Distributor Stabbing

#1

Instructor

Thread Starter

Member Since: Feb 2003

Location: Tee Tops off all year FL

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

Well I stabbed my first distributor today and all went well. Much easier than I thought. She is running smooth with a new GM Perf distributor.

However, at idle when I try to reduce my initial timing below 20 deg by rotating the housing clockwise I hit the bracket that holds the tach filter and can't go any further. What is the best way to get around this?

Remove the rear intake bolt holding the braket and move the bracket? or restab the distributor by going to the next closest position CCW? (I tied this and it is about 3/4" more CCW than the current position? When I tried to fire up she backfired so I went back to where I had it.)

However, at idle when I try to reduce my initial timing below 20 deg by rotating the housing clockwise I hit the bracket that holds the tach filter and can't go any further. What is the best way to get around this?

Remove the rear intake bolt holding the braket and move the bracket? or restab the distributor by going to the next closest position CCW? (I tied this and it is about 3/4" more CCW than the current position? When I tried to fire up she backfired so I went back to where I had it.)

Last edited by Dk Met Grn 80 L82; 03-31-2008 at 10:23 PM.

#2

Le Mans Master

Member Since: Jan 2006

Location: Boca Raton Florida

Posts: 9,192

Likes: 0

Received 24 Likes

on

23 Posts

Sounds like your off 1 tooth. You need to re stab the Distributor. Take it out, turn it about 1 tooth CCW and reinsert it, you will need to turn the oil pump shaft a bit to get it to match up

#4

Race Director

Member Since: Dec 2007

Location: Hartselle AL

Posts: 14,345

Likes: 0

Received 4 Likes

on

2 Posts

St. Jude Donor '09

There was a recent post about the dizzy being 180* off after the "stab". From what I have learned here, the dist. cap should be oriented perpendicular (90* orientation) to the center line of the engine.

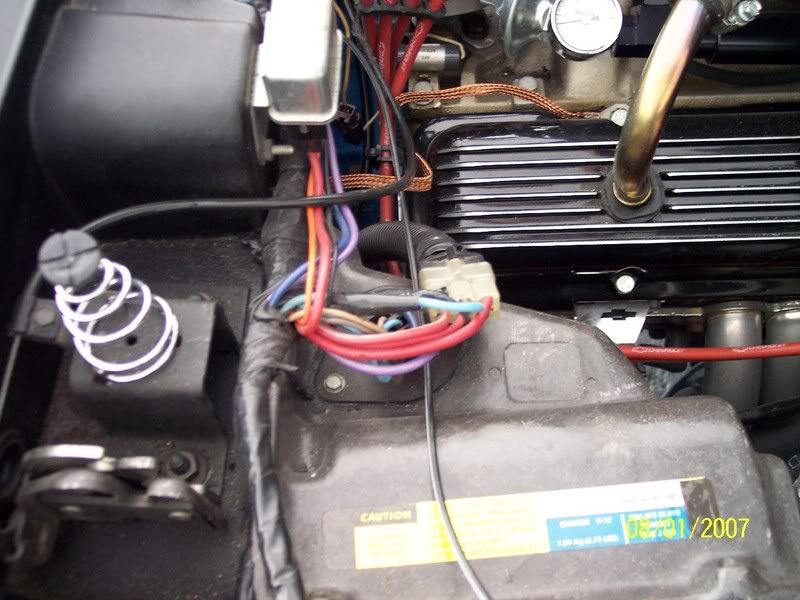

OT - spedaleden - that engine looks awesome. Someone is suffering from OCD (Obsessive Corvette Disorder). And I am working hard to contract the disorder!

OT - spedaleden - that engine looks awesome. Someone is suffering from OCD (Obsessive Corvette Disorder). And I am working hard to contract the disorder!

#5

Instructor

Thread Starter

Member Since: Feb 2003

Location: Tee Tops off all year FL

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

OK, thanks for the replies so far.

- I tried several times to get it to move only slightly CCW and I also adjusted the oil pump shaft. But the only time it would drop down is when it turned about 3/4" CCW. Is this the minimal by moving only one tooth?

- Nice looking engine compartment. Did you fab the bracket for the dist filter? Does it need to be grounded through the bracket or can I just tie wrap (hidden)? Also, if I pull the pass rear intake bolt to remove the bracket will this potentially cause a vacuum leak?

- I don't think that I am 180 deg off. My cap connector area is about 90 deg from the engine toward the driver side. Similar to where the prev distributor pointed.

- I tried several times to get it to move only slightly CCW and I also adjusted the oil pump shaft. But the only time it would drop down is when it turned about 3/4" CCW. Is this the minimal by moving only one tooth?

- Nice looking engine compartment. Did you fab the bracket for the dist filter? Does it need to be grounded through the bracket or can I just tie wrap (hidden)? Also, if I pull the pass rear intake bolt to remove the bracket will this potentially cause a vacuum leak?

- I don't think that I am 180 deg off. My cap connector area is about 90 deg from the engine toward the driver side. Similar to where the prev distributor pointed.

Last edited by Dk Met Grn 80 L82; 03-31-2008 at 10:24 PM.

#6

Safety Car

[QUOTE=Dk Met Grn 80 L82;1564805605]OK, thanks for the replies so far.

- Nice looking engine compartment. Did you fab the bracket for the cap? Does it need to be grounded through the bracket or can I just tie wrap (hidden)? Also if I pull the pass rear intake bolt to remove the bracket will this cause a vacuum leak?

Stock Dist hold down. The ground strap is for the plastic cover that goes over the dist cap to eliminate noise for the radio. Never put it back on, so I attached it to the heater motor.

I would try what Sixfooter is telling you. That will move the vacuum advace out of the way. I told you just to move it the suppressor but his way is the right way to do it.

- Nice looking engine compartment. Did you fab the bracket for the cap? Does it need to be grounded through the bracket or can I just tie wrap (hidden)? Also if I pull the pass rear intake bolt to remove the bracket will this cause a vacuum leak?

Stock Dist hold down. The ground strap is for the plastic cover that goes over the dist cap to eliminate noise for the radio. Never put it back on, so I attached it to the heater motor.

I would try what Sixfooter is telling you. That will move the vacuum advace out of the way. I told you just to move it the suppressor but his way is the right way to do it.

Last edited by spedaleden; 03-31-2008 at 09:48 PM.

#7

Instructor

Thread Starter

Member Since: Feb 2003

Location: Tee Tops off all year FL

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

OK, so if I move the distr by one tooth CCW, how much should the rotor physically move/turn? When I did this several times it turned the rotor about 3/4". Is this correct or should it be less?

#8

Le Mans Master

Well I stabbed my first distributor today and all went well. Much easier than I thought. She is running smooth with a new GM Perf distributor.

However, at idle when I try to reduce my initial timing below 20 deg by rotating the housing clockwise I hit the bracket that holds the tach filter and can't go any further. What is the best way to get around this?

Remove the rear intake bolt holding the braket and move the bracket? or restab the distributor by going to the next closest position CCW? (I tied this and it is about 3/4" more CCW than the current position? When I tried to fire up she backfired so I went back to where I had it.)

However, at idle when I try to reduce my initial timing below 20 deg by rotating the housing clockwise I hit the bracket that holds the tach filter and can't go any further. What is the best way to get around this?

Remove the rear intake bolt holding the braket and move the bracket? or restab the distributor by going to the next closest position CCW? (I tied this and it is about 3/4" more CCW than the current position? When I tried to fire up she backfired so I went back to where I had it.)

#9

Safety Car

Mark the rotor position on the housing of the dist. When you pull it out look at the gear on the the dist. You will see where the teeth meet. That is the distance the rotor will move once its set back in. To get the rotor there I align the oil pump to match the dist gear slot, then wiggle, wiggle, wiggle the dist to drop down. The distance that the rotor moved should be about the same as what you saw from the dist gear. Then checK timing

#11

Instructor

Thread Starter

Member Since: Feb 2003

Location: Tee Tops off all year FL

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the replies. Got er done...

I checked with my distr that was out of the car and one tooth really does move the rotor quiet a bit, about one hour on a clock face.

So I moved the distr CCW one tooth and kept the same relationship of installed rotor to cap and she fired right up. I think that is the point that I was missing. You could theoretically be at #1 TDC and then you could locate your distributor at any spot you want as long as the installed relationship of rotor to cap was maintained. Plenty of room to rotate and adjust my timing now.

I checked with my distr that was out of the car and one tooth really does move the rotor quiet a bit, about one hour on a clock face.

So I moved the distr CCW one tooth and kept the same relationship of installed rotor to cap and she fired right up. I think that is the point that I was missing. You could theoretically be at #1 TDC and then you could locate your distributor at any spot you want as long as the installed relationship of rotor to cap was maintained. Plenty of room to rotate and adjust my timing now.