AC Compressor dilemma

#1

Instructor

Thread Starter

Hi,

Okay, since I got the car it's needed the clutch bearing changed on the compressor. It's made a noise that hasn't been very Vette-like, but it seemed like a big job so I put it off and moving those metal hoses out of the way seemed pretty risky.

I eventually got the new bearing, but still put it off until now. The day before yesterday, black ooze came out of it. It was also much louder, forcing the issue.

Today I got the pressure plate off, moving the metal hoses was easy to do without trouble, I got the rotor off, and it was a mess. The ***** in the bearing were not in any grease at all, and the black ooze had crusted everywhere.

Here's the problem.

The bearing I bought doesn't fit. The part number must be wrong at Advanced Auto because all of them were that way.

I can buy the whole clucth assembly for $149 but what if the compressor went bad? Is there a way to test it?

I can buy a new compressor for $500 with the clutch, but I don't want to if it's not broken. Then again, I don't want to buy the clutch and then find out I need a compressor too.

Is the black ooze indicative of a compressor problem? or just from the bearing going bad?

Thoughts?

Bob 2.0

Okay, since I got the car it's needed the clutch bearing changed on the compressor. It's made a noise that hasn't been very Vette-like, but it seemed like a big job so I put it off and moving those metal hoses out of the way seemed pretty risky.

I eventually got the new bearing, but still put it off until now. The day before yesterday, black ooze came out of it. It was also much louder, forcing the issue.

Today I got the pressure plate off, moving the metal hoses was easy to do without trouble, I got the rotor off, and it was a mess. The ***** in the bearing were not in any grease at all, and the black ooze had crusted everywhere.

Here's the problem.

The bearing I bought doesn't fit. The part number must be wrong at Advanced Auto because all of them were that way.

I can buy the whole clucth assembly for $149 but what if the compressor went bad? Is there a way to test it?

I can buy a new compressor for $500 with the clutch, but I don't want to if it's not broken. Then again, I don't want to buy the clutch and then find out I need a compressor too.

Is the black ooze indicative of a compressor problem? or just from the bearing going bad?

Thoughts?

Bob 2.0

#2

Melting Slicks

Member Since: Aug 1999

Location: Baltimore, MD USA

Posts: 2,240

Likes: 0

Received 34 Likes

on

30 Posts

It appears the part you purchased could be a bearing for

the compressor itself.

Back colored oozing stuff usually is from the inside of the clutch coil when

it over heats. When that happens, there is a electrical burning type of odor.

If the AC is working, just change the clutch bearing and

go from there.

Go to http://www.napaonline.com

Input the vehicle type 94 Corvette.

In the Search Catalog box input this part number. PGB P5908VAW

It shows a picture of the compressor clutch pulley bearing.

ID 1.57 inches

OD 2.44 inches

Width .815 inches

the compressor itself.

Back colored oozing stuff usually is from the inside of the clutch coil when

it over heats. When that happens, there is a electrical burning type of odor.

If the AC is working, just change the clutch bearing and

go from there.

Go to http://www.napaonline.com

Input the vehicle type 94 Corvette.

In the Search Catalog box input this part number. PGB P5908VAW

It shows a picture of the compressor clutch pulley bearing.

ID 1.57 inches

OD 2.44 inches

Width .815 inches

Last edited by Hooked on Vettes; 02-21-2011 at 08:11 AM.

#3

Instructor

Thread Starter

Thanks for your help. There is a NAPA just down the street too.

I left something out in my description though, right after this happened, the AC controls all went blank. It doesn't show outside temps, no lights come on... the control panel is dead.

I'll start with changing the bearing as it is pretty cheep and I have everything off anyway. But, given all you know now, what do you think is ahead for me?

I left something out in my description though, right after this happened, the AC controls all went blank. It doesn't show outside temps, no lights come on... the control panel is dead.

I'll start with changing the bearing as it is pretty cheep and I have everything off anyway. But, given all you know now, what do you think is ahead for me?

#4

Former Vendor

Before you go any further, put the clutch plate back enough to engage the comp shaft and turn it by hand. You don't want to waist your time and money on a clutch if the comp has seized up.

#5

Melting Slicks

Member Since: Aug 1999

Location: Baltimore, MD USA

Posts: 2,240

Likes: 0

Received 34 Likes

on

30 Posts

The AC Control Head gets 12 volts from Fuse #18 (AC clutch) 10 amp located

passenger side end of dash fuse panel.

If that's blown the AC clutch coil could be shorted which would explain

the black goo.

There is also a diode that is placed across the AC clutch coil. If that shorted

it would blow the AC clutch fuse but wouldn't damage the AC clutch coil.

The diode maybe tucked inside the wiring harness so you can't see it.

You can disconnect the electrical connector at the AC clutch coil and with

a ohm meter measure the resistance of the AC clutch coil. It should be 3.6 ohms

if the ambient temperature is 70 degrees F.

passenger side end of dash fuse panel.

If that's blown the AC clutch coil could be shorted which would explain

the black goo.

There is also a diode that is placed across the AC clutch coil. If that shorted

it would blow the AC clutch fuse but wouldn't damage the AC clutch coil.

The diode maybe tucked inside the wiring harness so you can't see it.

You can disconnect the electrical connector at the AC clutch coil and with

a ohm meter measure the resistance of the AC clutch coil. It should be 3.6 ohms

if the ambient temperature is 70 degrees F.

Last edited by Hooked on Vettes; 02-21-2011 at 01:05 PM.

#6

Instructor

Thread Starter

Thanks for all of your input.

My current dilemma is finding the right bearing for the rotor. The one at autozone wasnt the right size. Contrary to the 1.57 inner diameter listed here, mine is 1.25. It doesn't look like it's an after market compressor.

My current dilemma is finding the right bearing for the rotor. The one at autozone wasnt the right size. Contrary to the 1.57 inner diameter listed here, mine is 1.25. It doesn't look like it's an after market compressor.

#7

Le Mans Master

You can try these guys and post on their Board too: www.ackits.com I think someone there might suggest a blown shaft seal which is what I'd suspect on any Nippo compressor.

#8

Le Mans Master

It is a bit of a gamble but don't rule out a "good/used/salvaged" complete (with clutch) compressors off of flEaBAY or another salvage site.....I've gotten used/good/leak free complete Nippo compressors for less than $30 (shipping included).

#9

Instructor

Thread Starter

Making progress....

As there doesn't seem to be a solution to my particular problem in the archives here, I'll post my progress for the knowledge bank on this issue.

After finding that the OEM bearing has a bigger core (1.57) than what mine comes to (at 1.2) I've discovered that my Nippondenso compressor is something of a freak.

Rather than throw the car away, or get a complete clutch (which would likely have the 1.57 bearing in it too) I decided to keep digging.

I eventually found a thread in another forum where a guy was having my problem, and found the correct bearing on line at Direct Bearing. He installed it and it worked. I got the dimensions of the bearing and called a local bearing dealer who will have it in tomorrow.

Hooked on Vettes was right, my fuse blew. I'll let you know how things go with the new bearing and fuse.

As there doesn't seem to be a solution to my particular problem in the archives here, I'll post my progress for the knowledge bank on this issue.

After finding that the OEM bearing has a bigger core (1.57) than what mine comes to (at 1.2) I've discovered that my Nippondenso compressor is something of a freak.

Rather than throw the car away, or get a complete clutch (which would likely have the 1.57 bearing in it too) I decided to keep digging.

I eventually found a thread in another forum where a guy was having my problem, and found the correct bearing on line at Direct Bearing. He installed it and it worked. I got the dimensions of the bearing and called a local bearing dealer who will have it in tomorrow.

Hooked on Vettes was right, my fuse blew. I'll let you know how things go with the new bearing and fuse.

#10

Instructor

Thread Starter

Yesterday, I used a vice and pressed out the old bearing. It came apart though leaving the outer sleeve. I found a big enough piece of pipe to push it through too but it was very difficult. the flanged metal ring got bent in the process.

I couldn't tell what that ring was for. It's between the plate and the pully. I looked at a picture of a new pully/rotor and there isn't one, so I'm assuming we're good without it.

So, I pushed in the new bearing and used locktite on it as opposed to pinging it in. (Per a youtube video I found.) Very tight fit but It went in too. I'm almost ready to install it back in the car.

Next, the shims. The service manual shows the bolt going through them into the compressor. I'm not sure about this though. Any input?

The compressor still has a charge so I'm hoping that when I reassemble this on Saturday, it will run. If any of you can clear up the shim issue though (where do they go?) that would be awesome and would raise my comfort level dramatically.

I couldn't tell what that ring was for. It's between the plate and the pully. I looked at a picture of a new pully/rotor and there isn't one, so I'm assuming we're good without it.

So, I pushed in the new bearing and used locktite on it as opposed to pinging it in. (Per a youtube video I found.) Very tight fit but It went in too. I'm almost ready to install it back in the car.

Next, the shims. The service manual shows the bolt going through them into the compressor. I'm not sure about this though. Any input?

The compressor still has a charge so I'm hoping that when I reassemble this on Saturday, it will run. If any of you can clear up the shim issue though (where do they go?) that would be awesome and would raise my comfort level dramatically.

Last edited by Bob2.0; 03-02-2011 at 09:34 AM. Reason: Clarity

#11

Instructor

Thread Starter

Never mind on the shim thing. I found a video on youtube at http://www.youtube.com/watch?v=xrB3pMVD4Cg

The shims go between the bolt and the hub to insure the proper air gap.

For future bearing changers, here is another useful thread

http://forums.corvetteforum.com/c4-t...lear-92-a.html

The shims go between the bolt and the hub to insure the proper air gap.

For future bearing changers, here is another useful thread

http://forums.corvetteforum.com/c4-t...lear-92-a.html

#12

Instructor

Thread Starter

This weekend I installed the bearing and rotor over the clutch. Sadly their seems to be a problem as it turns by hand for about a half a revoltution, and then binds up, turns and binds up. I went ahead and put my old serpentine belt on, thinking I had nothing to lose, and fired it up. The noise that I replaced my tensioners to fix was finally gone, letting the LT1 sound like itself again. Bad news is that the pully sped up and slowed down as it ran, making it clear that it wasn't going to make it. The A/C blew cold though, and everything else was fine.

I took the pulley off and I plan to put it on the bench again thinking that the bearing isn't seated right or that the pulley warped. I am going to crush the heck out of it with the big vice I have and see if that doesn't help it. If not, I'll be looking for a new clutch/pully assembly. My compressor is working great so I will just keep looking until I find what I need.

Bob

I took the pulley off and I plan to put it on the bench again thinking that the bearing isn't seated right or that the pulley warped. I am going to crush the heck out of it with the big vice I have and see if that doesn't help it. If not, I'll be looking for a new clutch/pully assembly. My compressor is working great so I will just keep looking until I find what I need.

Bob

#13

Instructor

Thread Starter

It looks like I am talking to myself, but I want to keep a complete record so here goes.

I managed to get the bearing to seat all the way to where it is flush and now it slips right on. It still binds a little, but not as badly as before. I put the belt on and it seems to rotate without a problem, but every time I flip on the a/c, it blows the fuse.

This weekend it didn't rotate okay but didn't blow a fuse. Any thoughts?...

I managed to get the bearing to seat all the way to where it is flush and now it slips right on. It still binds a little, but not as badly as before. I put the belt on and it seems to rotate without a problem, but every time I flip on the a/c, it blows the fuse.

This weekend it didn't rotate okay but didn't blow a fuse. Any thoughts?...

#14

Melting Slicks

Member Since: Aug 1999

Location: Baltimore, MD USA

Posts: 2,240

Likes: 0

Received 34 Likes

on

30 Posts

Disconnect the electrical connector at the AC Clutch coil and measure

the resistance of the coil. Should be around 3.6 ohms.

With the clutch coil plug disconnected start the engine. Turn on the AC

and if the fuse doesn't blow, that would indicated the coil is bad. If the

fuse blows could be the diode that is across the coil (hidden in the harness)

is bad or bad wiring some where.

Sounds like it's time for a new or used clutch assembly.

the resistance of the coil. Should be around 3.6 ohms.

With the clutch coil plug disconnected start the engine. Turn on the AC

and if the fuse doesn't blow, that would indicated the coil is bad. If the

fuse blows could be the diode that is across the coil (hidden in the harness)

is bad or bad wiring some where.

Sounds like it's time for a new or used clutch assembly.

Last edited by Hooked on Vettes; 03-07-2011 at 10:31 PM.

#15

Instructor

Thread Starter

Thanks for responding Hooked. I'll try that. To me it just doesn't make sense that it didn't blew cold but didn't blow a fuse on Sunday, but does now. I'll probably take it apart and see if I didn't do something wrong to cause this.

I'd love to get a new clutch, but I'm afraid that it won't match up with my compressor. For some reason the bore I need on the bearing has to be 1.2" but OEM keeps listing 1.57. There is a guy in Bowling Green with a C4 graveyard, who found a clutch for me so I'm looking at that tomorrow. I may just try it to see what happens.

More later...

I'd love to get a new clutch, but I'm afraid that it won't match up with my compressor. For some reason the bore I need on the bearing has to be 1.2" but OEM keeps listing 1.57. There is a guy in Bowling Green with a C4 graveyard, who found a clutch for me so I'm looking at that tomorrow. I may just try it to see what happens.

More later...

#16

Burning Brakes

I had essentially the same issue. I have ice cold air now after getting a compressor from Jason at Vette2Vette and replacing the whole thing. He gives a one year guarantee and it's OE. That has been 4 years ago.

#17

Instructor

Thread Starter

I didn't think of Vette2vette. I'm really trying to avoid the new compressor. All that went out was a $30 bearing. The compressor works fine, blows ice cold still without a problem. Sadly because of the bore discrepancy (OEM = 1.57, mine is 1.2) I might have to go that route in the end. I'm not giving up without a fight though!

#19

Instructor

Thread Starter

It's not about saving a buck, it's about saving over five-hundred and fifty of them!

It's also about adding something meaningful to the knowledge bank here. I've drawn off of it many times and I'd like to do my part. If I go through all of this and it ends with "get a new compressor" so be it... at least those who come after me wont have to got through all the trouble I have.

That said, today I bought a broken compressor from a Corvette parts dealer in Bowling Green. (Carter's Glass) It came off of a 94 Vette, so the clutch assembly should fit. We'll know tonight. I'm going to just try to use the rotor and see what happens. If it still trips the fuze, I'll replace the whole clutch assembly using the new-used one I got. He's only charging me $50 for it so this should answer all of my questions.

More later...

It's also about adding something meaningful to the knowledge bank here. I've drawn off of it many times and I'd like to do my part. If I go through all of this and it ends with "get a new compressor" so be it... at least those who come after me wont have to got through all the trouble I have.

That said, today I bought a broken compressor from a Corvette parts dealer in Bowling Green. (Carter's Glass) It came off of a 94 Vette, so the clutch assembly should fit. We'll know tonight. I'm going to just try to use the rotor and see what happens. If it still trips the fuze, I'll replace the whole clutch assembly using the new-used one I got. He's only charging me $50 for it so this should answer all of my questions.

More later...

#20

Melting Slicks

Member Since: Aug 1999

Location: Baltimore, MD USA

Posts: 2,240

Likes: 0

Received 34 Likes

on

30 Posts

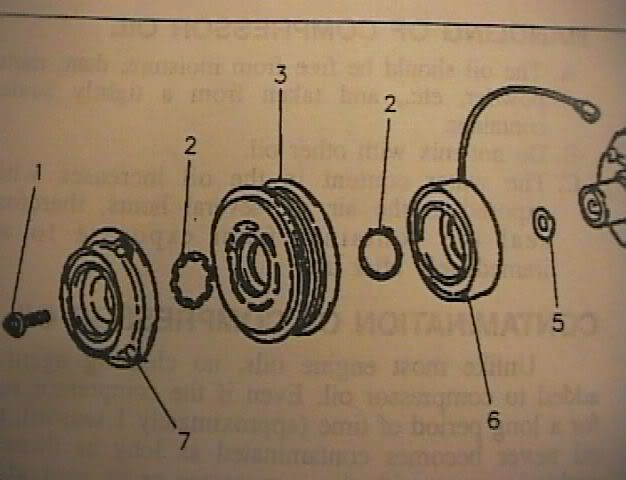

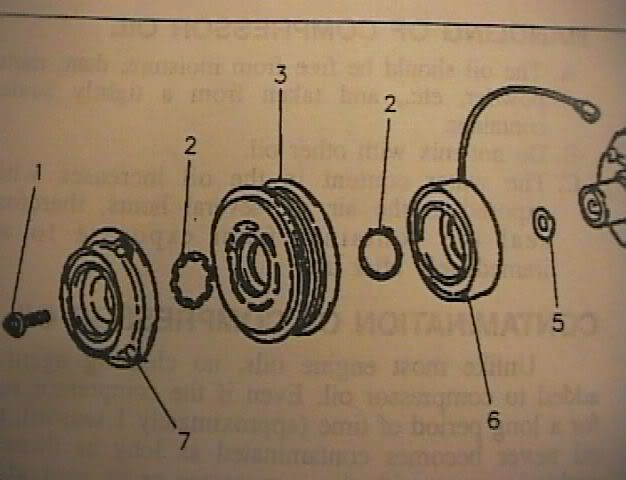

You mentioned black goo in your first post.

That usually indicates the clutch coil/stator is bad.

The windings are shorted causing the fuse to blow.

That's Item #6 in the picture.

Also you need to verify the clearance between the

Clutch plate Item #7 and the rotor/pulley Item #3.

Should be .02 inches +- .006 inches.

That's what the shim/shims Item #5 are for.

With engine off, use your hand and rotate Item #7. The compressor

should rotate with some resistance and no binding.

That usually indicates the clutch coil/stator is bad.

The windings are shorted causing the fuse to blow.

That's Item #6 in the picture.

Also you need to verify the clearance between the

Clutch plate Item #7 and the rotor/pulley Item #3.

Should be .02 inches +- .006 inches.

That's what the shim/shims Item #5 are for.

With engine off, use your hand and rotate Item #7. The compressor

should rotate with some resistance and no binding.

Last edited by Hooked on Vettes; 03-09-2011 at 09:14 PM.