Shims to change pinion angle

#1

Instructor

Thread Starter

I have read that some have changed the pinion angle of the rear end by adding shims under the four mounting bolts. For those folks, how much shimming was required to make the angle change, or what thickness of shim does it take to raise the pinion angle by say 2 degrees? I have already thinned the rubber cushion and got 1.5 degrees there but would like to raise the front of the rear end by another 1.5-2 degrees.

With my T5 conversion I am trying to reduce the working angle of the U joints by raising the pinion and lowering the tailshaft of the transmission. Since the body is still off I figured this would be the time to adjust the pinion angle.

Thanks

Mark

With my T5 conversion I am trying to reduce the working angle of the U joints by raising the pinion and lowering the tailshaft of the transmission. Since the body is still off I figured this would be the time to adjust the pinion angle.

Thanks

Mark

#2

Melting Slicks

Now you know why you should have paid more attention in math class when they were teaching trigonometry.

How far apart are the mounting bolts on the rear end? Once you know that, its a simple calculation to figure out how thick a shim you need.

How far apart are the mounting bolts on the rear end? Once you know that, its a simple calculation to figure out how thick a shim you need.

#3

Safety Car

Member Since: May 2004

Location: los altos hills california

Posts: 3,598

Received 1,116 Likes

on

726 Posts

Had a big post on this a short while back under 'driveshaft angle' or something like that. This was a very informative thread and I learned a lot about what angles work so you might want to look it up.

Anyway when I had the angles where I wanted them, there was almost no shim left and the snubber was practically hard mounted. Didn't seem to be a good thing. I took off the mounting bracket, filed off all the welds and repositioned and welded the heavy metal reinforcing plate to where it needed to be to get the full size rubber in place. Others have done the same thing.

I think I have a picture of this somewhere but you get the idea. A paper drawing of the geometry helped me get the repositioning right. I'll look for that and see about posting both.

Anyway when I had the angles where I wanted them, there was almost no shim left and the snubber was practically hard mounted. Didn't seem to be a good thing. I took off the mounting bracket, filed off all the welds and repositioned and welded the heavy metal reinforcing plate to where it needed to be to get the full size rubber in place. Others have done the same thing.

I think I have a picture of this somewhere but you get the idea. A paper drawing of the geometry helped me get the repositioning right. I'll look for that and see about posting both.

#4

Safety Car

Member Since: May 2004

Location: los altos hills california

Posts: 3,598

Received 1,116 Likes

on

726 Posts

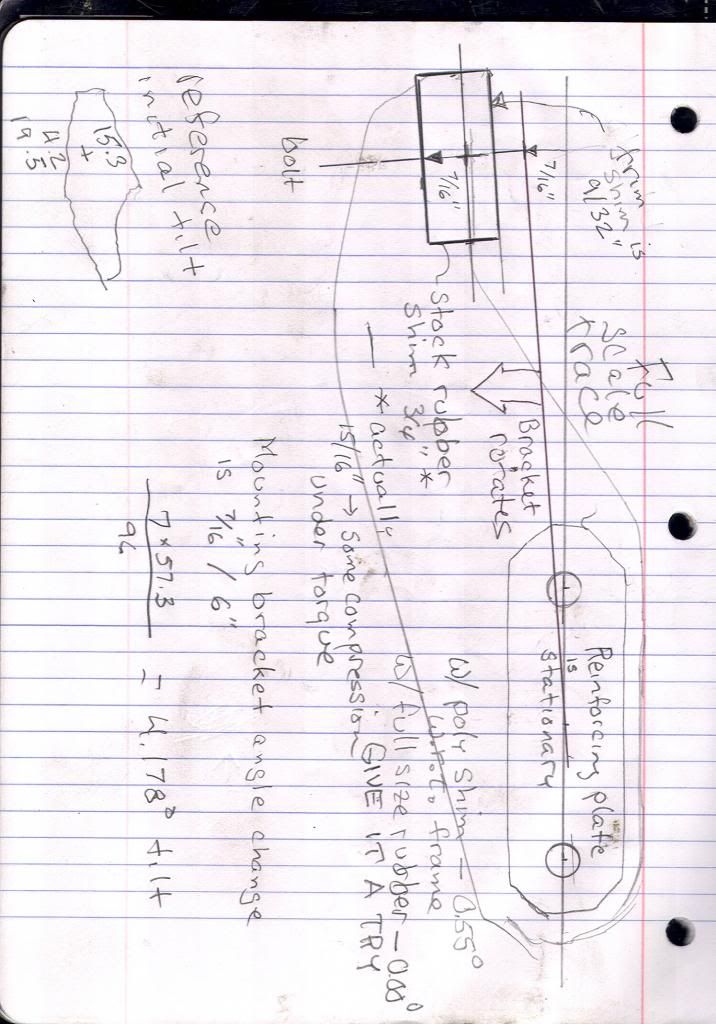

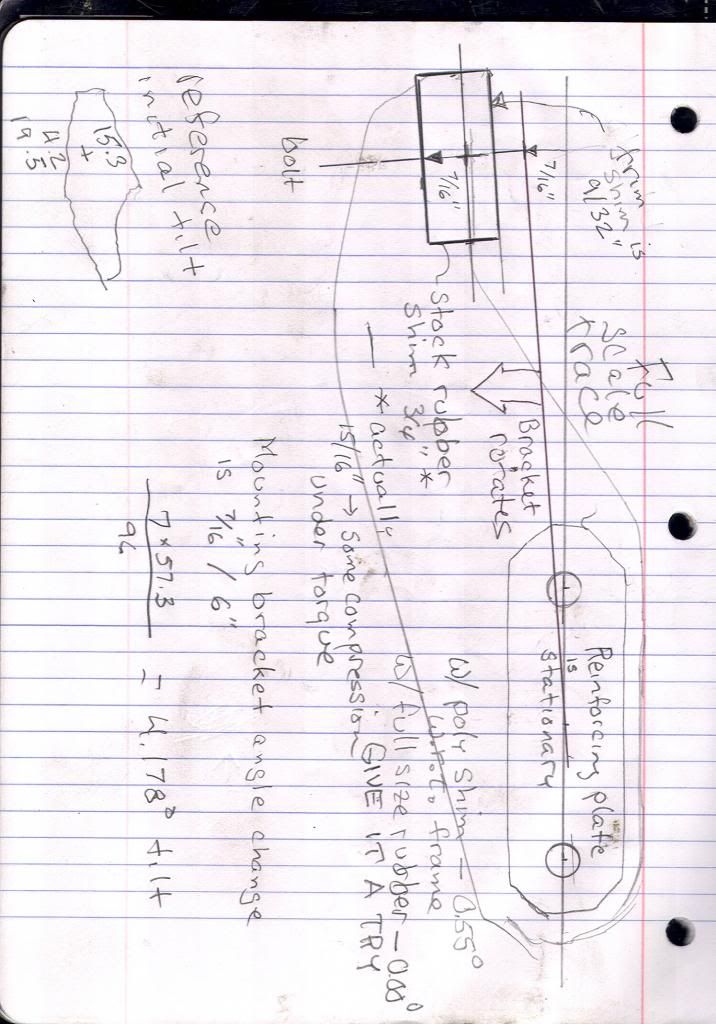

So to continue, once I had the cutoff shim in place I made a scale drawing to figure out the difference and how much I had to move the reinforcing plate to accommodate the full size rubber shim. Basically the way I thought of it is as the reinforcing plate remaining attached to the differential case in the correct position and the bracket rotating to where the full size shim would put it. Your numbers may vary, here's my drawing.

I also used a precision angle finder to scribe the new position of the plate. Once an engineer, always an engineer!

I also used a precision angle finder to scribe the new position of the plate. Once an engineer, always an engineer!

#5

Instructor

Thread Starter

IGNATZ

I have been thinking about moving the mounting bracket, only I was thinking about removing the bracket that the rubber donut sits on from the crossmember, and reattaching it at the desired height. I will look at doing it the way you did. My doughnut is down to about 1/4" now, I didn't want to make it any thinner, so the thought of moving the bracket is appealing. Thanks for the idea

I have been thinking about moving the mounting bracket, only I was thinking about removing the bracket that the rubber donut sits on from the crossmember, and reattaching it at the desired height. I will look at doing it the way you did. My doughnut is down to about 1/4" now, I didn't want to make it any thinner, so the thought of moving the bracket is appealing. Thanks for the idea