[Z06] Pushrod length issues

#1

Melting Slicks

Thread Starter

Trying to get correct pushrod length setup.

Just put on heads that were milled .030". Yella Terra rockers. BT SLR lifters. Stock cam.

Im not sure what is going on. I Have #6 and #1 at TDC (Placed there when putting on heads so I know its there and cam should be on base circle)

Drivers side:

2 1/2 turns exhaust

2 1/8 turns intake

Passenger side

1 7/8 turns exhaust

2 1/8 turns intake

I measured installed height of all my springs with a barrel mic, they are all within .005-.007 of each other which to me means the seats were not machined too deep. The intake is the same on both heads, so the mill work should be even from head to head, right?

So how to I get such a big discrepancy on the exhaust measurement? Ive measured several times using different rockers and different pushrods (OEM length for now to test) with the same results. So confused Any ideas?

Any ideas?

Just put on heads that were milled .030". Yella Terra rockers. BT SLR lifters. Stock cam.

Im not sure what is going on. I Have #6 and #1 at TDC (Placed there when putting on heads so I know its there and cam should be on base circle)

Drivers side:

2 1/2 turns exhaust

2 1/8 turns intake

Passenger side

1 7/8 turns exhaust

2 1/8 turns intake

I measured installed height of all my springs with a barrel mic, they are all within .005-.007 of each other which to me means the seats were not machined too deep. The intake is the same on both heads, so the mill work should be even from head to head, right?

So how to I get such a big discrepancy on the exhaust measurement? Ive measured several times using different rockers and different pushrods (OEM length for now to test) with the same results. So confused

Any ideas?

Any ideas?

Last edited by atljar; 07-17-2013 at 08:52 AM.

#2

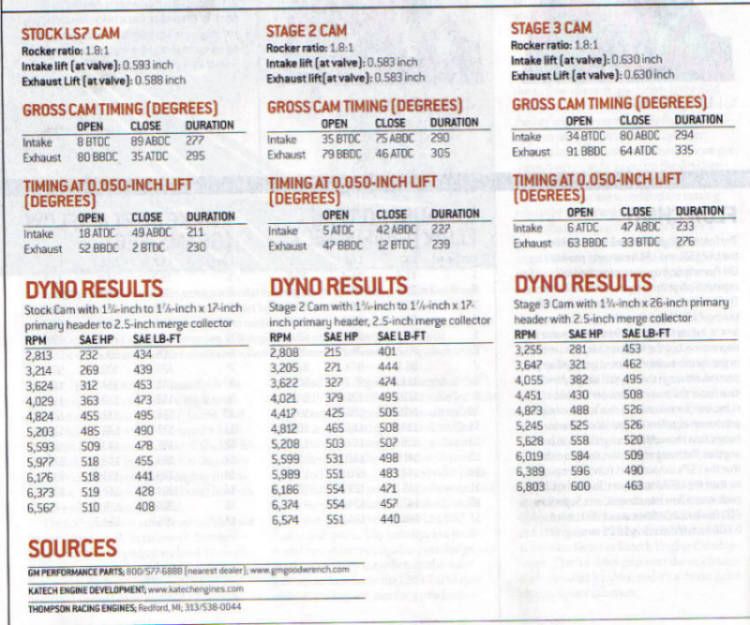

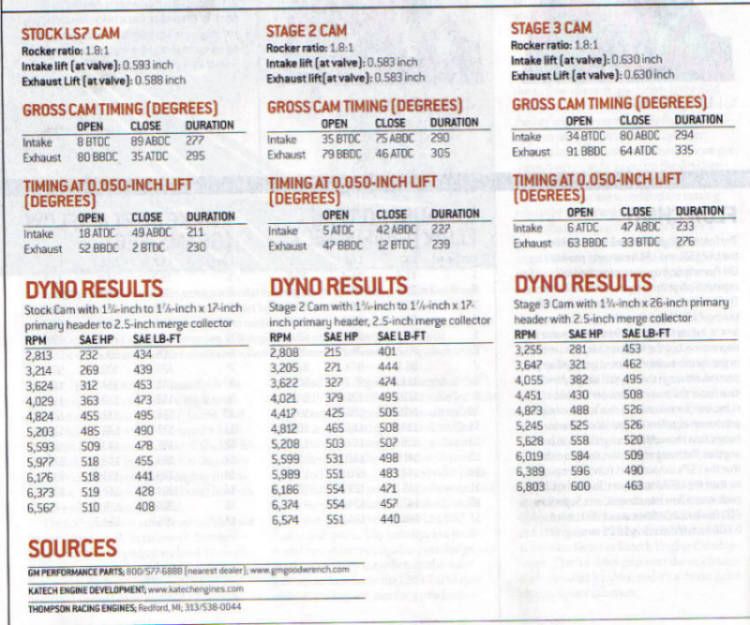

There are two TDC's on a 4 cycle engine -- TDC on compression stroke and TDC on exhaust stroke. Off the top of my head I'd say you've got #1 on TDC exhaust stoke, at which point the exhaust is still open (on the stock cam the exhaust closes @ 35° ATDC, or After TDC).

Turn the crank another 1/4 turn in engine firing direction and you should get a better match on the exhausts (#1 intake will be opening, however, if that cyl is the one on TDC exhaust stroke).

Your pushrods are at least .040 too long IMUO.... did Brian say what the cup travel is on those lifters?

Turn the crank another 1/4 turn in engine firing direction and you should get a better match on the exhausts (#1 intake will be opening, however, if that cyl is the one on TDC exhaust stroke).

Your pushrods are at least .040 too long IMUO.... did Brian say what the cup travel is on those lifters?

Last edited by Mark2009; 07-17-2013 at 10:17 AM. Reason: changed #6 to #1, parenthetical addition

#4

Melting Slicks

Thread Starter

DUH, that makes perfect sense.

I made the assumption that piston up = both valves closed regardless if it was on compression or exhaust stroke which isn't the case.

Brian said to run .015 to .045 preload on the lifters, but I did not get total travel of the plunger from him.

From what I am reading, 1 full turn - .042" preload. I will recheck the exhaust tonight (Use EOIC method) and order the correct length from there. Thank you again!

I made the assumption that piston up = both valves closed regardless if it was on compression or exhaust stroke which isn't the case.

Brian said to run .015 to .045 preload on the lifters, but I did not get total travel of the plunger from him.

From what I am reading, 1 full turn - .042" preload. I will recheck the exhaust tonight (Use EOIC method) and order the correct length from there. Thank you again!

#5

That's a fairly light preload which suggests less cup travel than the OEM lifter, so check your pushrods to make sure you didn't bend one if you tightened down on the rocker bolts pretty hard... better safe than sorry

I'm looking at the YT's too and, based on a few reports of broken bolts, one thing I would suggest checking is the length the bolt protrudes out of the bottom of the rocker, including the half moon thingie, compared to the length that an OEM bolt protrudes out of the bottom of the OEM rocker. Just in case the YT bolts were bottoming out (torquing out) in the pedestal hole before the proper clamping force is attained (which would probably break the bolt during engine operation).

If you have an electronic gram scale, I'd be very interested in the nose weight of a YT vs the nose weight of an OEM rocker. A crude check is to just rest the trunnion on the table right next to the scale, maybe sitting on a 3/8" spacer to get the rocker somewhat nose down, while resting the nose on the scale. I got around 8.5 grams with an OEM rocker (don't have a YT to check, but I suspect it would be around 20). As noted, crude but if both checked the same way it would at least give us some numbers which are difficult to obtain. YT AUS does not reply to my emails; they must have me on ignore

I'm looking at the YT's too and, based on a few reports of broken bolts, one thing I would suggest checking is the length the bolt protrudes out of the bottom of the rocker, including the half moon thingie, compared to the length that an OEM bolt protrudes out of the bottom of the OEM rocker. Just in case the YT bolts were bottoming out (torquing out) in the pedestal hole before the proper clamping force is attained (which would probably break the bolt during engine operation).

If you have an electronic gram scale, I'd be very interested in the nose weight of a YT vs the nose weight of an OEM rocker. A crude check is to just rest the trunnion on the table right next to the scale, maybe sitting on a 3/8" spacer to get the rocker somewhat nose down, while resting the nose on the scale. I got around 8.5 grams with an OEM rocker (don't have a YT to check, but I suspect it would be around 20). As noted, crude but if both checked the same way it would at least give us some numbers which are difficult to obtain. YT AUS does not reply to my emails; they must have me on ignore

#6

On preload, one turn = .049" bolt travel (1.25mm thread). Some precautions:

1. The one turn does not include torque. If you have one turn to snug up the rocker to the pedestal, then torquing to 22 ft lbs would be about another 1/3 turn which would add no preload.

2. The .049 is just the bolt movement... to correct for the rocker ratio multiplication you use this formula (for a 1.8 rocker): .049 * 2.8 / 1.8 = .076 actual preload at the lifter for one turn, no torque.

There was a big thread on this on LS1Tech which is where much of that came from... I believe the above to be correct. If in doubt, get an adjustable pushrod, an 8" dial caliper, and measure.

I did check my stock setup using the above calculations and it came out very close --

.123" using dial caliper/adj. pushrod,

1.75 turns using bolt to snug rocker down, no torque (= .133" using the above calcs).

1. The one turn does not include torque. If you have one turn to snug up the rocker to the pedestal, then torquing to 22 ft lbs would be about another 1/3 turn which would add no preload.

2. The .049 is just the bolt movement... to correct for the rocker ratio multiplication you use this formula (for a 1.8 rocker): .049 * 2.8 / 1.8 = .076 actual preload at the lifter for one turn, no torque.

There was a big thread on this on LS1Tech which is where much of that came from... I believe the above to be correct. If in doubt, get an adjustable pushrod, an 8" dial caliper, and measure.

I did check my stock setup using the above calculations and it came out very close --

.123" using dial caliper/adj. pushrod,

1.75 turns using bolt to snug rocker down, no torque (= .133" using the above calcs).

#7

Melting Slicks

Thread Starter

I do not have a scale...

The factory bolt with the factory rocker protrudes .826" from the bottom of the rocker base.

The YT bolt and YT rocker has the bolt extend .774" from the bottom of the base (with the provided cup). In other words less likely to bottom than the factory setup. Ive read the bottoming out issue too, as far as Im concerned its a myth or YT has started to provide shorter bolts

I don't claim to know the math behind this, but you do NOT multiply rocker ratio times turns of the bolt for actual lifter preload. In a rocker setup the pivot is considered the bolt and it is fixed in place. In measuring preload the roller tip is your fixed pivot. Figure out the math from there... I don't know it BUT putting a dial indicator parallel with the pushrod and turning the bolt 1 turn gives me between .047 and .049" everytime I have checked tonight.

BUT putting a dial indicator parallel with the pushrod and turning the bolt 1 turn gives me between .047 and .049" everytime I have checked tonight.

The factory bolt with the factory rocker protrudes .826" from the bottom of the rocker base.

The YT bolt and YT rocker has the bolt extend .774" from the bottom of the base (with the provided cup). In other words less likely to bottom than the factory setup. Ive read the bottoming out issue too, as far as Im concerned its a myth or YT has started to provide shorter bolts

I don't claim to know the math behind this, but you do NOT multiply rocker ratio times turns of the bolt for actual lifter preload. In a rocker setup the pivot is considered the bolt and it is fixed in place. In measuring preload the roller tip is your fixed pivot. Figure out the math from there... I don't know it

BUT putting a dial indicator parallel with the pushrod and turning the bolt 1 turn gives me between .047 and .049" everytime I have checked tonight.

BUT putting a dial indicator parallel with the pushrod and turning the bolt 1 turn gives me between .047 and .049" everytime I have checked tonight.

#8

So is there somewhere you should go instead of TDC to check both intake and exhaust pushrod lengths? How do you tell where you're at once you get the heads back on the car?

#9

1. The bolt is not moving 1.25mm per turn (unlikely).

2. There is some slack in the initial setup. Try 1.5 turns and see if you get exactly 1.5x the reading. Or try a dab of preload -- say .020 -- and then do the one turn (and see if you get .067 - .069)

3. The valve stem is depressing slightly when you tighten the bolt. Set up a second dial indicator atop the roller end or the retainer to check that (simultaneously w/the indicator on the pushrod cup). Again start w/.020 preload on the lifter to eliminate any initial slack.

#10

Melting Slicks

Thread Starter

Rotate the engine by hand, when the exhaust valve starts to open, then the intake is on the base circle and can be measured. When the intake starts to close, then the exhaust is on the base circle

#11

Melting Slicks

Thread Starter

The math/geometry is pretty straightforward (visualize a see-saw/teeter-totter in place of the rocker) so there are only 3 possible explanations:

1. The bolt is not moving 1.25mm per turn (unlikely).

2. There is some slack in the initial setup. Try 1.5 turns and see if you get exactly 1.5x the reading. Or try a dab of preload -- say .020 -- and then do the one turn (and see if you get .067 - .069)

3. The valve stem is depressing slightly when you tighten the bolt. Set up a second dial indicator atop the roller end or the retainer to check that (simultaneously w/the indicator on the pushrod cup). Again start w/.020 preload on the lifter to eliminate any initial slack.

1. The bolt is not moving 1.25mm per turn (unlikely).

2. There is some slack in the initial setup. Try 1.5 turns and see if you get exactly 1.5x the reading. Or try a dab of preload -- say .020 -- and then do the one turn (and see if you get .067 - .069)

3. The valve stem is depressing slightly when you tighten the bolt. Set up a second dial indicator atop the roller end or the retainer to check that (simultaneously w/the indicator on the pushrod cup). Again start w/.020 preload on the lifter to eliminate any initial slack.

#12

We need a webcast setup for these type of adventures... you could do the work, and 3 or 4 CF members could tune in and supervise

No, not that one the other one!

Yeah, turn it some more to the left... no, to your other left!

The only thing missing would be virtual beer

No, not that one the other one!

Yeah, turn it some more to the left... no, to your other left!

The only thing missing would be virtual beer