Just Rebuilt The Steering Box..

#1

Melting Slicks

Thread Starter

This steering box had rough action (corroded bearings) at the steering input shaft end. There was noticably play I could feel at the output shaft end as well. Both undoubtably contributed a lot to somewhat slopy steering. Car is an '81 w/110k mi. I didn't want to spend the money on a power steering box right now, or go R & P. I considered buying a rebuilt box, but, first off it's a couple hundred bucks, and, ya never know what you the parts inside are really like. Plus I wanted to dig into one to say I did it and save the $$.

Rebuilding was fairly easy, just needed to gather the right tools, particularly an 0-30 in/lb torque wrench. Hardest part was cleaning all the years of heavy caked-on grease and tons of grease inside it ...and getting the bearings out. I bought the 'blind hold puller' from Harbor Freight that did the trick for that. One challenge I had was there were deep corrosion pits on the worm gear bearing surface (probably where water leaked in past the steering shaft seal). I had to put it on a lathe and turn the surface down below the pits and polish with 1000 grit sand paper to restore it. If I didn't have access to a lathe I would have had to replace the box. I bought the $60 complete steering box rebuild kit from Zip Crovette Products. The bushings fit nice and tight - better than I thought they would. Used Mobil 1 grease. Looks like new, feels as tight as new as well. I'm sure handling won't be as crisp as rack and pinion, but I think it'll be a lot better than it was. Will share when I get the car back on the road (which won't be anytime soon, unfortunately). Just thought I'd share...

Mark G

Rebuilding was fairly easy, just needed to gather the right tools, particularly an 0-30 in/lb torque wrench. Hardest part was cleaning all the years of heavy caked-on grease and tons of grease inside it ...and getting the bearings out. I bought the 'blind hold puller' from Harbor Freight that did the trick for that. One challenge I had was there were deep corrosion pits on the worm gear bearing surface (probably where water leaked in past the steering shaft seal). I had to put it on a lathe and turn the surface down below the pits and polish with 1000 grit sand paper to restore it. If I didn't have access to a lathe I would have had to replace the box. I bought the $60 complete steering box rebuild kit from Zip Crovette Products. The bushings fit nice and tight - better than I thought they would. Used Mobil 1 grease. Looks like new, feels as tight as new as well. I'm sure handling won't be as crisp as rack and pinion, but I think it'll be a lot better than it was. Will share when I get the car back on the road (which won't be anytime soon, unfortunately). Just thought I'd share...

Mark G

Last edited by Mark G; 02-21-2010 at 04:04 PM.

#2

Race Director

Member Since: Sep 2002

Location: San Diego - Deep Within The State of CONFUSION!

Posts: 10,362

Likes: 0

Received 2 Likes

on

2 Posts

Hey Mark great job& thanks for sharing. I turned wrenches for a lotta years and most of the stuff on my C3 came easy ... but replacing my steering gear is one of the things on the 'future list.'

Thanks for making it sound easy. I don't have a lathe but OTOH my car only has 65K miles and it's been garaged. Hopefully the housing is good.

Thanks for making it sound easy. I don't have a lathe but OTOH my car only has 65K miles and it's been garaged. Hopefully the housing is good.

#3

Team Owner

If the box hasn't been re-greased for many years, you should at least add some synthetic grease to the box to service it. Remove the front and rear bolts on the upper housing plate. Shoot grease in the back hole untill you see it approaching the front hole. Leave some air space for grease expansion as it heats up. Install and retorque the bolts and it should be good to go.

#4

Melting Slicks

Thread Starter

SanDiegoPaul,

Given the miles of your vette, you might not need to rebuild the steering box at all. I read in some old 1980's Corvette Fever mags a series of articles about Corvette handling upgrades written by John Greenwood (Greenwood racing). In the first article he advocated that re-adjusting the steering box was almost essential after 20,000 miles. He claimed it was the number one thing a Corvette owner could do to improve their car's steering/handling. And the most inexpensive. In the article he explained the whole process and how to properly adjust to GM specs. Remember, this was back in the 80's when these cars were contemporary. The right way to do it is to remove from the car, grease like 7T1vette outlined (above), then retighten to factory specs.

What suprised me was that in the next issue, a number of readers wrote in that they had performed the readjustment proceedure and it was overwhelmingly agreed upon that it was the absolute best thing they had done to improve steering response in their cars. The responses were very enthusiastic. This inspired me to take action on mine. The reason I bring this up is if your car only has 65k Mi, I'd try to go that route first before performing a rebuild. It may be all you need to do. My car has twice the miles as yours and there was noticable play in the lower bushings (at the pitman arm), adjusting would not have cut it ..plus the corroded bearings made for rough action at the steering shaft side. What you would need to do is to remove the pitman arm, remove the steering box, ensure action felt smooth, add new grease to the internals, then perform the adjustment. Most guys don't have a 0-25 in/lbs torque wrench (you can guy off Ebay), and you really do need one of this range ...but if you took it to a garage or shop it shouldn't take more than 1/2 hour to adjust (more like 15 minutes). You can't effectively do it on the car. This link illustrates the adjustment process at the end of the article:

http://www.corvettemagazine.com/2001...ing/steer1.asp

For all others considering rebuilding the steering box, my suggestion is that if you don't have the right tools/pullers, etc, and not looking for a 'fun' challenge, I submit it's probably better to just buy one that's already rebuilt, or new. Check around on prices as they seem to vary quite a bit. Zip and Paragon, for example, were notably cheaper on rebuilt steering boxes than many of the other suppliers, but their kits were a tad pricier if I recall. A rebuilt box is only $189, which, when you think about it, is pretty fair IMO. For those considering a rebuild, take yours apart prior to ordering any parts. If it looks bad, or pitted in places like the main shaft, it's probably wiser to buy one already rebuilt ...or completely new. One should keep in mind that it is very possible the main worm gear upper bearing surface could be pitted (water easily leaks past the top seal). This is expensive to replace and the supply houses specify that if the main shafts are not usable, the $189 steering box will suddenly go up in price. Be aware of that ..and shipping costs. In my case, that's another reason I put it my box's shaft on a lathe to clean up the pitted surface. I used a mini-lathe and it was pretty easy using a carbide-tipped bit (and a lot of care). I used #400 wet sandpaper wrapped around a 1/4" dowel to form the proper final bearing radius. Then, #1000 wet sandpaper for final finish.

Of course, many on this newsgroup will contend that the Jeep P/S box replacement or a Rack N Pinion setup is the way to go, and they might have a good case. But for keeping the original steering, the above suggestion will hopefully help some out.

Mark G

Given the miles of your vette, you might not need to rebuild the steering box at all. I read in some old 1980's Corvette Fever mags a series of articles about Corvette handling upgrades written by John Greenwood (Greenwood racing). In the first article he advocated that re-adjusting the steering box was almost essential after 20,000 miles. He claimed it was the number one thing a Corvette owner could do to improve their car's steering/handling. And the most inexpensive. In the article he explained the whole process and how to properly adjust to GM specs. Remember, this was back in the 80's when these cars were contemporary. The right way to do it is to remove from the car, grease like 7T1vette outlined (above), then retighten to factory specs.

What suprised me was that in the next issue, a number of readers wrote in that they had performed the readjustment proceedure and it was overwhelmingly agreed upon that it was the absolute best thing they had done to improve steering response in their cars. The responses were very enthusiastic. This inspired me to take action on mine. The reason I bring this up is if your car only has 65k Mi, I'd try to go that route first before performing a rebuild. It may be all you need to do. My car has twice the miles as yours and there was noticable play in the lower bushings (at the pitman arm), adjusting would not have cut it ..plus the corroded bearings made for rough action at the steering shaft side. What you would need to do is to remove the pitman arm, remove the steering box, ensure action felt smooth, add new grease to the internals, then perform the adjustment. Most guys don't have a 0-25 in/lbs torque wrench (you can guy off Ebay), and you really do need one of this range ...but if you took it to a garage or shop it shouldn't take more than 1/2 hour to adjust (more like 15 minutes). You can't effectively do it on the car. This link illustrates the adjustment process at the end of the article:

http://www.corvettemagazine.com/2001...ing/steer1.asp

For all others considering rebuilding the steering box, my suggestion is that if you don't have the right tools/pullers, etc, and not looking for a 'fun' challenge, I submit it's probably better to just buy one that's already rebuilt, or new. Check around on prices as they seem to vary quite a bit. Zip and Paragon, for example, were notably cheaper on rebuilt steering boxes than many of the other suppliers, but their kits were a tad pricier if I recall. A rebuilt box is only $189, which, when you think about it, is pretty fair IMO. For those considering a rebuild, take yours apart prior to ordering any parts. If it looks bad, or pitted in places like the main shaft, it's probably wiser to buy one already rebuilt ...or completely new. One should keep in mind that it is very possible the main worm gear upper bearing surface could be pitted (water easily leaks past the top seal). This is expensive to replace and the supply houses specify that if the main shafts are not usable, the $189 steering box will suddenly go up in price. Be aware of that ..and shipping costs. In my case, that's another reason I put it my box's shaft on a lathe to clean up the pitted surface. I used a mini-lathe and it was pretty easy using a carbide-tipped bit (and a lot of care). I used #400 wet sandpaper wrapped around a 1/4" dowel to form the proper final bearing radius. Then, #1000 wet sandpaper for final finish.

Of course, many on this newsgroup will contend that the Jeep P/S box replacement or a Rack N Pinion setup is the way to go, and they might have a good case. But for keeping the original steering, the above suggestion will hopefully help some out.

Mark G

Last edited by Mark G; 02-22-2010 at 08:52 PM.

#5

Le Mans Master

Nothing wrong with rebuilding a original box as long as you follw the GM manual and get it back to factory specs. Adjusting the lash nut on top while the box is connected to the steering linkage in the car has created more problems than it has solved based on my observations over the years (impossible to properly adjust it while it is connected to steering linkage.)

#6

Team Owner

I think it is very possible to remove most of the 'slop' in that steering box without removing it...but you have to do it carefully, in very small steps, and test each change by driving to make sure you haven't overtightened it. A box with a lot of slack in the movement can get damaged very quickly, so that's not a good thing. If you can remove some of the slack without overtightening it, that is better than just leaving it alone IMO.

Also at issue, is where that 'slop' is coming from. Before any adjustment is made to the steering box, the other steering components [idler arm, steering links/joints, and ragjoint] need to be tested and/or replaced. Too often, folks go to the steering box first because it is easy to get to.

Also at issue, is where that 'slop' is coming from. Before any adjustment is made to the steering box, the other steering components [idler arm, steering links/joints, and ragjoint] need to be tested and/or replaced. Too often, folks go to the steering box first because it is easy to get to.

#7

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

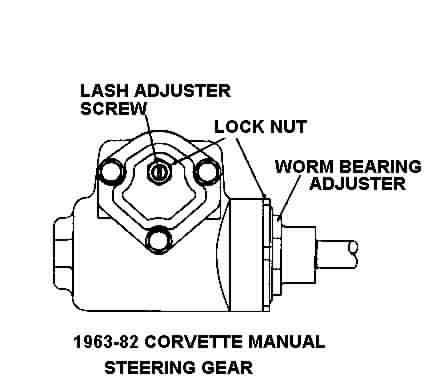

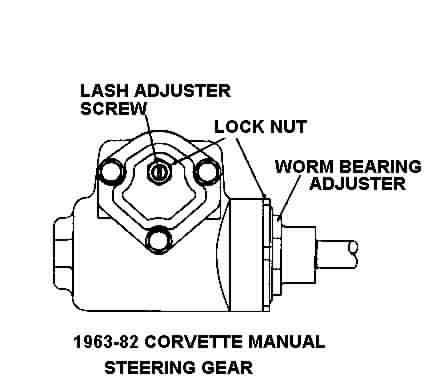

One of the things that a lot of people are forgetting (or donít realize) is that there are two adjustments to reduce or eliminate lash inside the manual steering gear. One is on the input side of the gear called the wormshaft bearing adjuster and the other is on the output side and affects the gear mesh inside the gear housing and is called the pitman shaft lash adjuster.

If you have a gear with wormshaft bearing lash, you will not eliminate it by just tightening the pitman shaft lash adjuster screw. With a 30+ year old steering gear you may have a combination of wormshaft (input) lash and pitman shaft (output) lash.

You must address wormshaft bearing lash first. Worm bearing lash will show up as an axial movement of the input shaft (in and out of the gear) as you turn the steering wheel clockwise and counterclockwise. This axial movement is lost motion and will result in you moving the steering wheel with no movement of the road wheels until the input shaft bottoms out against the internal gear bearings. You may even detect a small polished area on the wormshaft just where it enters the gear housing that will be an indication of it moving in and out.

If you see any movement of the wormshaft in and out of the gear housing, the wormshaft will need to be adjusted first.

Lastly, you make the wormshaft adjustment with the gear set near full lock. The pitman shaft adjustment is always made with the gear set exactly on center.

It is best to make the adjustment(s) using an inch-lb torque wrench with the gear out of the car.

Jim

If you have a gear with wormshaft bearing lash, you will not eliminate it by just tightening the pitman shaft lash adjuster screw. With a 30+ year old steering gear you may have a combination of wormshaft (input) lash and pitman shaft (output) lash.

You must address wormshaft bearing lash first. Worm bearing lash will show up as an axial movement of the input shaft (in and out of the gear) as you turn the steering wheel clockwise and counterclockwise. This axial movement is lost motion and will result in you moving the steering wheel with no movement of the road wheels until the input shaft bottoms out against the internal gear bearings. You may even detect a small polished area on the wormshaft just where it enters the gear housing that will be an indication of it moving in and out.

If you see any movement of the wormshaft in and out of the gear housing, the wormshaft will need to be adjusted first.

Lastly, you make the wormshaft adjustment with the gear set near full lock. The pitman shaft adjustment is always made with the gear set exactly on center.

It is best to make the adjustment(s) using an inch-lb torque wrench with the gear out of the car.

Jim

#8

Race Director

Member Since: Sep 2002

Location: San Diego - Deep Within The State of CONFUSION!

Posts: 10,362

Likes: 0

Received 2 Likes

on

2 Posts

Mark & Jim thanks for the feedback on my comment. I never even knew there was an adjustment on these other than the lash nut on top. Mine leaks from the pitman arm/sector shaft seal and has looseness. in the wheel too. The leak is minor and it has never bothered me but I like the idea of putting synthetic lube in it. That would make it last until I get around to pulling the box out of it.

I used to hate buying expensive items reman, and that's one of the reasons I never pulled the steering gearbox off. I've had the headers, heads etc off the motor since I put it in, but neglected that steering gear. Maybe it's time now that I know I can buy good quality reman stuff off this forum and it's vendors.

I probably wouldn't be rebuilding myself, just doing the R&R grunt work.

I used to hate buying expensive items reman, and that's one of the reasons I never pulled the steering gearbox off. I've had the headers, heads etc off the motor since I put it in, but neglected that steering gear. Maybe it's time now that I know I can buy good quality reman stuff off this forum and it's vendors.

I probably wouldn't be rebuilding myself, just doing the R&R grunt work.