[C2] Rear wheel bearing, maintenance?

#1

Drifting

Thread Starter

Do we C2 owners worry about rear wheel bearings? What would be the tell-tale signs of a coming problem? My car has less than 50K miles on it. Originally being a base engine Powerglide, and knowing the history of the car, I have no reason to think it was ever abused. I have a C4 with over 200K on the clock and the rear wheel bearings have never been an issue. The 67 sat for decades motionless which I would think is not good for wheel bearings. The car is in daily service now, am I worrying over a non-existent problem?

#2

Drifting

There is no maintenance you can do without completely disassembling the unit….and you will probably damage the bearings when trying to do it. Water intrusion and corrosion are you enemies. I have taken apart bearing assemblies with 85,000 miles that were still perfect. I have also seen low mileage cars that were driven in water at some point and water got it and created rust.

I just took a buddies 65 trailing off to change the front bushing…..55,000 miles, the bearing felt perfect with .002 end play.

you can easily check end play and feel the bearing without much disassembly.

I just took a buddies 65 trailing off to change the front bushing…..55,000 miles, the bearing felt perfect with .002 end play.

you can easily check end play and feel the bearing without much disassembly.

#4

Le Mans Master

Member Since: Mar 2010

Location: The Golden Triangle, Florida

Posts: 6,208

Received 1,590 Likes

on

822 Posts

2023 C2 of the Year Finalist - Unmodified

St. Jude Donor '20-'21-'22-'23-'24

One day while driving with my wife in the ‘67, she asked me what the high pitched “squeal” coming from the rear. I didn’t hear anything so drove on.

the next time she was in the car, she said she could still hear the squeal. I couldn’t hear anything.

A few weeks later I had the car in the shop for something and Bruce, my mechanic and friend told me the car’s driver side rear wheel bearing was bad.

Lessons learned:

1. Take your wife for a ride more often?

2. Pay attention to what she says?

3. Get hearing aids?

Now she’s telling me she hears a high-pitched squeal coming from the front of the engine. Should I listen?

Take care,

Steve

the next time she was in the car, she said she could still hear the squeal. I couldn’t hear anything.

A few weeks later I had the car in the shop for something and Bruce, my mechanic and friend told me the car’s driver side rear wheel bearing was bad.

Lessons learned:

1. Take your wife for a ride more often?

2. Pay attention to what she says?

3. Get hearing aids?

Now she’s telling me she hears a high-pitched squeal coming from the front of the engine. Should I listen?

Take care,

Steve

The following users liked this post:

63silver (02-28-2023)

#6

Le Mans Master

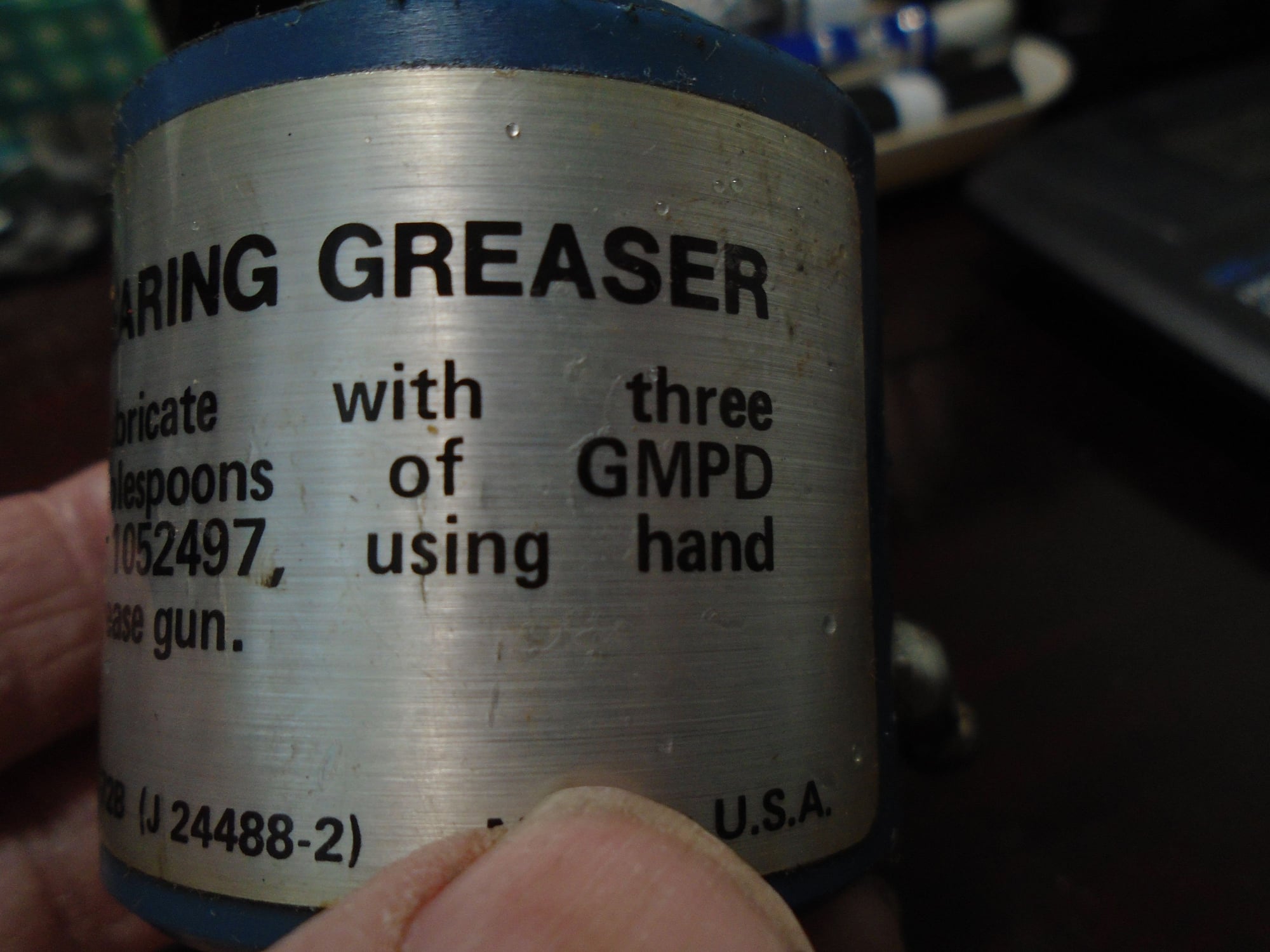

Great advise. Don't use the bearing greaser tool listed above. For a few reasons, it will not work and may cause damage. I am sure Gary will chime in soon. He is the go to guy about trailing arm bearing replacement and differential rebuilding. Jerry

#8

Race Director

Member Since: Jan 2002

Location: Close to DC

Posts: 14,553

Received 2,132 Likes

on

1,470 Posts

C2 of the Year Finalist - Modified 2020

#9

Tech Contributor

As mentioned, the rear grease tool is not worth the time or money. You have no way of gauging how much grease you are pumping in and the early supports have wells, the later ones don't - so there is different displacement. Pumping in from the inside means you need to get the grease pumped to the outer bearings, pushing all the old crap sludge along with it. IF it gets that far it will probably blow out the seal. BUT it makes guys feel like they did something, same thing as with steering boxes.

Some guy's slip fit the bearings for easy maintenance, again not a good idea since GM did that in 63 until axles broke and wheels came off the car driving. The only one who may benefit are racers who break down the car every year.

If the bearings are old or original, it is time. Regardless of how they may feel.

I had 2 different pairs of 66 original arms shipped to me years ago. One set from the East Coast and the other from the West Coast. Both were identical in the fact they had extremely low mileage, the cars sat in storage for years since new. They looked brand new, in fact I questioned if I was sent the correct ones as they felt perfect. Rotors riveted on, you would swear it was 1966.

When I broke them down, there was NO grease on the bearings, nothing. If the car was driven like that they would have failed.

Some guy's slip fit the bearings for easy maintenance, again not a good idea since GM did that in 63 until axles broke and wheels came off the car driving. The only one who may benefit are racers who break down the car every year.

If the bearings are old or original, it is time. Regardless of how they may feel.

I had 2 different pairs of 66 original arms shipped to me years ago. One set from the East Coast and the other from the West Coast. Both were identical in the fact they had extremely low mileage, the cars sat in storage for years since new. They looked brand new, in fact I questioned if I was sent the correct ones as they felt perfect. Rotors riveted on, you would swear it was 1966.

When I broke them down, there was NO grease on the bearings, nothing. If the car was driven like that they would have failed.

#11

Tech Contributor

I once had one of those tools, I think I tossed it out. But if I still had one and had the time, I would take my TA bearing cutaway I use in my seminars, measure out 3 tablespoons of grease and pump it in for a real test. I also have both types of supports here so it would be interesting to see how each one fills.

#13

Racer

there are two bearings in each trailing arm supporting the spindle.

this tool only lubricates one!

there is no way to lubricate both bearings without disassembly of the trailing arm.

If the grease is 50years old inside..... it's about time to repack them and go for the expense. There is no other way to be sure.

it's worth it

this tool only lubricates one!

there is no way to lubricate both bearings without disassembly of the trailing arm.

If the grease is 50years old inside..... it's about time to repack them and go for the expense. There is no other way to be sure.

it's worth it

#14

Drifting

Thread Starter

There are several 300 and 500 mile round trips I need to make this summer, so for peace of mind I think I'll replace the bearings and half shaft u-joints. Is there a good PDF out there for the procedure? How about special tools? I do have a four-point lift and several floor jacks. Looking at Ebay, they have new trailing arms with bushings installed for $200-$250. A guy could get a set, install the bearings and swap out the old ones. Seems cheap, am I missing something?

#15

Safety Car

Member Since: Apr 2001

Location: Sarver Pa

Posts: 4,587

Received 798 Likes

on

545 Posts

2021 C1 of the Year Finalist - Modified

Do you have torches ? I am going through this right now with a 70 that has 78k on it. Car was parked for almost 40yrs when I got it. Bolts were rusty and stuck, inner wheel brg was seized onto the shaft and had to be cut. Not a fun job. FWIW though the outer brg looked like new but hardly had any grease on it, what grease was on it looked like wax. I don't think it would have lived much longer. I am slowly bringing this car back to life. Every rubber bushing on the car was junk, so plan accordingly. Special tools will be needed and a press. Have fun !!

#16

Tech Contributor

There are several 300 and 500 mile round trips I need to make this summer, so for peace of mind I think I'll replace the bearings and half shaft u-joints. Is there a good PDF out there for the procedure? How about special tools? I do have a four-point lift and several floor jacks. Looking at Ebay, they have new trailing arms with bushings installed for $200-$250. A guy could get a set, install the bearings and swap out the old ones. Seems cheap, am I missing something?

If you are going to do them at home you need good tools, dial indicator, and Do Not go by the YT videos unless you want to do them again.

#17

Drifting

Thread Starter

Yea I have torches but I'm very fortunate with this car, it was sold, driven, and stored in Southern California before being moved and stored in Texas. All the metal is in great shape. A couple of years ago I replaced the body mounts and was surprised how nice the nuts and bolts were. But I can sympathize with you, dealing with rust is a pain.

#18

Drifting

Thread Starter

If you are going to do rear bearings, do your homework. There are a lot of places offering them, not all are the same. I have repaired the work of plenty of them and they were pretty bad.

If you are going to do them at home you need good tools, dial indicator, and Do Not go by the YT videos unless you want to do them again.

If you are going to do them at home you need good tools, dial indicator, and Do Not go by the YT videos unless you want to do them again.

Two more questions:

Are the Ebay trailing arms up to OE standards?

What are the best bearings?

#19

Safety Car

Member Since: Apr 2001

Location: Sarver Pa

Posts: 4,587

Received 798 Likes

on

545 Posts

2021 C1 of the Year Finalist - Modified

Use Timken bearings. Setting up the bearings is very time consuming, I'm doing my own. Right now in the process of making a dummy shaft with an old spindle. Cutting it down to make a slip fit to set end play, If your trailing arms are not too rusty, why not use em ? I sand blasted my old ones cause they are still solid. I separated my brg housing from the arm to make it easier to work on and paint everything up real nice. Neatness counts !

#20

Tech Contributor

I use USA Timken bearings and angle seals- no straight edge seals.

Now how you set up the bearings and rotors is the trick. The book spec is 001-008" endplay which is a mile long. Some of the worst arms I repaired were in the spec so they were "correct" however at 003" endplay you can feel the axle move in/out. You have one shot to get them right since they are or should be press fit. Do it wrong and you will see the endplay open up when done. Depends on what you want and what access you have to a surface grinder. Stock 17's should not be preloaded nor have loose endplay or freewheeling. I grind all mating parts parallel- flanges, bell spacer, shims, I set them up to a different procedure than you will find in a manual or on YouTube. It's the only way I'll do them, but you can follow the manual and decide for yourself.

Dennis

Dennis