Diy - build your own car ramps!

#1

Burning Brakes

Thread Starter

I did a search on google regarding building your own car ramps. I personally wouldn't trust the (2) 2x12 diagonal ramps to drive up on without beefing them up more. But the rest seems strong. Check this out:

http://www.corvettec3.ca/ramps.htm

Have you ever wished there was an easy way to get your Corvette up in the air so you could comfortably work under it? Here is a safe and inexpensive way to construct a set of portable ramps. Instructions:

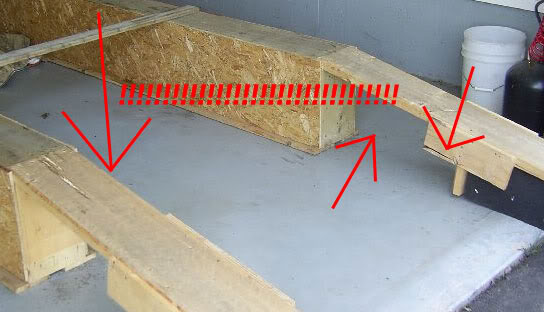

The ramps are indeed easy to build. Both sections are built identical. The ramps are 10'9" in length. You can construct them from 2"x10" or 2"x12". In this set I used 2"x10" and then nailed a couple of lengths of 1"x6" on each side on the bottom to give some extra lateral support. (If you use 2"x12" you will have more room to place a hydraulic jack under the frame in case you need to place jack stands under the frame). The top and bottom are 2"x10" or 12" with 2"X10" or 12" uprights on 16" centers. You will need 2 sheets of 1/2" plywood or wafer board for the sides. Rip each sheet of plywood into 3 strips 16" wide. It will take one sheet per ramp. Use 2 1/2" spiral nails or 2" drywall screws to attach the side pieces to your framework. Use 3 1/2" spiral on the actual framework. On the ends where the car comes up, attach another piece of 2" x 10" to support the planks for driving the car up on. These 2 planks only need to be about 7' long with a couple supports under them. I used a couple of rubber ramps to support the planks. With that short a length my side pipes still clear fine. You can mount a couple of permanent lights and a 110v receptacle on the inner sides of the supports if you wish. That makes it much easier than fighting power cords. If you have a good level floor they will be very stable and will support a bulldozer. I can almost sit on the floor under the car but not quite. I mark the floor with a felt marker so that each time it only takes me about 5 minutes to place them and drive the car up on them.

Here are some pictures of what your finished product will resemble.

http://www.corvettec3.ca/ramps.htm

Have you ever wished there was an easy way to get your Corvette up in the air so you could comfortably work under it? Here is a safe and inexpensive way to construct a set of portable ramps. Instructions:

The ramps are indeed easy to build. Both sections are built identical. The ramps are 10'9" in length. You can construct them from 2"x10" or 2"x12". In this set I used 2"x10" and then nailed a couple of lengths of 1"x6" on each side on the bottom to give some extra lateral support. (If you use 2"x12" you will have more room to place a hydraulic jack under the frame in case you need to place jack stands under the frame). The top and bottom are 2"x10" or 12" with 2"X10" or 12" uprights on 16" centers. You will need 2 sheets of 1/2" plywood or wafer board for the sides. Rip each sheet of plywood into 3 strips 16" wide. It will take one sheet per ramp. Use 2 1/2" spiral nails or 2" drywall screws to attach the side pieces to your framework. Use 3 1/2" spiral on the actual framework. On the ends where the car comes up, attach another piece of 2" x 10" to support the planks for driving the car up on. These 2 planks only need to be about 7' long with a couple supports under them. I used a couple of rubber ramps to support the planks. With that short a length my side pipes still clear fine. You can mount a couple of permanent lights and a 110v receptacle on the inner sides of the supports if you wish. That makes it much easier than fighting power cords. If you have a good level floor they will be very stable and will support a bulldozer. I can almost sit on the floor under the car but not quite. I mark the floor with a felt marker so that each time it only takes me about 5 minutes to place them and drive the car up on them.

Here are some pictures of what your finished product will resemble.

Car parked on ramps awaiting the blocks behind the rear wheels.

Ramps 2" wider than these will give you more room to place jack stands.

Note the blocks spiked up front for wheel stops.

You might want to place blocks behind the rear wheels if the car is going to be in neutral.

This gives you some idea of the height you have for working.

An old sleeping bag makes a nice pad for lying on when under the car.

You can see the rubber pads that I use for extra support for driving up and down.

I sometimes attach a board to keep the ramps aligned when I drive up on them.

You can store the ramps along the wall of your shop when not in use.

Glenn's ramps.

Glenn's setup for getting his car up on the ramps.

Shel Myers from British Columbia made a few modifications to better suit his particular use. The ramps have pot lights installed (three on one ramp, two on the other), which allow each lamp to pivot and swivel in order to place light where it is needed. Each ramp has a switch to control each set of lights. The drivers side ramp has a built-in extension cord and power outlet so power tools can be used while working under the vehicle. Shel also made the actual 'ramp' portions with vertical oriented 2 x 6 in order to allow a vehicle to drive on without the need for additional supports. Shel also decided to make his ramps a full 12" wide using 2 x 6 lumber to do it since it was far cheaper and allows for easier rebuilding if one section fails or is otherwise rendered unusable. Shel also left two openings between studs unsheeted on the inside of each ramp to allow for tool and parts storage which proves to be very handy. View the pictures below:

Last edited by vettemann62; 09-02-2009 at 10:33 PM.

The following users liked this post:

Art17 (02-01-2018)

#4

Drifting

Member Since: May 2007

Location: Canton/Detroit Michigan

Posts: 1,407

Likes: 0

Received 0 Likes

on

0 Posts

This is great! I like this option much better than those race ramps or whatever they are called that cost 2500 bucks and are made of plastic. I hates plastic.

#6

Melting Slicks

Nifty idea

I'm very much into the DIY thing... and, in the name of being over-cautious for safety's sake, I'm going to play devils' advocate here a bit...

Not long ago I had installed some new 2"X6" spans in my attic to support an air conditioning unit drip try... not much weight at all. The wood lengths were installed carefully, holes were pre-drilled and screws used for zero cracking / stress on the wood. Well, I went up there the other day and one of the 2"x6" completely split all on it's own on one end to the point were if it had been supporting any more than 50 pounds it would have failed and collapsed. That's wood.

Also, not too long ago I had a few 2"X10"s that I used to lay flat on the ground and I'd drive my C6 Vette up on them to get an extra 1.5" of clearance so I could get one of my hydraulic jacks underneath. One of those 2"X10" completely split in half one day as I drove up on it. In this case it wasn't a problem, but just another reminder to me about how unpredictable wood can be.

If you are going to use wood to support a lot of weight, you should have redundancy... meaning, you should never rely on just one single piece of wood as a critical weight supporting member. Like, having single wood ramp planks (leading up to the rectangular sections)... even with the extra black ramps under the middle, one of those planks could split at the top end (length-wise along the grain)... once that would happen, it could move or shift or who knows, a wheel could drop and the frame of the car would slam down on another portion of this wood structure, could cause further failure and the whole car could go down.

I'm not a master carpenter, but if you study the way most modern homes are framed for instance, you will note a lot of redundancy. I've never seen an instance where one single "2-by" piece of wood was responsible for supporting something very heavy and important. Most headers or girders are made of two or three "2-bys" nailed together, presumably for redundancy, if one splits, there's another one or two pieces to keep things together.

Also, side note, drywall screws have very little strength and should not be used in instances where you're dealing with real load-bearing structures. If anything, use deck screws which are considerably better than drywall screws... and, depending on the situation, back them up with good common nails for greater shear strength.

Just don't want to see anyone get hurt. Sometimes with DIY wood ramps, unless an architect (someone who would know the properties / load limits of various wood members and how things should be constructed etc) was to review the design, it's really an unknown as to how safe they might be. They could last forever, or could fail after three uses. They may seem solid and stable, but a weak point (due to an inherent split in a key section of wood) could allow a sudden failure. One's life is at stake when under a suspended automobile, so it's not the type of thing you really want to roll the dice with.

When in doubt, utilize additional safety measures, such as adding good jack stands under the car before crawling under it, etc. Do not trust the wood solely for supporting a car in this manner. That's my opinion anyway after having done a lot of general carpentry / framing work.

I think a lot of folks place perhaps a bit more faith in wood than they should. What I know is that you could go to Home Depot right now, buy two "brand new" lengths of 2"X10", try to support the same amount of weight with each, and one might be fine forever, the other might fail... and it might fail immediately or fail a month from now... that's wood. No two pieces are the same and they are not "guaranteed" by any means to support a great deal of weight all alone.

Driving a typical musclecar over a pair of single planks means a concentrated moving load of maybe 1,000 pounds (front wheel) on each plank... that's a lot to ask of a single typical 2"X10" in my opinion, at least when used in a non-kosher manner (horizontally, etc). We're not talking about an evenly distributed typical load within a professionally designed frame.

Another possible idea for DIY ramps out of wood that would theoretically be pretty safe... use stacked layers of plywood or even OSB... 12" wide strips laying flat on the ground, screwed together... stagger the strips to create a gradual incline to drive up with a nice flat section on top with stops. Ramps would essentially be solid. Multiple layers of ply or OSB make for lots of "redundancy", even if one piece totally cracked and split everywhere (which would not happen anyway), the ramp would still not come apart or shift etc at all.

For the front wheels, make two ramps using ten 3/4" thick strips for 7.5" of raise height.... and for the rear wheels, make two ramps using however many strips you can fit under the rocker panels of the car... I'll guess maybe 3.5" or so... then place all four ramps in front of all four wheels and drive up... the front end will be up 7.5" and the rear about 3.5"... or vise-versa depending on whether you drive up or back up. This should be enough height for most common jobs (though maybe not enough for major jobs). The best part, such ramps could never fail.... would be pretty much 100% safe.

The downsides to such ramps... each ramp would be quite heavy.... and might cost a little more to build than other common designs.... though they would be WAY easier to construct as long as you could get someone to rip the ply or OSB into 12" strips for you (Home Depot might do this for free). You wouldn't have to be an engineering genius or master carpenter to put together such DIY ramps and have them be 100% safe, it's somewhat of an "idiot-proof" design in terms of the construction / assembly. The concept is, it's "over-built" / "over-designed" which I'd say is a good idea when using any type of WOOD to support a car.

Upon looking at the OP's ramps once again, they do seem quite neat, perhaps fine, but I did want to mention my general feelings about wood ramps in general and how wood really should not be trusted for critical applications unless a good design with adequate redundancy is used throughout.

Ok, devil's advocate hat removed now. Just a little safety awareness.

I'm very much into the DIY thing... and, in the name of being over-cautious for safety's sake, I'm going to play devils' advocate here a bit...

Not long ago I had installed some new 2"X6" spans in my attic to support an air conditioning unit drip try... not much weight at all. The wood lengths were installed carefully, holes were pre-drilled and screws used for zero cracking / stress on the wood. Well, I went up there the other day and one of the 2"x6" completely split all on it's own on one end to the point were if it had been supporting any more than 50 pounds it would have failed and collapsed. That's wood.

Also, not too long ago I had a few 2"X10"s that I used to lay flat on the ground and I'd drive my C6 Vette up on them to get an extra 1.5" of clearance so I could get one of my hydraulic jacks underneath. One of those 2"X10" completely split in half one day as I drove up on it. In this case it wasn't a problem, but just another reminder to me about how unpredictable wood can be.

If you are going to use wood to support a lot of weight, you should have redundancy... meaning, you should never rely on just one single piece of wood as a critical weight supporting member. Like, having single wood ramp planks (leading up to the rectangular sections)... even with the extra black ramps under the middle, one of those planks could split at the top end (length-wise along the grain)... once that would happen, it could move or shift or who knows, a wheel could drop and the frame of the car would slam down on another portion of this wood structure, could cause further failure and the whole car could go down.

I'm not a master carpenter, but if you study the way most modern homes are framed for instance, you will note a lot of redundancy. I've never seen an instance where one single "2-by" piece of wood was responsible for supporting something very heavy and important. Most headers or girders are made of two or three "2-bys" nailed together, presumably for redundancy, if one splits, there's another one or two pieces to keep things together.

Also, side note, drywall screws have very little strength and should not be used in instances where you're dealing with real load-bearing structures. If anything, use deck screws which are considerably better than drywall screws... and, depending on the situation, back them up with good common nails for greater shear strength.

Just don't want to see anyone get hurt. Sometimes with DIY wood ramps, unless an architect (someone who would know the properties / load limits of various wood members and how things should be constructed etc) was to review the design, it's really an unknown as to how safe they might be. They could last forever, or could fail after three uses. They may seem solid and stable, but a weak point (due to an inherent split in a key section of wood) could allow a sudden failure. One's life is at stake when under a suspended automobile, so it's not the type of thing you really want to roll the dice with.

When in doubt, utilize additional safety measures, such as adding good jack stands under the car before crawling under it, etc. Do not trust the wood solely for supporting a car in this manner. That's my opinion anyway after having done a lot of general carpentry / framing work.

I think a lot of folks place perhaps a bit more faith in wood than they should. What I know is that you could go to Home Depot right now, buy two "brand new" lengths of 2"X10", try to support the same amount of weight with each, and one might be fine forever, the other might fail... and it might fail immediately or fail a month from now... that's wood. No two pieces are the same and they are not "guaranteed" by any means to support a great deal of weight all alone.

Driving a typical musclecar over a pair of single planks means a concentrated moving load of maybe 1,000 pounds (front wheel) on each plank... that's a lot to ask of a single typical 2"X10" in my opinion, at least when used in a non-kosher manner (horizontally, etc). We're not talking about an evenly distributed typical load within a professionally designed frame.

Another possible idea for DIY ramps out of wood that would theoretically be pretty safe... use stacked layers of plywood or even OSB... 12" wide strips laying flat on the ground, screwed together... stagger the strips to create a gradual incline to drive up with a nice flat section on top with stops. Ramps would essentially be solid. Multiple layers of ply or OSB make for lots of "redundancy", even if one piece totally cracked and split everywhere (which would not happen anyway), the ramp would still not come apart or shift etc at all.

For the front wheels, make two ramps using ten 3/4" thick strips for 7.5" of raise height.... and for the rear wheels, make two ramps using however many strips you can fit under the rocker panels of the car... I'll guess maybe 3.5" or so... then place all four ramps in front of all four wheels and drive up... the front end will be up 7.5" and the rear about 3.5"... or vise-versa depending on whether you drive up or back up. This should be enough height for most common jobs (though maybe not enough for major jobs). The best part, such ramps could never fail.... would be pretty much 100% safe.

The downsides to such ramps... each ramp would be quite heavy.... and might cost a little more to build than other common designs.... though they would be WAY easier to construct as long as you could get someone to rip the ply or OSB into 12" strips for you (Home Depot might do this for free). You wouldn't have to be an engineering genius or master carpenter to put together such DIY ramps and have them be 100% safe, it's somewhat of an "idiot-proof" design in terms of the construction / assembly. The concept is, it's "over-built" / "over-designed" which I'd say is a good idea when using any type of WOOD to support a car.

Upon looking at the OP's ramps once again, they do seem quite neat, perhaps fine, but I did want to mention my general feelings about wood ramps in general and how wood really should not be trusted for critical applications unless a good design with adequate redundancy is used throughout.

Ok, devil's advocate hat removed now. Just a little safety awareness.

The following 4 users liked this post by Vet:

#10

never ever ever ever would I put my car on that ... Just buy a real ramp lol. The money I would save building one .. would not make up for the loss of comfort know that the wood could break at any second

aahhh the more I look at it the more I cringe ... look at picture #7 .. the "sticks" you drive up on have cracks already! The problem I see with this idea ... is you will have no idea that the wood isn't holding up until your car smashes to the ground.

Last edit: why is it that some people will risk their beautiful cars to save a few bucks ... it seems by the pics. you have 2 classic vets ... I just don't get why you would risk destroying them to save money ... ok I'm done (maybe.)

aahhh the more I look at it the more I cringe ... look at picture #7 .. the "sticks" you drive up on have cracks already! The problem I see with this idea ... is you will have no idea that the wood isn't holding up until your car smashes to the ground.

Last edit: why is it that some people will risk their beautiful cars to save a few bucks ... it seems by the pics. you have 2 classic vets ... I just don't get why you would risk destroying them to save money ... ok I'm done (maybe.)

Last edited by Macbeth182; 09-03-2009 at 10:46 AM.

#12

It's all about how it's engineered... the boxes look fine (although I might go wider for more support and leeway), but those ramps scare me. As others have pointed out, those boards you drive up don't offer much support the way they're oriented. Beef those puppies up!

#13

I'll probably be doing this as I am a cheap *** and I don't have any issues with using wood. Ever since I was really little, I watched my dad park his '56 Ford pickup on wooden ramps and work on it. If it is built solidly, wood can handle it.

I should note however that the actual supporting and inclining ramp section on mine will be a lot more solid! That is the only change I would make to the design

I should note however that the actual supporting and inclining ramp section on mine will be a lot more solid! That is the only change I would make to the design

#14

Burning Brakes

I'll probably be doing this as I am a cheap *** and I don't have any issues with using wood. Ever since I was really little, I watched my dad park his '56 Ford pickup on wooden ramps and work on it. If it is built solidly, wood can handle it.

I should note however that the actual supporting and inclining ramp section on mine will be a lot more solid! That is the only change I would make to the design

I should note however that the actual supporting and inclining ramp section on mine will be a lot more solid! That is the only change I would make to the design

and make sure my life insurance premiums are paid up.

#19

If you look at the innards of the red and white stands, you see joists probably every 16"... I think the OP has his constructed the same way. For that application, as long as it doesn't get wet, OSB is fine, IMO.

#20