tools and building something similar. This will depend on your wheels. My stock YJ8 wheels have a large flat edge which only requires a simple tube steel $8 worth and cut to the proper length.

Last edited by cagotzmann; 06-15-2014 at 02:26 PM.

#16

With the stock wheels a 1 in by 1 inch square piece of tubing that sits on the flat machined area of the rim spanning from one side to the other would work. I think that it might be easy to use large rubber bands of bungee cords to attach it to the wheel.

#17

Nam Labrat

Member Since: Sep 2013

Location: New Orleans Loo-z-anna

Posts: 33,899

Received 4,179 Likes

on

2,739 Posts

Super Glue works well on a clean rim to attach the metal bar....use a rubber mallet to pop the tubing/whatever a-loose before driving the car!

#18

Le Mans Master

This weekend Power Nation's - Detroit Muscle, ran an episode called "Firebird Finale" where they did a bit on the use of QuickTricks new system called QuickSlide.

You can also go here http://www.quicktrickalignment.com/q...-videos-tos-2/ and see a number of demo's on how it is used and judge for yourself if it's something you want to try at home.

Good luck... GUSTO

You can also go here http://www.quicktrickalignment.com/q...-videos-tos-2/ and see a number of demo's on how it is used and judge for yourself if it's something you want to try at home.

Good luck... GUSTO

Last edited by GUSTO14; 06-16-2014 at 09:23 PM.

#19

For a one time use its not worth spending the money. I drive my cars on the track and change alignment many times, so for me its worth it.

If you have a good alignment shop to use then get it close and let them set it to your specs. If you wish to continue to do your own alignments then its best to get the easiest tool to use, or you will never really set out the time to do it correct.

There are other options,

http://www.smartracingproducts.com/smartcamber.html

not sure how well this works with caster, I think you read camber at 2 angles and use math to calculate caster. The longarc tools does this for you. But the main thing is a digital readout vs analog. I dont want to guess what the reading is, just read it.

If you have a good alignment shop to use then get it close and let them set it to your specs. If you wish to continue to do your own alignments then its best to get the easiest tool to use, or you will never really set out the time to do it correct.

There are other options,

http://www.smartracingproducts.com/smartcamber.html

not sure how well this works with caster, I think you read camber at 2 angles and use math to calculate caster. The longarc tools does this for you. But the main thing is a digital readout vs analog. I dont want to guess what the reading is, just read it.

I got the longacre digital camber gage and love it! Started working on the alignment tonight after work. Thanks for the info.

#20

Expensive but a very nice tool. What adapter did you purchase. I have 2 different adapters. I needed something for my 2010 GS 19" wheels, and the first one I purchased only went up to 17" wheels. I should have checked before I made the first purchase.