Borgeson Power Steering

#21

Melting Slicks

Thread Starter

Member Since: Mar 2006

Location: Piedmont Va

Posts: 3,456

Received 100 Likes

on

85 Posts

St. Jude Donor '11-'12-'13,'19-'20

Here is the reply from Borgeson regarding the rag joint:

I think at this point I am good with this and have no plans to change it.

The safety pins in your rag joint are of the shoulder bolt design and the bolts are a 3/8" with nylock nuts. These components are pre-assembled and torqued to the proper spec. This prevents excessive compression of the rubber disc and insures proper operation of the rag joint. This is a rag joint we use on all of our heavy duty truck steering shafts as well as cars. We have not had a problem with failures to date with MANY rag joints sold with this design since 1990. Please let me know if you have any further questions.

#22

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

You cannot develop and retain proper tension in a bolted connection that is just squeezing rubber. I suggest that you have a fastener supplier tool up a bolt with shoulders so the connection can be made securely.

I am sorry for being so direct but we (specifically Saginaw Steering Gear) put hundreds (if not thousands) of engineering hours into the design and testing of the connection between the steering gear and steering column. It is one of the most critical connections in the car. Failing to have metal to metal bolted connections is not the way to attach critical safety parts together.

Jim

I am sorry for being so direct but we (specifically Saginaw Steering Gear) put hundreds (if not thousands) of engineering hours into the design and testing of the connection between the steering gear and steering column. It is one of the most critical connections in the car. Failing to have metal to metal bolted connections is not the way to attach critical safety parts together.

Jim

#24

Burning Brakes

Jim,

Is it safe to use a ujoint to replace the flexible joint?If you install grade 8 shoulder bolts and torque to 18ftlbs with no rubber compression would that be good to go? Car feels great with the ujoint in place,just want it to be safe and durable. Thanks!

Is it safe to use a ujoint to replace the flexible joint?If you install grade 8 shoulder bolts and torque to 18ftlbs with no rubber compression would that be good to go? Car feels great with the ujoint in place,just want it to be safe and durable. Thanks!

#25

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

The engineering idea behind a shoulder bolt is that you place a controlled squeeze on the rubber disc. You are actually steering through the disc so you do want it tight and secure. Then if the disc loses its elasticity with age, you might begin to feel some slop and the disc may lose its squeeze but the fastener(s) remains securely tightened in place. I don't remember what percentage the rubber was actually squeezed.

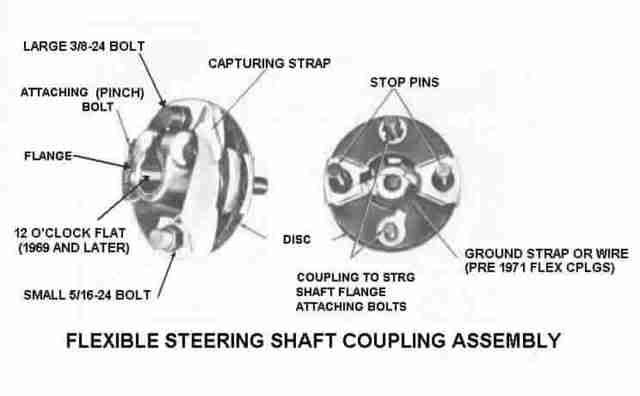

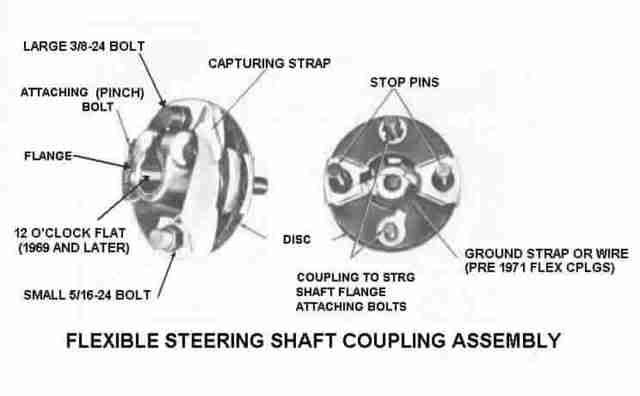

Here is another design parameter that was used by Saginaw and GM. Note that you either have to remove the gear fasteners and tip the gear or remove the steering column fasteners and pull it back into the driver compartment in order to gain clearance to remove the flexible coupling. The parts (strg column flange, stop pins, column flange, pinch bolts, etc) all overlap sufficiently such that they do not become totally disengaged even if one fastener is missing or not tightened correctly.

There is a good reason for this. The parts were designed such that if you theoretically dissolved the rubber disc out from the flex coupling the parts would still mechanically remain engaged with each other. The parts may clink and clank together (resulting in a lot of slop) but there would be considerable warning as to a dangerous condition that needs to be fixed.

The flexible coupling did evolve during the early years of the energy absorbing steering column. The stop pins were made longer (increasing the overlap with the column flange). A "capturing strap" was added that connected between the shoulder bolts. A flat was added to the gear input shaft and mating flex coupling flange.

GM and Saginaw decided not to use a cardon universal joint on the C2/C3 Corvette (and other car models where the steering column connected directly to the steering gear.) The reason was that a universal joint was not compliant in alignment or axial position. So if there is dynamic movement between the body and frame while driving, the movement would be translated into loading on the steering column lower bearing. Also, on vehicles with rubber, compliant body to frame mounts, settling of the body on the frame could also result in the parts moving out of alignment.

If I remember correctly, the Chevette steering system had a steering column directly attached to the gear. The coupling in that design was not very compliant. There was not a lower bearing in the Chevette steering column. This allowed the lower end of the steering shaft to actually "float". So there was no lower bearing to be loaded with dynamic motion.

When you have two cardon universal joints, this eliminates the offset problem.

Enough steering design 101.

Jim

Here is another design parameter that was used by Saginaw and GM. Note that you either have to remove the gear fasteners and tip the gear or remove the steering column fasteners and pull it back into the driver compartment in order to gain clearance to remove the flexible coupling. The parts (strg column flange, stop pins, column flange, pinch bolts, etc) all overlap sufficiently such that they do not become totally disengaged even if one fastener is missing or not tightened correctly.

There is a good reason for this. The parts were designed such that if you theoretically dissolved the rubber disc out from the flex coupling the parts would still mechanically remain engaged with each other. The parts may clink and clank together (resulting in a lot of slop) but there would be considerable warning as to a dangerous condition that needs to be fixed.

The flexible coupling did evolve during the early years of the energy absorbing steering column. The stop pins were made longer (increasing the overlap with the column flange). A "capturing strap" was added that connected between the shoulder bolts. A flat was added to the gear input shaft and mating flex coupling flange.

GM and Saginaw decided not to use a cardon universal joint on the C2/C3 Corvette (and other car models where the steering column connected directly to the steering gear.) The reason was that a universal joint was not compliant in alignment or axial position. So if there is dynamic movement between the body and frame while driving, the movement would be translated into loading on the steering column lower bearing. Also, on vehicles with rubber, compliant body to frame mounts, settling of the body on the frame could also result in the parts moving out of alignment.

If I remember correctly, the Chevette steering system had a steering column directly attached to the gear. The coupling in that design was not very compliant. There was not a lower bearing in the Chevette steering column. This allowed the lower end of the steering shaft to actually "float". So there was no lower bearing to be loaded with dynamic motion.

When you have two cardon universal joints, this eliminates the offset problem.

Enough steering design 101.

Jim

Last edited by Jim Shea; 06-11-2009 at 11:28 AM.

#26

Le Mans Master

Member Since: Sep 2001

Location: Unreconstructed, South Carolina

Posts: 7,739

Received 628 Likes

on

556 Posts

Jim Shea:

Thank you sir for sharing your expertise & your commentary; ever so clear.

Others:

I've followed Shea's posts for some time. I've never gotten any sense Shea held a "the sky is falling" position. But I do think he says it is what it is.

Thank you sir for sharing your expertise & your commentary; ever so clear.

Others:

I've followed Shea's posts for some time. I've never gotten any sense Shea held a "the sky is falling" position. But I do think he says it is what it is.

#27

Melting Slicks

Thread Starter

Member Since: Mar 2006

Location: Piedmont Va

Posts: 3,456

Received 100 Likes

on

85 Posts

St. Jude Donor '11-'12-'13,'19-'20

OK, I fully respect Jim Shea's knowledge in this area, and have learned quite a bit from reading his papers, and truly appreciate the time and effort spent sharing this detailed knowledge with this forum and other web sites.

However, whilst this argument may pose a theoretical risk, after review of the Borgeson design and inspection of the actual joint with local SME's which included a simple stress test, we have concluded this joint is more than adequate for my application. If I was road racing a car with manual steering I might be convinced, but lacking any factual evidence of real failures of this part I am going to trust Borgeson on this one. They have a pretty good reputation in this business, and if there was a risk there they would change the design to protect themselves from liability claims if nothing else.

So I will now be the forum guinea pig for this part!

However, whilst this argument may pose a theoretical risk, after review of the Borgeson design and inspection of the actual joint with local SME's which included a simple stress test, we have concluded this joint is more than adequate for my application. If I was road racing a car with manual steering I might be convinced, but lacking any factual evidence of real failures of this part I am going to trust Borgeson on this one. They have a pretty good reputation in this business, and if there was a risk there they would change the design to protect themselves from liability claims if nothing else.

So I will now be the forum guinea pig for this part!

#28

I supposed it's a matter of choosing the borgeson "good enough" ragjoint design and be vigilant in the periodic inspection

or

wait for a "fix", factory or DIY, based on Jim Shea's knowledge on the "the way it should be" ragjoint design.

Perhaps someone would lend Jim an actual borgeson ragjont for the "vette" Borgeson box so that he can look it over and maybe it's just a DIY shoulder bolt replacement he can recommend.

I really like the Borgenson box but kinda concerned about the ragjoint but it's on my top list of mods to do.

or

wait for a "fix", factory or DIY, based on Jim Shea's knowledge on the "the way it should be" ragjoint design.

Perhaps someone would lend Jim an actual borgeson ragjont for the "vette" Borgeson box so that he can look it over and maybe it's just a DIY shoulder bolt replacement he can recommend.

I really like the Borgenson box but kinda concerned about the ragjoint but it's on my top list of mods to do.

#29

Pro

Yes looks like a real nice setup and I'm seriously considering a purchase, but if I can make it as safe as I can I'm sure going too, so I'm all  and open to any suggestions.

and open to any suggestions.

Thanks to all that have taken the time to put in there 2 cents so far and to the op for starting and sharing his experience with this setup.

ikwhite

and open to any suggestions.

and open to any suggestions.Thanks to all that have taken the time to put in there 2 cents so far and to the op for starting and sharing his experience with this setup.

ikwhite

#30

I'm not tying to re route or change this thread as there is a lot of useful /valuable information shared.

Has there been any comparision between the Borgeson and ConceptOne power steering gears?

- are both the same physical size as the stock unit

- Concept One uses the stock type rag joint

- Brake line relocation

- cutting of the steering wheel shaft

- price - I beleive ConceptOne is twice the price

- header clearance SB and BB

- power steering pumps / reservior

- ease of installation

- power steering gear used for modification 600 605 700, or other

I'm looking to change my manual steering to one of these units due to going wiht 17 inch wheels/tires. Stock power steering will not fit due to using a non stock 8 qt oil pan.

Thanks

Has there been any comparision between the Borgeson and ConceptOne power steering gears?

- are both the same physical size as the stock unit

- Concept One uses the stock type rag joint

- Brake line relocation

- cutting of the steering wheel shaft

- price - I beleive ConceptOne is twice the price

- header clearance SB and BB

- power steering pumps / reservior

- ease of installation

- power steering gear used for modification 600 605 700, or other

I'm looking to change my manual steering to one of these units due to going wiht 17 inch wheels/tires. Stock power steering will not fit due to using a non stock 8 qt oil pan.

Thanks

#31

Melting Slicks

Thread Starter

Member Since: Mar 2006

Location: Piedmont Va

Posts: 3,456

Received 100 Likes

on

85 Posts

St. Jude Donor '11-'12-'13,'19-'20

I kinda hope Borgeson jumps back in this, I would like to see the debate on technical merit's of their design continue. Maybe they would be willing to provide an eval unit to Borgeson...what better advertising can you get for a Corvette steering solution than a Jim Shea endorsement!

In the mean time as stated I will keep this one installed for now and monitor. From what I can tell the safety pins on this part will provide a emergency (but probably sloppy) connection.

In the mean time as stated I will keep this one installed for now and monitor. From what I can tell the safety pins on this part will provide a emergency (but probably sloppy) connection.

#33

Burning Brakes

One thing that I think everyone is overlooking in this ragjoint vs. u-joint discussion, is some realworld experience over a number of years.

The "jeep" box that Tom at Corvette Steering sells is identical to the Borgeson box except for additional mods to the mount and pitman shaft areas. This Corvette Steering conversion has been on the market for a number of years and has been run by a fair number of people without mishap (see testimonials on the Corvette Steering website).

The connection between Tom's box and the steering shaft is--- A U-JOINT MADE BY BORGESON!

Jim Shea makes very good points from his engineering experience, and he is a wonderful resource for this forum. But keep in mind that these same GM engineers designed every feature on the C3 Corvette that we are all so busy modifying and improving.

In conclusion, this debate seems to be of the same sort as 'which is the best oil' or 'which is the best sparkplug'. There may be a best, but in the real world, on the street, there is little difference between them.

The "jeep" box that Tom at Corvette Steering sells is identical to the Borgeson box except for additional mods to the mount and pitman shaft areas. This Corvette Steering conversion has been on the market for a number of years and has been run by a fair number of people without mishap (see testimonials on the Corvette Steering website).

The connection between Tom's box and the steering shaft is--- A U-JOINT MADE BY BORGESON!

Jim Shea makes very good points from his engineering experience, and he is a wonderful resource for this forum. But keep in mind that these same GM engineers designed every feature on the C3 Corvette that we are all so busy modifying and improving.

In conclusion, this debate seems to be of the same sort as 'which is the best oil' or 'which is the best sparkplug'. There may be a best, but in the real world, on the street, there is little difference between them.

#34

I have the Concept One box on my 1973 Corvette. Bought the box about two years ago. Long term project so I don't have any driving experience with it. I can say that I had a horible time with clearance between the borgeson joint and my power brake booster. Solved the problem by placing a 1/4" aluminum spacer between the firewal and the booster (also exstended the coupler between booster and brake pedal the same amount to maintain pedal height). Also the borgeson joint supplied by Concept One required drilling and tapping to rotate the connection 90 degrees. Plan to get a Borgeson box for comparison in the near future since I am in final reassembly stage.