#4 Body Mount Question

#1

Pro

Thread Starter

Member Since: May 2007

Location: Warrenville IL

Posts: 593

Likes: 0

Received 0 Likes

on

0 Posts

So far my frame has been very good in terms of rust but the birdcage has some 'opportunity' areas. I'm just getting started with replacing the body mounts and went to pull the #4 on the passenger side and encountered the following issues:

1 - After multiple days of the nut sitting in a pool of PB Blaster it still didn't budge and pulled through the fiberglass. The nut was rounded off significantly so the hole hasn't been enlarged very much and will hold sufficiently with a good size washer and after the replacement of the reinforcement.

2 - The mount on the frame is rusted out and needs to be replaced or patched.

Question:

Is it possible to fix the frame mount without pulling the body? There is some clearance, so I would say it could be patched. But I don't think it could be replaced as the rear section of the body is too close.

One issue is that I don't weld, so I have to find someone who can I can hire to do it.

Thoughts?

1 - After multiple days of the nut sitting in a pool of PB Blaster it still didn't budge and pulled through the fiberglass. The nut was rounded off significantly so the hole hasn't been enlarged very much and will hold sufficiently with a good size washer and after the replacement of the reinforcement.

2 - The mount on the frame is rusted out and needs to be replaced or patched.

Question:

Is it possible to fix the frame mount without pulling the body? There is some clearance, so I would say it could be patched. But I don't think it could be replaced as the rear section of the body is too close.

One issue is that I don't weld, so I have to find someone who can I can hire to do it.

Thoughts?

#2

Le Mans Master

You could either weld in a new #4 bracket or patch the old one. Not seeing how bad it is makes it hard to comment but it can be done with the body on.

If you have to, you can pop off the back splash shield and glue it back on when the job is done.

http://blog.scottsvettetalk.com/2007...nt-repair.aspx

If you have to, you can pop off the back splash shield and glue it back on when the job is done.

http://blog.scottsvettetalk.com/2007...nt-repair.aspx

#3

It can definitely be done with the body on, but you will end up cutting/grinding/welding in a tight space. I called a few places to come out and weld mine for me, but they all wanted the same or more than I could by my own welder for...so now I have a welder. I did exactly what scott did and just replaced the top. One thing I'd recomend though is to drill the hole first. It's much easier on a drill press.

I also cut a steel plate to fit the inside of the nut well and welded a nut to that to replace the original captive nut.

I also cut a steel plate to fit the inside of the nut well and welded a nut to that to replace the original captive nut.

#6

Pro

Thread Starter

Member Since: May 2007

Location: Warrenville IL

Posts: 593

Likes: 0

Received 0 Likes

on

0 Posts

chris73cpe or Scott Marzahl what thickness sheet metal did you use?

Is this something that is easy enough to weld that I could go over to the local harbor freight, pick up a welder an do myself? I see a thread in the General section asking about welders but I don't know much about them.

Is this something that is easy enough to weld that I could go over to the local harbor freight, pick up a welder an do myself? I see a thread in the General section asking about welders but I don't know much about them.

#7

Safety Car

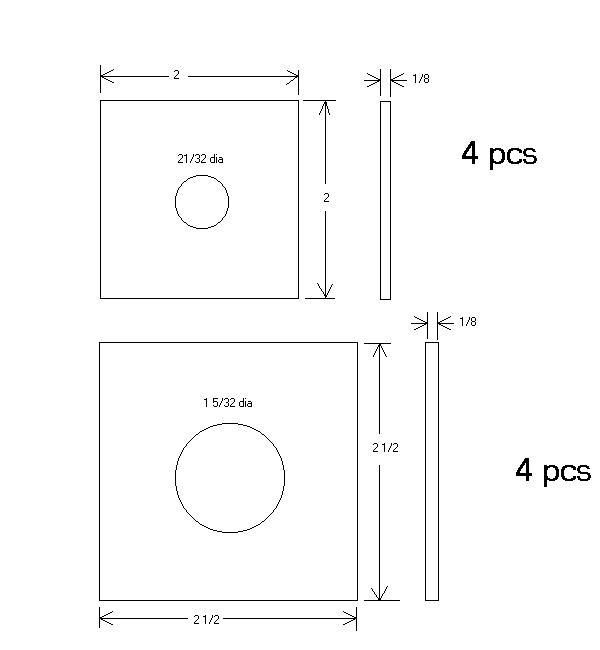

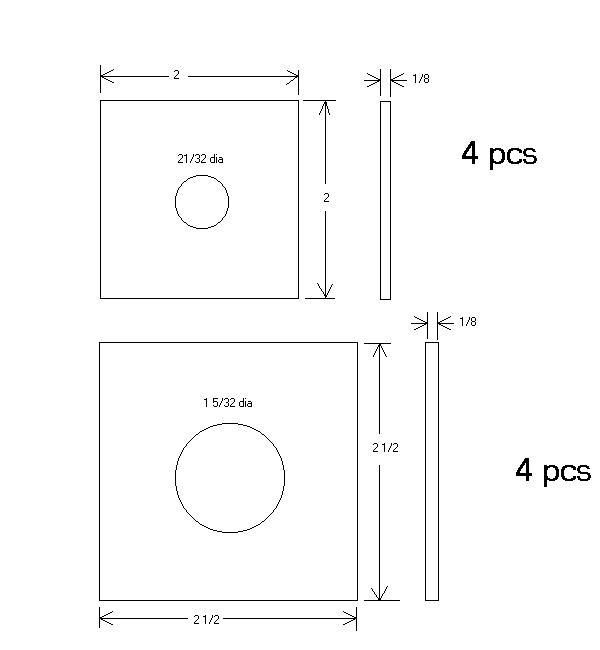

Here is what I used. The top pic is what I used for shims and the bottom pic is what I welded to the #1 and #4 frame mounts.

Last edited by redwingvette; 02-09-2008 at 10:39 AM.

#8

chris73cpe or Scott Marzahl what thickness sheet metal did you use?

Is this something that is easy enough to weld that I could go over to the local harbor freight, pick up a welder an do myself? I see a thread in the General section asking about welders but I don't know much about them.

Is this something that is easy enough to weld that I could go over to the local harbor freight, pick up a welder an do myself? I see a thread in the General section asking about welders but I don't know much about them.

Get a wirefeed welder that takes fluxcore so you do not need the gas and practice for a while on some scrap, you will be surprised how easy it is

I am sure the welder you buy will have some tips on how to weld or look up Miller welders and they have some good info on there site.

You could probably get an ok welder (for what you need) for under $300

#9

chris73cpe or Scott Marzahl what thickness sheet metal did you use?

Is this something that is easy enough to weld that I could go over to the local harbor freight, pick up a welder an do myself? I see a thread in the General section asking about welders but I don't know much about them.

Is this something that is easy enough to weld that I could go over to the local harbor freight, pick up a welder an do myself? I see a thread in the General section asking about welders but I don't know much about them.