ProCharger Pulley

#1

Racer

Thread Starter

Member Since: Feb 2004

Location: He who laughs last didn't get it... Georgia

Posts: 457

Likes: 0

Received 0 Likes

on

0 Posts

Two quick questions...

1. I'm looking for a smaller pulley for my P1SC, anyone know where I can purchase them besides ProCharger?

2. I read an article/post that noted for every .15" you go decrease your pulley size, you increase 2 psi. Any truth to this or .

.

Thanks in advance...

1. I'm looking for a smaller pulley for my P1SC, anyone know where I can purchase them besides ProCharger?

2. I read an article/post that noted for every .15" you go decrease your pulley size, you increase 2 psi. Any truth to this or

Thanks in advance...

#3

Safety Car

Two quick questions...

1. I'm looking for a smaller pulley for my P1SC, anyone know where I can purchase them besides ProCharger?

2. I read an article/post that noted for every .15" you go decrease your pulley size, you increase 2 psi. Any truth to this or .

.

Thanks in advance...

1. I'm looking for a smaller pulley for my P1SC, anyone know where I can purchase them besides ProCharger?

2. I read an article/post that noted for every .15" you go decrease your pulley size, you increase 2 psi. Any truth to this or

Thanks in advance...

2) BS no hard fast rule for driven pulley reduction to boost increase. Many factors influence boost increase.

#5

Two quick questions...

1. I'm looking for a smaller pulley for my P1SC, anyone know where I can purchase them besides ProCharger?

2. I read an article/post that noted for every .15" you go decrease your pulley size, you increase 2 psi. Any truth to this or .

.

Thanks in advance...

1. I'm looking for a smaller pulley for my P1SC, anyone know where I can purchase them besides ProCharger?

2. I read an article/post that noted for every .15" you go decrease your pulley size, you increase 2 psi. Any truth to this or

Thanks in advance...

#6

Racer

Thread Starter

Member Since: Feb 2004

Location: He who laughs last didn't get it... Georgia

Posts: 457

Likes: 0

Received 0 Likes

on

0 Posts

BrandX, thanks for the response. I've been looking but have been unable to locate a 3.25 - 3.5" gooved pulley for my P1SC. I keep reading that "there are a number of places that sell blower pulleys" but haven't found one yet. I looked for @ 30 min last night on the website posted above and could not find a grooved pulley for a P1SC. I'm still looking, but I will probably call them.

I've been looking but have been unable to locate a 3.25 - 3.5" gooved pulley for my P1SC. I keep reading that "there are a number of places that sell blower pulleys" but haven't found one yet. I looked for @ 30 min last night on the website posted above and could not find a grooved pulley for a P1SC. I'm still looking, but I will probably call them.

If you know of a site(s), post a link for me...thankx JS

I've been looking but have been unable to locate a 3.25 - 3.5" gooved pulley for my P1SC. I keep reading that "there are a number of places that sell blower pulleys" but haven't found one yet. I looked for @ 30 min last night on the website posted above and could not find a grooved pulley for a P1SC. I'm still looking, but I will probably call them.

I've been looking but have been unable to locate a 3.25 - 3.5" gooved pulley for my P1SC. I keep reading that "there are a number of places that sell blower pulleys" but haven't found one yet. I looked for @ 30 min last night on the website posted above and could not find a grooved pulley for a P1SC. I'm still looking, but I will probably call them. If you know of a site(s), post a link for me...thankx JS

#8

BrandX, thanks for the response. I've been looking but have been unable to locate a 3.25 - 3.5" gooved pulley for my P1SC. I keep reading that "there are a number of places that sell blower pulleys" but haven't found one yet. I looked for @ 30 min last night on the website posted above and could not find a grooved pulley for a P1SC. I'm still looking, but I will probably call them.

I've been looking but have been unable to locate a 3.25 - 3.5" gooved pulley for my P1SC. I keep reading that "there are a number of places that sell blower pulleys" but haven't found one yet. I looked for @ 30 min last night on the website posted above and could not find a grooved pulley for a P1SC. I'm still looking, but I will probably call them.

If you know of a site(s), post a link for me...thankx JS

I've been looking but have been unable to locate a 3.25 - 3.5" gooved pulley for my P1SC. I keep reading that "there are a number of places that sell blower pulleys" but haven't found one yet. I looked for @ 30 min last night on the website posted above and could not find a grooved pulley for a P1SC. I'm still looking, but I will probably call them.

I've been looking but have been unable to locate a 3.25 - 3.5" gooved pulley for my P1SC. I keep reading that "there are a number of places that sell blower pulleys" but haven't found one yet. I looked for @ 30 min last night on the website posted above and could not find a grooved pulley for a P1SC. I'm still looking, but I will probably call them. If you know of a site(s), post a link for me...thankx JS

http://www.reichardracing.com/pulleys.php

Last year at PRI, ATI had a sprag blower pulley at their booth. It was in prototype but they might be selling them by now. If you have a stick car, it might be worth looking into.

http://www.atiperformanceproducts.com

Also, why dont you want to buy a pulley from Procharger? Just curious.

Last edited by Brand-X; 09-20-2007 at 07:19 PM.

#9

Racer

Thread Starter

Member Since: Feb 2004

Location: He who laughs last didn't get it... Georgia

Posts: 457

Likes: 0

Received 0 Likes

on

0 Posts

IMHO, Their customer service/tech support have been poor. I just don't want to deal with it if I can avoid it. Thanks again for the links and info...

BTW, I have an auto and I'm trying to get more belt wrap as well as a tad bit more boost. I'm looking at Reichard Racing's site now. Again, Thanks Brand X and AKS Racing...JS

BTW, I have an auto and I'm trying to get more belt wrap as well as a tad bit more boost. I'm looking at Reichard Racing's site now. Again, Thanks Brand X and AKS Racing...JS

Last edited by jsavoy; 09-20-2007 at 09:23 PM.

#10

Safety Car

Have you done the calcs on MIS (max impellor speed)? You may find that you are at your limit currently, or you may find that you can go much further with the driven shive reduction.

It is important to do the tech work behind the change. ASP pulleys atr slightly cheaper than ProCharger, but I typically just order from ProCharger.

Aaron

It is important to do the tech work behind the change. ASP pulleys atr slightly cheaper than ProCharger, but I typically just order from ProCharger.

Aaron

#11

Hi JSAVOY, Greg from BlowerWorks here. I have blower pulleys for you. My pulleys are a little unique in that they utilize a keyed tapered collet. This allows you to place the pulley on the blower shaft wherever you want, then lock it into place with three 10-32 machine screws. This way you can align the pulley/belt as needed. I stock many sizes in 6 and 8 rib. Best regards, Greg

#12

Racer

Thread Starter

Member Since: Feb 2004

Location: He who laughs last didn't get it... Georgia

Posts: 457

Likes: 0

Received 0 Likes

on

0 Posts

AKS,

I believe that I have the correct formula. Please take a look and let me know:

(crank diameter/blower diameter) x RPM x 4.10 = impeller speed

I believe that I have the correct formula. Please take a look and let me know:

(crank diameter/blower diameter) x RPM x 4.10 = impeller speed

#13

Racer

Thread Starter

Member Since: Feb 2004

Location: He who laughs last didn't get it... Georgia

Posts: 457

Likes: 0

Received 0 Likes

on

0 Posts

Greg, well now I feel  ... I always associated you with Vortech, my apologies. As much as I remember reading your post/name in post right after I installed my S/C, it never dawned on me.

... I always associated you with Vortech, my apologies. As much as I remember reading your post/name in post right after I installed my S/C, it never dawned on me.

A PM is enroute, just one question. Do I have to dimple the shaft for the three 10/32 machine screws?

BTW - I have your GI catalog, GI troubleshooting and set up guide in .pdf/MS Word formats. I was looking into your GI system as a later upgrade/mod.

... I always associated you with Vortech, my apologies. As much as I remember reading your post/name in post right after I installed my S/C, it never dawned on me.

... I always associated you with Vortech, my apologies. As much as I remember reading your post/name in post right after I installed my S/C, it never dawned on me. A PM is enroute, just one question. Do I have to dimple the shaft for the three 10/32 machine screws?

BTW - I have your GI catalog, GI troubleshooting and set up guide in .pdf/MS Word formats. I was looking into your GI system as a later upgrade/mod.

#14

Safety Car

Quick Facts

- MIS is 62,000 for the P1SC

- L-98 drive pulleys are 7" (assuming factory pulley)

- P1SC step-up ratio is 4.10

- engine RPM should have approx 5% added to account for overspeed potential (5900 max RPM, so use 6200 for this example)

- driven pulley diameter will be 3.25" for the below example

The formula to use is:

[(drive pulley diameter*(22/7))*max engine RPM* step up ratio*(1/(driven pulley diameter*(22/7))] = impellor speed

This can be simplified to:

[(drive pulley diameter / driven pulley diameter) * max engine RPM * step-up ratio] = impellor speed

This equation yields a MIS of 54750 impellor speed at 6200RPM for a 3.25" driven shive, still over 13% from the top speed (even with the added 300RPM safety).

As an example, I am ~200 blower RPM over MIS at 6700 RPM, with a shift point of 6400RPM.

You have room to grow if that is your desire.

Aaron

#15

Racer

Thread Starter

Member Since: Feb 2004

Location: He who laughs last didn't get it... Georgia

Posts: 457

Likes: 0

Received 0 Likes

on

0 Posts

AKS,

I really appreciate you taking the time to explain and providing additional information. I believe the LT1 stock crankshaft pulley size is 7" also.

John

I really appreciate you taking the time to explain and providing additional information. I believe the LT1 stock crankshaft pulley size is 7" also.

John

#16

Intermediate

Member Since: Mar 2005

Location: Oliver Springs Tennessee

Posts: 34

Likes: 0

Received 1 Like

on

1 Post

I have a 3.4 inch pully on my kit and was told that was the smallest one they had for the p1sc. Smaller pulleys will slip more and probably won't be an advantage. But - - - ATI (the Harmonic balancer people) make a 7.5 inch balancer for the LT1, and it works great with less slip at the crank on the procharger kit.

Mike

Mike

#18

Pro

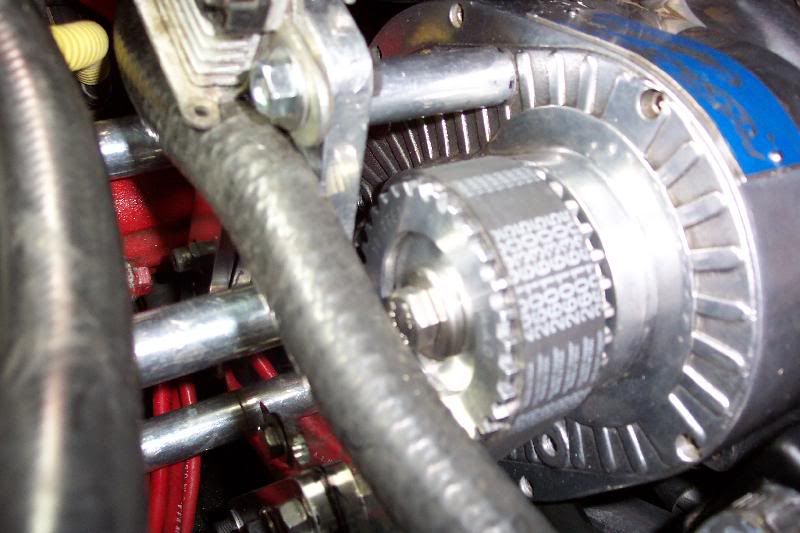

btw who's car is in the first pic ?

btw who's car is in the first pic ?

Last edited by makn u shiver; 10-26-2007 at 09:24 PM.

#19

Instructor

I got my cog pulleys from blackmountainprecision.com. Thanks for the Smokeshow for all the info and help!

As you see my setup is not ready yet. Some minor changes must be done. The belt is 2504mm long, 30mm wide, 8mm pitch.

As you see my setup is not ready yet. Some minor changes must be done. The belt is 2504mm long, 30mm wide, 8mm pitch.

#20

Safety Car

Looking good.

And yes Smokewhow (makin u shiver) did a great job in ironing out the details for the cogged drive with Black Mountain Presision. Mine was built by ASP Racing and was considerably more expensive than the package from Black Mountain Precision.

But on a word of caution, be aware that some of these cogged drives have done significant damage to the crank hub and or the transmission in the blower head unit. I no longer use the cog drive on mine.

Aaron

Nada?

Nada?