Replacing mech fuel pump C2

#1

Have a 1965 327 300hp Carter AFB just redone, and in place, new sender in tank and new gas, new rubber lines.. Runs great from float bowl fill but was not getting fuel to carb.

- Car had been hesitating under light load on hwy, we suspected it could be the pump anyway..

Checked fuel line output just before filter, none while cranking starter...

New and or clean lines from tank to pump, so only unchecked line is the one from the bottom to the top of the engine..

Have a new Carter pump to install and have a few questions I'd really appreciate some answers to..

1. Should I mess with the bolt on the lower block near the pump or just take off the pump? I see I'll have to leave the pushrod in and make sure it mates up with the pump arm, any suggestions on this?

silicone gasket maker on one or both sides of the paper one? Or just dry??

2. Should I assume the pump is functional and not overpressured? I've heard there's a high rate of poor quality pumps out there....

3. Do I need to prime the pump or anything? Or will it suck air until it fills up with gas?

4. There's a vacuum nubbin on the new pump, do I just cover that to deadhead? I don't think my car has any line there..

My plan is to jack stand the right front, remove wheel and fender and then it looks like I might need to move a water line or two, any thoughts? Should I try it from above and remove the heater lines? It looks a bit tight underneath with the front suspension right there..

Any and all flames or thoughts are always appreciated. Thanks!

(PS just posted similar thread and I can't find it now....)

- Car had been hesitating under light load on hwy, we suspected it could be the pump anyway..

Checked fuel line output just before filter, none while cranking starter...

New and or clean lines from tank to pump, so only unchecked line is the one from the bottom to the top of the engine..

Have a new Carter pump to install and have a few questions I'd really appreciate some answers to..

1. Should I mess with the bolt on the lower block near the pump or just take off the pump? I see I'll have to leave the pushrod in and make sure it mates up with the pump arm, any suggestions on this?

silicone gasket maker on one or both sides of the paper one? Or just dry??

2. Should I assume the pump is functional and not overpressured? I've heard there's a high rate of poor quality pumps out there....

3. Do I need to prime the pump or anything? Or will it suck air until it fills up with gas?

4. There's a vacuum nubbin on the new pump, do I just cover that to deadhead? I don't think my car has any line there..

My plan is to jack stand the right front, remove wheel and fender and then it looks like I might need to move a water line or two, any thoughts? Should I try it from above and remove the heater lines? It looks a bit tight underneath with the front suspension right there..

Any and all flames or thoughts are always appreciated. Thanks!

(PS just posted similar thread and I can't find it now....)

#2

Team Owner

Member Since: Feb 2003

Location: Sitting in his Nowhere land Hanover Pa

Posts: 49,056

Received 6,977 Likes

on

4,798 Posts

2015 C2 of Year Finalist

I would rebuild the pump you haver now

The following users liked this post:

80atez (04-23-2023)

#3

Tech Contributor

Here's a link to a document full of great information.

https://www.corvetteforum.com/forums...post1591508735

To you questions:

1) Use the front bolt

2) Your old pump sounds bad, given lack of fuel during cranking

3) No need to prime, but I like to put a little fuel down the carb so when I turn the key the car starts right away and accelerates getting fuel through the system

4) Not sure why you have that fitting but put a cap on it. Some older cars used the fuel pump as a vacuum source for vacuum operated windshield wipers (but not your car)

My 65 has factory A/C and I have to go in from the bottom and with an extension through the fenderwell. My 62 has less stuff in the way but I still go in from the bottom.

If your old fuel pump is the original style, then here is info on how to rebuild it.

https://www.corvetteforum.com/forums...post1577259612

https://www.corvetteforum.com/forums...post1591508735

To you questions:

1) Use the front bolt

2) Your old pump sounds bad, given lack of fuel during cranking

3) No need to prime, but I like to put a little fuel down the carb so when I turn the key the car starts right away and accelerates getting fuel through the system

4) Not sure why you have that fitting but put a cap on it. Some older cars used the fuel pump as a vacuum source for vacuum operated windshield wipers (but not your car)

My 65 has factory A/C and I have to go in from the bottom and with an extension through the fenderwell. My 62 has less stuff in the way but I still go in from the bottom.

If your old fuel pump is the original style, then here is info on how to rebuild it.

https://www.corvetteforum.com/forums...post1577259612

The following users liked this post:

80atez (04-23-2023)

#4

Thanks so much. The links are excellent, I could not find them on my deep dive into the forum ; )

I might rebuild it but I'll put in the new Carter on while I'm there I think, use the old one as backup.

How do you get to TDC with HEI? I assume line up timing marks and it's either best or worst spot, and check pushrod from there? Can't you just turn the engine with a long bar on the front of the engine? I used to do that with my 305 to get the starter to catch...

Unrelated question: I saw a pic of a '62 with what looked like a vent tube from the top of the gas tank to the bottom, like a way to replace spilled gas from around the filler hole down into the tank via the overflow tube. I just replaced by tube but in my '65 I thought it just vented to the bumper anything leaked, and I don't see a bottom fitting to recycle the gas. Is that an earlier model thing? I ask because I want to get it right, but also, I have found a lot of small rocks or grit in my tank previously and don't know how it gets there....

I might rebuild it but I'll put in the new Carter on while I'm there I think, use the old one as backup.

How do you get to TDC with HEI? I assume line up timing marks and it's either best or worst spot, and check pushrod from there? Can't you just turn the engine with a long bar on the front of the engine? I used to do that with my 305 to get the starter to catch...

Unrelated question: I saw a pic of a '62 with what looked like a vent tube from the top of the gas tank to the bottom, like a way to replace spilled gas from around the filler hole down into the tank via the overflow tube. I just replaced by tube but in my '65 I thought it just vented to the bumper anything leaked, and I don't see a bottom fitting to recycle the gas. Is that an earlier model thing? I ask because I want to get it right, but also, I have found a lot of small rocks or grit in my tank previously and don't know how it gets there....

Last edited by 80atez; 04-23-2023 at 08:20 PM.

#5

Tech Contributor

Unrelated question: I saw a pic of a '62 with what looked like a vent tube from the top of the gas tank to the bottom, like a way to replace spilled gas from around the filler hole down into the tank via the overflow tube. I just replaced by tube but in my '65 I thought it just vented to the bumper anything leaked, and I don't see a bottom fitting to recycle the gas. Is that an earlier model thing? I ask because I want to get it right, but also, I have found a lot of small rocks or grit in my tank previously and don't know how it gets there....

The following users liked this post:

80atez (04-29-2023)

#6

Wow what a job... My prior pump does not look original. If outlet was at 2oclock inlet was at 7oclock.. As stated prior it tested bad, when I removed it the lever spring was broken! A pretty bad oil leak may actually have been from that, as the stud that acts as a fulcrum was missing as well, what a mess. The bolts holding it on were about 1ft lbs tight... I think the threads stripped due to under torque or worked themselves out over time..

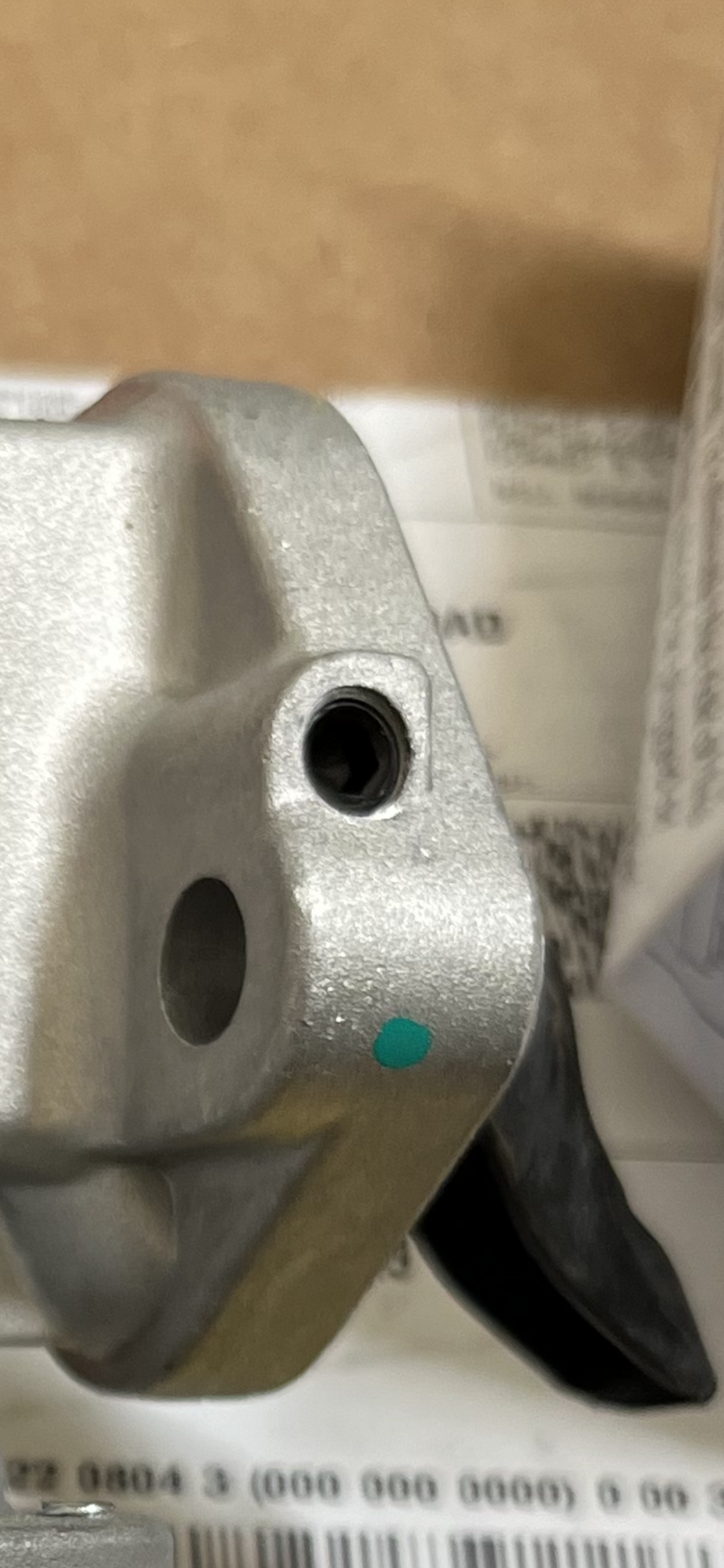

I replaced it with a Carter M3120 or some number, for "muscle cars" from Summit I think. It is for a SBC, 6psi max.. I had to cap the vacuum hose fitting as mentioned..

When putting that on I did not realize is has a thicker mating edge, and I stripped the front bold threads in the block!!. After reading around and coming up with many considerations, I simply bought grade 8 1.5" bolts, used an extra washer on the rear side, none needed on the front, it fit without using extra washers to prevent bottoming out due to the thickness of the Carter casting. I used orange thread locker, black oil resistant gasket seal on both sides of the paper one.

The car has aftermarket suspension, and it was really really tight. I used a 2ft extension through the wheel well. Needed new rigid copper tube from pump to filter, that was a pain but my local speed shop made one overnight. Old was just too short by about an inch.

All told, I tested it and it puts out a lot of fuel!.. Got er running just perfect.. If I'm lucky the oil ruining the garage floor might just be from the old pump. I have a few pics if anyone is interested.

I replaced it with a Carter M3120 or some number, for "muscle cars" from Summit I think. It is for a SBC, 6psi max.. I had to cap the vacuum hose fitting as mentioned..

When putting that on I did not realize is has a thicker mating edge, and I stripped the front bold threads in the block!!. After reading around and coming up with many considerations, I simply bought grade 8 1.5" bolts, used an extra washer on the rear side, none needed on the front, it fit without using extra washers to prevent bottoming out due to the thickness of the Carter casting. I used orange thread locker, black oil resistant gasket seal on both sides of the paper one.

The car has aftermarket suspension, and it was really really tight. I used a 2ft extension through the wheel well. Needed new rigid copper tube from pump to filter, that was a pain but my local speed shop made one overnight. Old was just too short by about an inch.

All told, I tested it and it puts out a lot of fuel!.. Got er running just perfect.. If I'm lucky the oil ruining the garage floor might just be from the old pump. I have a few pics if anyone is interested.

Last edited by 80atez; 05-07-2023 at 10:57 AM.

The following users liked this post:

62Jeff (05-05-2023)

#7

Race Director

Member Since: Jan 2002

Location: Close to DC

Posts: 14,548

Received 2,130 Likes

on

1,468 Posts

C2 of the Year Finalist - Modified 2020

Glad you adapted to the details. Hit the road for some smiles. Pics are always welcome.  Dennis

Dennis

Dennis

Dennis

#9

I thought I might need to use a stud to bottom out the threads, but started with the extra washer technique. That with the thicker flange on the new Carter pump allowed me to simply use a 1.5" bolt.

pump output is more than shade tree volume of 12oz in 30 sec.. despite the flat spot on the up pipe. I did not measure PSI.

#10

Thanks to the help here and HAMB (hokey *** message board) - a forum for hot rods with some good advice archived about this project..

HAMB ref had reported the block thread depth is 7/8"

HAMB ref had reported the block thread depth is 7/8"

Last edited by 80atez; 05-07-2023 at 06:01 PM.

#11

Instructor

Itís a vent hole that can be used for marine applications; however, I left mine capped the way it was out of the box and I had fuel gushing out of all sorts of places around the carb - it measured 11psi.

I called Carter tech support and they said the pump will over pressurize if you cap it. With the cap off the vent, the psi is down to 6 where it should be, but now I have to figure out whatís wrong with my carbÖ.

#12

I just finished installing an M3120 and came here to warn everyone about the extra nipple that you referenced in the original post.

It’s a vent hole that can be used for marine applications; however, I left mine capped the way it was out of the box and I had fuel gushing out of all sorts of places around the carb - it measured 11psi.

I called Carter tech support and they said the pump will over pressurize if you cap it. With the cap off the vent, the psi is down to 6 where it should be, but now I have to figure out what’s wrong with my carb….

It’s a vent hole that can be used for marine applications; however, I left mine capped the way it was out of the box and I had fuel gushing out of all sorts of places around the carb - it measured 11psi.

I called Carter tech support and they said the pump will over pressurize if you cap it. With the cap off the vent, the psi is down to 6 where it should be, but now I have to figure out what’s wrong with my carb….

I'm really confused because some expert level advice above seems to say to cap it. I also think I asked one or more of my local shop guys including the guy who rebuilt the carb, a very reputable source, who said to cap it. And the car has run great since my last post. I don't have an easy way to test the PSI from the pump myself, so I might just leave as is. If I do remove it I think I'd want to cover it with a little filter. I mean one thought is the cover I have on there is not air tight. I also can't really comprehend how it would increase pump fuel output pressure if there is a covered vacuum output (input). I'm just assuming there is a flapper valve somewhere in there and it would get to a stable vacuum neg pressure on that side of the pump diaphragm and that's it. I wonder if the rumors of variable pump output pressures on these pumps is 1) justified, and 2) the reason for the different outcomes we have. Hard to justify me messing with it if the crb isn't leaking fuel and the car is running great.

Wondering if you could post the phone number you called and I could just pick their brain at summit.

(really been a weird project overall because I read conflicting recommendations about this and the carb spacer gasket order - went with my carb guy's advice which was completely opposite of the internet "consensus")