Spal Wiring

#22

Former Vendor

Originally Posted by tersian

Tom,

Can I wire this into the old supplied sender and I see you need an additional relay to control a second fan, I am assuming I can re-use the relay I currently have from your original setup?

Can I wire this into the old supplied sender and I see you need an additional relay to control a second fan, I am assuming I can re-use the relay I currently have from your original setup?

I don't know what type of sender you have but the 195 & 185 switches that we used to supply with the harnesses will not work with the controller. These were "switches" which are on/off devices. The controller works with an analog device that varies the signal (ohms). If you have this type of device, it should work ok. The controller comes with a standard GM type oval (two prong) connector. If your's is a single prong, simply cut the plug off, and use the green wire only to your sender.

#23

Melting Slicks

Originally Posted by Tom DeWitt

You can (actually must) use the relay harness with the controller for dual fans. When you use a controller with dual fans you should wire one fan (primary) with the controller, and the second fan (secondary) with the relay harness. The control will ramp the primary fan speed up until it gets to full speed, then it kicks the relay harness on and the second fan goes on full. The primary fan drops down and begins the ramping again as required.

I don't know what type of sender you have but the 195 & 185 switches that we used to supply with the harnesses will not work with the controller. These were "switches" which are on/off devices. The controller works with an analog device that varies the signal (ohms). If you have this type of device, it should work ok. The controller comes with a standard GM type oval (two prong) connector. If your's is a single prong, simply cut the plug off, and use the green wire only to your sender.

I don't know what type of sender you have but the 195 & 185 switches that we used to supply with the harnesses will not work with the controller. These were "switches" which are on/off devices. The controller works with an analog device that varies the signal (ohms). If you have this type of device, it should work ok. The controller comes with a standard GM type oval (two prong) connector. If your's is a single prong, simply cut the plug off, and use the green wire only to your sender.

#24

Flex-a-lite has a similar product available at summit p/n FLX-31165.

*soft start ramp-up eliminates sudden start-up shock to electrical system

*adjustable on/off settings

*30 second run after engine shut-off

*30 amp rated

*under $80.00

*you don't need an extra relay

*no I don't work for summit or flex-a-lite

I have this on my car driving Becool's dual 11" set-up (spal fans), works great.

*soft start ramp-up eliminates sudden start-up shock to electrical system

*adjustable on/off settings

*30 second run after engine shut-off

*30 amp rated

*under $80.00

*you don't need an extra relay

*no I don't work for summit or flex-a-lite

I have this on my car driving Becool's dual 11" set-up (spal fans), works great.

#26

Pro

Member Since: Aug 2002

Location: The Valley of The Sun AZ

Posts: 560

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Tom DeWitt

I don't know what type of sender you have but the 195 & 185 switches that we used to supply with the harnesses will not work with the controller. These were "switches" which are on/off devices. The controller works with an analog device that varies the signal (ohms). If you have this type of device, it should work ok. The controller comes with a standard GM type oval (two prong) connector. If your's is a single prong, simply cut the plug off, and use the green wire only to your sender.

I have the old type on/off sender with the threaded nut on the top. I replaced my standard GM temp sender with it and now I can't find it. So now I have to buy a standard GM sender from you(or GM) to replace the one I bought from you to run the PWM unit I'm going to buy from you. I think I see a trend here

Thanks for the info Tom.

#28

i havent really investigated how its wired, but mine come on with the ignition key. i never really questioned this as in miami, we almost always run the ac and for the most part, ambient air is above 80.. were in the coldest part of the year now and it was still 76 by 3pm . can there be any problem with this? running them always?

#29

Originally Posted by Tom DeWitt

Puller fans are like vacuum cleaners, sucking air through the radiator core. Spal lists a range of air flow/amperage for different restrictions in front of the fan. The thicker the radiator or density of fin, the higher the restriction. The higher the restriction, the higher the amp draw. Just like when you put your hand over the vacuum hose, you can hear that motor scream. In most cases, you can use the middle of the range to estimate your air flow/amperage unless of course you're doing something really special.

#30

Originally Posted by shafrs3

Well I said that makes perfect sense but after a second thought I don't think the vacuum cleaners motor is screaming because of a greater load, it's screaming because of the lack of load; it has no air to pump and is freewheeling. And if that is true the amperage draw should go down.

Apply Voltage to an electric motor, put an ammeter in series with it and squeeze the shaft with your fingers as it spins. You will see that the current reading will rise. Your fingers squeezing the shaft increases the load on the motor.

In its most basic form: Power = Voltage * Current. By squeezing the rotating shaft you are demanding more power from the motor. Voltage stays constant so Current must rise in order for Power to rise.

#31

Originally Posted by Boofers

The term load implies opposing force. The more restriction to airflow, the higher the load.

Apply Voltage to an electric motor, put an ammeter in series with it and squeeze the shaft with your fingers as it spins. You will see that the current reading will rise. Your fingers squeezing the shaft increases the load on the motor.

In its most basic form: Power = Voltage * Current. By squeezing the rotating shaft you are demanding more power from the motor. Voltage stays constant so Current must rise in order for Power to rise.

Apply Voltage to an electric motor, put an ammeter in series with it and squeeze the shaft with your fingers as it spins. You will see that the current reading will rise. Your fingers squeezing the shaft increases the load on the motor.

In its most basic form: Power = Voltage * Current. By squeezing the rotating shaft you are demanding more power from the motor. Voltage stays constant so Current must rise in order for Power to rise.

If you loose some suction, you'll loose some of the load, if you loose all suction you'll loose all load. Your right, squeezing the shaft would increase load.

Last edited by shafrs3; 01-16-2006 at 07:46 PM.

#32

"Rodstoration &am p;quot; In Progres

Member Since: Jun 2004

Location: Frisco TX

Posts: 1,397

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Tom DeWitt

We have now changed to standardize on the SPWM (controller) for our fan controls. The older relay package and switch is still available but I think Spal will eventually drop it because the controller does so much more. The SPWM controls one fan by itself and for dual fans you need to buy the extra relay harness (SPFRH). You never want to wire the fans together or in series. Each fan should be individually fused and protected so you loose a fuse, not a fan.

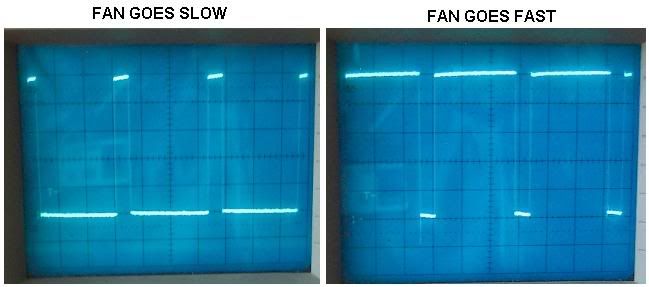

The SPWM will ramp the fan speed as needed instead of running full blast. It is also capable of using the stock temp (gauge) sending units so you do not have to install anything into the engine, simply tap off the gauge sender. The controller has a two-prong plug for the sender and a lot of the older ones are single. This can still work by using the green wire only. But just to make sure that you are not going to have trouble, we now include a two prong switch with each controller. When you run two fans (duals) the controller works in conjunction with a relay harness. You then have a primary and secondary system. The controller ramps up the primary fan and if it gets to full speed, then it kicks on the seconday fan and starts ramping the primary again. It has auto AC accuation if you have that feature. Direct link

Direct link

The SPWM will ramp the fan speed as needed instead of running full blast. It is also capable of using the stock temp (gauge) sending units so you do not have to install anything into the engine, simply tap off the gauge sender. The controller has a two-prong plug for the sender and a lot of the older ones are single. This can still work by using the green wire only. But just to make sure that you are not going to have trouble, we now include a two prong switch with each controller. When you run two fans (duals) the controller works in conjunction with a relay harness. You then have a primary and secondary system. The controller ramps up the primary fan and if it gets to full speed, then it kicks on the seconday fan and starts ramping the primary again. It has auto AC accuation if you have that feature.

Direct link

Direct link