1971 Journey

#821

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi Craig,

Great looking car and a terrific set-up to work on it!

Regards,

Alan

Great looking car and a terrific set-up to work on it!

Regards,

Alan

Last edited by Alan 71; 02-03-2016 at 08:13 AM.

The following users liked this post:

CraigH (02-09-2016)

#822

Melting Slicks

Thread Starter

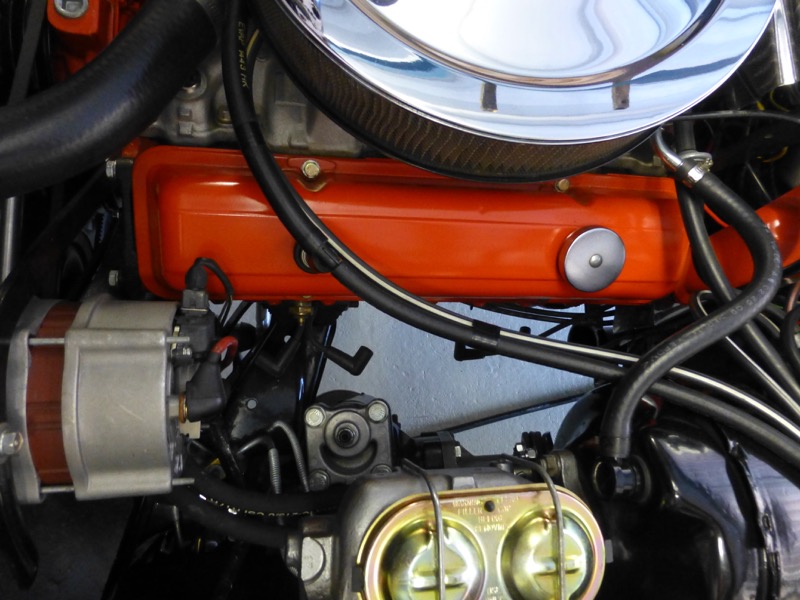

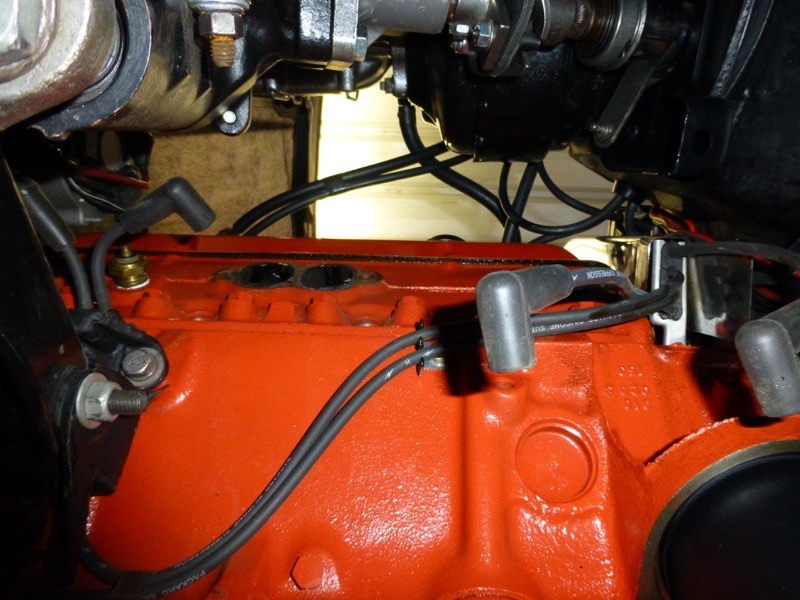

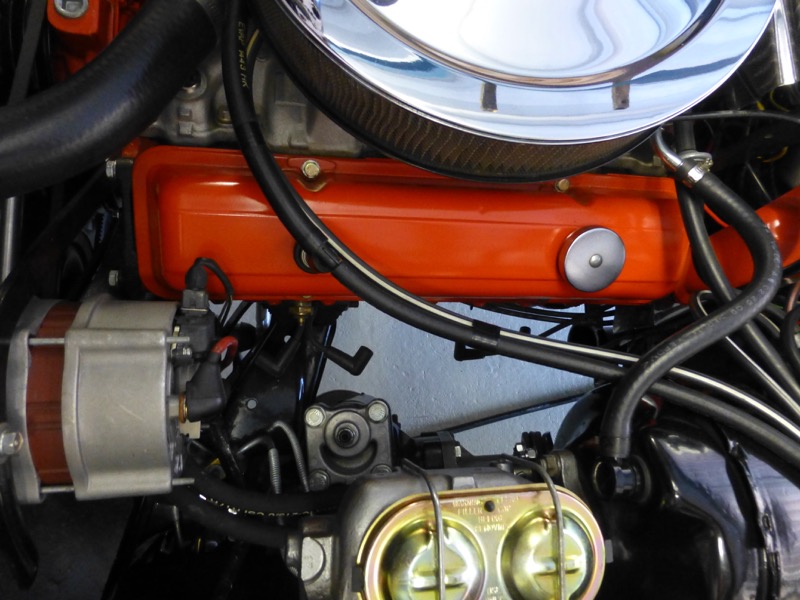

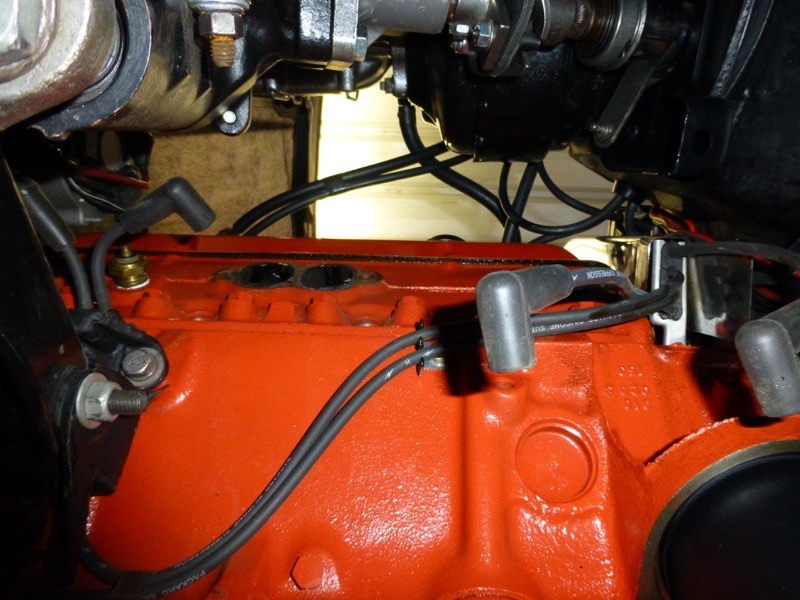

First real use for the Quickjack.

Need to swap the Borgeson steering box, so header needs to come off to give some clearance.

All out in no time and a lot simpler than in the past.

Need to swap the Borgeson steering box, so header needs to come off to give some clearance.

All out in no time and a lot simpler than in the past.

Last edited by CraigH; 04-10-2023 at 05:15 AM.

#823

Melting Slicks

Thread Starter

Before fitting the new Borgeson box wondered if anyone had experience Tyre rubbing on the steering box bolt heads.

They supply normal hex head bolts when the stock ones were carriage bolts.

I used stock bolts with first Borgeson box but needed a few washers as they were a bit longer than needed and thread did not go down far enough.

May just go to the local fastener shop and try and get carriage ones correct length.

They supply normal hex head bolts when the stock ones were carriage bolts.

I used stock bolts with first Borgeson box but needed a few washers as they were a bit longer than needed and thread did not go down far enough.

May just go to the local fastener shop and try and get carriage ones correct length.

#824

Nam Labrat

Member Since: Sep 2013

Location: New Orleans Loo-z-anna

Posts: 33,883

Received 4,153 Likes

on

2,726 Posts

Clean......and very good pics!

The following users liked this post:

CraigH (02-09-2016)

#826

Melting Slicks

Thread Starter

Thanks....

Now the floor is painted i find myself wiping up all the dirt or fluids that drop when you do any work. Previously they stained the floor but now just wipe off the paint.

I like taking lots of pictures as ......

1) it helps me remember what i have done, so next time i have to do it i can quickly review and get going without having to make the same mistakes over :-)

2) it may help others that may need to do the same thing. (Lots of other posts here have certainly helped me)

Re the bolts I may look for grade 5 round headed carriage bolts as the last thing i want is to damage a tyre on full lock.

Now the floor is painted i find myself wiping up all the dirt or fluids that drop when you do any work. Previously they stained the floor but now just wipe off the paint.

I like taking lots of pictures as ......

1) it helps me remember what i have done, so next time i have to do it i can quickly review and get going without having to make the same mistakes over :-)

2) it may help others that may need to do the same thing. (Lots of other posts here have certainly helped me)

Re the bolts I may look for grade 5 round headed carriage bolts as the last thing i want is to damage a tyre on full lock.

Last edited by CraigH; 05-19-2017 at 07:57 AM.

#827

Melting Slicks

Thread Starter

Love the large wheels but have a soft spot for the originals as well.

#828

Race Director

I put the 215 size under the car while on the lift, they looked too small, the 225 looked better. Their size is close to original.

The 215 to me just looked to small, from the rear. The F70 I have, which is original spare is about the same with as the 225. I would guess there is a difference in the dimension's with different manufacturers. as I measured my stock F70 against my friends and there is a 1/2 " difference -

The 215 to me just looked to small, from the rear. The F70 I have, which is original spare is about the same with as the 225. I would guess there is a difference in the dimension's with different manufacturers. as I measured my stock F70 against my friends and there is a 1/2 " difference -

#829

Melting Slicks

Thread Starter

That interesting. I always thought the 215/70/15 had the correct rolling diameter to match the old style tyres.

So it may be the 215 is the correct height but 225 is closer in width.

So it may be the 215 is the correct height but 225 is closer in width.

#830

Melting Slicks

Thread Starter

I have been sourcing all the bits i need to finish putting in the replacement Borgeson box and I was a bit fixated on the bolts

1 is the stick bolt with a carriage head. Grade 5.

2 is the bolts that came with my Borgeson in 2010. Grade 5.

3 is the bolts that came with my newest Borgeson box. Grade 5.

4 is all i could get here in Australia with a carriage head. Grade 2 :-(

But luckily I found great place on line in the US called the BoltDepot

http://www.boltdepot.com

They had both Grade 5 and Grade 8 carriage head bolts in 4" and all the bits i needed so a quick order and its on its way to California where i will pick it up in a few weeks when i am over for work.

Now no concerns of the tyres rubbing on the bolt heads

Also noticed that my Pitman arm looks a bit sad in its threads so have sourced another on eBay and its on its way as well.

This explains why it would not go on fully last time.

1 is the stick bolt with a carriage head. Grade 5.

2 is the bolts that came with my Borgeson in 2010. Grade 5.

3 is the bolts that came with my newest Borgeson box. Grade 5.

4 is all i could get here in Australia with a carriage head. Grade 2 :-(

But luckily I found great place on line in the US called the BoltDepot

http://www.boltdepot.com

They had both Grade 5 and Grade 8 carriage head bolts in 4" and all the bits i needed so a quick order and its on its way to California where i will pick it up in a few weeks when i am over for work.

Now no concerns of the tyres rubbing on the bolt heads

Also noticed that my Pitman arm looks a bit sad in its threads so have sourced another on eBay and its on its way as well.

This explains why it would not go on fully last time.

Last edited by CraigH; 04-10-2023 at 05:15 AM.

#831

Race Director

For bolts did you try a MARINE SUPPLY house, they also have Stainless Steel in structural bolts. If there is a local boat builder he may have all the parts you need.

I have also used a Tractor trailer repair / builder for strange parts / bolts.

Hope this may help.

I have also used a Tractor trailer repair / builder for strange parts / bolts.

Hope this may help.

#832

Melting Slicks

Thread Starter

The local specialty fastener shop only had the Grade 2 carriage bolts but recommended I go to the local Tractor replacement parts place as he thought they had them.

They did but not 4".

Not a lot of marine places near where i am but I did ring number of specialty bolt paces in Sydney and Melbourne and all had a big no.

In the end http://www.boltdepot.com came through :-)

Last edited by CraigH; 02-09-2016 at 08:58 PM.

#833

Melting Slicks

since we don't get to see you much on the local Oz forum anymore,

and i have to catch up with your updates here,

will you be going to Bendigo for the convention at easter time?

and i have to catch up with your updates here,

will you be going to Bendigo for the convention at easter time?

#834

Melting Slicks

Thread Starter

yes I stopped updating the thread on the Australian site and just do this one.

Not registered for the Bendigo Convention but dependant on other travel etc i may drive down to have a look anyway.

Last edited by CraigH; 02-09-2016 at 08:59 PM.

#835

Drifting

Member Since: Aug 2015

Location: NSW, Australia

Posts: 1,939

Received 472 Likes

on

344 Posts

C3 of Year Finalist (track prepared) 2019

In the end http://www.boltdepot.com came through :-)

#836

Melting Slicks

Thread Starter

I will pick them up from there when i am in the US next week.

Once i get them and get back i will fit it up and ensure they do the job as expected.

If it turns out they won't ship to Australia PM me and I can add some to a future package i get shipped over.

Not sure when that will be but there seems to be one every 3-4 months based on history :-).

The following users liked this post:

Metalhead140 (02-10-2016)

#837

Drifting

Member Since: Aug 2015

Location: NSW, Australia

Posts: 1,939

Received 472 Likes

on

344 Posts

C3 of Year Finalist (track prepared) 2019

Thanks! Let me know if all is well when you get them home. I've ordered the ridetech steering box brace also, as the chassis flex is (to me) quite alarming around the steering box, but I intend to modify the holes in the brace (which are round) to take the standard carriage style bolts. I do polish the bolt heads at full lock, so don't think hex heads are a good idea for me...

#840

Race Director

a supplier for hardware nuts and bolts is :

http://www.mcmaster.com/#

they have grade 5 and grade 8. Don't know if they ship out of the US, buy probably will.

No. 3 Square Neck with Flat Head—Bolts are zinc-plated Grade 5 medium-strength steel. The top of the head is marked with three radial lines to indicate Grade 5. Minimum tensile strength is 120,000 psi. Minimum Rockwell hardness is C25. Dimensions meet ASME B18.9.

No. 3 Square Neck with Dome Head—Bolts are zinc-plated Grade 8 high-strength steel. The top of the head is marked with six radial lines to indicate Grade 8. Minimum tensile strength is 150,000 psi. Minimum Rockwell hardness is C33.

Carriage Bolts

Square Neck

The neck shape keeps these bolts from turning when tightening a nut. The bolts have a smooth, rounded head. Length is measured from under the head. Stainless steel and galvanized steel bolts are a good choice for ACQ-treated (arsenic-free) lumber. Inch sizes have a Class 2A thread fit. Inch size square-neck bolts meet ANSI B18-5. Metric sizes have a Class 6g thread fit, except M6 bolts have a Class 8g thread fit.

Type 316 Stainless Steel—These are our most corrosion resistant carriage bolts.

18-8 Stainless Steel—More corrosion resistant than zinc-plated and hot-dipped galvanized steel bolts.

Zinc-Plated Steel—Offer good corrosion resistance. Medium-strength steel (Grade 5) meets SAE J429. Low-strength steel (Grade 2) meets ASTM A307 or SAE J429.

Hot-Dipped Galvanized Steel—These low-strength (Grade 2) steel bolts are more corrosion resistant than zinc-plated steel bolts. They meet ASTM A307; galvanization meets ASTM 153. Bolts must be used with hot-dipped galvanized nuts.

Bronze—These bolts are corrosion resistant and stand up to salt water. They are not rated for hardness.

For technical drawings and 3-D models, click on a part number.For technical drawings and 3-D models, click on a part number.

Square Neck—Zinc-Plated Medium-Strength Steel (Grade 5)

1/4"-20—Neck: Wd. 0.26"

3/4" Full 50 90185A540 5.34

1" Full 50 90185A542 7.24

1 1/4" Full 50 90185A544 7.34

1 1/2" Full 50 90185A546 8.16

2" Full 50 90185A550 10.16

2 1/2" Full 25 90185A552 5.82

3" Full 50 90185A555 13.48

5/16"-18—Neck: Wd. 0.32"

3/4" Full 50 90185A581 8.37

1" Full 50 90185A583 9.88

1 1/4" Full 50 90185A589 12.26

1 1/2" Full 25 90185A587 7.08

2" Full 25 90185A591 7.11

2 1/2" Full 25 90185A593 11.15

3" Full 25 90185A595 11.47

4" Full 10 90185A598 6.83

3/8"-16—Neck: Wd. 0.39"

3/4" Full 50 90185A621 12.13

1" Full 50 90185A624 11.47

1 1/4" Full 25 90185A626 7.07

1 1/2" Full 25 90185A628 6.73

1 3/4" Full 25 90185A630 7.94

2" Full 25 90185A632 9.19

2 1/4" Full 25 90185A633 12.73

2 1/2" Full 25 90185A634 10.55

3" Full 25 90185A636 12.84

3 1/2" Full 10 90185A638 5.71

4" Full 10 90185A640 6.38

1/2"-13—Neck: Wd. 0.52"

1" Full 10 90185A708 5.47

1 1/4" Full 10 90185A712 5.73

1 1/2" Full 10 90185A716 5.79

1 3/4" Full 10 90185A718 7.82

2" Full 10 90185A720 7.09

2 1/2" Full 10 90185A722 8.40

3" Full 10 90185A724 10.58

3 1/2" Full 10 90185A726 10.78

4" Full 10 90185A728 12.39

4 1/2" Full 10 90185A732 13.02

5" Full 5 90185A736 7.48

6" Full 5 90185A740 8.38

5/8"-11—Neck: Wd. 0.64"

2" Full 10 90185A810 11.93

2 1/2" Full 5 90185A814 6.97

3" Full 5 90185A818 6.50

3 1/2" Full 5 90185A822 8.28

4" Full 5 90185A826 9.36

4 1/2" Full 5 90185A830 8.33

5" Full 5 90185A834 9.55

6" Full 5 90185A838 10.73

3/4"-10—Neck: Wd. 0.77"

3" Full 5 90185A875 12.02

4" Full 5 90185A879 12.50

5" Full 1 90185A883 2.60

6" Full 1 90185A887 3.03

Square Neck—Hot Dipped Galvanized Low-Strength Steel (Grade 2)

1/4"-20—Neck: Wd. 0.26"

3/4" Full 100 93604A611 6.85

1" Full 100 93604A613 7.45

1 1/4" Full 100 93604A615 7.86

1 1/2" Full 100 93604A617 8.78

1 3/4" Full 100 93604A619 9.53

2" Full 100 93604A621 11.31

2 1/2" Full 100 93604A623 13.32

3" Full 50 93604A625 8.19

3 1/2" Full 50 93604A627 9.18

4" Full 50 93604A629 9.61

4 1/2" Full 50 93604A631 10.14

5" Full 50 93604A633 12.40

5 1/2" Full 50 93604A635 12.87

6" Full 50 93604A637 14.40

7" Partial to Full 10 93604A638 5.84

8" Partial to Full 10 93604A901 6.31

5/16"-18—Neck: Wd. 0.32"

3/4" Full 100 93604A639 12.50

1" Full 100 93604A641 12.93

1 1/4" Full 50 93604A643 8.00

1 1/2" Full 50 93604A645 8.62

1 3/4" Full 50 93604A647 9.54

2" Full 50 93604A649 9.76

2 1/2" Full 50 93604A651 11.64

3" Full 50 93604A653 13.63

3 1/2" Full 50 93604A655 14.31

4" Full 25 93604A657 8.38

4 1/2" Full 25 93604A659 9.43

5" Full 25 93604A661 10.02

5 1/2" Full 25 93604A663 12.35

6" Full 25 93604A665 12.37

3/8"-16—Neck: Wd. 0.39"

1" Full 50 93604A667 9.43

1 1/4" Full 50 93604A669 10.88

1 1/2" Full 50 93604A671 12.87

1 3/4" Full 50 93604A673 13.27

2" Full 50 93604A675 14.10

2 1/4" Full 25 93604A677 8.03

2 1/2" Full 25 93604A679 8.66

3" Full 25 93604A681 9.51

3 1/2" Full 25 93604A683 9.87

4" Full 25 93604A685 11.15

4 1/2" Full 25 93604A687 13.15

5" Full 25 93604A689 14.44

5 1/2" Full 10 93604A691 6.31

6" Full 10 93604A693 7.01

6 1/2" Partial to Full 10 93604A695 7.33

7" Partial to Full 10 93604A697 8.31

8" Partial to Full 10 93604A699 8.45

9" Partial to Full 10 93604A701 11.02

10" Partial to Full 10 93604A703 12.43

12" Partial to Full 5 93604A704 6.98

14" Partial to Full 5 93604A706 8.81

16" Partial to Full 5 93604A708 11.02

1/2"-13—Neck: Wd. 0.52"

1 1/2" Full 25 93604A711 10.68

2" Full 25 93604A713 13.54

2 1/2" Full 10 93604A715 6.37

3" Full 10 93604A717 7.59

3 1/2" Full 10 93604A719 8.46

4" Full 10 93604A721 9.04

4 1/2" Full 10 93604A723 9.92

5" Full 10 93604A725 10.62

6" Full 10 93604A729 12.12

6 1/2" Partial to Full 10 93604A731 13.16

7" Partial to Full 10 93604A733 13.78

8" Partial to Full 5 93604A735 8.41

9" Partial to Full 5 93604A737 9.11

10" Partial to Full 5 93604A739 8.81

12" Partial to Full 5 93604A743 12.43

14" Partial to Full 1 93604A745 3.23

16" Partial to Full 1 93604A749 3.45

5/8"-11—Neck: Wd. 0.64"

2" Full 10 93604A753 10.40

2 1/2" Full 10 93604A755 10.21

3" Full 10 93604A757 12.95

4" Full 5 93604A761 8.50

4 1/2" Full 5 93604A763 9.92

5" Full 5 93604A765 9.15

6" Full 5 93604A767 9.55

8" Partial to Full 5 93604A769 12.75

10" Partial to Full 5 93604A773 13.96

12" Partial to Full 1 93604A777 3.09

14" Partial to Full 1 93604A780 3.55

16" Partial to Full 1 93604A783 4.57

Metric Square Neck—Zinc-Plated Medium-Strength Steel (Class 8.8)

M6 × 1—Neck: Wd. 6.48 mm

12 Full 25 98930A020 $6.19

16 Full 25 98930A024 6.88

20 Full 25 98930A026 7.22

25 Full 25 98930A032 7.56

30 Partial 25 98930A038 8.80

35 Partial 25 98930A042 9.35

40 Partial 25 98930A048 11.00

M8 × 1.25—Neck: Wd. 8.58 mm

16 Full 100 98930A114 13.00

20 Full 100 98930A116 12.00

25 Full 50 98930A118 8.50

30 Full 50 98930A122 9.00

35 Full 50 98930A124 11.50

40 Full 50 98930A126 11.00

45 Full 50 98930A128 11.00

50 Full 50 98930A132 13.50

55 Partial to Full 25 98930A134 9.50

60 Partial to Full 25 98930A136 8.00

80 Partial to Full 25 98930A142 8.50

90 Partial to Full 25 98930A144 11.25

M10 × 1.5—Neck: Wd. 10.58 mm

20 Full 50 98930A211 11.00

25 Full 25 98930A213 7.25

35 Full 25 98930A217 7.75

40 Full 25 98930A219 10.00

45 Full 25 98930A221 9.00

50 Full 25 98930A223 10.00

60 Partial to Full 10 98930A227 6.60

70 Partial to Full 10 98930A229 4.80

80 Partial to Full 10 98930A231 5.30

90 Partial to Full 10 98930A233 7.90

M12 × 1.75—Neck: Wd. 12.7 mm

30 Full 25 98930A326 10.75

40 Full 25 98930A332 10.50

45 Full 25 98930A334 11.66

50 Full 25 98930A336 11.75

60 Partial to Full 10 98930A342 6.00

http://www.mcmaster.com/#

they have grade 5 and grade 8. Don't know if they ship out of the US, buy probably will.

No. 3 Square Neck with Flat Head—Bolts are zinc-plated Grade 5 medium-strength steel. The top of the head is marked with three radial lines to indicate Grade 5. Minimum tensile strength is 120,000 psi. Minimum Rockwell hardness is C25. Dimensions meet ASME B18.9.

No. 3 Square Neck with Dome Head—Bolts are zinc-plated Grade 8 high-strength steel. The top of the head is marked with six radial lines to indicate Grade 8. Minimum tensile strength is 150,000 psi. Minimum Rockwell hardness is C33.

Carriage Bolts

Square Neck

The neck shape keeps these bolts from turning when tightening a nut. The bolts have a smooth, rounded head. Length is measured from under the head. Stainless steel and galvanized steel bolts are a good choice for ACQ-treated (arsenic-free) lumber. Inch sizes have a Class 2A thread fit. Inch size square-neck bolts meet ANSI B18-5. Metric sizes have a Class 6g thread fit, except M6 bolts have a Class 8g thread fit.

Type 316 Stainless Steel—These are our most corrosion resistant carriage bolts.

18-8 Stainless Steel—More corrosion resistant than zinc-plated and hot-dipped galvanized steel bolts.

Zinc-Plated Steel—Offer good corrosion resistance. Medium-strength steel (Grade 5) meets SAE J429. Low-strength steel (Grade 2) meets ASTM A307 or SAE J429.

Hot-Dipped Galvanized Steel—These low-strength (Grade 2) steel bolts are more corrosion resistant than zinc-plated steel bolts. They meet ASTM A307; galvanization meets ASTM 153. Bolts must be used with hot-dipped galvanized nuts.

Bronze—These bolts are corrosion resistant and stand up to salt water. They are not rated for hardness.

For technical drawings and 3-D models, click on a part number.For technical drawings and 3-D models, click on a part number.

Square Neck—Zinc-Plated Medium-Strength Steel (Grade 5)

1/4"-20—Neck: Wd. 0.26"

3/4" Full 50 90185A540 5.34

1" Full 50 90185A542 7.24

1 1/4" Full 50 90185A544 7.34

1 1/2" Full 50 90185A546 8.16

2" Full 50 90185A550 10.16

2 1/2" Full 25 90185A552 5.82

3" Full 50 90185A555 13.48

5/16"-18—Neck: Wd. 0.32"

3/4" Full 50 90185A581 8.37

1" Full 50 90185A583 9.88

1 1/4" Full 50 90185A589 12.26

1 1/2" Full 25 90185A587 7.08

2" Full 25 90185A591 7.11

2 1/2" Full 25 90185A593 11.15

3" Full 25 90185A595 11.47

4" Full 10 90185A598 6.83

3/8"-16—Neck: Wd. 0.39"

3/4" Full 50 90185A621 12.13

1" Full 50 90185A624 11.47

1 1/4" Full 25 90185A626 7.07

1 1/2" Full 25 90185A628 6.73

1 3/4" Full 25 90185A630 7.94

2" Full 25 90185A632 9.19

2 1/4" Full 25 90185A633 12.73

2 1/2" Full 25 90185A634 10.55

3" Full 25 90185A636 12.84

3 1/2" Full 10 90185A638 5.71

4" Full 10 90185A640 6.38

1/2"-13—Neck: Wd. 0.52"

1" Full 10 90185A708 5.47

1 1/4" Full 10 90185A712 5.73

1 1/2" Full 10 90185A716 5.79

1 3/4" Full 10 90185A718 7.82

2" Full 10 90185A720 7.09

2 1/2" Full 10 90185A722 8.40

3" Full 10 90185A724 10.58

3 1/2" Full 10 90185A726 10.78

4" Full 10 90185A728 12.39

4 1/2" Full 10 90185A732 13.02

5" Full 5 90185A736 7.48

6" Full 5 90185A740 8.38

5/8"-11—Neck: Wd. 0.64"

2" Full 10 90185A810 11.93

2 1/2" Full 5 90185A814 6.97

3" Full 5 90185A818 6.50

3 1/2" Full 5 90185A822 8.28

4" Full 5 90185A826 9.36

4 1/2" Full 5 90185A830 8.33

5" Full 5 90185A834 9.55

6" Full 5 90185A838 10.73

3/4"-10—Neck: Wd. 0.77"

3" Full 5 90185A875 12.02

4" Full 5 90185A879 12.50

5" Full 1 90185A883 2.60

6" Full 1 90185A887 3.03

Square Neck—Hot Dipped Galvanized Low-Strength Steel (Grade 2)

1/4"-20—Neck: Wd. 0.26"

3/4" Full 100 93604A611 6.85

1" Full 100 93604A613 7.45

1 1/4" Full 100 93604A615 7.86

1 1/2" Full 100 93604A617 8.78

1 3/4" Full 100 93604A619 9.53

2" Full 100 93604A621 11.31

2 1/2" Full 100 93604A623 13.32

3" Full 50 93604A625 8.19

3 1/2" Full 50 93604A627 9.18

4" Full 50 93604A629 9.61

4 1/2" Full 50 93604A631 10.14

5" Full 50 93604A633 12.40

5 1/2" Full 50 93604A635 12.87

6" Full 50 93604A637 14.40

7" Partial to Full 10 93604A638 5.84

8" Partial to Full 10 93604A901 6.31

5/16"-18—Neck: Wd. 0.32"

3/4" Full 100 93604A639 12.50

1" Full 100 93604A641 12.93

1 1/4" Full 50 93604A643 8.00

1 1/2" Full 50 93604A645 8.62

1 3/4" Full 50 93604A647 9.54

2" Full 50 93604A649 9.76

2 1/2" Full 50 93604A651 11.64

3" Full 50 93604A653 13.63

3 1/2" Full 50 93604A655 14.31

4" Full 25 93604A657 8.38

4 1/2" Full 25 93604A659 9.43

5" Full 25 93604A661 10.02

5 1/2" Full 25 93604A663 12.35

6" Full 25 93604A665 12.37

3/8"-16—Neck: Wd. 0.39"

1" Full 50 93604A667 9.43

1 1/4" Full 50 93604A669 10.88

1 1/2" Full 50 93604A671 12.87

1 3/4" Full 50 93604A673 13.27

2" Full 50 93604A675 14.10

2 1/4" Full 25 93604A677 8.03

2 1/2" Full 25 93604A679 8.66

3" Full 25 93604A681 9.51

3 1/2" Full 25 93604A683 9.87

4" Full 25 93604A685 11.15

4 1/2" Full 25 93604A687 13.15

5" Full 25 93604A689 14.44

5 1/2" Full 10 93604A691 6.31

6" Full 10 93604A693 7.01

6 1/2" Partial to Full 10 93604A695 7.33

7" Partial to Full 10 93604A697 8.31

8" Partial to Full 10 93604A699 8.45

9" Partial to Full 10 93604A701 11.02

10" Partial to Full 10 93604A703 12.43

12" Partial to Full 5 93604A704 6.98

14" Partial to Full 5 93604A706 8.81

16" Partial to Full 5 93604A708 11.02

1/2"-13—Neck: Wd. 0.52"

1 1/2" Full 25 93604A711 10.68

2" Full 25 93604A713 13.54

2 1/2" Full 10 93604A715 6.37

3" Full 10 93604A717 7.59

3 1/2" Full 10 93604A719 8.46

4" Full 10 93604A721 9.04

4 1/2" Full 10 93604A723 9.92

5" Full 10 93604A725 10.62

6" Full 10 93604A729 12.12

6 1/2" Partial to Full 10 93604A731 13.16

7" Partial to Full 10 93604A733 13.78

8" Partial to Full 5 93604A735 8.41

9" Partial to Full 5 93604A737 9.11

10" Partial to Full 5 93604A739 8.81

12" Partial to Full 5 93604A743 12.43

14" Partial to Full 1 93604A745 3.23

16" Partial to Full 1 93604A749 3.45

5/8"-11—Neck: Wd. 0.64"

2" Full 10 93604A753 10.40

2 1/2" Full 10 93604A755 10.21

3" Full 10 93604A757 12.95

4" Full 5 93604A761 8.50

4 1/2" Full 5 93604A763 9.92

5" Full 5 93604A765 9.15

6" Full 5 93604A767 9.55

8" Partial to Full 5 93604A769 12.75

10" Partial to Full 5 93604A773 13.96

12" Partial to Full 1 93604A777 3.09

14" Partial to Full 1 93604A780 3.55

16" Partial to Full 1 93604A783 4.57

Metric Square Neck—Zinc-Plated Medium-Strength Steel (Class 8.8)

M6 × 1—Neck: Wd. 6.48 mm

12 Full 25 98930A020 $6.19

16 Full 25 98930A024 6.88

20 Full 25 98930A026 7.22

25 Full 25 98930A032 7.56

30 Partial 25 98930A038 8.80

35 Partial 25 98930A042 9.35

40 Partial 25 98930A048 11.00

M8 × 1.25—Neck: Wd. 8.58 mm

16 Full 100 98930A114 13.00

20 Full 100 98930A116 12.00

25 Full 50 98930A118 8.50

30 Full 50 98930A122 9.00

35 Full 50 98930A124 11.50

40 Full 50 98930A126 11.00

45 Full 50 98930A128 11.00

50 Full 50 98930A132 13.50

55 Partial to Full 25 98930A134 9.50

60 Partial to Full 25 98930A136 8.00

80 Partial to Full 25 98930A142 8.50

90 Partial to Full 25 98930A144 11.25

M10 × 1.5—Neck: Wd. 10.58 mm

20 Full 50 98930A211 11.00

25 Full 25 98930A213 7.25

35 Full 25 98930A217 7.75

40 Full 25 98930A219 10.00

45 Full 25 98930A221 9.00

50 Full 25 98930A223 10.00

60 Partial to Full 10 98930A227 6.60

70 Partial to Full 10 98930A229 4.80

80 Partial to Full 10 98930A231 5.30

90 Partial to Full 10 98930A233 7.90

M12 × 1.75—Neck: Wd. 12.7 mm

30 Full 25 98930A326 10.75

40 Full 25 98930A332 10.50

45 Full 25 98930A334 11.66

50 Full 25 98930A336 11.75

60 Partial to Full 10 98930A342 6.00

Last edited by BLUE1972; 02-10-2016 at 11:29 PM.