how did GM determine the shim #s for body mounts

#1

Drifting

Thread Starter

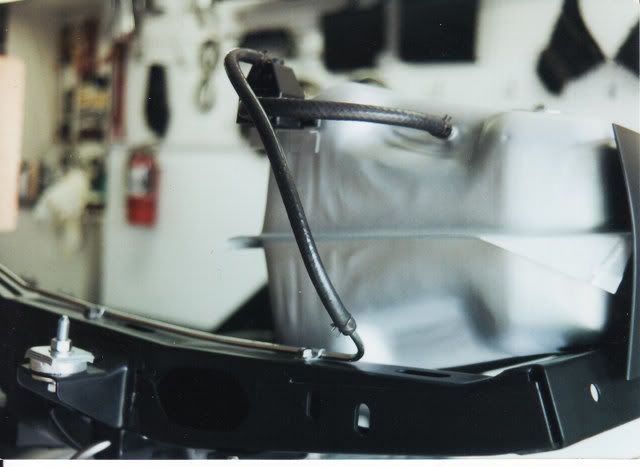

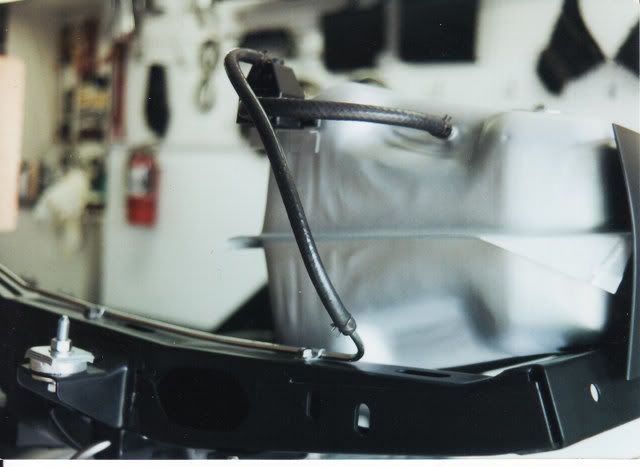

I have photos that show what I think I took off of the car during disassembly. Does anyone know the logic GM used when leveling the body/determining the number of shims at each body mount location?

Thanks

Thanks

#2

Former Vendor

I believe that they put as many shims as needed to get the gaps and general fit of body to frame adequate to fit within their guidelines. Some required more, some less, depending on the particular car.

Unfortunately, for the most part their guidelines and QC were not very strict, so there is a ton of variance between cars.

Most nicely restored these days are fit far better than GM ever fit them.

Unfortunately, for the most part their guidelines and QC were not very strict, so there is a ton of variance between cars.

Most nicely restored these days are fit far better than GM ever fit them.

#3

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi SJ and RRV,

I believe that the factory had a method of measuring each frame. The number of shims needed at each mount location to bring the mount height to a certain dimension was marked in crayon on the frame and later that number of shims was put on the mount and held in place with a strip of paper tape. I believe the frame was measured while it was still upside but the shims were put on after it was flipped. (I Think.)

After the body was dropped the gaps were adjusted (or so they say) to standards shown in the Body Checking Section of the AIM.

The gaps were pretty bad.

Regards,

Alan

I believe that the factory had a method of measuring each frame. The number of shims needed at each mount location to bring the mount height to a certain dimension was marked in crayon on the frame and later that number of shims was put on the mount and held in place with a strip of paper tape. I believe the frame was measured while it was still upside but the shims were put on after it was flipped. (I Think.)

After the body was dropped the gaps were adjusted (or so they say) to standards shown in the Body Checking Section of the AIM.

The gaps were pretty bad.

Regards,

Alan

The following users liked this post:

larryg3 (01-22-2022)

#4

Melting Slicks

wouldnt it be nice to have someone that actually worked on these from the factory here. there has got to be ex employees around but where are they ?

#6

Melting Slicks

The factory had a large jig that was read and shim count marks put on the frame as Allen said. If you don't know put two shims on both #2&3 mounts. On convertibles fit the front of the doors to the fender. Then shim #4 mount to make the door gap the same at the rear from top to bottom. Fit shims at #1 to make them tight.

#7

Le Mans Master

Here is the description John Hinckley posted recently on the C2 board:

"The shim pack was determined by a master gage fixture in the first station on the frame upside-down line which showed the number of shims needed at each location to position each mount at the zero vertical design datum; the body was already at zero design datum, as the underbody was bolted solid to machined pedestals on a precision steel build truck in the Body Shop. The shim determination fixture was moved to the last station on the Chassis Line before Body Drop in 1969 in order to get a more accurate datum measurement with all the chassis components and the complete drivetrain installed."

"The shim pack was determined by a master gage fixture in the first station on the frame upside-down line which showed the number of shims needed at each location to position each mount at the zero vertical design datum; the body was already at zero design datum, as the underbody was bolted solid to machined pedestals on a precision steel build truck in the Body Shop. The shim determination fixture was moved to the last station on the Chassis Line before Body Drop in 1969 in order to get a more accurate datum measurement with all the chassis components and the complete drivetrain installed."

#8

Safety Car

I wrote this up after an interview with a St Louis plant engineer who worked on several lines during the 70's:

Shims were used to ensure the body would retain its flat, level plane, as designed and built when mated with the chassis…that when mounted to the chassis, this platform would not be distorted by the tightening of body mounts. Careful attention was paid to the elimination of stress, twisting or distortion of the body once mounted on the chassis and the plant used a “Shim Predictor” fixture (geometrical fixture) to accomplish this task. Frames were more likely to be out of alignment than the body and the shims absorbed the tolerance differential.

The shim predictor with plunger like devices at each body mount position was attached to the frame. A shim indicator was inserted between the plunger and frame, and referenced the number of shims required. The shim indicator was wedge shaped and indexed for the number of shims required to align the frame with the body.

Workers would write with grease pencil the number of shims needed from 0-5. Various colors were used including yellow, green and red. In later years, colors were used to denote one side from the other. Rarely were more than five shims required. Until 1969, vertical grease pencil marks were marked on the frame at the body mount location. The workers taped the shim pack at each body mount position in place so they did not get lost as the chassis moved along the line. The tape ran vertical to the horizontal frame. Once the body was in place on the chassis, the bolts would be shot and pushed through the tape and tightened. Today tape can still be seen in low mileage original Corvettes and used as a clue to determine whether the body was removed.

Shims were used to ensure the body would retain its flat, level plane, as designed and built when mated with the chassis…that when mounted to the chassis, this platform would not be distorted by the tightening of body mounts. Careful attention was paid to the elimination of stress, twisting or distortion of the body once mounted on the chassis and the plant used a “Shim Predictor” fixture (geometrical fixture) to accomplish this task. Frames were more likely to be out of alignment than the body and the shims absorbed the tolerance differential.

The shim predictor with plunger like devices at each body mount position was attached to the frame. A shim indicator was inserted between the plunger and frame, and referenced the number of shims required. The shim indicator was wedge shaped and indexed for the number of shims required to align the frame with the body.

Workers would write with grease pencil the number of shims needed from 0-5. Various colors were used including yellow, green and red. In later years, colors were used to denote one side from the other. Rarely were more than five shims required. Until 1969, vertical grease pencil marks were marked on the frame at the body mount location. The workers taped the shim pack at each body mount position in place so they did not get lost as the chassis moved along the line. The tape ran vertical to the horizontal frame. Once the body was in place on the chassis, the bolts would be shot and pushed through the tape and tightened. Today tape can still be seen in low mileage original Corvettes and used as a clue to determine whether the body was removed.

#9

Burning Brakes

Member Since: Feb 2004

Location: In the Beautiful Shenandoah Valley of VA

Posts: 958

Likes: 0

Received 1 Like

on

1 Post

Interesting information. Last year I replaced all of the original body mounts (trust me, they have never been out). There weren't any shims on any of the mounts and rust was minimal, so I don't think they rusted out and fell away. The doors and fenders all seem to be in reasonable alignment with the car sitting on the tires (gaps reasonable, etc). Has anyone else ever seen a Vette without any shims? Or did I just have a very lucky, very straight frame and body?

Steve

Steve

#10

Melting Slicks

The frame was the only thing checked for shims so you may have had a perfect frame or somehow the frame did not get checked so no shims were installed. I would say this is rarer than an L88 but won't get any extra resale money.

#11

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi...

I've seen some factory pictures with a '0' at a mount but not '0s' on the entire side. Plus I don't think I've ever seen factory photos of BOTH sides of the same frame. So could there be a whole frame with no shims...I guess so? Would it matter????????????

Regards,

Alan

I've seen some factory pictures with a '0' at a mount but not '0s' on the entire side. Plus I don't think I've ever seen factory photos of BOTH sides of the same frame. So could there be a whole frame with no shims...I guess so? Would it matter????????????

Regards,

Alan

#12

Burning Brakes

Member Since: Feb 2004

Location: In the Beautiful Shenandoah Valley of VA

Posts: 958

Likes: 0

Received 1 Like

on

1 Post

Hi...

I've seen some factory pictures with a '0' at a mount but not '0s' on the entire side. Plus I don't think I've ever seen factory photos of BOTH sides of the same frame. So could there be a whole frame with no shims...I guess so? Would it matter????????????

Regards,

Alan

I've seen some factory pictures with a '0' at a mount but not '0s' on the entire side. Plus I don't think I've ever seen factory photos of BOTH sides of the same frame. So could there be a whole frame with no shims...I guess so? Would it matter????????????

Regards,

Alan

#13

Drifting

Thread Starter

Thanks guys. Body went on fine with not too much drama. This was just a test fit.

Body and paint haven't been done. I'm going to use the time to seat the rings and put some miles on the new suspension. When I'm done. We'll pull the body for prep and paint. then I'll recheck all the torques on the body.

Damn it rides high, but I guess that's to be expected missing several hundred pounds of interior, doors, glass, headlights, spare, etc.

Body and paint haven't been done. I'm going to use the time to seat the rings and put some miles on the new suspension. When I'm done. We'll pull the body for prep and paint. then I'll recheck all the torques on the body.

Damn it rides high, but I guess that's to be expected missing several hundred pounds of interior, doors, glass, headlights, spare, etc.

#16

Team Owner

Member Since: Jun 2000

Location: Southbound

Posts: 38,928

Likes: 0

Received 1,468 Likes

on

1,247 Posts

Cruise-In II Veteran

The A.O. Smith company made the frames, massed produced, and welded up in jigs. The perfect frame would meet all the GM design tolerances. Less than perfect frames were still usuable frames, but required a shim or two.

For Your Consideration: I attended a seminar at Bloomington conducted by Dave Burroughs concerning assembly at St. Louis. He smiled when recalling the sound of shims dropping off frames before body drop. Folks on the line were not stopping to pick up dropped shims.

#17

Le Mans Master

#18

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi RJ,

You can see some shims sitting on the #4 mount in this picture. They're as GD described. The factory used a strip of 1 1/2" wide tape (kinda like masking tape) that was supposed to hold the shim stack in place.

Regards,

Alan

You can see some shims sitting on the #4 mount in this picture. They're as GD described. The factory used a strip of 1 1/2" wide tape (kinda like masking tape) that was supposed to hold the shim stack in place.

Regards,

Alan

#19

Team Owner

Interesting information. Last year I replaced all of the original body mounts (trust me, they have never been out). There weren't any shims on any of the mounts and rust was minimal, so I don't think they rusted out and fell away. The doors and fenders all seem to be in reasonable alignment with the car sitting on the tires (gaps reasonable, etc). Has anyone else ever seen a Vette without any shims? Or did I just have a very lucky, very straight frame and body?

Steve

Steve