Engine Mount alignment - 66' vette???

#1

Instructor

Thread Starter

Member Since: Oct 2009

Location: Ipswich MA

Posts: 167

Likes: 0

Received 0 Likes

on

0 Posts

I have a 66' roadster that was involved in a front end accident. Just

finishing a frame off restoration when I installed the engine and

realized that the tailshaft is offset to the right (about 3/4"-1") making

the tranny mount impossible to bolt together. Any suggestions

for dimensions that I can check, or where I should take my measurements. The motor mounts do not appear bent.

I would assume that the drive train should be straight inline from

the engine damper to the differential yoke. Are there tolerances

for misalignment?

finishing a frame off restoration when I installed the engine and

realized that the tailshaft is offset to the right (about 3/4"-1") making

the tranny mount impossible to bolt together. Any suggestions

for dimensions that I can check, or where I should take my measurements. The motor mounts do not appear bent.

I would assume that the drive train should be straight inline from

the engine damper to the differential yoke. Are there tolerances

for misalignment?

#2

Race Director

Member Since: Mar 2009

Location: Canada's capital

Posts: 19,777

Received 4,583 Likes

on

2,157 Posts

2020 Corvette of the Year Finalist (appearance mods)

C1 of Year Finalist (appearance mods) 2019

Who straightened the frame???????????

#3

Le Mans Master

I have a 66' roadster that was involved in a front end accident. Just

finishing a frame off restoration when I installed the engine and

realized that the tailshaft is offset to the right (about 3/4"-1") making

the tranny mount impossible to bolt together. Any suggestions

for dimensions that I can check, or where I should take my measurements. The motor mounts do not appear bent.

I would assume that the drive train should be straight inline from

the engine damper to the differential yoke. Are there tolerances

for misalignment?

finishing a frame off restoration when I installed the engine and

realized that the tailshaft is offset to the right (about 3/4"-1") making

the tranny mount impossible to bolt together. Any suggestions

for dimensions that I can check, or where I should take my measurements. The motor mounts do not appear bent.

I would assume that the drive train should be straight inline from

the engine damper to the differential yoke. Are there tolerances

for misalignment?

#4

Race Director

I have a 66' roadster that was involved in a front end accident. Just

finishing a frame off restoration when I installed the engine and

realized that the tailshaft is offset to the right (about 3/4"-1") making

the tranny mount impossible to bolt together. Any suggestions

for dimensions that I can check, or where I should take my measurements. The motor mounts do not appear bent.

I would assume that the drive train should be straight inline from

the engine damper to the differential yoke. Are there tolerances

for misalignment?

finishing a frame off restoration when I installed the engine and

realized that the tailshaft is offset to the right (about 3/4"-1") making

the tranny mount impossible to bolt together. Any suggestions

for dimensions that I can check, or where I should take my measurements. The motor mounts do not appear bent.

I would assume that the drive train should be straight inline from

the engine damper to the differential yoke. Are there tolerances

for misalignment?

Last edited by DansYellow66; 03-06-2010 at 06:07 PM.

#5

Le Mans Master

#6

Team Owner

Your frame is still bent

jack

jack

#7

Team Owner

Member Since: Mar 2003

Location: Greenville, Indiana

Posts: 26,118

Received 1,843 Likes

on

1,398 Posts

You could cheat and pry the transmission around and get the bolts in or start elongating holes. Both are poor choices and will probably result in other problems.

It doesn't take much of a bump on the front frame horn to drive the frame back, just in front of the side rail.

I'd take the thing to a frame rack if you're sure you're not overlooking something obvious. That frame could also be off, up/down and you won't know it until you get all the weight back on the suspension.

#8

Instructor

Thread Starter

Member Since: Oct 2009

Location: Ipswich MA

Posts: 167

Likes: 0

Received 0 Likes

on

0 Posts

The front end accident was minor... basic fiberglass damage...frame is OK but one engine mount was torn (old rubber) away. I figured that

several hundred pound of force at a quick stop could impact the steel

motor mount a bit too. I would figure that both motor mounts should be

equal in distance from the transmission cross member. I don't want to

bend the wrong one with my portapower! Engine fits nice otherwise.

several hundred pound of force at a quick stop could impact the steel

motor mount a bit too. I would figure that both motor mounts should be

equal in distance from the transmission cross member. I don't want to

bend the wrong one with my portapower! Engine fits nice otherwise.

#9

Le Mans Master

Take a old bare block, hang a bellhousing and transmission off of it, and take the car back to the frame shop. The reason for the old block and all is so if it gets damaged, you don't lose anything.

When the frame bends in the accident, the engine bends the engine mount horns because it isn't letting it move. So when the frame is "straightened", the horns now move as there is nothing holding them. Having an engine in there will let the shop see how much they have to bend the horns around to get it aligned. They will bend with the engine in place and that could break the block, so it is best to have a junk block in there for this.

When the frame bends in the accident, the engine bends the engine mount horns because it isn't letting it move. So when the frame is "straightened", the horns now move as there is nothing holding them. Having an engine in there will let the shop see how much they have to bend the horns around to get it aligned. They will bend with the engine in place and that could break the block, so it is best to have a junk block in there for this.

#10

Instructor

Thread Starter

Member Since: Oct 2009

Location: Ipswich MA

Posts: 167

Likes: 0

Received 0 Likes

on

0 Posts

I have the car assembled now....everything went together fine, new body mounts, bumper

alignment etc. I don't believe the frame is bent however I would like to check diagonal tolerances on the frame to verify. Any suggestions on key point-to-point frame measurements that I should take? I have the car on a lift that will allow plumb bobs and measurements easy for this evaluation. The car body sites perfect right now and there

is no stress on any the fiberglass body parts.

I

alignment etc. I don't believe the frame is bent however I would like to check diagonal tolerances on the frame to verify. Any suggestions on key point-to-point frame measurements that I should take? I have the car on a lift that will allow plumb bobs and measurements easy for this evaluation. The car body sites perfect right now and there

is no stress on any the fiberglass body parts.

I

#11

Race Director

#12

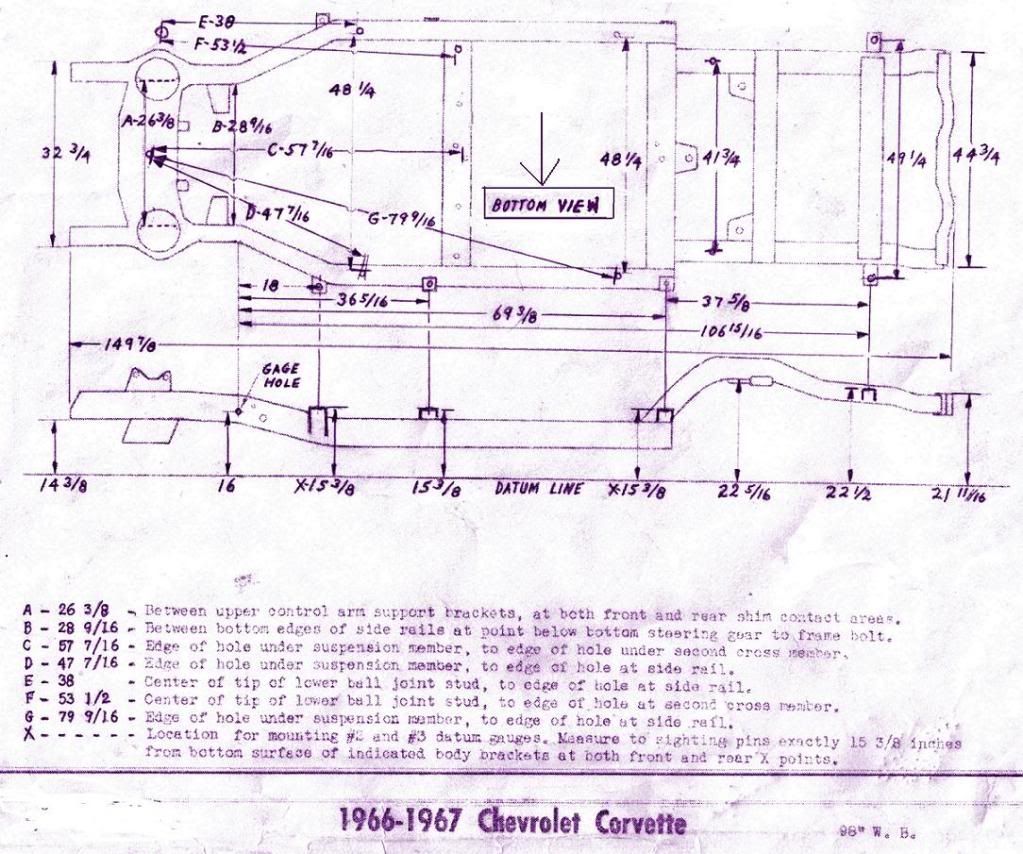

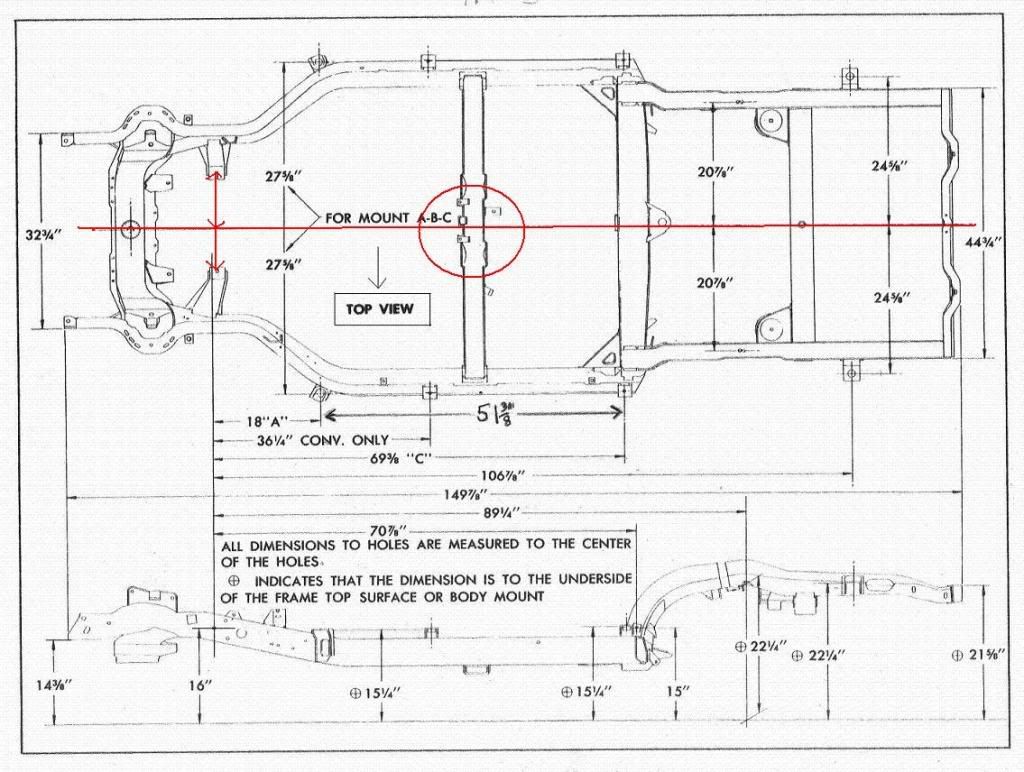

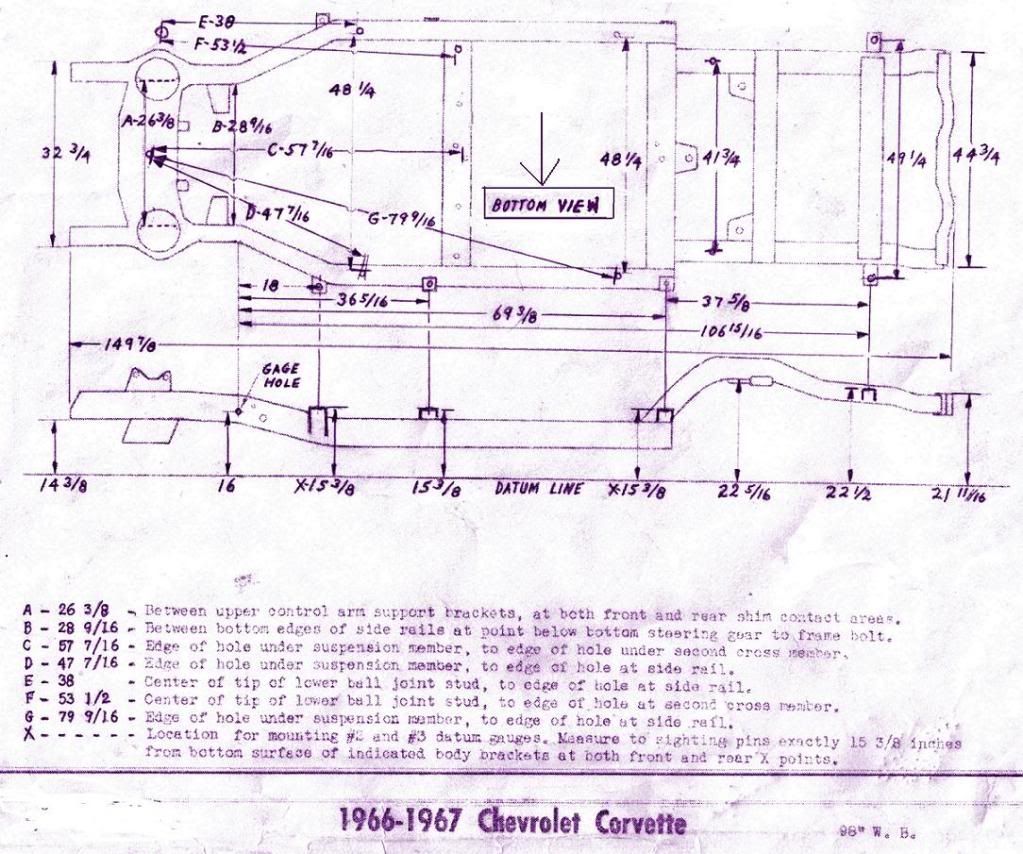

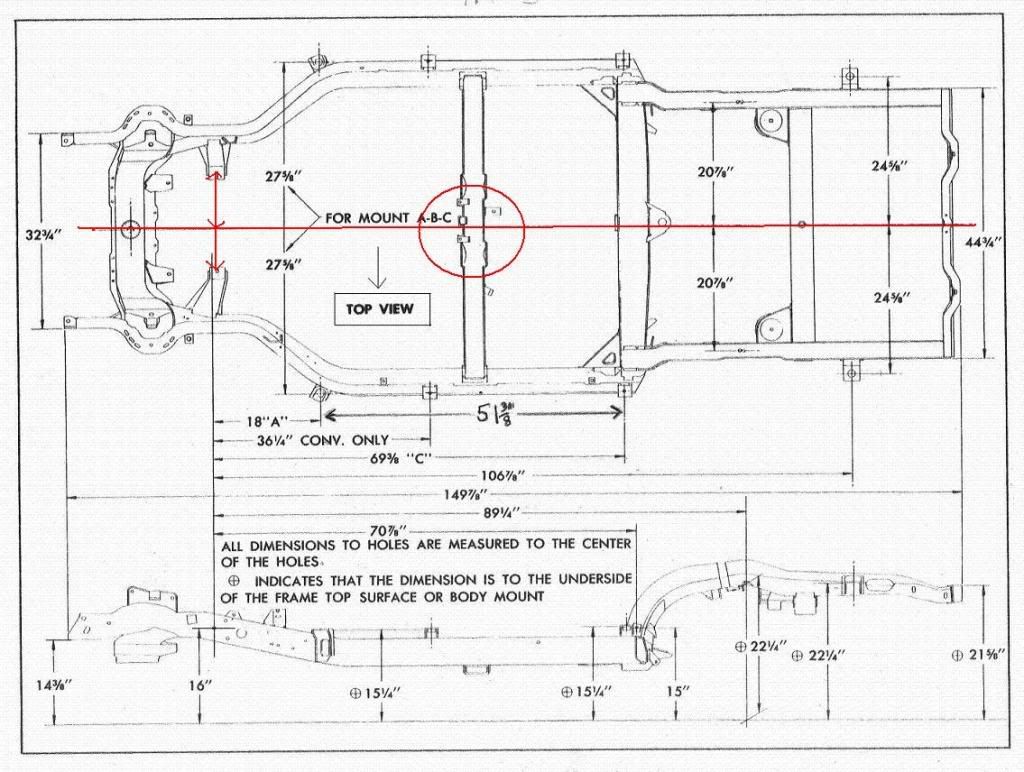

Here are some diagrams that might help. The first is the bottom view which will help if you have the body on. Unfortunately there are no measurements for the engine and trans mounts.

#13

Instructor

Thread Starter

Member Since: Oct 2009

Location: Ipswich MA

Posts: 167

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the diagram & dimensions. Measurement C (59 3/8") should

be adequate. The frame rails on my car site perfectly in alignment as

a matter of fact I got the tranny bolted in today. I took several rough

measrements today and they looked OK, got the tranny bolted in too

without much effort (slid over with a 18" prybar. I suspect the problem that I had was the brand new motor mounts from Corvette America. These are so tight that you would swear they didn't use rubber between the plates...I guess I expected the tailshaft to position itself right down the middle of the tunnel and forgot that the manufacturing tolerances are not what they are today.

I would guess that the rubber motor mounts will stabilize after some mileage and use.

Want to thank everybody for their help! My new GM ZZ383 is looking

pretty sweet right now.

be adequate. The frame rails on my car site perfectly in alignment as

a matter of fact I got the tranny bolted in today. I took several rough

measrements today and they looked OK, got the tranny bolted in too

without much effort (slid over with a 18" prybar. I suspect the problem that I had was the brand new motor mounts from Corvette America. These are so tight that you would swear they didn't use rubber between the plates...I guess I expected the tailshaft to position itself right down the middle of the tunnel and forgot that the manufacturing tolerances are not what they are today.

I would guess that the rubber motor mounts will stabilize after some mileage and use.

Want to thank everybody for their help! My new GM ZZ383 is looking

pretty sweet right now.

#14

Le Mans Master

...

The frame rails on my car site perfectly in alignment as

a matter of fact I got the tranny bolted in today. ...

got the tranny bolted in too

without much effort (slid over with a 18" prybar. I suspect the problem that I had was the brand new motor mounts from Corvette America. ...

forgot that the manufacturing tolerances are not what they are today.

I would guess that the rubber motor mounts will stabilize after some mileage and use.

...

The frame rails on my car site perfectly in alignment as

a matter of fact I got the tranny bolted in today. ...

got the tranny bolted in too

without much effort (slid over with a 18" prybar. I suspect the problem that I had was the brand new motor mounts from Corvette America. ...

forgot that the manufacturing tolerances are not what they are today.

I would guess that the rubber motor mounts will stabilize after some mileage and use.

...

Frame rails can be perfect and the engine mount horns can be bend way out. That what I was saying above. that is because in a wreck, the side rails move from impact, but the engine block holds the mount horns in place, so they are bent in relationship to the side rails.

When the side rails are pulled back in place on the frame rack, the engine mount horns are now out of alignment.

1 inch is NOT manufacturing tolerance. 1/8 inch is more likely.

All you have done is place the engine rubber mounts and the transmission rubber mount in stress. They will eventually rip and then you will have an engine that jumps with you jump on it or a transmission that wants to bash on the tunnel.

You asked for advice, and you have been given it from someone who has already been where you are.

#15

Race Director

Member Since: Mar 2009

Location: Canada's capital

Posts: 19,777

Received 4,583 Likes

on

2,157 Posts

2020 Corvette of the Year Finalist (appearance mods)

C1 of Year Finalist (appearance mods) 2019

I'm gonna hazard another guess as to what's happened. Since the impact tore the mount up, I'm gonna guess there was stress on it, like a lot of stress and the impact made it pop, so previous damage is what I'm thinking, to the frame and it's overall alignment . Someone pushed the trans over to get it bolted up, knowing the u-joints would make up for the angle, and now another jolt made it worse. In any case you need the best lazer frame machine and operator to make sure you get it perfect, and going down the road in a straight line. That's what I would do.

~~~~~~~~~~~ ~~~~~~~~~~~

~~~~~~~~~~~

~~~~~~~~~~~

~~~~~~~~~~~

~~~~~~~~~~~

Last edited by Kerrmudgeon; 03-08-2010 at 12:38 AM.