Think you want a 6 speed auto?

#1

Melting Slicks

Thread Starter

You might not want to order one just yet....LOL

Haven't even got the chassis and all ready fighting first problem with one.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

When I ordered my frame, engine and trans from Street Shop back last October, I had two goals in mind, one was not to have side pipes but 3.0" exhaust out the back and GM's new six speed auto.

Knew going in there were only a few cars/trucks that had been converted from 3 or 4 speed automatics or manual transmissions to a 6 speed auto and all would have their on conversion problems that would be different form installing one in a Mid-Year Vette.

Got a call from Street Shop telling me I had a problem with the transmission and exhaust, reguardless if I use 2.0", 2.5" or my 3.0" and I might want to reconsider using Side Exhaust instead of out the back exhaust and for that matter, consider not using the 6 speed auto, but 4L60E automatic instead of it my 2nd frame package.

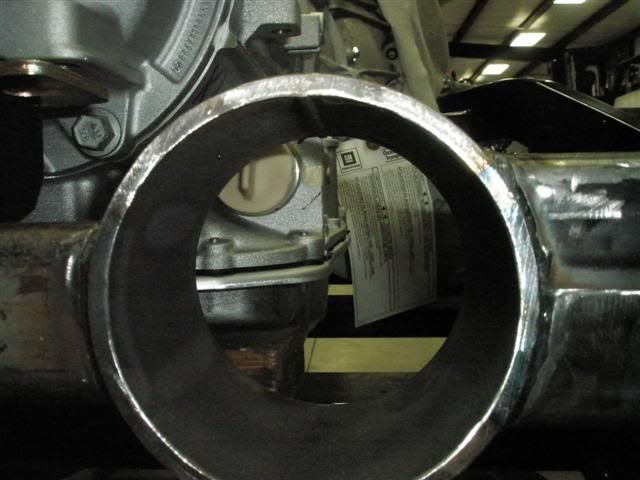

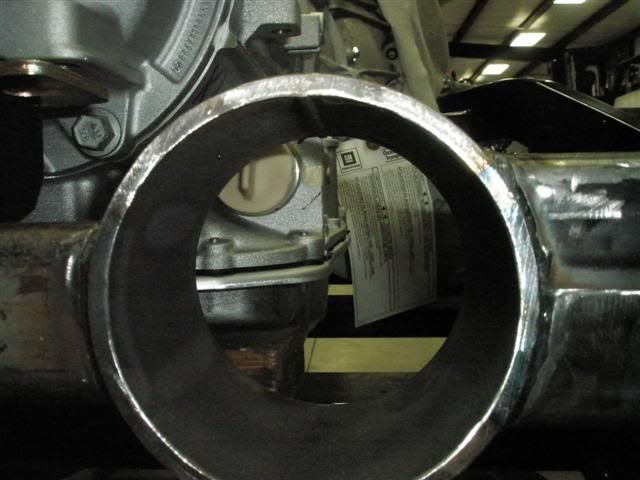

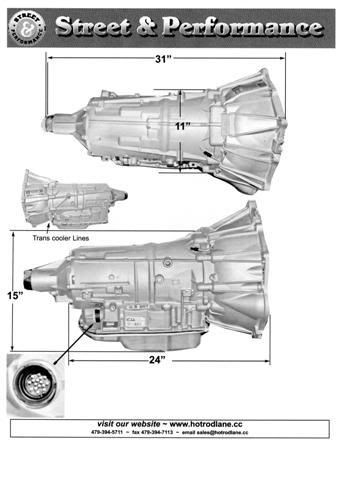

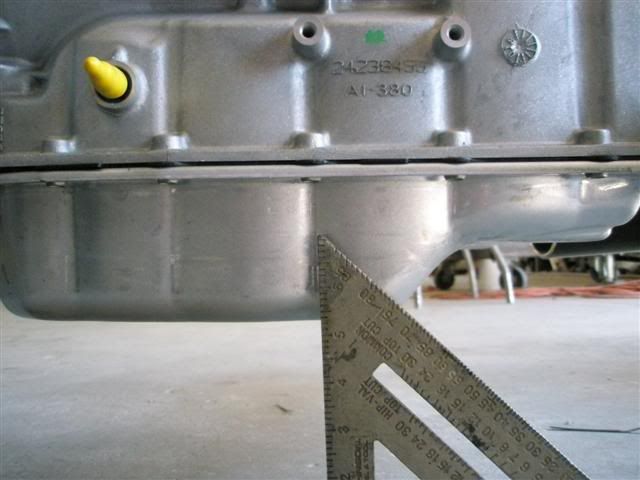

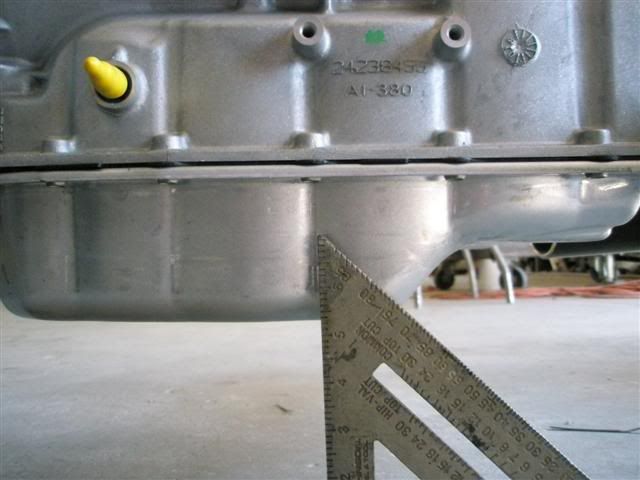

As you can see from the pictures the pan on this trans extends farther back than other GM autos so there is not enough room to get exhaust pipe thru even a 4.0" opening. It is also 2 inches narrower than the 4L60E trans in the pan area and that helps fitment issue caused by wider pan, but pan depth is about 1 3/4 inches deeper than the 60E's and may hange below the frame making speed bumps, etc threats to take out the pan if one is not real careful.

I refuse to use side exhaust so me and a friend spend about 2 hours at Street Shop seeing what could be done to get exhaust out the back. Tried moving the engine forward 1 1/2 but still not enough room to get 3.0 inch exhaust pipe by trans and thur the opening in crossmember, but that still may need to be done if where the bellhousing and trans meet, it hits the tunnel at firewall with engine mounter in stock location.

We decided that the only way and best way to deal with problem, was to make a new crossmember and move the openings for the exhaust outboard of there stock location so exhaust will not have to be bent like standard Mid Year exhaust to fit through the openings.

In order to do this the top of the pipe for exhaust openings needs to me droped down and welded in flush with top of cross member so they clear the floorpan. This will put the bottom of the openings at about the same depth as the bottom of the transmission's pan, and with it's more mid car location make it more of a threat to hit/hang speed bumps than trans pan. Looks like I may need to start thinking about making and fitting a skid plate to protect the pan at least.

As soon as I get the chassis, I'll let y'all know if there is a fitment issue at firewall. At this time, I don't believe there will be and issue with the trans hittting the top or sides of the tunnel at the back. Only time will tell if I guessed right on that.

Haven't even got the chassis and all ready fighting first problem with one.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]

When I ordered my frame, engine and trans from Street Shop back last October, I had two goals in mind, one was not to have side pipes but 3.0" exhaust out the back and GM's new six speed auto.

Knew going in there were only a few cars/trucks that had been converted from 3 or 4 speed automatics or manual transmissions to a 6 speed auto and all would have their on conversion problems that would be different form installing one in a Mid-Year Vette.

Got a call from Street Shop telling me I had a problem with the transmission and exhaust, reguardless if I use 2.0", 2.5" or my 3.0" and I might want to reconsider using Side Exhaust instead of out the back exhaust and for that matter, consider not using the 6 speed auto, but 4L60E automatic instead of it my 2nd frame package.

As you can see from the pictures the pan on this trans extends farther back than other GM autos so there is not enough room to get exhaust pipe thru even a 4.0" opening. It is also 2 inches narrower than the 4L60E trans in the pan area and that helps fitment issue caused by wider pan, but pan depth is about 1 3/4 inches deeper than the 60E's and may hange below the frame making speed bumps, etc threats to take out the pan if one is not real careful.

I refuse to use side exhaust so me and a friend spend about 2 hours at Street Shop seeing what could be done to get exhaust out the back. Tried moving the engine forward 1 1/2 but still not enough room to get 3.0 inch exhaust pipe by trans and thur the opening in crossmember, but that still may need to be done if where the bellhousing and trans meet, it hits the tunnel at firewall with engine mounter in stock location.

We decided that the only way and best way to deal with problem, was to make a new crossmember and move the openings for the exhaust outboard of there stock location so exhaust will not have to be bent like standard Mid Year exhaust to fit through the openings.

In order to do this the top of the pipe for exhaust openings needs to me droped down and welded in flush with top of cross member so they clear the floorpan. This will put the bottom of the openings at about the same depth as the bottom of the transmission's pan, and with it's more mid car location make it more of a threat to hit/hang speed bumps than trans pan. Looks like I may need to start thinking about making and fitting a skid plate to protect the pan at least.

As soon as I get the chassis, I'll let y'all know if there is a fitment issue at firewall. At this time, I don't believe there will be and issue with the trans hittting the top or sides of the tunnel at the back. Only time will tell if I guessed right on that.

#2

Advanced

Member Since: Nov 2007

Location: Inver Grove Heights Minnesota

Posts: 87

Likes: 0

Received 0 Likes

on

0 Posts

Do you have the measurements for the 6L80 and the 4L60 to see where the issues withthe tunnel are ging to be?

I'm thinking about the same conversion with a different frame but I will be running side exhaust.

The big question for me is how much if any modifications to the tunnel will have to be done.

Tim

I'm thinking about the same conversion with a different frame but I will be running side exhaust.

The big question for me is how much if any modifications to the tunnel will have to be done.

Tim

#3

Advanced

Member Since: Nov 2007

Location: Inver Grove Heights Minnesota

Posts: 87

Likes: 0

Received 0 Likes

on

0 Posts

One other question.

What are you going to do for shifter? I have been looking for something that will alow for full automatic shifting and also manual shifting like some of the newer sports cars have.

What are you going to do for shifter? I have been looking for something that will alow for full automatic shifting and also manual shifting like some of the newer sports cars have.

#4

Melting Slicks

Thread Starter

Do you have the measurements for the 6L80 and the 4L60 to see where the issues withthe tunnel are ging to be?

I'm thinking about the same conversion with a different frame but I will be running side exhaust.

The big question for me is how much if any modifications to the tunnel will have to be done.

Tim

I'm thinking about the same conversion with a different frame but I will be running side exhaust.

The big question for me is how much if any modifications to the tunnel will have to be done.

Tim

What I'm afraid of is due to the 6L80 not sloping down as much as the 4L60 right at the bellhousing, the trans will hit the tunnel at the fire wall if you using an LS engine as it does not have the 2.0" of space between back of engine and bellhousing like older style engines do. That probably would not be that much of a problem to deal with as if it hit tunnel where the mount is. Any modification to the firewall would not be seen.

Should have the chassis in hand 1st of April to sit the body on to see if there will be any trans to body interference.

Originally Posted by Snake Pilot

What are you going to do for shifter? I have been looking for something that will alow for full automatic shifting and also manual shifting like some of the newer sports cars have.

I'll be using one of the GM console shifters use in the Caddie models, 08 GTO, GMC trucks or Hummer that use the 6L80 or 90 transmissions and column shift delete. I also believe one of the aftermarket Steering wheel paddle setups could be modified to make it shift manual also.

You might find these two threads from LStech interesting.

http://ls1tech.com/forums/showthread...ight=speartech

http://ls1tech.com/forums/showthread...ight=speartech

#5

Drifting

What I'm afraid of is due to the 6L80 not sloping down as much as the 4L60 right at the bellhousing, the trans will hit the tunnel at the fire wall if you using an LS engine as it does not have the 2.0" of space between back of engine and bellhousing like older style engines do. That probably would not be that much of a problem to deal with as if it hit tunnel where the mount is. Any modification to the firewall would not be seen.

Full length headers and 3" exhaust under these cars with a big trans is a MFer. We fabricated full length 1 7/8" primary/3" merge collectors and it's pretty tight, if you can find a junk cowl section to lift on and off during mock up it really makes life easier!

Your next challenge will be getting a decent size drive shaft to fit out the back side of the tunnel! I widened my tunnel to accommodate the 3" chrome moly I am using. Good luck with your project, will be pretty sweet with 6 automatic gears.

I just remembered that a guy here on the forum that has a 632 cid beast (900-1000 HP), moved his exhaust openings in the X member outboard, if I find the pics I will post them for ya.

Jeff

Last edited by 1coolC2; 03-16-2008 at 07:52 AM.

#6

Safety Car

We decided that the only way and best way to deal with problem, was to make a new crossmember and move the openings for the exhaust outboard of there stock location so exhaust will not have to be bent like standard Mid Year exhaust to fit through the openings.

In order to do this the top of the pipe for exhaust openings needs to me droped down and welded in flush with top of cross member so they clear the floorpan. This will put the bottom of the openings at about the same depth as the bottom of the transmission's pan, and with it's more mid car location make it more of a threat to hit/hang speed bumps than trans pan. Looks like I may need to start thinking about making and fitting a skid plate to protect the pan at least.

In order to do this the top of the pipe for exhaust openings needs to me droped down and welded in flush with top of cross member so they clear the floorpan. This will put the bottom of the openings at about the same depth as the bottom of the transmission's pan, and with it's more mid car location make it more of a threat to hit/hang speed bumps than trans pan. Looks like I may need to start thinking about making and fitting a skid plate to protect the pan at least.

Charles

#7

Safety Car

I moved the exhaust holes outward and down to make for some more clearance on the 4l65E trans pan. You can move the holes outward at least 1.5" on each side before you get close to the floor pan, even more if you offset the holes toward the bottom instead of the top of the crossmember.

Regards, John McGraw

Regards, John McGraw

#8

Le Mans Master

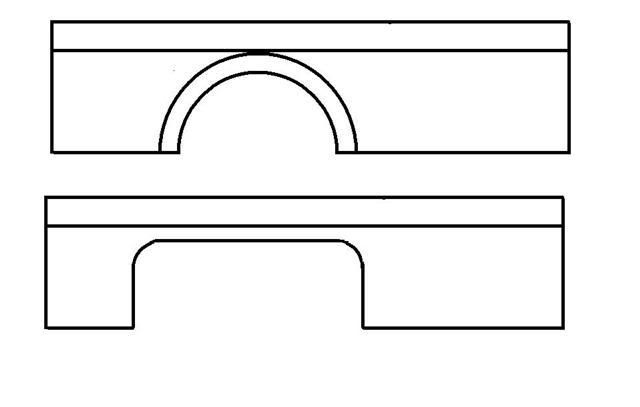

Probably too late now, but why not make a cross member like the one pictured below. Just delete the tubes and hang the exhaust under the cross member, that way you can put the exhaust pipes anywhere you want. That is a 4L80E transmission and 3" exhaust pipes in the picture.

Charles

Charles

- Pat

- Pat

#9

Melting Slicks

Thread Starter

Thanks everyone for the ideas and what you've done to solve problems. I'll probably be running into more problems as project progresses.

Charles,

A new crossmember has to be welded up, and that want start until at least Monday, probably a day or two later, so doing what you did could be done. What I'm trying to do by using 4.0 Id x 4.5 OD pipe welded in, is to get max ground clearance for exhaust.

Please don't take below wrong. It's just my reasoning on using pipe to pass exhaust through. Also looks like your dealing with C1 and you may not have effected exhaust to ground system as much as if it had been done that way with with a C2. The bad part about it is, I don't have longtube headers to see where openings should be located.

By doing like John said, "moving openings outboard as needed, which is more than 1 1/2 inches outboard on each side to provide adaquate clearance between exhaust pipe and transmission, and weld pipe in with top of it flush with top of cossmember", should allow me to get max ground clearance for 3.25 OD exhaust system, yet maintain about the same floorpan to exhaust clearance as stock system has.

Doing it like John said and I posted in my original post, would make the low point the bottom of exhaust opening and not exhaust pipe. Bottom of exhaust pipe should be around 3/4 of inch higher than that. If I'm guessing right on thickness of your crossmember being around 2.0 inches.

If I do the math using floorpan as point of reference to start from, the differance in bottom of floorpan to bottom of exhaust would be around this, if I've done the math and number of clearances and min clearances right.

0.250" clearance between top of crossmember and floor pan.

2.000" thick crossmember.

0.250" clearance between exhaust pipe and crossmember.

3.250" OD of 3.0" ID exhaust pipe

-----

5.750 inches total distance from bottom of floorpan to bottom of exhaust pipe.

Using 4.500 inch OD pipe to run 3.250" OD exhaust through crossmemeber.

0.250" clearance between top of crossmember and floor pan.

4.500" OD pipe welded in flush with top of crossmember.

-----

4.750 inches total distance from bottom of floorpan to bottom of opening for exhaust pipe and only for about 2.500 inches for that low point.

Bottom of Exhaust pipe it'self should be .750 inches above that low point, making bottom of exhaust about 4.000" below floorpan.

Doing it with pipe should gain me 1.750" of ground clearance for exhaust pipe it'self and 1.000" for lowest point.

Jere

PS: Don't pick on me for holding the tolerances tighter by not using carpenter fraction tolerances the car was build to, instead of 1/4 inch, 3 decimal places .....LOL .

Charles,

A new crossmember has to be welded up, and that want start until at least Monday, probably a day or two later, so doing what you did could be done. What I'm trying to do by using 4.0 Id x 4.5 OD pipe welded in, is to get max ground clearance for exhaust.

Please don't take below wrong. It's just my reasoning on using pipe to pass exhaust through. Also looks like your dealing with C1 and you may not have effected exhaust to ground system as much as if it had been done that way with with a C2. The bad part about it is, I don't have longtube headers to see where openings should be located.

By doing like John said, "moving openings outboard as needed, which is more than 1 1/2 inches outboard on each side to provide adaquate clearance between exhaust pipe and transmission, and weld pipe in with top of it flush with top of cossmember", should allow me to get max ground clearance for 3.25 OD exhaust system, yet maintain about the same floorpan to exhaust clearance as stock system has.

Doing it like John said and I posted in my original post, would make the low point the bottom of exhaust opening and not exhaust pipe. Bottom of exhaust pipe should be around 3/4 of inch higher than that. If I'm guessing right on thickness of your crossmember being around 2.0 inches.

If I do the math using floorpan as point of reference to start from, the differance in bottom of floorpan to bottom of exhaust would be around this, if I've done the math and number of clearances and min clearances right.

0.250" clearance between top of crossmember and floor pan.

2.000" thick crossmember.

0.250" clearance between exhaust pipe and crossmember.

3.250" OD of 3.0" ID exhaust pipe

-----

5.750 inches total distance from bottom of floorpan to bottom of exhaust pipe.

Using 4.500 inch OD pipe to run 3.250" OD exhaust through crossmemeber.

0.250" clearance between top of crossmember and floor pan.

4.500" OD pipe welded in flush with top of crossmember.

-----

4.750 inches total distance from bottom of floorpan to bottom of opening for exhaust pipe and only for about 2.500 inches for that low point.

Bottom of Exhaust pipe it'self should be .750 inches above that low point, making bottom of exhaust about 4.000" below floorpan.

Doing it with pipe should gain me 1.750" of ground clearance for exhaust pipe it'self and 1.000" for lowest point.

Jere

PS: Don't pick on me for holding the tolerances tighter by not using carpenter fraction tolerances the car was build to, instead of 1/4 inch, 3 decimal places .....LOL .

#10

Melting Slicks

Thread Starter

Do you have the measurements for the 6L80 and the 4L60 to see where the issues withthe tunnel are ging to be?

I'm thinking about the same conversion with a different frame but I will be running side exhaust.

The big question for me is how much if any modifications to the tunnel will have to be done.

Tim

I'm thinking about the same conversion with a different frame but I will be running side exhaust.

The big question for me is how much if any modifications to the tunnel will have to be done.

Tim

Here is another issue with the 6 speed you need to consider. I should have checked it before ordering. You might want to measure from ground to your existing bellhousing and then subtract around 2 inches from it. That will give you a good idea of how much ground clearance the transmission pan will have. It is around 2.0 inches below the bottom of bellhousing.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]

#12

Melting Slicks

Thread Starter

Don't know who makes the electronics to control it. I do know the trans module is contain inside the trans and not a seperate module. Have to have ECM that can comunicate with it.

Understand one source said they were working on an ECM that will allow it to be used with non computer controled engines or as a bridge for ones that have computers that can't comunicate with it. Wouldn't hold my breath on that.

Understand one source said they were working on an ECM that will allow it to be used with non computer controled engines or as a bridge for ones that have computers that can't comunicate with it. Wouldn't hold my breath on that.

#13

Advanced

Member Since: Nov 2007

Location: Inver Grove Heights Minnesota

Posts: 87

Likes: 0

Received 0 Likes

on

0 Posts

I figured the biggest issue with the 6L80E would probably be the clearence in the tunnel. Now it looks like it could be the pan sticking down too far and being below the frame.

Tim

Tim

#14

Melting Slicks

Thread Starter

Frame arrive Friday so we got started this morning doing a body to transmission fit.

First thing I wanted to check was ground clearance as this is a deep transmission and pan depth along is 3.3" deep measured. Looks like with stock truck pan I have 5.25" of ground clearance. Haven't verified it but rumor is Pontiac G8 and Caddy use one that is 0.75" shorter than trucks. If so, I could get 6.0" of ground clearance by swapping over to one.

The 6L80 also is a fat transmission from front to back. It has the same fitment issues as a 6 speed manual and requires tunnel modification to accommodate it.

I would recomend anyone wanting to use one 6l80 to make sure that the chassis used with it as at a minmum, stock MY ride height.

My transmission crossmember for 3.0" exhaust has to be redesigned also so that exhaust can go through it. This time the left and right foot wells are problem. We had to notch out the pipe for the exhaust to pass thru to get the body to sit on frame mounts. Looks like it down a another 1/2 inche and outboard around 2.0 inches.

First thing I wanted to check was ground clearance as this is a deep transmission and pan depth along is 3.3" deep measured. Looks like with stock truck pan I have 5.25" of ground clearance. Haven't verified it but rumor is Pontiac G8 and Caddy use one that is 0.75" shorter than trucks. If so, I could get 6.0" of ground clearance by swapping over to one.

The 6L80 also is a fat transmission from front to back. It has the same fitment issues as a 6 speed manual and requires tunnel modification to accommodate it.

I would recomend anyone wanting to use one 6l80 to make sure that the chassis used with it as at a minmum, stock MY ride height.

My transmission crossmember for 3.0" exhaust has to be redesigned also so that exhaust can go through it. This time the left and right foot wells are problem. We had to notch out the pipe for the exhaust to pass thru to get the body to sit on frame mounts. Looks like it down a another 1/2 inche and outboard around 2.0 inches.

#16

Melting Slicks

Thread Starter

The subject has come up twice. The second time showing one of the sickest system you would ever want to see that was done for a 900+ HP Camaro and done because owner didn't want exhaust hanging below frame rails.

http://www.zilvia.net/f/showthread.php?t=171389&page=11

I've gone so for as to layout a couple of different exhaust openings in tranny crossmember. One is to accomodate oval pipe. Not to good a drawing with paint but here what I came up with. Problem with both is what kind of strength is there and what will be needed to make sure it's strong enough, doublers and like.

Last edited by Poorhousenext; 04-22-2008 at 08:51 PM.

#17

Burning Brakes

Member Since: Jan 2006

Location: NC

Posts: 1,072

Received 167 Likes

on

63 Posts

2022 C2 of the Year Finalist - Modified

Jere,

Perhaps you could do a crossmember like in post #6 with the tube turned wide side down. Then run oval pipes under it.

I live in the Mooresville, NC area where most of the Nascar teams are based from, and I have a few friends I can go to when I have questions, so I'm kind of spoiled when it comes to this.

There are a few Used Racecar Parts stores around here, and you would be amazed at the parts you'll see there. On superspeedway cars, I've seen exhaust that are about 1" tall and 18" wide. Of course this is to get ground clearance and they exhaust flow that their engines require.

Good luck with your project, and keep us posted on your progress.

BILL SR

Perhaps you could do a crossmember like in post #6 with the tube turned wide side down. Then run oval pipes under it.

I live in the Mooresville, NC area where most of the Nascar teams are based from, and I have a few friends I can go to when I have questions, so I'm kind of spoiled when it comes to this.

There are a few Used Racecar Parts stores around here, and you would be amazed at the parts you'll see there. On superspeedway cars, I've seen exhaust that are about 1" tall and 18" wide. Of course this is to get ground clearance and they exhaust flow that their engines require.

Good luck with your project, and keep us posted on your progress.

BILL SR

#19

Race Director

with the other two posts with this suggestion. I would prefer a rear exit exhaust too and it would be a cleaner more aggressive look in the cross member. A skid pan would protect the trans pan.

with the other two posts with this suggestion. I would prefer a rear exit exhaust too and it would be a cleaner more aggressive look in the cross member. A skid pan would protect the trans pan.

#20

Melting Slicks

Thread Starter

Side pipes would be the easy way out for just hanging and exhaust on car.

Two major problems with them.

1. Loud

1.1. Way to loud

1.2. - 1.9. Too Damn loud

2. 2.5" exhaust out the back are not condusive to making power with LS7 engine, or for that matter smaller LS3 or LS2. MY Vette Side exhaust are even worst as they have two 90 degree bends and air does not like to bend. LS7 and LS3 come from factory with 3.0" exhaust. Guess what a big after market seller is for LS2s? If you guessed 3.0" cat backs you guessed right. The factory 3.0" length neck down to 2.5" at muffler on LS7 exhaust system cost you 5 Horsepower...

If I'm going to pay for Horsepower, I want as much of what I paid for as I can get no matter what the headach is to do it. I also didn't like the way they burnt my legs in 60's when I was proud to be LOUD.

Sorry for rant, but that my O on side pipes even for a stock 327 engine.

Two major problems with them.

1. Loud

1.1. Way to loud

1.2. - 1.9. Too Damn loud

2. 2.5" exhaust out the back are not condusive to making power with LS7 engine, or for that matter smaller LS3 or LS2. MY Vette Side exhaust are even worst as they have two 90 degree bends and air does not like to bend. LS7 and LS3 come from factory with 3.0" exhaust. Guess what a big after market seller is for LS2s? If you guessed 3.0" cat backs you guessed right. The factory 3.0" length neck down to 2.5" at muffler on LS7 exhaust system cost you 5 Horsepower...

If I'm going to pay for Horsepower, I want as much of what I paid for as I can get no matter what the headach is to do it. I also didn't like the way they burnt my legs in 60's when I was proud to be LOUD.

Sorry for rant, but that my O on side pipes even for a stock 327 engine.